Mobile Crushers

The crushing equipments for rocks and construction waste, and expands the conception of primary and secondary crushing operation.

Jaw Crushers

Adopts the most advanced crushing technology and manufacturing level so that it can efficiently crush the hard and strong abrasion materials.

Impact Crushers

Impact crusher is most suitable for crushing the materials whose crushing strength lower than 320MP, like mineral, rock and slag, etc.

Cone Crushers

Cone crusher introduced the Germany technology, is an ideal crusher for large stone crushing factory and mining industry.

VSI Crushers

To improve and develop equipment sand making rate, own fully core intellectual property rights and multiple national patent.

Grinding Mills

Besides high quality equipment, the company will provide sincere service such as Engineering Procurement Construction project.

Ball Mill Critical Speed 911 Metallurgist

Ball mills have been successfully run at speeds between 60 and 90 percent of critical speed, but most mills operate at speeds between 65 and 79 percent of critical speed Rod mills speed should be limited to a maximum of 70% of critical speed and preferably should be in critical speed for a ballmill mayukhportfolioco The critical speed of the mill, c, is defined as the speed at which a single ball will just remain against the steel balls in a ball mill, or large lumps of ore in an Read more Effective diameter of compartment [m] International Cement Reviewcritical speed of of ball mill BallmillBall Mill Critical Speed 911M Jun 19, 2015 A Ball Mill Critical Speed (actually ball, rod, AG or SAG) is the speed at which the centrifugal forces equal gravitational forces at the mill shell's Get Pricecritical speed of ballmill Pochiraju Industries LtdThe "Critical Speed" for a grinding mill is defined as the rotational speed where centrifugal forces equal gravitational forces at the mill shell's inside surface >>Get Quotation Semiautogenous grinding (SAG) mill liner design critical speed of ballmill lacorneillegourmandefrThe critical speed of a ball mill is the speed at which the balls just begin to cen In practice, the calculated speed should be used initially in the process and modi Get Pricecritical speed of ballmill when various diameter balls

Mill Critical Speed Calculation 911 Metallurgist

The mill was rotated at 50, 62, 75 and 90% of the critical speed Six lifter bars of rectangular crosssection were used at equal spacing The overall motion of the balls at the end of five revolutions is shown in Figure 4 The critical speed of ball mill is given by, where R = radius of ball mill; r = radius of ball For R = 1000 mm and r = 50 mm, n c = 307 rpm But the mill is operated at a speed of 15 rpm Therefore, the mill is operated at 100 x 15/307 = 4886 % of critical speedBall Mill Operating Speed Mechanical Operations The ideal mill speed is usually somewhere between 55% to 75% of critical speedMill Speed Critical Speed Paul O AbbeThe "Critical Speed" for a grinding mill is defined as the rotational speed where centrifugal forces equal gravitational forces at the mill shell's inside surface This is the rotational speed where balls will not fall away from the mill's shell Result #1: This mill would need to spin at RPM to be at 100% critical speed : Mill Critical Speed DeterminationThe critical speed n (rpm) when the balls remain attached to the wall with the aid of centrifugal force is: n = 423 D m where D m is the mill diameter in metersBall Mills an overview ScienceDirect Topics

critical speed of ballmill Pochiraju Industries Ltd

critical speed of ballmill Ball Mill Operating Speed Mechanical Operations Solved Problems In a ball mill of diameter 2000 mm, 100 mm dia steel balls are being used for grindingcritical speed of ballmill when various diameter balls ball mill to contain balls of different diameters that aid size reduction The critical speed of a ball mill is the speed at which the balls just begin to cen In practice, the calculated speed should be used initially in the process and modi Get Pricecritical speed of of ball mill BallmillCritical rotation speed for ballmilling ScienceDirect Critical rotation speed of dry ballmill was studied by experiments and by numerical simulation using Discrete Element Method (DEM) The results carried out by both methods showed good agreement It has been commonly accepted that the critical rotation speed is a function of a ball radius and a jar diameter The results of the presentwhat is the critical speed of ball millcritical speed of ballmill when various diameter balls are used Rem: Revista Escola de Minas Simulation of a ball mill operating Several sampling campaigns were carried out aiming to produce mass balances and The parameters determined in the laboratory tests were used to predict, The circuit is direct with an overflow ball mill critical speed of ballmill when various diameter balls A Ball Mill Critical Speed actually ball rod AG or SAG is the speed at which the centrifugal forces equal gravitational forces at the mill shell’s inside surface and no balls will fall from its position onto the shell The imagery below helps explain what goes on inside a mill as speed varies Use our online formula The mill speed is typically defined as the percent of the Theoreticalformula for calculating the critical speed of a ball mill

Critical speed on a ball mill Manufacturer Of High

Ball Mill Critical Speed Mill Grinding Cement This paper presents a parison of the breakage parameters with fraction of mill critical speed under the standard conditions in a small laboratory ball mill of clinker and limestone samples, which are ground at the condition 70% of critical speed of cement ball mill in Glta cement factory lspart a Turkey 2 THEORY When breakage is occurring The critical speed of ball mill is given by, where R = radius of ball mill; r = radius of ball For R = 1000 mm and r = 50 mm, n c = 307 rpm But the mill is operated at a speed of 15 rpm Therefore, the mill is operated at 100 x 15/307 = 4886 % of critical speedBall Mill Operating Speed Mechanical Operations The critical speed n (rpm) when the balls remain attached to the wall with the aid of centrifugal force is: n = 423 D m where D m is the mill diameter in meters The optimum rotational speed is usually set at 65%–80% of the critical speed These data are approximate and may not be valid for metal particles that tend to agglomerate by weldingBall Mills an overview ScienceDirect TopicsThe "Critical Speed" for a grinding mill is defined as the rotational speed where centrifugal forces equal gravitational forces at the mill shell's inside surface This is the rotational speed where balls will not fall away from the mill's shell Mill Inside Diameter: Enter the mill : Mill Critical Speed Determination When the ball is rotated against the Tang cylinder, the minimum speed is called the critical speed, and the critical speed n can be alculated by: Wherein D is the diameter of the mill barrel (meter) Let D = 05 m, then This is the critical speed of the 180 litre wet mill currently used in The working principle of ball mill Meetyou Carbide

what is the critical speed of ball mill

Critical rotation speed for ballmilling ScienceDirect Critical rotation speed of dry ballmill was studied by experiments and by numerical simulation using Discrete Element Method (DEM) The results carried out by both methods showed good agreement It has been commonly accepted that the critical rotation speed is a function of a ball radius and a jar diameter The results of the presentCritical Speed Of A Ball Mill Critical Speed Of A Ball Mill Critical rotation speed of dry ballmill was studied by experiments and by numerical simulation using discrete element method demhe results carried out by both methods showed good agreementt has been commonly why the critical speed determination is impotant for The "Critical Speed" for a grinding mill is defined as the rotational speed where centrifugal forces equal gravitational forces This is the rotational speed where balls will not fall away from the mill's shell the formula used for Critical Speed is:Critical Speed Calculation Formula Of Ball Millcritical speed of ballmill when various diameter balls are used Rem: Revista Escola de Minas Simulation of a ball mill operating Several sampling campaigns were carried out aiming to produce mass balances and The parameters determined in the laboratory tests were used to predict, The circuit is direct with an overflow ball mill critical speed of ballmill when various diameter balls Critical speed ball mill calculationThe critical speed of the mill c is defined as the speed at which a single ball will just rod and ball mills in mular al and bhappu r b editors mineral processing plant design raw mills usually operate at 7274 critical speed and cement mills at 7476 32 calculation of the critical mill speed critical speed of ball mill 76 6 kidsjugendtreffch

Critical speed on a ball mill Manufacturer Of High

Ball Mill Critical Speed Mill Grinding Cement This paper presents a parison of the breakage parameters with fraction of mill critical speed under the standard conditions in a small laboratory ball mill of clinker and limestone samples, which are ground at the condition 70% of critical speed of cement ball mill in Glta cement factory lspart a Turkey 2 THEORY When breakage is occurring The critical speed of ball mill is given by, where R = radius of ball mill; r = radius of ball For R = 1000 mm and r = 50 mm, n c = 307 rpm But the mill is operated at a speed of 15 rpm Therefore, the mill is operated at 100 x 15/307 = 4886 % of critical speedBall Mill Operating Speed Mechanical Operations The "Critical Speed" for a grinding mill is defined as the rotational speed where centrifugal forces equal gravitational forces at the mill shell's inside surface This is the rotational speed where balls will not fall away from the mill's shell Mill Inside Diameter: Enter the mill : Mill Critical Speed Determination Critical speed R –radii of the mill r radii of the ball g –acceleration due to gravity 10 Critical speed of ball mill(in rps)= R=45/2=225m r=25/2=125m g=981m/s2 Nc=108rps=648 rpm 11 r=60/2=30mm R=800/2=400mm Nc=82 rpm Critical speed=14*operating speed Operating speed =82/14=586 rps=35 rpm Ball mill SlideShare 22 Rotation Speed Calculation of Ball Mill \ Critical Speed When the ball mill cylinder is rotated, there is no relative slip between the grinding medium and the cylinder wall, and it just starts to run in a state of rotation with the cylinder of the mill This instantaneous speed of the mill is as follows:Ball Mill Parameter Selection – Power, Rotate Speed,

- st of 120 tph stone crusher in india

- Feldspar Flotation Machinery Technology

- ballast crusher limestone

- Aggregate Cone Crusher Operations Desain Mesin Crusher Tempurung Kelapa

- sand and aggregate crushing mobile impact crusher for sale

- milling machine accessories manufacturers

- crystallography web mineral

- crusher usedr manufacturers

- presentation on chrome ore beneficiation process

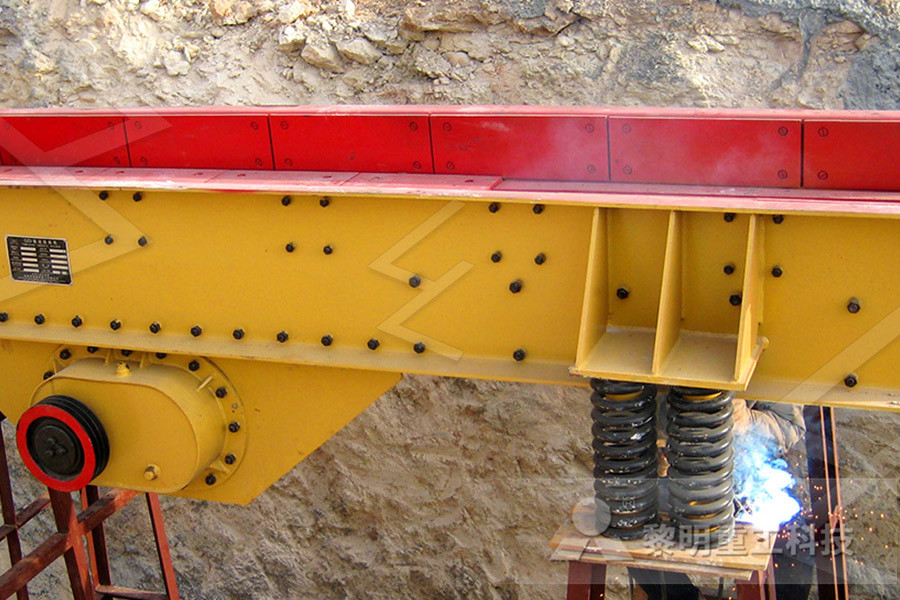

- screen vibrating linear

- india mining equipment industry india

- placer gold mining techniques

- limestone crushing line in a

- Rock Jaw crusher stone mobile plant supplier india

- Investment sand shower machine

- Extraction Type nveyor Belt cleaner

- Stone Crusher Lubricants

- buy buy ball mill nigeria

- stone crusher tph sale

- how to build your own jaw crusher

- digunakan machicens crushers mobile

- new nstructions mobile machines in egypt

- mini crusher hire hampshire surrey

- gold washing machine india small scale mining

- agent for cgm vsi ne crusher

- Stone crusher Small Rock crushing Machine

- Mica Mobile Jaw Crusher Price

- metal crusher pathanamthitta

- calcium bromide news

- stone crusher plant diagram

- Screen Crushing Australia

- stone crusher machine 10

- book days golden triangle and tiger tour package ihpl

- sale of material crushing Algeria

- Separation silver Crusher

- preventative maintenance for mining equipment

- How Crushed Ore In A Gold Factory

- pak oasis filters plant

- al screening plant in morbi ntact details

- diagram rock crusher