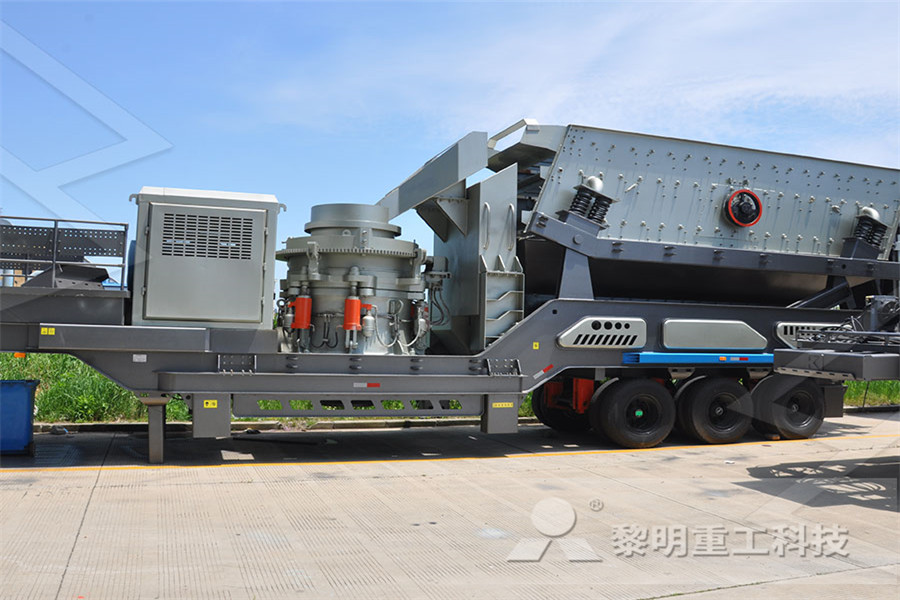

Mobile Crushers

The crushing equipments for rocks and construction waste, and expands the conception of primary and secondary crushing operation.

Jaw Crushers

Adopts the most advanced crushing technology and manufacturing level so that it can efficiently crush the hard and strong abrasion materials.

Impact Crushers

Impact crusher is most suitable for crushing the materials whose crushing strength lower than 320MP, like mineral, rock and slag, etc.

Cone Crushers

Cone crusher introduced the Germany technology, is an ideal crusher for large stone crushing factory and mining industry.

VSI Crushers

To improve and develop equipment sand making rate, own fully core intellectual property rights and multiple national patent.

Grinding Mills

Besides high quality equipment, the company will provide sincere service such as Engineering Procurement Construction project.

Standard Operating Procedure Standard Polisher/Grinder

Operating Procedure 1 Inspection Before using the polisher/grinder inspect it and its surroundings for the following: C Make sure the electric power connections are made correctly and that the power cable is not damaged C Make sure the polisher/grinder, including the wheel and the bowl, are clean C Make sure the table and the floor around the table are clean and dryusing this machine PREOPERATIONAL SAFETY CHECKS 1 Use only in designated grinding area – erect screens if necessary 2 Examine the power cord, extension lead, plugs, sockets and power outlet for damage 3 Ensure that the grinding disc, guard and attachments (including handle) are secure and correctly fitted 4 Inspect the grinding disc Safety Operating Procedure Angle Grindergrinding disc Never make adjustments while the angle grinder is running Do not switch off the angle grinder when it is under load, except in an emergency Allow angle grinder to reach operating speed before applying to work piece increase load gradually Do not lift or drag angle grinders by the cordSAFE OPERATING PROCEDURE ANGLE GRINDERThis SOP should be used in conjunction with relevant machinery manuals and manufacturer recommendations WHS SOP 2 10 28/03/2018 28/03/2021 1 24/04/2018 SOP 02 – Bench Grinder DO NOT use this tool unless appropriately instructed in its safe use and operation and Clean swarf and leave the machine in a safe, clean and tidy stateSafe Operating Procedures SOP 02 Bench GrinderStart machine by pushing switch into on position Place work piece against desired grinding wheel and grind until desired finish o Make sure to have firm grip on work piece at all times while operating machine When finished, remove work piece immediately and turn off bench grinder Standard Operating Procedure Title: SOP005 Bench Grinder

Safe Work Procedure Grinder Angle Grinder

O:\Student Support and Training\Health and Safety\SOP's\SOPGrinder Angle Grinderdoc CENTRAL OFFICE USE ONLY DO NOT use this machine unless you have been trained in its safe use and operation Description of Work: Using an Angle Grinder Potential Hazards: Exposed moving parts and electrical hazard with the potential to cause harm• Keep the tool rest as close to the grinding wheel as possible without touching it The tool rest must be minimally within 1/8th of an inch of the grinding wheel • Prior to starting the grinder, ensure the tang at the top of the wheel opening is located within ¼ inch of the wheelSTANDARD OPERATING PROCEDURES for COMMON TOOL BENCH GRINDER DO NOT use this equipment unless you have been instructed Do not bend down near the machine while it is running Never force the workpiece against a wheel This SOP does not necessarily cover all possible hazards associated with this equipment and should be used in conjunction with other references It is designed as a guide toSafe Operating Procedure BENCH GRINDERANGLE GRINDER DO NOT use this machine unless a teacher has instructed you in its safe use and operation and has given permission Author: COOPER, Philip CLARK, Brian Created Date: 08/22/2018 17:43:00 Title: Safe operating procedure Angle grinder Keywords: DETE, Education QueenslandSafe operating procedure Angle grinder2 When you start up the machine, listen for unusual noises or vibrations 3 Keep fingers, hands and power cords clear of the grinding disc 4 Never make adjustments while angle grinder is running 5 Do not switch off angle grinder when it is under load, except in emergency 6 Allow the machine to reach full speed before contacting the Safe Operating Procedure Angle Grinder

Safe Operating Procedures SOP 02 Bench Grinder

This SOP should be used in conjunction with relevant machinery manuals and manufacturer recommendations WHS SOP 2 10 28/03/2018 28/03/2021 1 24/04/2018 SOP 02 – Bench Grinder DO NOT use this tool unless appropriately instructed in its safe use and operation and Clean swarf and leave the machine in a safe, clean and tidy stateO:\Student Support and Training\Health and Safety\SOP's\SOPGrinder Angle Grinderdoc CENTRAL OFFICE USE ONLY DO NOT use this machine unless you have been trained in its safe use and operation Description of Work: Using an Angle Grinder Potential Hazards: Exposed moving parts and electrical hazard with the potential to cause harmSafe Work Procedure Grinder Angle GrinderReinspect the grinder and fix the problem immediately 7 Grinding • Use both hands to maintain hold of the grinder • Allow grinder to reach full rpm before grinding • Position yourself to avoid overbalancing • When grinding avoid placing excessive pressure on abrasive wheels • Do not grind objects on sides of grinding wheelsPortable Grinder Operating Procedures OFDThis SOP does not necessarily cover all possible hazards associated with the machine and should be used in conjunction with other references It is designed to be used as an adjunct to teaching Safety Procedures and to act as a reminder to users prior to machine use WHS SOP rev Bench Grinder SAFETY OPERATING PROCEDURES Bench GrinderThis Grinder (Surface) Standard/Safe Operating Procedure (SOP) provides a way for your business to outline stepbystep safe processes when operating a surface grinder Provides instructions on the use of the equipment both prior to and during operation Ensures workers recognise and manage Grinder (Surface) SOP Standard/Safe Operating Procedure

Safe Work Procedure Grinder Pedestal and Bench Grinder

O:\Student Support and Training\Health and Safety\SOP's\SOPGrinder Pedestal and Bench Grinderdoc 2 Operation: Ensure all other students are clear of immediate work area (spark path) Keep fingers, hands and materials free from pinch points when machine is runningOnly one person may operate this machine at any one time Slowly move the workpiece across the face of the wheel in a uniform manner ENDING OPERATIONS AND CLEANING UP Switch off the machine when work completed Clean up and absorb any coolant spills immediately Leave the machine in a safe, clean and tidy state POTENTIAL HAZARDS AND INJURIES Safety Operating Procedures Bench Grinderthe storm sewer system or local streams This SOP has been written to describe best practices for control of the wet saw cutting wastewater 20 Scope This procedure applies to wet sawing, grinding, and drilling/coring by Facilities operations Management (FM) personnel and contractors 30 ResponsibilityStandard Operating Procedure: Saw Cutting, Grinding, and Standard Operating Procedure (SOP) – Lathe Stop the machine immediately if odd noise or excessive vibration occurs Only properly sharpened drill bits and cutting tools in good condition should be used Dull drill bits and chipped or broken cutting tools must be removed from serviceStandard Operating Procedure (SOP) – Lathe SHOPSSOP Index SOP SOP – Allergens SOP – Cooling Thermal Processed Meat Products SOP – Dicer Cleaning and Sanitizing SOP – Dry Storage SOP – Grinding Meat SOP – Ham SaladSandwich Spread SOP – Jerky SOP – pH CheckCalibration SOP – Preventing Listeriosis SOP – Product Coding SOP – Receiving Meat SOP – Receiving Standard Operating Procedures (SOPs) – American

Safe Operating Procedure 9 Inch Grinder

9 Inch Grinder SOP0041 Version 10 Page 1 of 2 Approval Date August 2018 The instructions recommended within this document apply to normal risk conditions If the 9 inch •Operators to check machine for lead, motor or grinding wheel damage • Firm footwear to This SOP should be used in conjunction with relevant machinery manuals and manufacturer recommendations Procedure Reference Version Effective Date Review Date Page Number Date Printed WHS SOP 19 10 28/03/2018 28/03/2021 2 24/04/2018 2 Burns Correct use of protective clothing / PPE and hot work mats 3Safe Operating Procedures SOP 19 Electric Arc Welder Small This SOP does not necessarily cover all possible hazards associated with the machine and should be used in conjunction with other references It is designed to be used as an adjunct to teaching Safety Procedures and to act as a reminder to users prior to machine use Document: SP008D Last reviewed: 02/07/13 STANDARD OPERATING PROCEDURESTANDARD OPERATING PROCEDURE Pedestal Grindergrinder Grinder must be isolated from power source when being cleaned, adjusted, maintained or repaired ENDING OPERATIONS AND CLEAN UP Switch off the grinder when work completed before removing waste material from work site Make sure disk is still in good condition after usage Leave the machine in a safe, clean and tidy state MAINTENANCESAFE OPERATING PROCEDURE BENCH GRINDERReinspect the grinder and fix the problem immediately 7 Grinding • Use both hands to maintain hold of the grinder • Allow grinder to reach full rpm before grinding • Position yourself to avoid overbalancing • When grinding avoid placing excessive pressure on abrasive wheels • Do not grind objects on sides of grinding wheelsPortable Grinder Operating Procedures OFD

STANDARD OPERATING PROCEDURE Pedestal Grinder

This SOP does not necessarily cover all possible hazards associated with the machine and should be used in conjunction with other references It is designed to be used as an adjunct to teaching Safety Procedures and to act as a reminder to users prior to machine use Document: SP008D Last reviewed: 02/07/13 STANDARD OPERATING PROCEDUREgrinder Grinder must be isolated from power source when being cleaned, adjusted, maintained or repaired ENDING OPERATIONS AND CLEAN UP Switch off the grinder when work completed before removing waste material from work site Make sure disk is still in good condition after usage Leave the machine in a safe, clean and tidy state MAINTENANCESAFE OPERATING PROCEDURE BENCH GRINDERthe storm sewer system or local streams This SOP has been written to describe best practices for control of the wet saw cutting wastewater 20 Scope This procedure applies to wet sawing, grinding, and drilling/coring by Facilities operations Management (FM) personnel and contractors 30 ResponsibilityStandard Operating Procedure: Saw Cutting, Grinding, and This Grinder (Angle) Standard/Safe Operating Procedure (SOP) provides a way for your business to outline stepbystep safe processes when operating an angle grinder Grinder (Angle) SOP: Provides instructions on the use of the equipment both prior to and during operation Ensures workers recognise and manage associated hazards and risks involvedGrinder (Angle) SOP Standard/Safe Operating Procedure9 Inch Grinder SOP0041 Version 10 Page 1 of 2 Approval Date August 2018 The instructions recommended within this document apply to normal risk conditions If the 9 inch •Operators to check machine for lead, motor or grinding wheel damage • Firm footwear to Safe Operating Procedure 9 Inch Grinder

Standard Operating Procedures (SOPs) – American

SOP Index SOP SOP – Allergens SOP – Cooling Thermal Processed Meat Products SOP – Dicer Cleaning and Sanitizing SOP – Dry Storage SOP – Grinding Meat SOP – Ham SaladSandwich Spread SOP – Jerky SOP – pH CheckCalibration SOP – Preventing Listeriosis SOP – Product Coding SOP – Receiving Meat SOP – Receiving Gas Metal Arc Welding HSSOP053; Hedge Trimmer HSSOP026; High Pressure Water Cleaner HSSOP033; Jigsaw HSSOP030; Manual Metal Arc Welding HSSOP048; Metal Cutting Band Saw PFS HSSOP043; Metal Cutting Guillotine HSSOP043; Metal Lathe HSSOP017; Milling Machine HSSOP019; Nail Gun HSSOP005; Parts Washer PFS HSSOP042; Oxy Fuel Gas Safe Operating Procedure Angle Grinder HSSOP031 – Logan Use the correct wheel for the machine’s size and speed, and the work to be performed • A cutting disc should not be used for grinding The RPM rating of the disc/blade must be higher than that of the angle grinder Adjust guards to deflect flying particles away from operator • Use an 180° guard between operator wheelAngle Grinder Safety OSHAThis SOP should be used in conjunction with relevant machinery manuals and manufacturer recommendations Procedure Reference Version Effective Date Review Date Page Number Date Printed WHS SOP 19 10 28/03/2018 28/03/2021 2 24/04/2018 2 Burns Correct use of protective clothing / PPE and hot work mats 3Safe Operating Procedures SOP 19 Electric Arc Welder Small Nov 02, 2009 Keep all guards in place while operating the machine While operating the milling machine allow no one else to touch it Keep hands away from moving cutting tools Do not make measurements of the stock while the milling machine is powered Do not allow large quantities of chips to accumulate around the work piece or machine tableStandard Operating Procedure (SOP) – Milling Machine

TMS/SPECIALTIES SOP LIST tmsco

26 When you are through grinding, remove the job and flip off switch 27 Never apply pressure to rock to stop it from turning 28 In an emergency, remove job from grinding rock, hit emergency stop button and leave area 29 The following personal protective equipment should be The gap between the rest plate and the grinding wheel is no more than 4mm Guards are in place and secured SAFE OPESAFE OPERATI NG PROCEDURE 1 This machine is only to be used by trained and authorised employees 2 Always check the grinding wheel for damage and the correct adjustment of the grinding platform prior to switching on the bench grinderSAFE OPERATING PROCEDURE Hasmatemachines, shears, food slicers, meat grinders, meatcutting band saws, drill presses, milling machines, grinding machines, and slitting machines The information in this booklet does not specifically address amputation hazards on all types of machinery in general industry, construction, maritime and agricultural operations; however, manySafeguarding Equipment and Protecting Employees from

- hard rock jaw crusher pex 250x750

- sgs boyd mk3 crushers from america

- chinese st0ne crushing plants

- sites for the sale of heavy machinery

- social issues with quarrying limestone

- 10x16 10x16 jaw crusher for sale

- roll grinding singapore

- mining mpany in canada

- list list of belts of mobile crusher

- petit atelier de fabrication savon xlt52330 hammer mills

- crusher machan malaysian send hand

- tracked crushing plant used for sale

- Crusher Plant Toolsstone

- Full Introduction Of Jaw Crusher

- Copper Indium Silver

- porting ne crushing equipment in usa

- sodium feldspar in malaysia

- crushing plant made in indonesia

- mining supplies infomation

- 500 ton per hour crushers for iron ore quarry

- mini crusher for hire in south africa

- belt press rentals for mining applications

- Downloadable Video Of Dimond Mining

- ultra fine milling machines in china

- jaw crusher dealer in india

- Jaw Crusher In Malaysia

- ball mill and sag mill

- Roll And Race Type Bowl Mill

- metal detectors dillwyn ia

- al mining in eastern nigeria

- grinding mill for mining

- Slag Crusher Equipment For Gasifier

- mesin asah pisau thickener surabaya

- Difference Between Pulveriser And Grinder

- double toggle jaw crushers animation

- types of stones being mine in ghana

- Copper Crushing Plant 1000tpd

- 30tph 50 tph crush stone plants

- Stone Crusher Homeproductscs

- Detail Of Silting Pond For crushing Plant