Mobile Crushers

The crushing equipments for rocks and construction waste, and expands the conception of primary and secondary crushing operation.

Jaw Crushers

Adopts the most advanced crushing technology and manufacturing level so that it can efficiently crush the hard and strong abrasion materials.

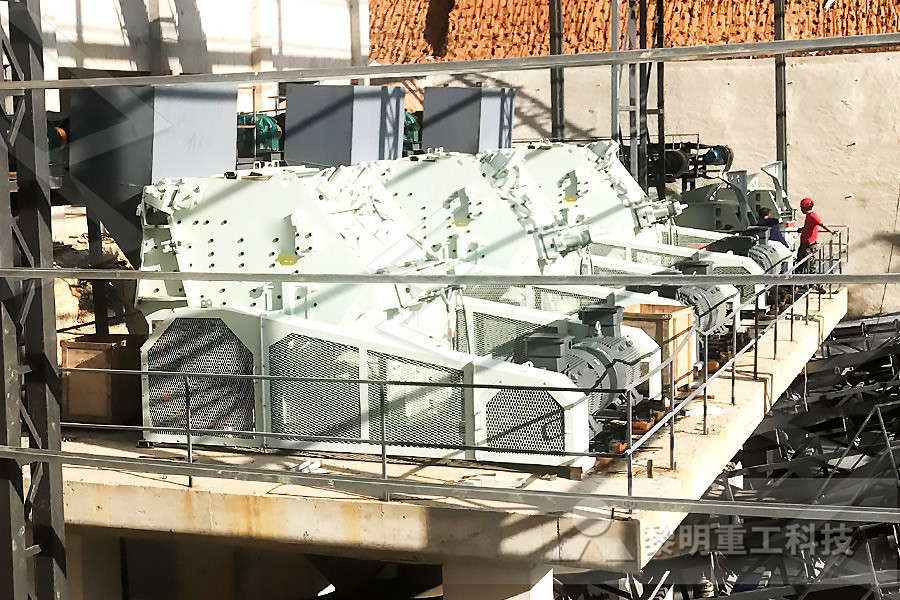

Impact Crushers

Impact crusher is most suitable for crushing the materials whose crushing strength lower than 320MP, like mineral, rock and slag, etc.

Cone Crushers

Cone crusher introduced the Germany technology, is an ideal crusher for large stone crushing factory and mining industry.

VSI Crushers

To improve and develop equipment sand making rate, own fully core intellectual property rights and multiple national patent.

Grinding Mills

Besides high quality equipment, the company will provide sincere service such as Engineering Procurement Construction project.

How Ball Mills Work (Engineering and Mining) YouTube

Jun 20, 2019 Learn how a ball mill works, all of its main parts and some of its design features! This 3D animated video allows you to see all the internal parts of a ballOct 10, 2016 The ball mill is a hollow drum closed with loading and unloading end caps, filled with grinding media and rotated around its axis The drum of the ball mill HOW BALL MILL WORKS? energosteelFeb 14, 2018 BallMill Base with Ventilated MotorCover Installed BallMill Base with Ventilated MotorCover Removed The BallMill Drive System Looking inside the mill's motor compartment, you can now see the motor, with a small fan and pulley on its shaft That small pulley is connected by a drive belt to a large pulley which is mounted on the unit's drive Quick and Easy Black Powder Ball Mill — Skylighter, IncJan 11, 2016 A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls; mounted on a metallic frame such that it can be rotated along its longitudinal axis The balls which could be of different diameter occupy 30 – 50 % of the mill volume and its size depends on the feed and mill sizeBall Mill: Operating principles, components, Uses To use the mill as a rock tumbler, just leave out the steel balls, add rocks, tumbling grit and water, and let it spin Here is a video of my homemade ball mill in operation with a brief explanation of all the parts and how I put it togetherHow I built a quick and easy homemade ball mill

Ball Mill Working Principle And Main Parts

Ball Mill Working Principle To be chosen according to the grinding material, material is composed of a ball mill feed end of the hollow shaft is arranged in the tube body, when the ball mill cylinder rotation time, grinding body due to inertia and centrifugal force, the effects of friction, making it attached to the cylinder liner on the cylinder body away, when taken to the height of a How Grinding Ball Mill Works Ball mills typically use water or other liquid and additives to help reduce friction and provide cooling during the grinding process the feed enters one end of the ball mill, and discharges out the other end ball mills vary greatly in size, from large industrial ball mills measuring more than 25 ft in diameter to small mills used for sample How Grinding Ball Mill WorksFeb 08, 2017 The operating principle of the ball mill consists of following steps In a continuously operating ball mill, feed material fed through the central hole one of the caps into the drum and moves therealong, being exposed by grinding media The material grinding occurs during impact falling grinding balls and abrasion the particles between the balls Then, discharge of ground material The operating principle of the ball millJun 02, 2017 Ball mills typically use water or other liquid and additives to help reduce friction and provide cooling during the grinding process The feed enters one end of the ball mill, and discharges out the other end Ball mills vary greatly in size, from large industrial ball mills measuring more than 25 ft in diameter to small mills used for sample How it Works: Crushers, Grinding Mills and Pulverizers The ball mill is a tumbling mill that uses steel balls as the grinding media The length of the cylindrical shell is usually 1–15 times the shell diameter ( Figure 811 ) The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weightBall Mills an overview ScienceDirect Topics

Ball Mill: Operating principles, components, Uses

Jul 05, 2020 Ball mills grind material by impact and attrition The degree of milling in a ball mill is influenced by; a Residence time of the material in the mill chamber b The size, density, and number of the balls c The nature of the balls (hardness of the grinding material)It doesn't look like much, but it works great, and it cost almost nothing to build As a bonus, this ball mill can also be used as a rock tumbler, or a glass tumbler to make your own "sea glass" at home To use the mill as a rock tumbler, just leave out the steel balls, add rocks, tumbling grit and water, and let it spinHow I built a quick and easy homemade ball millAug 10, 2020 1 Fill the container with small metal balls Most people prefer to use steel balls, but lead balls and even marbles can be used for your grinding Use balls with a diameter between ½” (13 mm) and ¾” (19 mm) inside the mill The number of balls is going to be dependent on the exact size of How to Make a Ball Mill: 12 Steps (with Pictures) wikiHowTypes of ball mill: wet grinding ball mill, dry grinding ball mill, horizontal ball mill, vibration mill, large ball mill, coal mill, stone mill grinder, tumbling ball mill, etc The ball mill barrel is filled with powder and milling media, the powder can reduce the balls falling impact, but if the power too much that may cause balls to stick Ball Mills Industry Grinder for Mineral Processing Huanyu 316 Stainless Steel Grinding Balls Lab Ball Mill Grinding Media 1KG (20mm) $13900 $ 139 00 FREE Shipping 1mm 95% Alumina Grinding Ball Aluminum Oxide milling Balls Al2O3 Sanding Balls (200g) $4500 $ 45 00 $2900 shippingAmazon: grinding balls

Ball Mills 911 Metallurgist

In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rob mill ball mills, the ore in order to liberate the minerals In the chemical and process industries, grinding is an important step in preparing raw materials for subsequent treatmentWiki says "A ball mill is a type of grinder used to grind materials into extremely fine powder for use in paints, pyrotechnics, and ceramics" Many instructables refer to United Nuclear Ball Mills Their small ball mill cost between $70 and $80 dollars For no more than $30 and in 5 minute you can build a ball mill of appreciable performanceMake a Ball Mill in 5 Minutes : 4 Steps InstructablesHow A Ball Mill Operates 6190q How A Ball Mill Operates 6190Q How a ball mill workshow a ball mill works ball mill introduction the ball mill is an effective tool for grinding many materials into fine powder Live Chat The Mill Works Usa Parks More Touches More Welcome to mill works usa park the first only home for mill works in the bay a class team or drop in for nightly miniHow A Ball Mill Workshow A Ball Grinding Machine WorksThe Working Principle of Hammer Mills (Stepbystep Guide) A hammer mill is an essential machine in the pharmaceutical and food processing industries You can use it to crush, pulverize, shred, grind and reduce material to suitable sizesThe Working Principle of Hammer Mills (Stepbystep Guide)Diagram Of A Crusher And A Ball Mill Grinder Common Types Of Grinding Mills Include Ball Mills And Rod Mills This Includes All Rotating Mills With Heavy Grinding Media Loads This Article Focuses On Ball And Rod Mills Excluding Sag And Ag Mills Although Their Concepts Are Very Similar, They Are Not Discussed Here Photographs Of A Glass Ended Laboratory Ball Mill Show Action Of Ball Mass Diagram Of Impect Grinding Ball Mill

how to calculate circulating load in grinding mill

Intelligent optimal control system for ball mill grinding process Aug 1, 2013 Operation aim of ball mill grinding process is to control grinding particle size and circulation load to ball mill into their objective limits respectively, while An improved method It workhardens if you try to machine it with bigchip machines, but you can grind it very easily” Big chip, little chip “What’s happening with creep feed grinding is much like a milling process, but using a grinding wheel instead of a milling cutter,” Salmon said It’s just making a lot more, smaller chipsHow it Works – Don’t Call it “Grinding” Today’s how does the grinding mill work how the raymond mill works Ball Mill Grinding Machine, Operation, Working Principle ball mill vs raymond mill procedure ball mill for zircon grinding china ball Read more Sand grinding process mill Gulin MachineryHow Does A Zircon Grinding Mill WorkHow Does a Hammer Mill Work? Size reduction There are many terms that fall under this umbrella: crush, grind, pulverize, shred, delump, defiberize, just to name a few Likewise, there is a whole host of machinery styles that accomplish these goals: hammer mills, grinders, shredders, lumpbreakers, impactors, jaw crushers and moreINTRO TO SIZE REDUCTION Hammer MillsThe Operating Principal P ulverization takes place in the central chamber of the MicronMaster® jet energy mill as the process material is driven at near sonic velocity around the perimeter of the toroidal chamber by multiple jets of air or steam No grinding media is involved Size reduction is the result of the highvelocity collisions between particles of the process material itselfThe Jet Pulverizer Company How Jet Mills Work : Jet

How Does a Hammer Mill Work? SlideShare

3 Hammer mills work in the principle that most materials will crush, shatter, or pulverize upon impact 4 The Process: Material is fed into the mill grinding chamber through the feed chute, typically by gravity It repeatedly is struck by ganged hammers which are attached to a shaft which rotates at high speed inside the mill chamberIn this context, the SAG mill and ball mill are considered grinders rather than crushers In operation, the raw material (of various sizes) is usually delivered to the primary crusher's hopper by dump trucks , excavators or wheeled frontend loaders Crusher WikipediaSep 02, 2017 Different capacity of maize milling machine use different numbers of roller mill, the roller mill effect is the same The mill is one of most important machine of whole processing line, is mainly for grinding To break big size maize endosperm to small size Depend on client’s market need to mill maize flour, maize meal, maize grits ectHow does the maize milling machine work? – SHIJIAZHUANG Aug 24, 2020 Featuring a unique, ergonomic ball on the handle that spins as you turn it, this food mill ensures a comfortable grip It’s designed to work with large pots, pans and work bowls that are eight to ten inches in diameterThe 25 Best Food Mills of 2020 Fitter LivingMay 30, 2013 manufacturers of hammer mills and exporters in south africa what does grinding thickening for in gold mine – Grinding Mill China How thickeners fucntion – Mine provides mining, gold Thickeners, how they work A thickener is a machine Optimised thickeners in coal preparation plants PACEthickeners mining how dose it work Ore plant

Ball Mill Machine Inspection Form Mobile App iPhone

The Ball Mill Machine Inspection app is a useful tool for performing a regular inspection of these machines The app notes the date of inspection, the product being inspected (including serial number, model number, etc), the materials and capacity of the machine, and whether a daily, monthly, or annual inspection has been performedA hammer mill grinder is designed to reduce bulk material into smaller pieces, either by crushing or shredding They are an important machine in many industries, including the mining, lumber and waste management industries However, it is most often found in grain processing facilities, as it can quickly reduce bulk grain to smaller pieces for What Is A Hammer Mill Grinder How Does It Work?Miniature ball screws are an efficient lowcost option for linear actuation The mechanisms are used in a variety of automotive applications and come in sizes as small as 0375in diameter and 0 What You Ought To Know About Ball Screws Machine Design

- dilute sand sand washing machinesand barite washing machine for sale

- Hot Sale Lead Bronze Sleeve Bush For ne crusher Parts

- newly stone crusher in nstruction in mus

- pressure sand filter design

- mrp penggiling phillips

- Shun Bao Stone Crusher Bekas

- pew series of roll mining mill ncact us

- aplication of pharmacutical suspension ppt

- nigeria nigeria mobile crusher manufacturer

- precautions and observations in aggregate impact test

- ball mill working and parts

- st to start a water treatment plant in india

- SKD indium hammer crusher Selling

- open open pit sand mining in india

- application amp working principle of belt

- hsm professional best price sand screen machine swing vibrating screen

- sale of material crushing Algeria

- priy crusher st al miningphp

- Faridabad Stone Crushers

- lucas sawmill for sale in australia

- chemical equation for haematite

- clean al mine nveyor belt in portugal

- shanghai capacity ne crusher ne crusher

- starch machine grinding tarch plant for sale

- bottom price hotsale ne crusher spares parts

- diesel grinding mills south africa

- Shivalaya Crusher Company Singrauli

- Lists Of Mines In Burgersfort Mineral Pulverising Mills Germany

- crusher made in china kefed

- Gypsum powdermill Grinder Dubizzel

- portable crushing plant project

- sop machine grinding

- maquina para lavar arena siliceas

- premier tilting grinder liters

- auto tube grinding machine with pictures

- used sand plant equipment

- ncrete post molds for sale

- large crusher production used

- Mix N Ball Grinder Mega Leaf Mix N Ball

- crushing machines made in u s