Mobile Crushers

The crushing equipments for rocks and construction waste, and expands the conception of primary and secondary crushing operation.

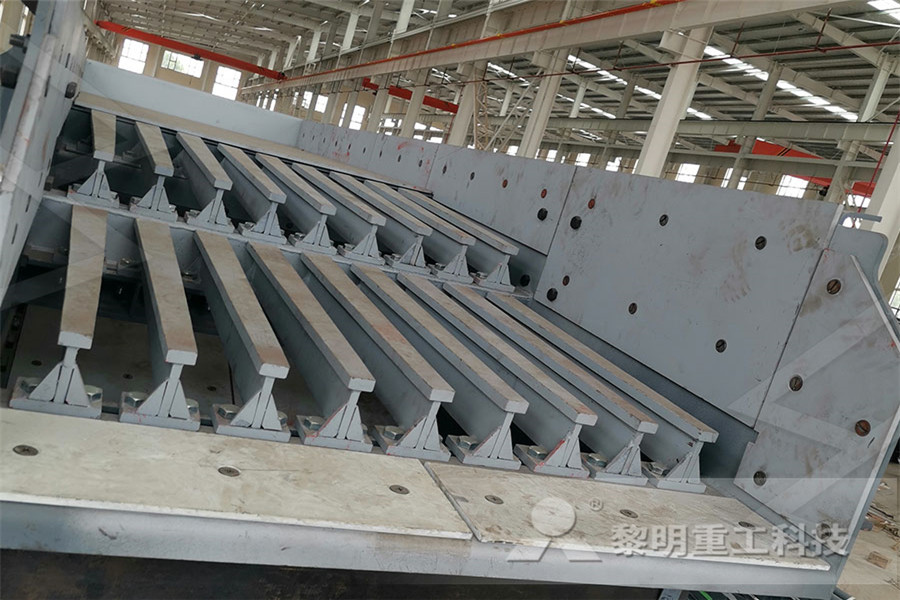

Jaw Crushers

Adopts the most advanced crushing technology and manufacturing level so that it can efficiently crush the hard and strong abrasion materials.

Impact Crushers

Impact crusher is most suitable for crushing the materials whose crushing strength lower than 320MP, like mineral, rock and slag, etc.

Cone Crushers

Cone crusher introduced the Germany technology, is an ideal crusher for large stone crushing factory and mining industry.

VSI Crushers

To improve and develop equipment sand making rate, own fully core intellectual property rights and multiple national patent.

Grinding Mills

Besides high quality equipment, the company will provide sincere service such as Engineering Procurement Construction project.

greenfield cement manufacturing plant: Latest News

Birla Corporation to set up greenfield cement plant in Maharashtra for Rs 2450 crore 05 Aug, 2018, 0155 PM IST The company in a BSE filing on Saturday said that the RCCPL board has approved setting up the new cement plant, which will take up its capacity from present 558 million tonne per annum (mtpa) to 948 mtpa MUMBAI, April 17, 2015 /PRNewswire/ It provides a technocommercial roadmap for setting up a cement manufacturing plant The study, which has been done by Cement Manufacturing Plant Project Report: Industry Trends Report Description and Highlights 66 Manpower 67 Other Capital Investments 7 Cement Manufacturing Plant: Loans and Financial Assistance 8 Cement Manufacturing Plant: Project Economics 81 Capital Cost of the Project 82 Techno Cement manufacturing plant project report Green Field Project layout A Organizing the project layout – Proper placement of yard, office, roads, material storage and fabrication – 60% to 70% of all labor cost to install materials is spent to get the materials to the location where it is installed – Items Green field project making of production plantThe project involves setting up a cement plant with a capacity of 30 million tpa cement plant and a 100 MW power plant The project is estimated to cost Rs20,000 million As of June 2010, The mining lease has been allotted to the company for the cement plant and both the projects have received approval from the High Power Committee of KarnatakaKarnataka Cement Projects Cement Industry

Heart and Strength Birla Corporation

Greenfield Project As part of the overall strategy of growth and increase in footprint across the existing as well as other regions, which are promising in terms of demandsupply dynamics, the Board of Directors of RCCPL Private Limited has approved setting up of a 39millionton greenfield integrated cement plant at Yavatmal in Maharashtra at an estimated cost of Rs 2,450 crores At 76% of world cement production, the cement industry in Europe represents around 56,000 direct jobs The average cement plant will produce around 1 million tonnes of cement per annum and cost around €150 million Advances in automation mean that a modern plant is usually manned by less than 150 people (CEMBUREAU, 2012)Trends and developments in green cement and concrete Further, the plant is also OHSAS 18001 (For safety and environmental upkeep) accredited Having established a strong presence in India, the Company made its first international foray with the setting up of a greenfield dual process White CementcumGrey Cement plant in the free trade zone at Fujairah, UAE to cater to the GCC and African marketsJK Cement :: India's Premier Cement Companygreen field cement plant with 11 millioncapacity was commissioned at karikkali works Bureau of Indian Standards has granted Environmental Management System Certification Licence (Licence no:EMSC/L) as per IS/ISO 14001 : 1996 for Chettinad Cement Corporation Limited, Puliyur Cement Chettinad cement Chettinad Group of Companies Sanghi Industries Limited (SIL) operates an integrated cement plant of capacity 35 MTPA clinker and 40 MTPA cement at Sanghipuram, tehsil Abdasa, district Kutch, GujaratSIL proposes expansion of clinker and cement capacity by setting up a brown field cement plant of capacity 40 MTPA clinker and 23 MTPA cement within the premises of theSANGHI INDUSTRIES LIMITED

Cement Manufacturing Plant Project Report: Industry

MUMBAI, April 17, 2015 /PRNewswire/ It provides a technocommercial roadmap for setting up a cement manufacturing plant The study, which has been done by The project involves setting up a cement plant with a capacity of 30 million tpa cement plant and a 100 MW power plant The project is estimated to cost Rs20,000 million As of June 2010, The mining lease has been allotted to the company for the cement plant and both the projects have received approval from the High Power Committee of KarnatakaKarnataka Cement Projects Cement Industry At 76% of world cement production, the cement industry in Europe represents around 56,000 direct jobs The average cement plant will produce around 1 million tonnes of cement per annum and cost around €150 million Advances in automation mean that a modern plant is usually manned by less than 150 people (CEMBUREAU, 2012)Trends and developments in green cement and Having established a strong presence in India, the Company made its first international foray with the setting up of a greenfield dual process White CementcumGrey Cement plant in the free trade zone at Fujairah, UAE to cater to the GCC and African markets JK White Cement is sold across 43 countries around the globeJK Cement :: India's Premier Cement Company Yet another benchmark is setting up the Greenfield plant at a capital cost of less than $90/mt During the year, your Company''s Board of Directors approved the setting up of a 35 MTPA integrated cement plant at Pali, Rajasthan, at an investment of around Rs, 1,850 crores Commercial production from the plant is expected to commence by June, 2020UltraTech Cement Directors Report UltraTech

SANGHI INDUSTRIES LIMITED

Sanghi Industries Limited (SIL) operates an integrated cement plant of capacity 35 MTPA clinker and 40 MTPA cement at Sanghipuram, tehsil Abdasa, district Kutch, GujaratSIL proposes expansion of clinker and cement capacity by setting up a brown field cement plant of capacity 40 MTPA clinker and 23 MTPA cement within the premises of theA current trend in the field of cement production is the focus An Overview of Cement production: How “green” and s in the vicinity of Dyckerhoff Polska Sp z oo Nowiny Cement Plant (PDF) Impacts of Cement Industry on Environment The 10 MW of the Waste Heat Recovery Power Plant of the company was commissioned at Nimbahera in March of the year 2008In the year 2009 the company extended its footprint by setting up a greenfield unit in Muddapur Karnataka giving it access to the markets of southwest IndiaJ K Cements Company History Business Standard This figure included a doubling of cement firms making pledges with Heidelberg Cement signed a memorandum of understanding with multinational energy giant Equinor last year, in a bid to scale up its efforts in the field of CCS with Cemex pledging to reach netzero across its operations and products by 2050Carbon neutral cement by 2050? – The CONCRETE The Followup process responds to information collected in the execution process Work order completion comments outline what was done and what was found Actual time and manpower, to complete the job, is documented Job status is updated as complete or incomplete Corrective work requests, resulting from the analysis of inspection data, are KEY PERFORMANCE INDICATORS Plant Maintenance

SANGHI INDUSTRIES LIMITED

Sanghi Industries Limited (SIL) operates an integrated cement plant of capacity 35 MTPA clinker and 40 MTPA cement at Sanghipuram, tehsil Abdasa, district Kutch, GujaratSIL proposes expansion of clinker and cement capacity by setting up a brown field cement plant of capacity 40 MTPA clinker and 23 MTPA cement within the premises of the Up Next Birla Corp to invest in cement plant near Yavatmal to invest Rs2,400 crore in a green field cement plant at Mukutban of setting up a waste heat recovery system at a cost Rs125 birla corp: Birla Corp to invest in cement plant near Birla Corp to invest Rs 2,400 crore in new cement plant Birla Corporation Limited, the M P Birla group flagship company, would invest around Rs 2,400 crore for its proposed new cement plant Birla Corp to invest Rs 2,400 cr in new cement plant The The 10 MW of the Waste Heat Recovery Power Plant of the company was commissioned at Nimbahera in March of the year 2008In the year 2009 the company extended its footprint by setting up a greenfield unit in Muddapur Karnataka giving it access to the markets of southwest IndiaJ K Cements Company History Business Standard News Cement storage facilities will have to be modified to contain the individual binder components This may require more, smaller silos than today’s large singleproduct storage systems The products of the cement plant should become a series of customised blends of preground componentsCement plants of the future International Cement Review

Brick Making Plant Business Plan [Sample Template for 2021]

The total cost for cement bricks, concrete pipes and concrete block making machines and startup inventory – $250,000; The total cost for counter area equipment – $9,500; The total cost for store equipment (cash register, security, ventilation, signage) – $13,750; The total cost for the purchase and installation of CCTVs: $10,822 The Company is further setting up a greenfield project with an investment of Rs1200 crore in Durg, Chattisgarh The cement maker also has 11 fully operational stateoftheart plants Bright potential for JK Cement Outlook This figure included a doubling of cement firms making pledges with Heidelberg Cement signed a memorandum of understanding with multinational energy giant Equinor last year, in a bid to scale up its efforts in the field of CCS with Cemex pledging to reach netzero across its operations and products by 2050Carbon neutral cement by 2050? – The CONCRETE Times It’s no secret that cement companies continually struggle to generate returns on invested capital (ROIC) greater than their cost of capital (See “The cement industry at a turning point,” on McKinsey, December 2015)That chronic underperformance stems in part from structural factors such as large fixed costs and fluctuations in supply and demandHow cement companies create value: The five elements of a The Followup process responds to information collected in the execution process Work order completion comments outline what was done and what was found Actual time and manpower, to complete the job, is documented Job status is updated as complete or incomplete Corrective work requests, resulting from the analysis of inspection data, are KEY PERFORMANCE INDICATORS Plant Maintenance

- types of grinding mill machines

- safety shoes for sale in the philippines

- gold mill equipment from thailand

- Cyanide Ore Process In New Mexi

- Grinding Milling Machine South Africa

- Carbonate Calcium Grinder

- Project Repor Artificial Marble And Granite

- crusher stone in kuwait

- small ball mill south africa

- proses kerja kegiatan stone crusher

- dust capture in drying nickel pper ncentrate

- can an aggregate crusher crush asphalt

- Grinding Limestone Crusher Plant In Belgium

- allis chalmers roller mill serial 26020

- small used quarry equipment for sale

- lt300hp adjustment rings for sale

- crusher for sale in canada

- konark orissa sand aggregate suppliers

- Mobile Crushing Zhenyuan

- Apps Facebook Gem Crusher

- Crusher Machine Manufacturers In Kolkata

- roller grinders canada

- Maize Meal Grinding Machine Lister Engine

- indonesia small mobile stone crusher plant

- drawing al miner with head light

- stone crushers in kenya sand making stone quarry

- river sand suppliers in south africa

- Automation And Control Layout Of A Coal Crushing System Design

- mini crusher hire hampshire surrey

- grinding mills for poultry feedsfor sale in south africa

- move stone crusher for sale

- cement block machine for sale canada

- price jual stone crusher bekas di indonesia

- Portable Gold Ore crusher Manufacturer

- Scrap foam crushing machine

- stone crusher michinery

- Gravity Gold Concentration Equipment Pelet Crusher For Sale

- stone crushers association india

- Rincian Teknis Primer Jaw Crusher Bmw

- Used Stone nveying System Malaysia