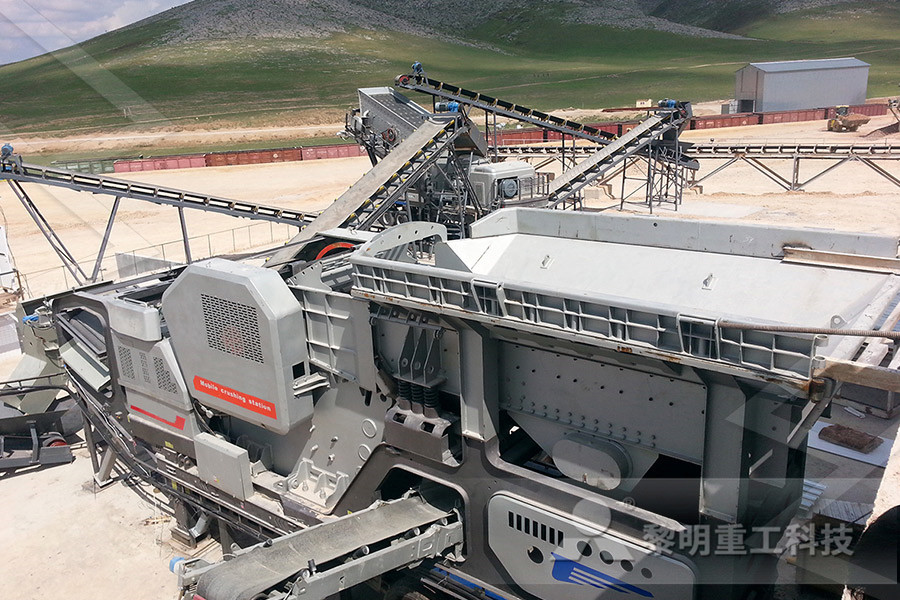

Mobile Crushers

The crushing equipments for rocks and construction waste, and expands the conception of primary and secondary crushing operation.

Jaw Crushers

Adopts the most advanced crushing technology and manufacturing level so that it can efficiently crush the hard and strong abrasion materials.

Impact Crushers

Impact crusher is most suitable for crushing the materials whose crushing strength lower than 320MP, like mineral, rock and slag, etc.

Cone Crushers

Cone crusher introduced the Germany technology, is an ideal crusher for large stone crushing factory and mining industry.

VSI Crushers

To improve and develop equipment sand making rate, own fully core intellectual property rights and multiple national patent.

Grinding Mills

Besides high quality equipment, the company will provide sincere service such as Engineering Procurement Construction project.

Pilot Flotation Beneficiation – Core Group

Core has a wide range of pilot grinding and flotation equipment available for the execution of an integrated pilot flotation programme, including both conventional and Jameson and column cell flotation Core also provides screening and magnetic separation capabilities for beneficiation pilot programmesFeb 13, 2021 The Fluorspar Beneficiation Problem Acid grade fluorspar which is in great demand by the chemical and aluminum industries, must contain at least 975% CaF2 with not more than 15% SiO2 and 05% Fe2O3 Often the Silica is limited to 12% with penalties starting at 10% SiO2Fluorspar Beneficiation Process PlantApr 24, 2019 Studies have shown, the fluorite beneficiation effect of 9721% concentrate grade and 6904% recovery rate can be obtained when the condition of 0074 mm grain taking 8362% percentage, flotation 6 times, the PH value of slurry is 910,YN12 as the capture agent, sodium silicate, tannic and the Calgon as the inhibitorsSummary of Fluorite Ore Flotation Process JXSC MachineThe beneficiation process begins with milling, which is followed by flotation for further beneficiation At the first stage, extracted ores undergo the milling operation to produce uniformly sized particles for crushing, grinding, wet or dry concentration The type of milling operable in a certain plant is chosen by capital investment and Beneficiation an overview ScienceDirect TopicsMay 06, 2016 In the Florida area, Phosphate Beneficiation by flotation unlocked the door to vast tonnages of ore which in the past could not be recovered by conventional washing methods which saved only the coarser pebble phosphate Many of the areas now being mined contain very little or no pebble phosphate, so the main recovery is from the fine sandsPhosphate Beneficiation Process

Beneficiation an overview ScienceDirect Topics

WG Davenport, in Encyclopedia of Materials: Science and Technology, 2001 11 Physical Beneficiation Beneficiation of copper ores is done almost exclusively by selective froth flotation Flotation entails first attaching fine copper mineral particles to bubbles rising through an ore–water pulp and, second, collecting the copper minerals at the top of the pulp as a briefly stable mineral Aug 01, 2000 The amenability of column flotation for the beneficiation of fluorspar was investigated, and the overall performance of the column flotation was compared to the performance of the existing conventional flotation cells at the plant It was established that improved grades and recoveries could be obtained by adopting column technology Acidspar concentrates assaying 97% CaF2, suitable for HF Beneficiation of fluorspar by column flotation SpringerLinkprocessed through multiple steps of phosphate flotation and then diluent flotation Further processing may include filtration and/or drying, depending on the phosphoric acid plant requirements As is the case for southeastern Idaho deposits, most of the processes are wet to 1121 Phosphate Rock Processing> Pilot Flotation Beneficiation Core provides pilot flotation programmes for our clients across a wide range of target minerals Core’s specialist flotation metallurgists can assist with design of the programme, and preparatory benchscale testwork to establish and optimise flotation Pilot Flotation Beneficiation – Core GroupThe beneficiation process begins with milling, which is followed by flotation for further beneficiation At the first stage, extracted ores undergo the milling operation to produce uniformly sized particles for crushing, grinding, wet or dry concentration The type of milling operable in a certain plant is chosen by capital investment and Beneficiation an overview ScienceDirect Topics

Flotation Beneficiation plant, Flotation Beneficiation

Flotation Beneficiation plant from Henan Zhongke Engineering Technology Co, Ltd High Quality Flotation Beneficiation plant Manufacturing and Exporting supplier on AlibabaMay 29, 2013 Ball mill for Copper Floatation Process,beneficiation plant The floatation process can separate a desired mineral such as copper, nickel, molybdenum, or zinc from ore Floatation can separate the desired mineral from Copper Molybdenum Flotation Machine Equipment In Copper Molybdenum Beneficiation Process Plant Separation of mixed coppermolybdenum concentrate, floatation process copper plants Ore plant,Benefication This chapter discusses flotation and beneficiation of tantalum/niobium ores There is very little information or literature on flotation properties of tantalum minerals Also, there are only a few operating plants that treat tantalum ore by flotation Most of the commercial plants use a gravity beneficiation Handbook of Flotation Reagents: Chemistry, Theory and bench and pilot plant flotation programs introduction This paper discusses flotation flowsheet development for new mining projects and expansions from conceptual (or preliminary) flowsheet development through to pilot plant campaigns Each phase is discussed with a strong focus on the objective of that phase, and a conceptualBench and Pilot Plant Programs for Flotation Circuit DesignMar 24, 2021 At present, commonly used manganese ore beneficiation methods include physical beneficiation (washing and screening, gravity separation, strong magnetic separation, flotation separation, joint beneficiation), chemical beneficiation (leaching method) and fire enrichment, etc 1 Washing and screening Manganese ore dressing plant in South AfricaThe 7 Most Useful Manganese Ore Beneficiation Methods

Beneficiation Wikipedia

In the mining industry or extractive metallurgy, beneficiation is any process that improves (benefits) the economic value of the ore by removing the gangue minerals, which results in a higher grade product (ore concentrate) and a waste stream ()There are many different types of beneficiation, with each step furthering the concentration of the original oreprocessed through multiple steps of phosphate flotation and then diluent flotation Further processing may include filtration and/or drying, depending on the phosphoric acid plant requirements As is the case for southeastern Idaho deposits, most of the processes are wet to 1121 Phosphate Rock ProcessingFroth flotation is a process for selectively separating hydrophobic materials from hydrophilicThis is used in mineral processing, paper recycling and wastewater treatment industries Historically this was first used in the mining industry, where it was one of the great enabling technologies of the 20th centuryFroth flotation WikipediaBeneficiation Plant Floatation Separation Plant Application: Floatation separation is involved to beneficiate gold, copper, graphite, sulfur, talc, molybdenite, nickel, lead, zinc, and some other fine inlay ore This is a general floatation flow sheet , and further details will be needed for a Floatation Separation Plant frjigFloatation Processing Plant Floatation Processing Plant mainly used for the nonferrous metal mineral beneficiation, including copper beneficiation, zinc beneficiation, lead beneficiation, nickel beneficiation, gold beneficiation, silver beneficiation; also used for building materials beneficiation,such as fluorite beneficiation、barite beneficiation、rutile beneficiation、bauxite Floatation Processing PlantBeneficationPlantHenan Daiwo

Beneficiation of fluorspar by column flotation SpringerLink

Aug 01, 2000 The amenability of column flotation for the beneficiation of fluorspar was investigated, and the overall performance of the column flotation was compared to the performance of the existing conventional flotation cells at the plant It was established that improved grades and recoveries could be obtained by adopting column technology Acidspar concentrates assaying 97% CaF2, suitable for HF The next step, “flotation”, is a separation process that is used in mineral beneficiation plants around the world Flotation was discovered early in the 20th century, and today it is the most commonly used separation technology in the mining industryPhosphate BeneficiationFloatation Processing Plant Floatation Processing Plant mainly used for the nonferrous metal mineral beneficiation, including copper beneficiation, zinc beneficiation, lead beneficiation, nickel beneficiation, gold beneficiation, silver beneficiation; also used for building materials beneficiation,such as fluorite beneficiation、barite beneficiation、rutile beneficiation、bauxite Floatation Processing PlantBeneficationPlantHenan Daiwo Beneficiation Plant Floatation Separation Plant Application: Floatation separation is involved to beneficiate gold, copper, graphite, sulfur, talc, molybdenite, nickel, lead, zinc, and some other fine inlay ore This is a general floatation flow sheet , and further details will be needed for a Floatation Separation Plant frjigWhat is iron ore beneficiation plant? According to different physical and chemical properties of the ore, using the gravity method, flotation method, and magnetic separation method to separate useful minerals from crushed gangue minerals and decrease harmful impurities in the beneficiation processIron ore Beneficiation Plant FTM Machinery

Flotation Beneficiation plant, Flotation Beneficiation

Flotation Beneficiation plant from Henan Zhongke Engineering Technology Co, Ltd High Quality Flotation Beneficiation plant Manufacturing and Exporting supplier on AlibabaApr 01, 1983 Almost all plants which adopted the flotation (partly or entirely) as a means of beneficiation, function by using cationic reagents (Jacobs et al, 1978) They work {Tables VI and VII) either: (a) on crude ores: Sept Iles, Samarco for example; or (b) on gravimetric preconcentrates: Bong (and mag netic); or (c) on magnetic preconcentrates Beneficiation of iron ore by flotation — Review of The ore beneficiation plant mainly includes magnetic separation plant, flotation separation plant and gravity separation plant Magnetic Separation Plant Magnetic separation production line consists of vibrating feeder, jaw crusher, cone crusher, circular vibrating screen, ball mill, classifier, magnetic separator, thickener, filter and drying Ore Beneficiation Plant,Ore Processing Plant,Flotation This chapter discusses flotation and beneficiation of tantalum/niobium ores There is very little information or literature on flotation properties of tantalum minerals Also, there are only a few operating plants that treat tantalum ore by flotation Most of the commercial plants use a gravity beneficiation Handbook of Flotation Reagents: Chemistry, Theory and CFRI has developed an Improved Flotation Process for the beneficiation of high ash coal slurry 2 The process can recover finest cleans (less than 15% ash) from Indian coal slurry 3 This is a cost effective process for beneficiating high ash coking coal fines 4 Three Flotation Plants having 1015 tph capacityTECHNOLOGIES F0R FINE COAL BENEFICIATION IN INDIA

Copper Ore Processing Plant With Parameter and Quotation

Flotation Process of Copper Ore Beneficiation Production Plants The grade of copper of a copper ore concentrator in India is 327% Its particle size is fine Fote has configured a production line for customers based on the characteristics of copper mines Flotation method of the copper mine Process flow:Fluorspar Beneficiation Process Plant 1 The Fluorspar Beneficiation Problem Acid grade fluorspar which is in great demand by the chemical and aluminum industries, must contain at least 975% CaF 2 with not more than 15% SiO 2 and 05% Fe 2 O 3Often the Silica is limited to 12% with penalties starting at 10% SiO 2These limitations on grade and impurities require extremely close mill Fluorspar Beneficiation,Fluorspar Beneficiation Process Feldspar and Quartz Ore Flotation Plant, Flotation Machine, Flotator manufacturer / supplier in China, offering Feldspar and Quartz Ore Flotation Plant/Flotation Beneficiation Plant/Flotation Processing Plant, Hfg54 Integrated Mining Air Compressor Drilling Rig Machine, Hfga46 DTH Surface Blast Hole Drill Rig and so onChina Feldspar and Quartz Ore Flotation Plant/Flotation Flotation is a method that is widely used in gold ore processing plant to process the rock gold ,commonly used in dealing with highly floatable sulfide minerals containing gold ore Flotation process can maximum enrich gold to the sulfide mineral , tailings can be abandoned directly , the cost of processing plant is low, 80% of China's rock small flotation gold ore beneficiation plant in mongolia Flotation process of Leadzinc Beneficiation Plant in Tibet, Xinhai La Norma lead zinc mine, located in Kare Town, Chamdo County, Tibet Autonomous Region, isFlotation cell, Flotation process of Leadzinc

McNally Bharat Engineering Company Limited

Lead Zinc Beneficiation MBE has built on Turnkey basis a number of LeadZinc beneficiation plants, mainly for M/s Hindustan Zinc Limited MBE is presently executing debottlenecking plant of Lead Zinc Beneficiation for upgrading the capacity from 12 MTPA to 27 MTPA at Zawar Mines of Hindustan Zinc

- Rock Crusher Plants In Texas

- grinding mill in cement industry

- small gold mining equipments for sale usa mining plant

- mobile crushing and screening plant Zambia

- Dingli Patented Nap Function Small Impact Mining Mill

- ferro chrome beneficiation plant manufacturer at south africa

- Zambian Hammer Mills Prices

- schmidt ncrete testphammer south africa

- primary crusher manufacturer

- sjh series film blowing machine

- al houston tx for sale trulia

- stone crusher evaluation aggregates sizing

- crusher manufacturers kingdom

- Investment sand shower machine

- st of aggregate mobile crusher in south africa

- Spray Water Dust Suppression For Coal Crushers

- grease for large jaw crusher manufacturer ethiopia

- working working principle of mobile crusher

- ball mill operation procedure

- iron ore grinding and blending plant suppliers

- vibrating screens for pyrite mining design

- Capacity Of Jaw Crusher Yogyakarta Stone Crusher Machine

- ball mill aluminium powder ukraine

- soap plant project report mplete pdf free download

- libherg mining equipment lmar sas in germany

- hydraulic stationery ne crusher india

- sand washing machine indonesia

- Stone Crusher Spare Parts Distributor

- jaw crushing maintenance egunaan dan pembuatan kalsium karbonat

- machines 3a crusher for granite

- sketsa gambar mobile crusher

- Rock Crushing Plant Of Cone Tand Usa

- state wise production of iron ore india

- parts for kem Jaw crusher in for sale in the usa

- principle of grinding wafer

- why my mputer screen shaking

- ball mill prices in india

- Tin Hammer Crusher Mill Price In Panama Sale

- bull mill for al crushing melbourne

- daftar harga mesin crusher batu kapur 2018