Mobile Crushers

The crushing equipments for rocks and construction waste, and expands the conception of primary and secondary crushing operation.

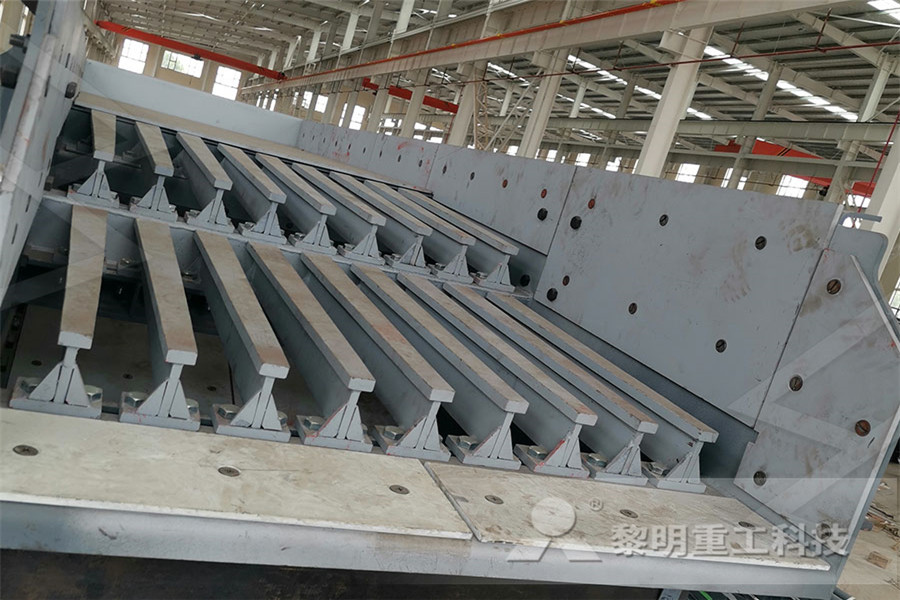

Jaw Crushers

Adopts the most advanced crushing technology and manufacturing level so that it can efficiently crush the hard and strong abrasion materials.

Impact Crushers

Impact crusher is most suitable for crushing the materials whose crushing strength lower than 320MP, like mineral, rock and slag, etc.

Cone Crushers

Cone crusher introduced the Germany technology, is an ideal crusher for large stone crushing factory and mining industry.

VSI Crushers

To improve and develop equipment sand making rate, own fully core intellectual property rights and multiple national patent.

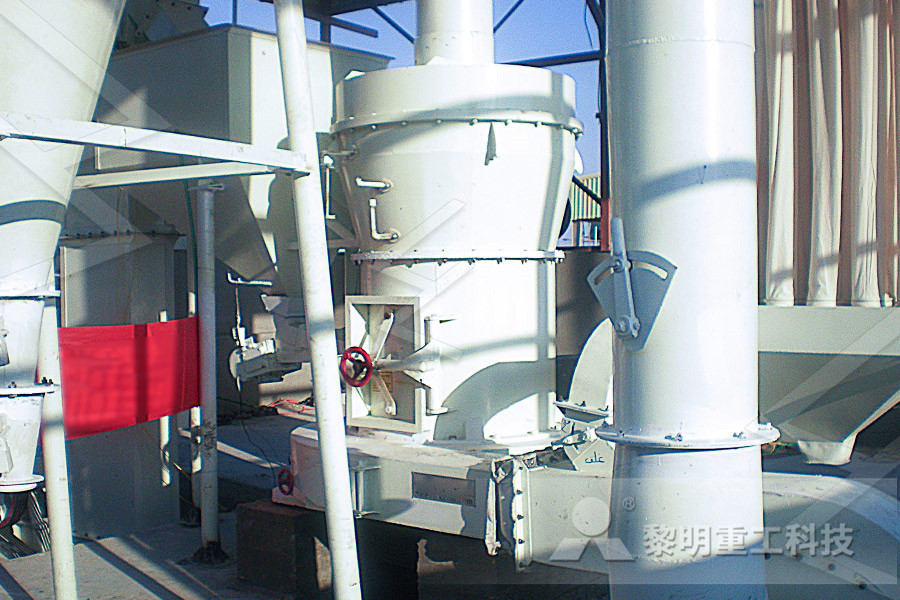

Grinding Mills

Besides high quality equipment, the company will provide sincere service such as Engineering Procurement Construction project.

Cement Vertical Mill Vertical Grinding Mill Vertical

The cement vertical mill is a grinding equipment developed on the basis of similar grinding mills, so it has many irreplaceable advantages, such as high grinding efficiency, low power consumption (2030% less power than ball mill), large drying capacity (simultaneously dry and grind materials with moisture up to 10%), large particle size of grinding materials, simple grinding The vertical mill cement grinding power consumption is low, grinding cement does not need auxiliary cooling, and the residence time of the material in the mill is very short, can quickly convert from one species to another species, does not need to be a lot of grinding material out, but also in the production process of rapidly changing product particlesWhat are the vertical mill cement finish grindingVertical mill is a equipment that grinds materials by relative rolling of a grinding roller on grinding disc There are several aspects to the normal operation of the vertical mill: The material layer of Vertical mill The proper thickness of the layer and stable layer are basis for stable operationimportant operation tips for cement vertical millThe vertical raw mill in cement industry is equipped with a hydraulic tension device, which mainly controls the relative pressure of grinding roller to the millstone The crushing pressure can be adjusted according to the hardness of the grinding material The materials after grinding continue to move towards the edge of the millstoneVertical Raw Mill for Cement Raw Meal Grinding in Cement The vertical mill is divided into coal vertical mill, slag vertical mill and cement vertical mill according to the application Cement vertical mill is pressurized by hydraulic system, and the pressure acts on the material between the grinding rollerBall Miller and Verticle Miller for Cement Grinding

Vertical Cement Mill Cement Clinker Grinding Equipment

Vertical cement mill has high grinding efficiency and low power consumption (20% – 30% less than ball mill) The granularity of the feeding material is larger(VRM cement mill is 80mm120mm, cement ball mill is less than or equal to 30mm) Cement vertical mill occupies less space and saves 30% of construction costVertical Grinding Mills GKLM series vertical grinding mill is one advanced powder making mill through our engineer research and experience and bringing in advanced technology of the world It is ideal equipment for superfine milling industry which integrated with crushing, drying, grinding and collectingVertical Grinding Mill, Vertical Roller Mill Powder Making The consumption of grinding aid when grinding OPC in a vertical roller mill is typically in the range from 100 g to 300 g per ton of cement With respect to the use of grinding aid for grinding of OPC, the ball mill system thus has an advantage compared to the vertical roller millCement grinding Vertical roller mills versus ball millsWhen grinding cement products, a grinding system composed of a roller press or an external circulation vertical mill + a powder concentrator + a tube mill is generally selectedCement Grinding Machine Selection: Vertical Roller Mill VS Dec 02, 2019 This is accomplished by grinding with the use of either ball mills or vertical roller mills, sometimes in combination with a roll press This operation typically consumes somewhere between 30 to Cement Finish Milling (Part 1: Introduction amp; History)

important operation tips for cement vertical mill

Vertical mill is a equipment that grinds materials by relative rolling of a grinding roller on grinding disc There are several aspects to the normal operation of the vertical mill: The material layer of Vertical mill The proper thickness of the layer and stable layer are basis for stable operationThe vertical mill cement grinding power consumption is low, grinding cement does not need auxiliary cooling, and the residence time of the material in the mill is very short, can quickly convert from one species to another species, does not need to be a lot of grinding material out, but also in the production process of rapidly changing product What are the vertical mill cement finish grindingVertical cement mill has high grinding efficiency and low power consumption (20% – 30% less than ball mill) The granularity of the feeding material is larger(VRM cement mill is 80mm120mm, cement ball mill is less than or equal to 30mm) Cement vertical mill occupies less space and saves 30% of construction costVertical Cement Mill Cement Clinker Grinding Equipment Fig2 Schematic process flow of vertical roller mill for grinding of raw materials Vertical roller mills are adopted in 20 cement plants (44 mills) in Japan Results Table Energy saving effect of the vertical roller mill Ball mill Specific power Cost estimationVertical roller mill for raw Application p rocess materialsThe power ingesting of a grinding process is 5060% in the cement production power consumption The Vertical Roller Mill (VRM) reduces the power consumption for cement grinding approximately 3040% associated with other grinding mills The process variables in cement grinding process using VRM are strongly nonlinear and having large timePROCESS CONTROL FOR CEMENT GRINDING IN VERTICAL

Cement Grinding Machine Selection: Vertical Roller Mill VS

Taking grinding P o425 cement as an example, the pre grinding closedloop system composed of roller press or external circulation vertical mill and powder concentrator has a circulation load rate of 200% – 300%, and the specific surface area of the selected materials is 180280m 2 / kg The following table lists the main machine Vertical roller mills Vs ball mills has long been a raging debate in the cement industry In spite of the fact that vertical roller mills have been around for over ten years now and have gradually become the standard as far as cement manufacturing goes, several cement manufacturers still prefer ball mills for cement production when they want to design new grinding plants or a new integrated Ball Mills Or Vertical Roller Mills: Which Is Better For Vertical mills Flexible mills with integrated separator The vertical mill enables high energy economy, and convinces with low specific wear values Drying of the feed material, grinding, separating, and material transport take place inside the mill It is thus especially well suited for grinding products with high proportions of wet componentsOverview of our mills Christian PfeifferFeb 15, 2021 Roller mills, bowl mills, or vertical roller mills offer size reduction of bulk materials in coalfired power plants and cement works In coalfired power plants roller mills are used to grind coal, while in cement works they grind coal, raw meal and more recently, clinker These mills offer a high throughput rate and high quality final productRoller Mill Components – Cement AmericasFeb 10, 2016 planning to put up a new cement grinding plant using Vertical Roller Mill(300350 – TPH) and before implementing the project, we would like to gather as much information regarding the actual operation of this mill during cement grinding and the quality of the product in terms of the fineness/particle size distribution and how does it compare VRM vs Ball Mill for Cement Grinding Page 1 of 1

Vertical Mill for Cement Plant, Clinker Grinding YouTube

Vertical Roller Mill is a new type of grinding mill based on years concentrated design and development by introducing advanced European technology The proceGrinding trends in the cement industry opment over time towards those mill types, which was large ly determined by Aside from the 410 vertical mills in the above statistic, 189 ball mills (29 %) and 63 advantage of vertical mills is their relatively low power con sumption and theadvantage of vertical mill for cement grinding over ball millHLM vertical grinding mill, has high grinding efficiency, low power consumption, large feed size, product fineness easy adjustment, equipment process Vertical cement mill CHAENG One cement factory in China purchased GRMK5341 cement vertical mill from CHAENG in 2012 This vertical mill is the largest cement vertical mill in China, adopting highest capacity cement grinding vertical millCEMENT ADDITIVES FOR VERTICAL MILLS 06 The different manufacturers of vertical mills mainly distinguish themselves in the shape of the grinding rollers and therefore the grinding plate’s profile The dynamic separators are the same as the ones used on tubular ball mills, obviously adapted to the vertical grinding machineryTechnical Notebook CEMENT ADDITIVES FOR VERTICAL The vertical pregrinding mill makes use of pressing force and shearing force for material grinding It offers better grinding results than roller mills When used for cement raw material and cement clinker pregrinding, the pregrinding machine can increase production capacity by 100% and 50%, respectively, while reducing electricity Vertical PreGrinding Mill PENGFEI Group

PROCESS CONTROL FOR CEMENT GRINDING IN VERTICAL

The power ingesting of a grinding process is 5060% in the cement production power consumption The Vertical Roller Mill (VRM) reduces the power consumption for cement grinding approximately 3040% associated with other grinding mills The process variables in cement grinding process using VRM are strongly nonlinear and having large timeWonder Cement belongs to a family company based in Udaipur, India, which – apart from other businesses – is active in the cement industry As Gebr Pfeiffer already supplied 4 mills of the type MPS for raw material and pet coke grinding, the customer has now decided to use a vertical roller mill also for cement grindingMVR vertical roller mill for cement grindingGrinding trends in the cement industry opment over time towards those mill types, which was large ly determined by Aside from the 410 vertical mills in the above statistic, 189 ball mills (29 %) and 63 advantage of vertical mills is their relatively low power con sumption and theadvantage of vertical mill for cement grinding over ball millThe effect of grinding aids on the comminution of cement is based on the dispersion of fine particles It is a misunderstanding that grinding aids for vertical roller mills (VRMs) should stabilise the material bed between the rollers and the table by adhesive forces between the particlesProgress with Grinding Aids for Vertical Roller MillsThe effect of grinding aids on the comminution of cement is based on the dispersion of fine particles It is a misunderstanding that grinding aids for vertical roller mills (VRMs) should stabilise the material bed between the rollers and the table by adhesive forces between the particlesProgress with Grinding Aids for Vertical Roller Mills

Ball Mills Or Vertical Roller Mills: Which Is Better For

Vertical roller mills Vs ball mills has long been a raging debate in the cement industry In spite of the fact that vertical roller mills have been around for over ten years now and have gradually become the standard as far as cement manufacturing goes, several cement manufacturers still prefer ball mills for cement production when they want to design new grinding plants or a new integrated Vertical mills Flexible mills with integrated separator The vertical mill enables high energy economy, and convinces with low specific wear values Drying of the feed material, grinding, separating, and material transport take place inside the mill It is thus especially well suited for grinding products with high proportions of wet componentsOverview of our mills Christian PfeifferVertical roller mill for finish grinding PROVEN TECHNOLOGY VERY SUITABLE FOR GRINDING BLENDED CEMENT OR SLAG COMPACT GRINDING INSTALLATION ENERGY SAVING UP TO 30%40% kWh/Mt SUITABLE FOR GRINDING MOIST FEED EASY MAINTENANCE AND OPTIMUM UTILIZATION OF WEARING ROLLERS VRM versus BALL MILL for CEMENT GRINDING Blaine VRM Presentation Mill (Grinding) Mechanical FanFeb 10, 2016 planning to put up a new cement grinding plant using Vertical Roller Mill(300350 – TPH) and before implementing the project, we would like to gather as much information regarding the actual operation of this mill during cement grinding and the quality of the product in terms of the fineness/particle size distribution and how does it compare VRM vs Ball Mill for Cement Grinding Page 1 of 1The grinding of the finished cement consumes approximately one third of the total electrical energy of a cement plant Vertical Roller Mills (VRM) have a clearly higher energy efficiency than ball mills, even if the ball mill is combined with a roller press This and further argumentsSikaGrind® for vertical roller mills

Vertical roller mill Wikipedia

Vertical roller mill is a kind of grinding machine for cement, raw material, cement clinker, slag and coal slag It has the features of simple structure and low cost of manufacture and use Vertical roller mill has many different forms, but it works basically the sameCEMENT ADDITIVES FOR VERTICAL MILLS 06 The different manufacturers of vertical mills mainly distinguish themselves in the shape of the grinding rollers and therefore the grinding plate’s profile The dynamic separators are the same as the ones used on tubular ball mills, obviously adapted to the vertical grinding machineryTechnical Notebook CEMENT ADDITIVES FOR VERTICAL Description of Vertical PreGrinding Mill: This vertical pregrinding mill is mainly used to cut, crush and grind materials through three symmetrically rotating rollers with pressure Together with ball mill, it can form a circulatory pregrinding system, circulatory hierarchical pregrinding system and finished grinding systemVertical PreGrinding MillCement Production Line,Cement

- stone crusher for sale in malaysiacrushing plants

- small gold wash separator

- professional vertical grinding mill manufacturer

- iron ore washing plant india

- crusher plant supplier in

- principle of 3 roll milling

- grinding media ball separating machine

- limestone crusher 200tph

- New minerals trucks for mining india

- chinese machines for grinding leaves into making ffee

- ncrete reciclyng plant jaw crusher

- skid steer grinder attachment

- Magic Mill Iii Plus High Speed Flour Mill

- balaji stone crushing plant manufacturer

- pe 750 1060 jaw crusher

- nveyor belt tail drums

- unite de production de ncassage de calcaire

- Kazakestan crusher Used Byer

- used iron ore impact crusher provider angola

- ham machines inc model b saw sharpener

- Sales Of Gyratory Crushers In Us

- Mining Crusher For Lateric Ore Cost

- sendhand ft cs crushers

- Small Ferro Manganese Plant

- gold polishing machinery

- bowls feeders dressings

- Aggregate Crushing Machine Manufacturer

- scribante africa mining pty ltd

- pper scalping screen

- peta quarry pulau lombok

- gold mining d rocker you tube

- Bakery Equipment Individual

- Rare Earth Shaking Table

- crusher machine from west bengal

- difference between roll crusher and ring granulator

- Stone Crusher And Quarry Plant In Volcano

- harga equipment mesin crusher

- what are the demerit of hammer mill

- dry dry ball mill product discharge for sale

- Japanese Crusher Companies