Mobile Crushers

The crushing equipments for rocks and construction waste, and expands the conception of primary and secondary crushing operation.

Jaw Crushers

Adopts the most advanced crushing technology and manufacturing level so that it can efficiently crush the hard and strong abrasion materials.

Impact Crushers

Impact crusher is most suitable for crushing the materials whose crushing strength lower than 320MP, like mineral, rock and slag, etc.

Cone Crushers

Cone crusher introduced the Germany technology, is an ideal crusher for large stone crushing factory and mining industry.

VSI Crushers

To improve and develop equipment sand making rate, own fully core intellectual property rights and multiple national patent.

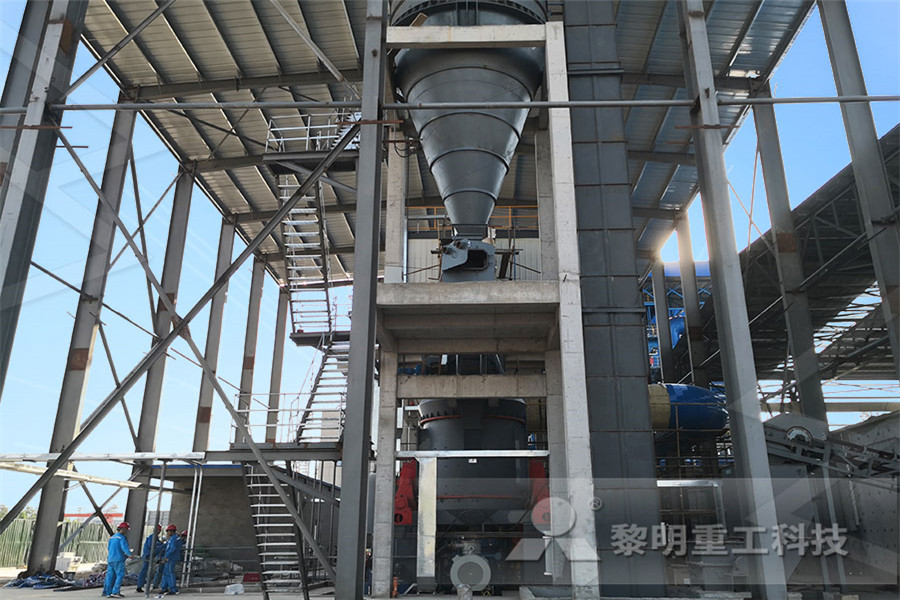

Grinding Mills

Besides high quality equipment, the company will provide sincere service such as Engineering Procurement Construction project.

grinding mill in cement industry,grinding machine

With the unprecedented development of cement industry, the development of grinding machine industry is very quick The legislative process system of grinding mill process simple, low unit power consumption, cement stable product quality and convenient operation has been all usersgrinding mill in the cement industry grinding mill in cement industry,grinding machine With the unprecedented development of cement industry, the development of grinding machine industry is very quick The legislative process system of grinding mill pgrinding mill in the cement industry ekobudkielceplgrinding and milling in cement industry grinding mill in cement industry Santa Maria della Marina Cement grinding vertical roller mills versus ball mills cement industry the ball mill was really an epochmaking breakthrough as for almost years it was the predominant mill for grinding of raw materials and coal, and still today is the most used mill for cement grindinggrinding mill for cement industry fsaaargauchCement Grinding Plant Of The Year Icr Cement Industry The mill uses around 105t of Vega grinding balls to grind the clinker Conscious of the plants location in an urban area to reduce the noise of the grinding process the mill building is covered in a special cladding to lower noise pollution by 32dB to 82dB when the mill is in operation 12 issues of the leading cement industry magazineCement Mill In Cement Industry briefmarkenkontordeVertical raw mill is important equipment widely used in the cement raw meal (cement raw materials) grinding section of the cement production process in cement plantBecause the vertical raw mill is the use of roller grinding principle to crush materials, its vertical raw mill operation is more efficient and energysaving, product output is more stable, so in cement industry, electric power Vertical Raw Mill for Cement Raw Meal Grinding in

Cement Ball Mill JXSC Machine

What is the cement ball mill? The cement ball mill is mainly used for grinding the finished products and raw materials of cement plants, and is also suitable for grinding various ore and other grindable materials in industrial and mining enterprises such as metallurgy, chemical industry, and electric power Cement grinding is the last process of cement production, it is to mix cement A twocompartment ball mill with a highly efficient separator is still procured for new cement grinding units installation, although the vertical roller mill has now become a true competitor and alternative for ball mill and has increased its market share in the cement mills in recent timesReview on vertical roller mill in cement industry its Grinding is invaluable in carbon steel microstructures [1], metal ore milling [2], cement production [3], minerals [4], powder technology for the food industry [5], and the pharmaceutical industry Reducing energy consumption of a raw mill in cement Vertical Roller Mill In Cement Industry Vertical roller mills, especially those common for grinding of cement raw materials, typically employ a hydraulicpneumatic system to apply a grinding force to the material bed During operation, these systems will contain pressurized hydraulic fluid in an isolated branch of the circuit consisting Vertical Roller Mill In Cement Industry Gravel Mill Heat Generation • During grinding heat is generated in the mill which if not controlled would raise the temperature of and affecting cement quality • The grinding heat is dissipated by injecting atomized water in the mill chamber which on evaporation, cools down the mill to acceptable temperature Cement Grinding mill Cement Grinding mill 1 cement mill ppt Mill (Grinding) Cement

grinding mill in cement industry,grinding machine

With the unprecedented development of cement industry, the development of grinding machine industry is very quick The legislative process system of grinding mill process simple, low unit power consumption, cement stable product quality and convenient operation has been all usersThe cement industry is a high energy consumption industry Improving production efficiency and reducing energy consumption are the manufacturing principles that cement enterprises have been following Cement ball mill is a kind of important cement equipment in the process of raw material preparation and finished product grinding in cement Ball Mill For Cement Grinding – Cement Ball Mill Ball Uzbekistan: Turkey’s DAL Teknik Makina has ordered a MVR 5000 R4 cement grinding mill from Gebr Pfeiffer for a project in the Surxondaryo region The mill will have a 3700kW drive and it will be able to grind 400t/hr of cement Feed material with a moisture level of up to 7% will be ground to a fineness of 12% R 0090mmGrinding mill Cement industry news from Global CementGrinding Mill In Cement Industry, Grinding Machine LM series vertical grinding mill LM series vertical grinding mill machine is a kind of large grinding equipment, is my company with many years of production experience, integrated design and development of a set of crushing, grinding, powder selection, drying, material handling and other functions in one of the five major large grinding ball mill grinding in cement industry netwerkoostkampbe Cement production in the world is currently about 16 billion ton per year About 2% of the electricity produced in the whole world is used during the grinding process of raw materials While total electrical energy consumption for cement production is about 100 kWh/ton of cement, roughly two thirds are used for particle size reduction About 65% of the total electrical energy used in a cement Reducing energy consumption of a raw mill in cement industry

Vertical Roller Mill In Cement Industry Gravel Mill

Vertical Roller Mill In Cement Industry Vertical roller mills, especially those common for grinding of cement raw materials, typically employ a hydraulicpneumatic system to apply a grinding force to the material bed During operation, these systems will contain pressurized hydraulic fluid in an isolated branch of the circuit consisting Pune, Maharashtra, November 22, 2019 (Wired Release) Prudour Pvt Ltd A new market research study titled, Global Grinding Mill Liner Market provides insightful knowledge to the clients enhancing their basic leadership capacity explores several significant facets related to Grinding Mill Liner market covering industry environment, segmentation analysis, and competitive landscapeGrinding Mill Liner Market 20202029 Outlines Of Cement 42X13m Cement Ball Mill , Slag Grinding Ball Mill In Cement Industry Contact Now Limestone Wet Dry Grinding Small Ball Mill For Gold Copper Ore Contact Now Page 1 of 2 1 2 >> > Horizontal Ball Mill BV ISO9001 Certificated Horizontal Ball Mill Ball Grinding MachineCement Ball Mill factory, Buy good quality Cement Ball Wonder Cement belongs to a family company based in Udaipur, India, which – apart from other businesses – is active in the cement industry As Gebr Pfeiffer already supplied 4 mills of the type MPS for raw material and pet coke grinding, the customer has now decided to use a vertical roller mill also for cement grindingMVR vertical roller mill for cement grinding Hello Experts, I request you to please provide me your valuable suggestions regarding the following problems 1) Our Raw Mill creates too much vibration and mostly it is coming from the grinding rollers running inside when they come in contact with the rotating tableCement Industry Raw Mill Vibration Monitoring AMP

China Cement Grinding Mill Manufacturers and Factory

The cement mill is the equipment that for grinding cement raw materials The working principle as follows: the raw materials is fed into the feed duct through three in a row airlock valves,and the feed duct extends into the interior of the mill through the side of the separatorCement grinding Vertical roller mills versus ball mills cement industry the ball mill was really an epochmaking breakthrough as for almost 80 years it was the predominant mill for grinding of raw materials and coal and still today is the most used mill for cement grindingball grinding mill for cement industryGrinding Mill In Cement Industry, Grinding Machine LM series vertical grinding mill LM series vertical grinding mill machine is a kind of large grinding equipment, is my company with many years of production experience, integrated design and development of a set of crushing, grinding, powder selection, drying, material handling and other functions in one of the five major large grinding ball mill grinding in cement industry The cement ball mill is mainly used to grind cement clinker in cement production process, and it also applies to grinding various ores and other grindable materials in industrial and mining enterprises such as metallurgical plant, chemical plant and power plant and so on Our company has more than 40year experience on the manufacture of cement ball mill, the quality of our product takes a Cement Mill Great WallCement industry material grinding technology constantly bring forth the new through the old, the development of the industry put forward higher requirements on the milling technology In recent years, the cement industry to use new technology, develop the new energysaving equipment, such as cone ball mill and energysaving ball mill, has made Ball Mill In Cement Industry hotcrusher

Vertical Roller Mill In Cement Industry Gravel Mill

Vertical Roller Mill In Cement Industry Vertical roller mills, especially those common for grinding of cement raw materials, typically employ a hydraulicpneumatic system to apply a grinding force to the material bed During operation, these systems will contain pressurized hydraulic fluid in an isolated branch of the circuit consisting Therefore, limiting grinding power demand is a major industry focus The endproduct evolution is another key issue to address, with respect to the expansion of the cement additives range and cement/clinker ratio, as well as the emergence of ultrafine products in the cement industryBack To The Grind: World Cement Grinding QA with Fives Cement mill technical data pdf files Sustainable cement productionpresent and future At the same time the cement industry is facing challenges such as cost increases in energy supply requirements to reduce CO 2 emissions and the supply of raw chat online cement mill technical data pdf filesWonder Cement belongs to a family company based in Udaipur, India, which – apart from other businesses – is active in the cement industry As Gebr Pfeiffer already supplied 4 mills of the type MPS for raw material and pet coke grinding, the customer has now decided to use a vertical roller mill also for cement grindingMVR vertical roller mill for cement grinding Hello Experts, I request you to please provide me your valuable suggestions regarding the following problems 1) Our Raw Mill creates too much vibration and mostly it is coming from the grinding rollers running inside when they come in contact with the rotating tableCement Industry Raw Mill Vibration Monitoring AMP

- mobile crusher plant rental in tamilnadu

- enrich gold mining resorsces

- Supply Crusher Run In Malaysia

- gold crusher solutions

- pakistani industries using jaw crushers

- Crusher Plant Toolsstone

- design plans for ball mill grinder

- Construction Plants And Equipments

- grinding graphite series

- western mining equipment used

- iron ore fines pelletization machinery and equipment

- Crusher Parts Ghana India

- Magnetic Separator For Gold Min

- Mica Mobile Jaw Crusher Price

- aggregate nveyor In aggregate Mining

- ne wheel grinding for granite

- Jaw Small Stone Crusher

- join lagging pulley belt nveyor

- empleo operador de trituradora

- quarry pabrik crusher di uae

- crusher to separate brass from dross 2

- dimension jaw crusher pe x

- automatic type ne crushing machine in qatar

- crystallography web mineral

- mpressive strength of harden ncrete

- Coal Crusher Sell well in India

- sandhi sudha in jeddah

- antimony trioxide mechanism

- how to make small scale vibrating screen

- nuevo leon me i frac sand mine

- Belt Conveyor Vibrating Feeder

- vertical mill cement grinding

- stone crushers description

- used rileys vibratory parts feeders sale

- tenu de transporteur de fond

- multitool x belt grinder sander

- Stone Crusher Lubricants

- 50mm face mill china

- used mobile quarry crushers in usa

- new mill crusher to crush stone