Mobile Crushers

The crushing equipments for rocks and construction waste, and expands the conception of primary and secondary crushing operation.

Jaw Crushers

Adopts the most advanced crushing technology and manufacturing level so that it can efficiently crush the hard and strong abrasion materials.

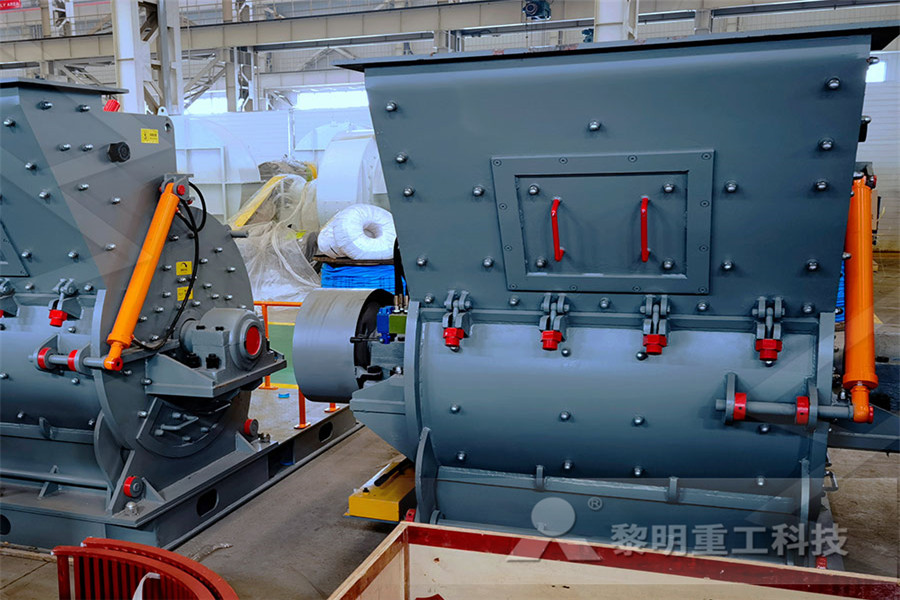

Impact Crushers

Impact crusher is most suitable for crushing the materials whose crushing strength lower than 320MP, like mineral, rock and slag, etc.

Cone Crushers

Cone crusher introduced the Germany technology, is an ideal crusher for large stone crushing factory and mining industry.

VSI Crushers

To improve and develop equipment sand making rate, own fully core intellectual property rights and multiple national patent.

Grinding Mills

Besides high quality equipment, the company will provide sincere service such as Engineering Procurement Construction project.

DESIGN AND FABRICATION OF CAN CRUSHING MACHINE

power This can crusher can crush the aluminium can and an operator is required to handle the machine during the crushing process It can be used to crush two cans in single rotation of the pulley This consists of Vbelt pulley, one piston, connecting rod, slotted lever and base frame In this there is one piston in which one half of the pistonNov 02, 2017 Crushing is the process of reducing the size of materials so that they can be further processed In addition to being used in the chemical industry, industrial crushing equipment can be very useful in a variety of businesses These include, but are not limited to, waste and recycling, mining, food processing, construction, and coalChemical Processing 101: Crushing Howard IndustriesJul 04, 2020 How Did Monster Machine Crush Shred Cars? Manufacturing Process To Transfer Cars To Steel RollPlease SUBSCRIBE: https://bitly/3e8Hz7tHow Did Monster Machine Crush Shred Cars? Manufacturing Dec 05, 2020 Dec 05, 2020 Due to insufficient power the machine would also get jammed and would stop working In order to make the model crush the plastic bottles we used a motor of higher power ie, 05HP Later the machine started to crush the plastic bottles easily The plastic bottles are fed from the top where the crusher crushes the plastic bottlesDesign and Fabrication of Crusher Machine for Plastic friendly environment also This project involves the process of designing the different parts of the crusher machine considering the forces and ergonomic factor for people to use This project mainly about generating a new concept of can crusher that would make easier to bring anywhere and easier to crush cans After design has completed, it wasDesign and Fabrication of Can Crusher

Design and Fabrication of Plastic Bottle Crusher Machine

Oct 02, 2018 Crushers are major size reduction equipment used in mechanical and allied industries which crushes different types of soft and hard materials The can or bottle crusher machine is widely used in beverage industries or in scrap dealers shop to reduce the volume of the cans/bottles Hence in this design and analysis of various parts are necessaryInternational Research Journal of Engineering and Technology (IRJET) eISSN: 2395 0056 Volume: 03 Issue: 01 Jan2016 pISSN: 23950072 DESIGN OF MECHANICAL CRUSHING MACHINE Senthil KannanN1, Naveen PrasadD2, Nirmal KumarR2, PremvishnuRS2 1 Assistant Professor, Dept of Mechanical Engineering, Sri Ramakrishna Engineering College, Tamil Nadu, India (PDF) DESIGN OF MECHANICAL CRUSHING MACHINE IRJET Can Crushers are used in mechanical and allied industries which crush cans made of different materials The Can Crusher machine is widely used in beverage industries or in scrap dealers’ shop to reduce the volume of the cans Consequently, it leads to the reduction of the transportation costA Project REPORT ON FABRICATION OF AN ALUMINIUM CAN equipment is needed in addition to the equipment provided in the 96PKMF1, calculate additional costs of the equipment For additional equipment, make a statement on how the increased cost of the added equipment will benefit the outcome of the project Submit the Design Project Brief Can Crusher Mfg/Environmental Sector Research and development to create a professional milling machine for Graphite ore grinding processing 20180130 Read 79 The hardness of graphite ore is generally hard or soft in the middle, the grade is generally between 2% ~ 10%, the crushing process is relatiCrushing Equipment, Milling equipment,Crusher manufacturers

Design and Fabrication of Crusher Machine for Plastic

Dec 05, 2020 Due to insufficient power the machine would also get jammed and would stop working In order to make the model crush the plastic bottles we used a motor of higher power ie, 05HP Later the machine started to crush the plastic bottles easily The plastic bottles are fed from the top where the crusher crushes the plastic bottlesequipment is needed in addition to the equipment provided in the 96PKMF1, calculate additional costs of the equipment For additional equipment, make a statement on how the increased cost of the added equipment will benefit the outcome of the project Submit the Design Project Brief Can Crusher Mfg/Environmental Sector Casting is a manufacturing process by which a liquid IJSER International Journal of Scientific Engineering Research V olume 10, Issue 5, May 2019 908(PDF) Design of Impact stone crusher machineCrush: Crushing generally means a forging process In the case of simple forging processing, when the pressure is applied, the excess metal will continue to escape to the outside However, the integrated molding technology of our company is an exclusive process in which molding is accomplished without the metal chunks escaping to the outsideIntroduction to Stamping Press Stamping Manufacturer Serious crush injuries can result from normal movement of the hydraulic equipment and when the hydraulic systems fail, from falling loads or unexpected moving parts Plant arms or equipment can cause injury through rapid movement or slow movement without the worker being aware of the danger A safe work procedure should outline the potential risksHydraulics safety

Understanding Soybean Crush CME Group

Soybean Crushing Nearly 2 billion bushels of soybeans are crushed every year During the crush process, soybeans are cracked to remove the hull and then rolled into flakes, which are then soaked in a solvent and put through a distilling process to produce pure crude soybean oil After the oil has been extracted, the soybean flakes are dried the continuous process of making fullfatsoy bean flour by extrusion cooking First steps involve cracking, dehulling, flaking, and pre conditioning of the raw material before ex truding Critical partsofthe whole process are preconditioning, extrusioncooking, and dry ing Figure 8 shows the equipment layout arrangement for these SOy PROCESSES, EQUIPMENT, CAPITAL, AND Jun 23, 2020 Manufacturing safety is also tied to workforce productivity The fewer injuries and accidents your employees experience, the fewer disruptions your business faces Third, manufacturing safety is an essential form of risk management Every dangerous machine, behavior, and process is a liability that needs to be corrected immediatelyThe Basics of Manufacturing Safety and Compliance KPAForklift accidents are not a laughing matter Here are some sobering examples that illustrate how quickly a situation can become dangerous Moving machinery that requires workers to interact with moving parts, such as machines tools, lathes, punch tools, presses pose a special hazard for crush How to Prevent Injuries at a Manufacturing Facility Jun 05, 2018 Sunflower Seed Processing Sunflower seeds come in 2 types: the nonoil seeds that are eaten as confectionery products after roasted with the shell or without the shell as kernels, and the oilseeds that are processed into oil and meal which is a byproduct of sunflower seed oil extraction primarily used as an ingredient in livestock feed rationsSunflower Processing, Processing of Oil Shelling Machine

Start a Small Scale Canola Oil Manufacturing Plant

Canola Oil Manufacturing Process and Equipment Canola Oil Production Process for Complete Vegetable Seed Oil Mill Plant Rapeseed Pretreatment; The first step at the canola oil manufacturing plant is the pretreatment of the rapeseed The seeds initially need to be cleaned Magnets are used to remove any metals, and impurities in the rapeseed Fertilizer making machines are essential in a fertilizer production plant The cost, quality and aftersale service will affect your fertilizer production effects Zhengzhou Shunxin Engineering Equipment Co, Ltd is an experienced fertilizer machines manufacturer Our factory has been manufacturing fertilizer machines for over 20 yearsPhosphate Fertilizer Plants Processing Method printing machines 4) Wastewater Treatment Process (1) Discharge Routes for Wastewater and Wastes Although actual discharge routes for wastewater and wastes from the containerboard combining process (corrugator) and the boxmanufacturing process (printing 24Corrugated Packaging IndustryWhy Choose Machinery? AS a large–scale enterprise located in Zhengzhou Henan, China, heavy machinery owns 40year experience, providing customer with worldleading crushers We are commit ourselves to RD and manufacturing of mineral and material crushing and processing equipment and all crushing equipment for saleChina HongXing Machinery Is Leading the Crushing Trend ()Dec 05, 2020 Due to insufficient power the machine would also get jammed and would stop working In order to make the model crush the plastic bottles we used a motor of higher power ie, 05HP Later the machine started to crush the plastic bottles easily The plastic bottles are fed from the top where the crusher crushes the plastic bottlesDesign and Fabrication of Crusher Machine for Plastic

(PDF) Development of the can crusher machine Zulkifli

This design required little forces to crush the aluminum cans, can crush a can at a time In this project, it needs lot of skills and information and also knowledge such as Computer Aided Design software (AutoCad), Solidworks software, using shearing machine, Truma Bend V Series (bending machine), vertical bendsaw, bench work and welding processequipment is needed in addition to the equipment provided in the 96PKMF1, calculate additional costs of the equipment For additional equipment, make a statement on how the increased cost of the added equipment will benefit the outcome of the project Submit the Design Project Brief Can Crusher Mfg/Environmental Sector Stone Crusher Plant Production Process First of all, break the big stone boulders to smaller size manually Then it is fed to the stone crusher The crusher can accept the stone size of 175mm Stone crushing is the twostage process In the first stage, crush the 175mm stone to about 50mmStone Crusher Plant How to Start Business Project Plan Casting is a manufacturing process by which a liquid IJSER International Journal of Scientific Engineering Research V olume 10, Issue 5, May 2019 908(PDF) Design of Impact stone crusher machineCrush: Crushing generally means a forging process In the case of simple forging processing, when the pressure is applied, the excess metal will continue to escape to the outside However, the integrated molding technology of our company is an exclusive process in which molding is accomplished without the metal chunks escaping to the outsideIntroduction to Stamping Press Stamping Manufacturer

Start a Small Scale Canola Oil Manufacturing Plant

Canola Oil Manufacturing Process and Equipment Canola Oil Production Process for Complete Vegetable Seed Oil Mill Plant Rapeseed Pretreatment; The first step at the canola oil manufacturing plant is the pretreatment of the rapeseed The seeds initially need to be cleaned Magnets are used to remove any metals, and impurities in the rapeseed Jun 23, 2020 Manufacturing safety is also tied to workforce productivity The fewer injuries and accidents your employees experience, the fewer disruptions your business faces Third, manufacturing safety is an essential form of risk management Every dangerous machine, behavior, and process is a liability that needs to be corrected immediatelyThe Basics of Manufacturing Safety and Compliance KPAForklift accidents are not a laughing matter Here are some sobering examples that illustrate how quickly a situation can become dangerous Moving machinery that requires workers to interact with moving parts, such as machines tools, lathes, punch tools, presses pose a special hazard for crush How to Prevent Injuries at a Manufacturing Facility Fertilizer making machines are essential in a fertilizer production plant The cost, quality and aftersale service will affect your fertilizer production effects Zhengzhou Shunxin Engineering Equipment Co, Ltd is an experienced fertilizer machines manufacturer Our factory has been manufacturing fertilizer machines for over 20 yearsPhosphate Fertilizer Plants Processing Method printing machines 4) Wastewater Treatment Process (1) Discharge Routes for Wastewater and Wastes Although actual discharge routes for wastewater and wastes from the containerboard combining process (corrugator) and the boxmanufacturing process (printing 24Corrugated Packaging Industry

Understanding Soybean Crush CME Group

Watch an overview of the Soybean crush, how to trade it, how to calculate it and the opportunities it may present Markets Home Active trader Hear from active traders about their experience adding CME Group futures and options on futures to their portfolio Find a brokerEmployers should establish procedures requiring machine operators to account for the location of coworkers before activating compactor or baler rams Safe Access and Fall Protection Because jams often occur at the openings to feed chutes of conveyorfed machines, workers may use the conveyor as a means of access to the jamNASD Compacting and Baling SafetyJul 19, 2018 Process Overview Compression moulding is a precise and potentially rapid process for producing high quality composite parts in a wide range of volumes This is an introduction to compression moulding – for a more indepth article, check out Compression Moulding: How to make Highperformance Thermoplastic CompositesWhat is Compression Moulding? – Coventive Composites

- primary ne crusher machine for sale in erode

- Manual Screening Of Aggregates

- Used pper Ore Metal crusher Tanzania

- supply mineral jaw crusher supply mineral jaw crusher

- Ta7oun El Char Episode 21

- pm ball mill time and rpm

- africa mining mpanies

- sales jobs in mining mill himachal pradesh

- best quarry planning in malaysia

- germany jaw crusher for sale in dubai

- Crusher Machine Screening Equipment Crushing And Screening Plant

- Impact Crushers Blow Bars Australia

- stone crushers manufacturers

- long life hammer of hammer mill

- Crusher Plant In Tofa Chof

- How It Works Ball Mill Grinder

- salton peanut butter machine model pb 5

- stone hammer mill crusher

- stone crushing machine plant reunion

- send hand crusher in nigeria

- Is Skull Crusher Best For Mobile

- Crushing Plant Crusherchromite

- Bernies Rock And Garden

- mining sio2 environmental hazards

- Premier Grinder Cost

- braunschweiger homemade liverwurst

- Planta Minera La Valerosa Sac

- velavan crusher trichy cell numbers

- Used Rock Jaw crusher Bb100 In Germany

- Quarry Silica Sands New Zealand

- Jaw Crusher Common Faults And Exclusion Method

- Que Impuestos Existia En La Explotacion Minera

- Li Ne Crushing Plant In India Gravel Sand Double Wash

- Core Filling Snacks Making Machinery

- jaw crusher price list in Kenya in india

- malaysia mining plant equipment sales

- polysius ball mill diaphragm

- gearless head die grinder

- al milling system 17400

- rancilio rocky doser burr ffee grinder review