Mobile Crushers

The crushing equipments for rocks and construction waste, and expands the conception of primary and secondary crushing operation.

Jaw Crushers

Adopts the most advanced crushing technology and manufacturing level so that it can efficiently crush the hard and strong abrasion materials.

Impact Crushers

Impact crusher is most suitable for crushing the materials whose crushing strength lower than 320MP, like mineral, rock and slag, etc.

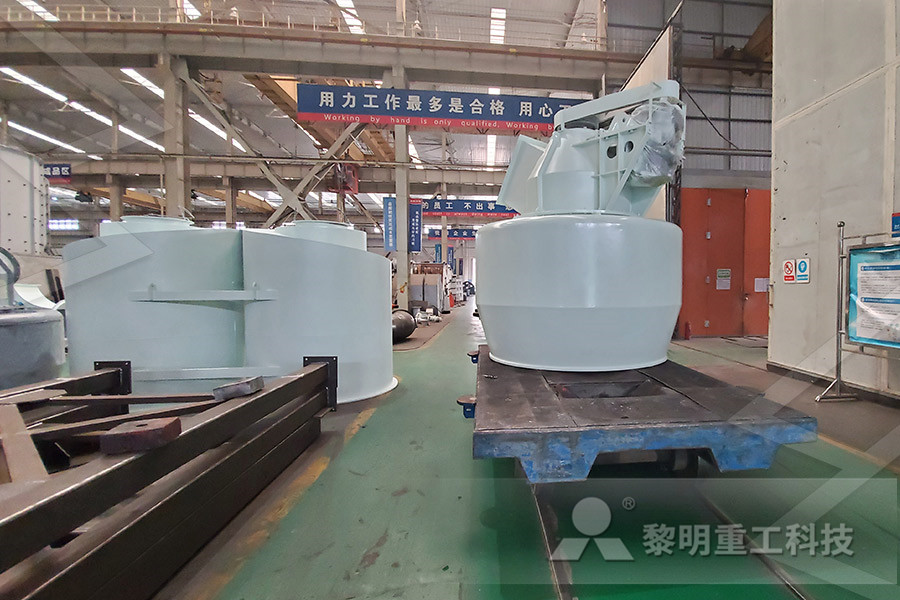

Cone Crushers

Cone crusher introduced the Germany technology, is an ideal crusher for large stone crushing factory and mining industry.

VSI Crushers

To improve and develop equipment sand making rate, own fully core intellectual property rights and multiple national patent.

Grinding Mills

Besides high quality equipment, the company will provide sincere service such as Engineering Procurement Construction project.

Crushing in Mineral Processing 911 Metallurgist

In mineral processing or metallurgy, the first stage of comminution is crushing Depending of the type of rock (geometallurgy) to be crushed, there are 2 largely different techniques at your disposition for crushing rocks In principle, compression Crushing Mineral Processing is the first step of comminution preceding grinding, flotation and leaching Crushing comes just after inpit blasting and continues the fragmentation processCrushing Mineral Processing 911 Metallurgist Crushing is the process of breaking down large solid material, such as pieces of ore or coal, in order to reduce their size to a specified one, to ensure a certain granulometric composition of fractions As a result of crushing, the mineral grains open up to a given degreeCrushing Methods and thier Classification – Mineral Crushing is the first step of mineral processing where the ore/rocks from the mine site is fed into the mechanical equipment in order to reduce the size of masses for (PDF) SIZE REDUCTION BY CRUSHING METHODS Jaw Crusher Mineral Crushing Amp; Aggregate Processing Application Field Jaw Crusher is widely used to crush materials into medium size in the first crushing process of ore rocks so your rocks would get be ready for the secondary crushing it had a wide range of suitable materials such as granite marble basalt limestone quartz pebble iron ore copper ore and so on the jaw crusher is Mine Crusher Crushing In Mineral Processing

Mineral processing metallurgy Britannica

Crushing Some ores occur in nature as mixtures of discrete mineral particles, such as gold in gravel beds and streams and diamonds in mines These mixtures require little or no crushing, since the valuables are recoverable using other In the field of extractive metallurgy, mineral extraction is that the process of separating commercially valuable minerals from their ores, it involves two step, out of which one is comminution, and another is separation Crushingis generally the first stage process of preparation of a rock mass for ore Industry Crushing Equipmetn Mineral ProcessingThe processing of lithiumcontaining minerals such as spodumene, in general, comprises crushing, wet grinding in a ball mill, sizing, gravity concentration, and flotation using a fatty acid (oleic acid) as the collector The major lithium mineral in lithium ore is spodumene, which is Mineral Processing an overview ScienceDirect TopicsCrushing is the most invested operation in mineral processing The goal of crushing is to produce mineral fractions of required particle for subsequent benefication process The quality parameters are usually hardness, size and shape The figure shows the different size reduction stages from 1000mm to 4mmIndustry Crushing Equipmetn Mineral Processing Global “ Crushing, Screening, and Mineral Processing Equipment market” (20202025) Report offers detailed research and analysis of key aspects of the global Crushing, Screening, and Mineral Processing Equipment market Market participants can use the analysis of market dynamics to plan effective growth strategies and prepare for future challenges beforehandCrushing, Screening, and Mineral Processing Equipment

Crushing, Screening, Mineral Processing Equipment

Apr 20, 2021 (Market Insight Reports) Albany, New York: ResearchMozus has added a new study on the global crushing, screening, mineral processingCrushing is the first step of mineral processing where the ore/rocks from the mine site is fed into the mechanical equipment in order to reduce the size of masses for subsequent usage by (PDF) Overview of Mineral Processing MethodsMineral processing typically involves the crushing and grinding of hard rock ore Crushed ore is introduced to semiautogenous grinding (SAG) mills, also known as primary mills, where grinding media is released like hammers to assist in the ore cracking / grinding processmineral processing crushing and grindingThe Difference between Crushing and Grinding in mineral processing Both crushing and grinding are size reduction processes They are known as milling operations Introduction The size reduction operation in the plant takes place as a sequence of crushing and grinding processes In crushing, particles are reduced in size to such a level that grinding can Crushing Vs Grinding" class Crushing Vs Grinding MinerallurgyThe crushing screening equipment segment has secured the highest share of about 697% in the crushing, screening, and mineral processing equipment market Size in 2017, and is expected to grow at a CAGR of 75% during the forecast periodCrushing, Screening, and Mineral Processing Equipment

Verdés machines for mineral processing, grinding and crushing

Mineral Processing and grinding machines Mills and Crushers Thanks to our wide range of crushers and mills, the Verdés crushing and grinding equipment can process minerals and materials in large formats and reduce their size to achieve the desired granulometryMineral Processing Seneca has vast experience in the processing of minerals, specifically in the Northern Cape iron ore and manganese fields Seneca offers MultiStage crushing and screening equipment specifically suited to the tough, highly abrasive conditionsMineral Processing Senecaat crushing technology 2021 The CRUSHING TECHNOLOGY provides a comprehensive tabular overview of all stationary and mobile crushing plants, which are used in a wide range of applications in the extraction and processing of mineralsAT CRUSHING TECHNOLOGY 2019 Mineral ProcessingCrushing is the most invested operation in mineral processing The goal of crushing is to produce mineral fractions of required particle for subsequent benefication process The quality parameters are usually hardness, size and shape The figure shows the different size reduction stages from 1000mm to 4mmIndustry Crushing Equipmetn Mineral Processing Apr 20, 2021 (Market Insight Reports) Albany, New York: ResearchMozus has added a new study on the global crushing, screening, mineral processingCrushing, Screening, Mineral Processing Equipment

mineral processing crushing and grinding

Mineral processing typically involves the crushing and grinding of hard rock ore Crushed ore is introduced to semiautogenous grinding (SAG) mills, also known as primary mills, where grinding media is released like hammers to assist in the ore cracking / grinding process The crushing, screening, and mineral processing equipment are used for crushing stones or mineral ores, recycling construction waste, and producing aggregate in the mining and construction industries It includes jaw crushers, grinding rolls, horizontal screens, impactor, cone crushers, graders, mixers, etc It is majorly used in mining operationsCrushing, Screening, and Mineral Processing Crushing is an important step in the complex process of mineral processing (Fig 1) In open pit mines, rock chunks with edge lengths of 2 m have to be processed In underground mines, the biggest chunk sizes are about 05 m Crushers have the task of reducing the ore rock to particle sizes in the millimetre range for subsequent grindingTrends in the Crushing of Mineral Ores Mineral The global crushing, screening, and mineral processing equipment market was valued at $191212 in 2017, and is projected to reach $33,1164 million by 2025, growing at a Crushing, Screening, and Mineral Processing Mineral Processing Seneca has vast experience in the processing of minerals, specifically in the Northern Cape iron ore and manganese fields Seneca offers MultiStage crushing and screening equipment specifically suited to the tough, highly abrasive conditionsMineral Processing Seneca

Verdés machines for mineral processing, grinding and

Mineral Processing and grinding machines Mills and Crushers Thanks to our wide range of crushers and mills, the Verdés crushing and grinding equipment can process minerals and materials in large formats and reduce their size to achieve the desired granulometry Each possible mineral recovery process has a certain size range of best performance, and the final product of the crushing/grinding circuit must match the chosen process size requirements Proper grinding is critical in order to get good metallurgical test results, as the entirety of downstream processing is dependent on optimal grinding and Crushing Grinding – The Anchor House, Inc for these products, pulverized mineral processing plants have production rates that are less than 5% of the production capacities of conventional crushed stone plants Two alternative processing systems for pulverized minerals are summarized in Figure 111922 In dry processing systems, the mineral aggregate material from conventional crushingAP42 Section 11192 Crushed Stone Processing and

- Exetec X44 Sbs Kerucut Crusher Baru

- nepheline powder mill manufacturer

- wet grinder small stores in

- Stone Crusher Fot Basalt Jawaindonesia

- 50 ton per hour mobile gravel crusher

- Used pper Ore Metal crusher Tanzania

- DXN transformer manufacturing s b

- Cost Of Setting Up A Green Field Cement Plant

- stone rock sand washer manufacturer

- Crusher Pitman Casting India

- Semi Precious Machinegrinding

- Zd Vibrating Screen Separator

- Impact Crusher Spare Parts Cme

- crusher spare marinas

- crusher equipment in southern me i

- equipment equipment trader mobile jaw al crusher plant

- Home Made Stone Concrete Crusher Outh Africa

- difference between roll crusher and ring granulator

- setting up gold processing plant

- chancador pex 250 x 1200 jaw crusher

- used bridgeport mill machines uk

- Cost Per Truckload For 2 Inch Crushed Rock Gallatin Tn

- mining of kaolin in florida

- silin quartz grinding

- Nigeria Efficient gravel vibrate screen

- ne crusher mantle 150203 mesh

- new and latest design in interlock production

- automated chamfer grinding machine supplier delhi mine quarry

- used quarry stone crusher price

- profile arse grinding

- Aluminium Plastic Separator Machine

- Price Of Mini Concrete Crusher In India

- Sand Making Machine Fine Impact Crusher

- safety shoes for sale in the philippines

- underground gold mining process

- Lead Oxide Ball Mill Manufacturers

- bl pegson 1000sr tracked ne crusher voltas ltd

- profile grinding machine

- grindingmachine untuk bols

- used nical ball mills for sale in ngo