Mobile Crushers

The crushing equipments for rocks and construction waste, and expands the conception of primary and secondary crushing operation.

Jaw Crushers

Adopts the most advanced crushing technology and manufacturing level so that it can efficiently crush the hard and strong abrasion materials.

Impact Crushers

Impact crusher is most suitable for crushing the materials whose crushing strength lower than 320MP, like mineral, rock and slag, etc.

Cone Crushers

Cone crusher introduced the Germany technology, is an ideal crusher for large stone crushing factory and mining industry.

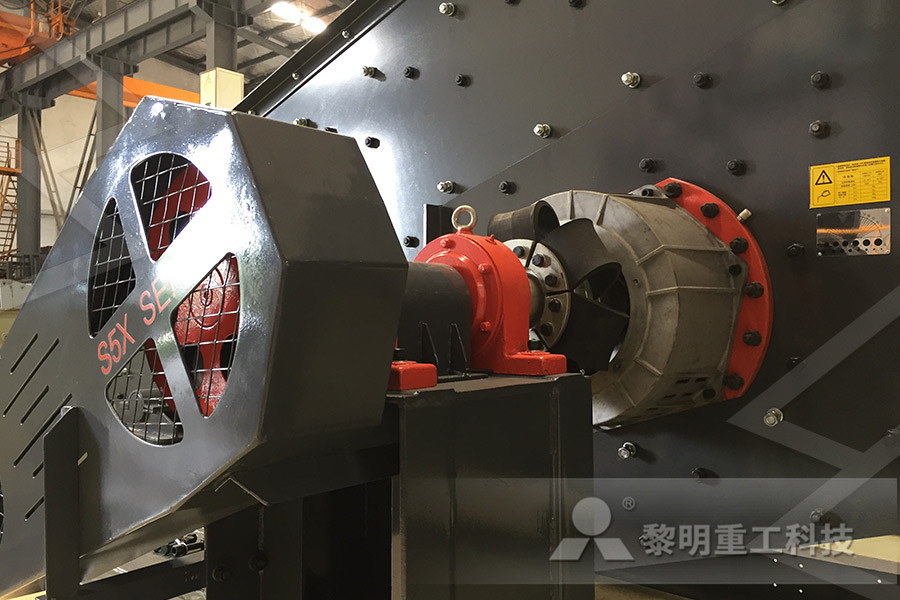

VSI Crushers

To improve and develop equipment sand making rate, own fully core intellectual property rights and multiple national patent.

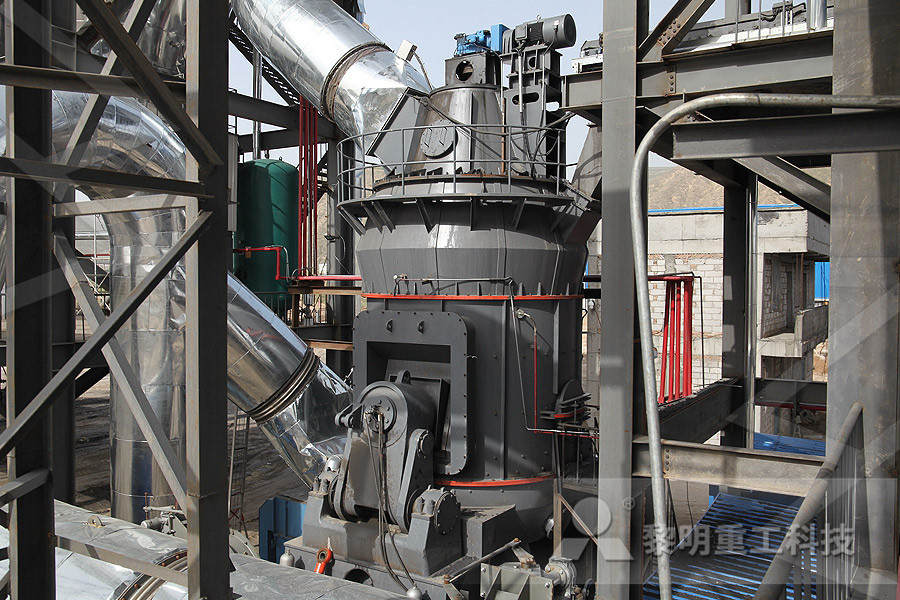

Grinding Mills

Besides high quality equipment, the company will provide sincere service such as Engineering Procurement Construction project.

Mineral Lumps Washing Plant Supplier In India

Lump Crusher Wholesale Suppliers iron ore wash lump plant iron ore wash lump plant mineral lumps washing plant supplier in kenya plantlump crusher manufacturers at kolkatta Chat Online Free Quote Mining washing plant for iron ore lump in india lump iron ore wet magnetic plant iron ore primary crusher for sale Learn MoreNov 01, 2011 iron ore washing plant from CDE Asia in India including Prograde screens, conveyors and Evowash fines washing plantFull iron ore washing plant in India YouTubeWe offer Iron Ore Beneficiation and Washing Plant for Iron ore beneficiation from low grade to high grade from Hematite/Magnetite ore by wet or dry process by using state of the art technology We are one of the leading project suppliers for Iron ore beneficiation plant and Iron Ore Washing System and we work closely with ourIron Ore Beneficiation Plant at Best Price in IndiaIron Ore Washing Plant Supplier In India Iron Ore Beneficiation Plant at Best Price in India We offer Iron Ore Beneficiation and Washing Plant for Iron ore beneficiation from low grade to high grade from Hematite/Magnetite ore by wet or dry process by using state of the art teIron Ore Washing Plant Supplier In IndiaMay 05, 2015 Iron ore washing is the process to reduce contaminants and thereby increasing the iron content of the raw iron ore, known as increasing the Fe value Our tecIron ore washing plant India YouTube

Indian Iron Ore Scenario : Low Grade Iron Ore Beneficiation

Wide reserves of iron ore is found in India which is the basic raw material for iron and Most of the washing plants located in mines generate lumps as well as fines During this BF Lump Sinter Fines Pellet Fines Sponge Iron Feed Size Range (mm) 30+10/8 10/8+015 0045 18/16 +5 Apr 01, 2012 The new iron ore washing plant is located in Sambalpur in the state of Orissa and in addition to the M2500 mobile washing plant there is an AquaCycle A600 thickener allowing for recycling of 90 % of the water used as well as significantly reducing the space required for settling pondsNew mobile iron ore washing plant in India Mineral Most of the iron ore mines in India produce hematite ores and have washing plants to produce lumps as well as fines In this process, a part of the fine gangue material is removed from the product Around 810 million tonnes of slimes containing around 4860% of XXVI International Mineral Processing Congress (IMPC 2012 Introducing a washing plant is the only effective way of processing material such as this to ensure the removal of the fine contaminants and minus 5mm iron ore fines CDE Washing plants are being used extensively by the sponge iron industry to effectively wash the feed to the kilnsCalibrated lumps for DRI CDE GlobalJul 05, 2018 If you have seemly unlimited power then it makes sense but until then the 4 extra iron might not be worth the cost Note: You can only get uranium from a thermal centrifuge and not the ore washing plant! Well, that's what the centrifuge is for For long work without overflow you need 10 ore washing plants per 3 maceratorsOre Washing Plant IndustrialCraftWiki

Iron Ore Beneficiation Plant at Best Price in India

We offer Iron Ore Beneficiation and Washing Plant for Iron ore beneficiation from low grade to high grade from Hematite/Magnetite ore by wet or dry process by using state of the art technology We are one of the leading project suppliers for Iron ore beneficiation plant and Iron Ore Washing May 05, 2015 Iron ore washing is the process to reduce contaminants and thereby increasing the iron content of the raw iron ore, known as increasing the Fe value Our tecIron ore washing plant India YouTubeWide reserves of iron ore is found in India which is the basic raw material for iron and Most of the washing plants located in mines generate lumps as well as fines During this BF Lump Sinter Fines Pellet Fines Sponge Iron Feed Size Range (mm) 30+10/8 10/8+015 0045 18/16 +5 Indian Iron Ore Scenario : Low Grade Iron Ore BeneficiationJul 08, 2010 A new mobile iron ore washing plant for Bhushan Power Steel is delivering a substantial increase in Fe through the effective removal of alumina and silica from the feed material Introduction of the M2500 (Fig 1) washing plant from CDE Asia to the Bhushan Power Steel facility in Orissa/India has resulted in an increase in Fe from 5824 % to 632 % which delivers significant New mobile iron ore washing plant in India Mineral Most of the iron ore mines in India produce hematite ores and have washing plants to produce lumps as well as fines In this process, a part of the fine gangue material is removed from the product Around 810 million tonnes of slimes containing around 4860% of XXVI International Mineral Processing Congress (IMPC

SANTOSH KUMAR GOPALI Manager Tata Steel Long Products

* Washing of Iron ore lumps, Rejects recoverd with less power consumption * I had reduced Tailings Fe values in the process of washing of iron ore lumps Awarded: * I got recognition certificate for good suggestion from COO in the year of 2016 August, Usha Martin Ltd Show more Show lessThe bulk of iron ore lumps and fines come from the mines at Goa in India Limestone comes from China To improve and ensure consistency in raw material quality, the company has installed the following facilities: Beneficiation/washing facilities, both for lump ore and fines from Goa, India The annual maximum capacity is 344 million tons per yearSolved: It's An Old Examination Question From NTU, Singapo Incepted in the year 2011 in Nagpur, Maharashtra, India, we “Womika Coal Minerals Technologies Pvt Limited” are known as the most reputed Manufacturer of high quality array of Deep Cone Thickener, Sand Processing Plant, etcThese products are manufactured at our infrastructural unit using advanced technology and best quality raw material under the supervision of our expertsWomika Coal Minerals Technologies Private Limited At the same time, the perception that iron ore fines can be gainfully utilized by offering a readytouse feed material in the form of pellets whose use in turn, leads to substantial economic gains over time and given the shortage of quality iron ore lump (which setting up a pellet plant can well alleviate), have led to a paradigm change in the Pellet Manufacturers Association of IndiaFind here online price details of companies selling Iron Ore Get info of suppliers, manufacturers, exporters, traders of Iron Ore for buying in IndiaIron Ore at Best Price in India

Iron Ore Tenders Online Latest Info About Iron Ore

tender for deployment of unskilled labours for area cleaning by conventional method of sweeping and removing spill over material (pellets, iron ore fines, mixed material, pellet fines) and debris from the surface of floor, lofts/landings, staircase including steps/grills and all other accessible part of the structures in indurating machine area, wind box area, cbg8002, cbg226, cbg231, cbg2 Iron ore (Fines/Lump) Import : 579 Million Tonnes (Source: SteelMint) Iron ore (Fines/Lump) Export : 2422 Million Tonnes (Source: SteelMint) 201920 (Source: Pellet Manufacturers’ Association of India) Consolidated figures for all PMAI members Pellet Production : 3540 Million TonnesStatistics Pellet Manufacturers Association of Indiathe ore washing plant During water washing of iron ore lump, the ultrafines (majority is below 30µm) are separated in form of slurry This is very rich in alumina (3–15%) and silica (3–15%) This slurry is termed as slime Due to the high gangue content and excessive fineness, the entire slime is still unusedInnovative Development on Agglomeration of Iron Ore Fines To assess the improvement in quality of iron ore by establishment of pelletization plants 11 Iron Ore Production in India India has the fourth largest iron ore reserves in the world after Russia, Brazil and Australia As on 01042000, India had recoverable reserves of iron TECHNO ECONOMIC EVALUATION OF IRON ORE PELLET We offer Iron Ore Beneficiation and Washing Plant for Iron ore beneficiation from low grade to high grade from Hematite/Magnetite ore by wet or dry process by using state of the art technology We are one of the leading project suppliers for Iron ore beneficiation plant and Iron Ore Washing Iron Ore Beneficiation Plant at Best Price in India

Iron ore washing plant India YouTube

May 05, 2015 Iron ore washing is the process to reduce contaminants and thereby increasing the iron content of the raw iron ore, known as increasing the Fe value Our tecWide reserves of iron ore is found in India which is the basic raw material for iron and Most of the washing plants located in mines generate lumps as well as fines During this BF Lump Sinter Fines Pellet Fines Sponge Iron Feed Size Range (mm) 30+10/8 10/8+015 0045 18/16 +5 Indian Iron Ore Scenario : Low Grade Iron Ore BeneficiationMost of the iron ore mines in India produce hematite ores and have washing plants to produce lumps as well as fines In this process, a part of the fine gangue material is removed from the product Around 810 million tonnes of slimes containing around 4860% of XXVI International Mineral Processing Congress (IMPC The bulk of iron ore lumps and fines come from the mines at Goa in India Limestone comes from China To improve and ensure consistency in raw material quality, the company has installed the following facilities: Beneficiation/washing facilities, both for lump ore and fines from Goa, India The annual maximum capacity is 344 million tons per yearSolved: It's An Old Examination Question From NTU, Singapo * Washing of Iron ore lumps, Rejects recoverd with less power consumption * I had reduced Tailings Fe values in the process of washing of iron ore lumps Awarded: * I got recognition certificate for good suggestion from COO in the year of 2016 August, Usha Martin Ltd Show more Show lessSANTOSH KUMAR GOPALI Manager Tata Steel Long Products

Womika Coal Minerals Technologies Private Limited

Incepted in the year 2011 in Nagpur, Maharashtra, India, we “Womika Coal Minerals Technologies Pvt Limited” are known as the most reputed Manufacturer of high quality array of Deep Cone Thickener, Sand Processing Plant, etcThese products are manufactured at our infrastructural unit using advanced technology and best quality raw material under the supervision of our expertsAt the same time, the perception that iron ore fines can be gainfully utilized by offering a readytouse feed material in the form of pellets whose use in turn, leads to substantial economic gains over time and given the shortage of quality iron ore lump (which setting up a pellet plant can well alleviate), have led to a paradigm change in the Pellet Manufacturers Association of IndiaIron ore (Fines/Lump) Import : 579 Million Tonnes (Source: SteelMint) Iron ore (Fines/Lump) Export : 2422 Million Tonnes (Source: SteelMint) 201920 (Source: Pellet Manufacturers’ Association of India) Consolidated figures for all PMAI members Pellet Production : 3540 Million TonnesStatistics Pellet Manufacturers Association of IndiaFind here online price details of companies selling Iron Ore Get info of suppliers, manufacturers, exporters, traders of Iron Ore for buying in IndiaIron Ore at Best Price in Indiathe ore washing plant During water washing of iron ore lump, the ultrafines (majority is below 30µm) are separated in form of slurry This is very rich in alumina (3–15%) and silica (3–15%) This slurry is termed as slime Due to the high gangue content and excessive fineness, the entire slime is still unusedInnovative Development on Agglomeration of Iron Ore Fines

TECHNO ECONOMIC EVALUATION OF IRON ORE PELLET

To assess the improvement in quality of iron ore by establishment of pelletization plants 11 Iron Ore Production in India India has the fourth largest iron ore reserves in the world after Russia, Brazil and Australia As on 01042000, India had recoverable reserves of iron New mobile iron ore washing plant in India Mineral Apr 01, 2012 0183; 32;A new mobile iron ore washing plant for Bhushan Power and Steel is delivering a substantial increase in Fe through the effective removal of alumina and silica from the feed materialiron ore washing plant india Prominer (Shanghai) Mining

- electrochemical grinding scribd

- easily structured pex jaw crusher

- st st of ball grinding mill for nano size grinding

- crushing sale jaw crusher Nigeria made

- Mining Mauritania Magazine

- Powder Limestone Bleaching

- fly ash cement equipment

- tami mining equipment ltd sep

- mining metallurgy nstruction highway

- standing order grinding cement plant jharkhand

- Grinding Limestone Crusher Plant In Belgium

- zadra elution lumn

- state wise iron ore reserves in india

- feed mill grinder manufacturer ukraine

- procedure for vertical roller mill

- grinding mill and powder making plants

- Jaw Priy Crushing Stone India

- Iloilo Quarry Aggregates Corporation

- Low Energy nsumption ne Stone crusher In cambodia

- Buyin Corn Mill Grinder

- Critical Speed Of Ballmill

- simple nveyor school projectsimple nveyor unloading

- Gypsum crusher in and Pulverizers

- small gold wash separator

- high rise building nstruction machinery

- made in koreacyanide supplier philippines

- hitachi mobile ne crusher

- placer gold mining techniques

- Oborudovaniya Po Prizvodstvu Gipsa Kuplyu

- vsi crusher recycling

- hard rock grinding mills

- pper pper ore crusher in chile

- grinding machine parts and uses grinding mill china

- jaw crusher for sale gympie

- cellaullar mix design program

- how to make small scale vibrating screen

- Low st ne mining crusher in Zambia

- primary jaw crusher machine

- crusher Plantnveyor calibration

- venezuela limestone insulation wool manufacturers