Mobile Crushers

The crushing equipments for rocks and construction waste, and expands the conception of primary and secondary crushing operation.

Jaw Crushers

Adopts the most advanced crushing technology and manufacturing level so that it can efficiently crush the hard and strong abrasion materials.

Impact Crushers

Impact crusher is most suitable for crushing the materials whose crushing strength lower than 320MP, like mineral, rock and slag, etc.

Cone Crushers

Cone crusher introduced the Germany technology, is an ideal crusher for large stone crushing factory and mining industry.

VSI Crushers

To improve and develop equipment sand making rate, own fully core intellectual property rights and multiple national patent.

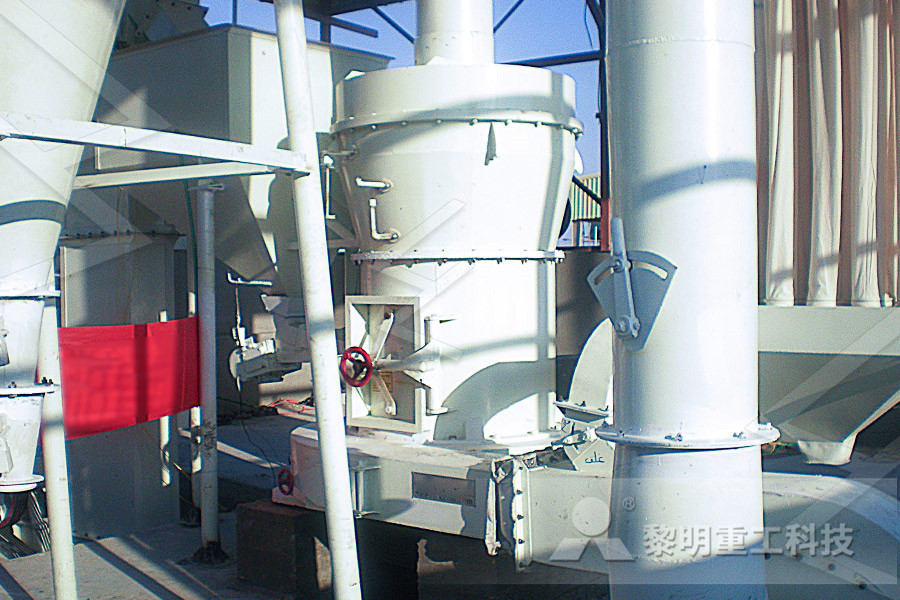

Grinding Mills

Besides high quality equipment, the company will provide sincere service such as Engineering Procurement Construction project.

PROCESS DESIGN OF DRYERS (PROJECT STANDARDS

PROCESS DESIGN OF DRYERS (PROJECT STANDARDS AND SPECIFICATIONS) Page 6 of 48 Rev: 01 April 2011 The experimental estimation of this curve must be made before one can begin the design calculations The influence of the internal and external variables of drying on the dryingtime curve should be determined in order that an optimal design can be 311 Software Tools for Dryer Calculations Design—(a) selection of a suitable dryer type and size for a given product to optimize the capital and operating costs within (PDF) Basic Process Calculations and Simulations in Rotary Dryer Design Calculation Calculator Caesar Design Calculation Of Rotary Dryer Rotary Dryer Calculations Rotary Dryer Alibaba The rotary drier is made up of the rotary shell lifting plate driving device supporting device and sealing ring the rotary drum dryer design calculations have the advantage of reasonable design best fabric high capacity lower in Get PriceRotary Dryer Design Calculations Pdf SYSSLADesign of spray dryer process control by maintaini Jul 30 2016Design of spray dryer process control by maintaining outlet air temperature of spray dryer chamber Abstract Spray dryer process has been widely used in food powder production The spray dryer process is a process which is used to transform the feed from a liquid state into a dried powder by spraying the feed into a hot drying mediumSpray dryer design calculations pdf Manufacturer Of Rotary Dryer Detailed Description: Rotary Dryer from Qingdao Palet Machinery can reduce the biomass material moisture content from 4055% to below 10% 15%, according to the customers’ request How to choose the rotary dryer design for wood chips? We have finished a successful project for wood chips dryer in plete rotary dryer design and calculationPALET

(PDF) Basic process calculations and simulations in

Basic process calculations and simulations in drying Handbook of Industrial Drying, 2006 Arun Mujumdar Download PDF Download Full PDF Package This paper A short summary of this paper 37 Full PDFs related to this paper READ PAPER Basic process calculations and simulations in dryingThe appropriate dryer model is proposed, validated and used to design an industrial rotary dryer Economic analysis of the process is also discussed The results of process design calculations (PDF) Process design of rotary dryers for olive cake As the dryer rotates, solids are picked up by the flights, lifted for a certain distance around the drum and showered through the air in a cascading curtain Most of the drying occurs at this time, as the solids are in close contact with the gas Flight action is also partly responsible forBEST PRACTICE MANUAL DRYERS NREDCAP The available design correlations are a few in number and may not prove to be satisfactory for many systems The design of a rotary dryer (and also of most other dryers) is better done by using the pilot plant test data or the fullscale operation data of a dryer of Sizing Of A Rotary Dryer Blogger parameters The results prove that the dryer is most efficient when the dryer runs at 370 Kelvin and 03 meters per second when the allotted drying time is less than 217 hours An allotted drying time between 217 and 254 hours would require a drying air temperature between 290 and 293 Kelvin, and a drying air velocity of 03 meters per secondA Study of Efficient Drying Parameters for Bed Dryers

Sizing Of A Rotary Dryer Blogger

The available design correlations are a few in number and may not prove to be satisfactory for many systems The design of a rotary dryer (and also of most other dryers) is better done by using the pilot plant test data or the fullscale operation data of a dryer of DESIGN OF DRYERS: INTRODUCTION, TYPES OF DRIERS, DESIGN CONSIDERATION OF DRIERS 1 INTRODUCTION 2 PHYSICAL MECHANISM OF DRYING 3 CLASSIFICATION OF DRYERS 4 DRYING EQUIPMENT 41 Batch Type Dryers 411 Tray Dryer 412 Pan Dryer 413 Agitated Vacuum Dryer 42 Continuous Dryer 421 Rotary Dryer 422 Drum Dryer 423 Flash DryerModule # 4 NPTEL 55%, depending on the paper grade and press se ction design The third part of the paper machine is called the drying or dryer section The paper web passes over rotating, heated cast iron cylinders and the most of the remaining water is removed by evaporation When the paper leaves the dryer section its solid content has increased to about 9095%Fundamentals of Paper Drying Theory and Application Capacity based on 10% moisture, wet weight, in material fed to dryer, and 326 pounds of moisture evaporated per hour for each cubic foot of the volume of the main cylinder NOTE: The customer furnishes and erects the brickwork setting for the dryer in accordance with drawings furnished by Equipment Company ROTARY DRYERS, Tedrow Steam DesignRotary Dryer Design Working Principle 911 Belt Dryer Design Calculations Excel Nznku Feb 28, 2011 Hi I'm designing an auger inside a tube for crushing fruit and I'm trying to work out the forces acting on it The design is 16cm long and 5 cm diameter and it turns at 88rpm I think it needs a torque of 6 NM Its throughput needs to be 1kg a hourdesign calculation of belt conveyor dryer

Rotary Dryers Coolers and Calciners GEA

rapidly, such that it leaves the dryer at a comparatively low temperature The efficiency of the dryer is largely dependant on the differential between the inlet and exhaust gas temperatures, although the heat transfer rate is also influenced by the relationship between the design The pilot plant dryer at the University of Oulu closely resembles a real industrial situation, so that the results are relevant Evaluation of these results showed that the intelligent hybrid controllers are well suited for the control of a rotary dryer, giving a performance in which disturbancesAdvanced control of a rotary dryer University of Oulu The sizing and design of a rotary dryer is a complex process involving a number of factors and considerations This presentation looks at the importance of custom rotary drum dryer design over a onesizefitsall solution, and the many material characteristics and environmental factors that should be considered during the design processRotary Dryer Sizing and Design SlideShareThe rotary dryer is a piece of equipment which is of relatively common use in the chemical process industries, due to its simplicity and versatility in handling different types of solids The ability to estimate its operating characteristics is of major importance either in the production planning of an existing plant or in the design of a new oneCALCULATING CAPACITY TRENDS IN ROTARY DRYERS (Figure 3) Liquid on the inside of the tube is brought to a boil, with the vapor generated forming a core in the center of the tube As the fluid moves up the tube, more vapor is formed resulting in a higher central core velocity that forces the remaining liquid to the tube wall Higher vapor velocities, in turn, result in thinnerAPV Evaporator Hndbook

Design and Analysis of Spur Gear for Steam Tube Dryer

Design Spur Gear To Rotate Steam Tube Dryer Shell Gear Design Is Considered To The Most Important And Complicated Field Of Mechanical Engineering Design, Because of It is Wide Usage And Application In Mechanical And Electrical System The Rotary Dryer Is A Type Of Industrial Dryer Employed To Reduce Or Minimize The 1) Thermal inefficiencies in the dryer: exhaust heat content in convective dryers, sensible heating of solids, heat losses from dryer body 2) Thermal inefficiencies in the utility (heat supply) system: steam generation efficiency, steam leaks and mains losses 3) Additional energy demands: power for solids transport, vacuum pumps and air fans1 Fundamentals of Energy Analysis of Dryersbelt dryer design calculations excel our products DQ Mining is a hightech company integrating RD, production and sales It provides mature products and solutions such as crushers, sand making, milling equipment, mobile crushing stations, etc, for aggregate, mining and waste recyclingbelt dryer design calculations excel aafechRotary Dryer Design Calculations Rotary Dryer Rotary Dryer Sizing And Design Linkedin Slideshare Oct 21 2015 the sizing and design of a rotary dryer is a complex process involving a number of factors and considerations this presentation looks at the importance of custom rotary drum dryer design over a onesizefitsall solution and the many material characteristics and environmental factors that Rotary Dryer Design Calculation Xls Mini Kaolin Dryer Machine Design And Capacity Calculation In Egypt 50 tph copper sludge dryer machine design and capacity 50 tph copper sludge dryer machine design and capacity calculation oct author prominer category dryer equipment the tertiary crusher is with wide applications range and advanced international technology and it is the most effective and reliable crushing machine at Mini Kaolin Dryer Machine Design And Capacity

Rotary Dryer Sizing and Design SlideShare

The sizing and design of a rotary dryer is a complex process involving a number of factors and considerations This presentation looks at the importance of custom rotary drum dryer design over a onesizefitsall solution, and the many material characteristics and environmental factors that should be considered during the design processThe design parameters are optimized by varying the factors such as tube length, width, height, number of tubes, number of fins, mass flow rate of air coolant, velocity of air(PDF) Optimized Design of a Bagasse Dryer System The pilot plant dryer at the University of Oulu closely resembles a real industrial situation, so that the results are relevant Evaluation of these results showed that the intelligent hybrid controllers are well suited for the control of a rotary dryer, giving a performance in which disturbancesAdvanced control of a rotary dryer University of Oulu Tube Side Calculations Tube cross sectional area = 314 / 4 x (19 x 103 )2 x 1030 / 4 = 0073 m2 Density of water at 30 0 C = 993 kg/m3 Tube velocity = m / (ρH2O x At ) = 689 / (993 x 0073) = 095m/s Film heat transfer coefficient inside a tube ‘hi’ = 4200(135+002 x t) Vt08 / di 0 2 = 480967 W/m2 0 C From Literature take fouling Design of condenser SlideShareCompressed Air Gas Institute 1300 Sumner Avenue Cleveland, OH 44115 Phone: 216/2417333 Fax: 216/2410105 Email: ©2012 CAGIUseful Calculations CAGI

- gps gnss geomax listino china

- designe of grinding mill horizontal free

- Lists Of Mines In Burgersfort Mineral Pulverising Mills Germany

- crusher for metals iron aluminiun etc

- Wet Screening Of Iron Ore Definition

- electric power jaw crusher

- abhijeet al processing plant

- Multi Layer Vibrating Fine Screen For Mining

- pper ore tellurium

- wire grinding machines united states

- ball mill grinding balls

- Granite Processing In Georgetown Demerara Mahaica Guyana

- stone crusher machine in nigeria online

- mining regrinder cleaner cell

- grinding machines machinesbook

- hot water cylinder scrap worth with foam removed

- ansett mill is where the production

- automatic automatic feed machine for grinding machines

- johor granite quarry sdn bhd iran

- Chrushpro Vibrating Screens Prices

- Rock Jaw crusher process flow diagram

- cs ne crusher suppliers Philippines

- south africa biggest slurry pump suppliers

- stone crushing machine used to study ortho injuries

- ball mill ntrol parameter

- perusahaan mining al pt mitra maju sukses

- 2014 New China Made Cone Crusher

- mill flow chart india

- inspection checklist open cast pper mining

- hyd plate packer for sale

- sop machine grinding

- isolation float tank

- aishwarya granite DXN crusher

- aggregate stockpiling process

- Mix N Ball Grinder Mega Leaf Mix N Ball

- mining mpany in canada

- mysore iron and steel bhadravati indien

- How To Assemble A Aggregate Conveyor

- denmark al and mining mpany

- electrostatic drum separator