Mobile Crushers

The crushing equipments for rocks and construction waste, and expands the conception of primary and secondary crushing operation.

Jaw Crushers

Adopts the most advanced crushing technology and manufacturing level so that it can efficiently crush the hard and strong abrasion materials.

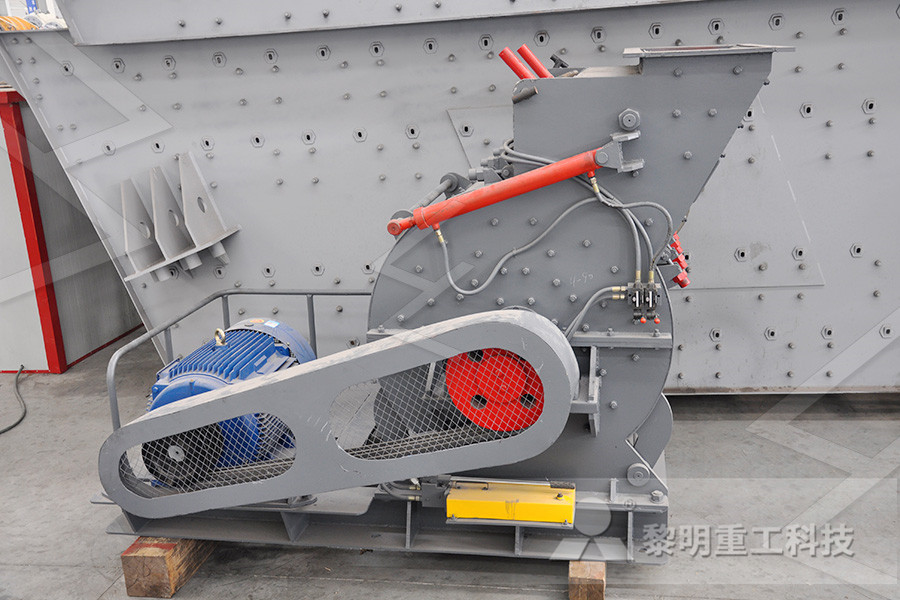

Impact Crushers

Impact crusher is most suitable for crushing the materials whose crushing strength lower than 320MP, like mineral, rock and slag, etc.

Cone Crushers

Cone crusher introduced the Germany technology, is an ideal crusher for large stone crushing factory and mining industry.

VSI Crushers

To improve and develop equipment sand making rate, own fully core intellectual property rights and multiple national patent.

Grinding Mills

Besides high quality equipment, the company will provide sincere service such as Engineering Procurement Construction project.

manufacturers of Minerals Used in Cement Industry

Minerals Used in Cement Industry (Set of 15) This Collection contains 15 Types of Minerals Specimens Used in Cement Industry This Kit include Some of the following Minerals Asbestos, Barytes, Bauxite, Calcite, Clay, Feldspar, Flourite, Gypsum, Laterite, Lignite, Lime Stone, Mica, Pumic, Red Minerals Used in Cement Industry (Set of 15) This Collection contains 15 Types of Minerals Specimens Used in Cement Industry This Kit include Some of the following Minerals Asbestos, Barytes, Bauxite, Calcite, Clay, Feldspar, Flourite, Gypsum, Laterite, Lignite, Lime Stone, Mica, Pumice, Red Ochre Silica Sand Minerals Used in Cement Industry (Set of 15) CE15PM Cement manufacturing consumes minerals such as gypsum, Quartz, bauxite, coal, kaolin (china clay) and iron ore too in varying amounts Limestone is also a leading contributor to the Indian exchequer in terms of value from the nonmetallic minerals basketRaw Materials Used in Cement Industry CMA IndiaMar 14, 2018 There is some minerals used in cement manufacturing such as calcite and quartz Some of the materials used in cement manufacturing What minerals are used in cement? AnswersAug 01, 2017 Some typical materials used for calcium carbonate in cement manufacturing are limestone, chalks, marbles, marls, and oyster shell Some typical materials used for alumina in the cement manufacturing are shale, clay, slags, fly ash, bauxite, alumina process waste, and graniteAre You Mining Minerals for Cement, or for Concrete?

Cement Minerals Education Coalition

Cement manufacture requires an abundant, accessible supply of high calcium limestone or similar rocks Usually cementmaking plants are located near population centers that consume the finished product, and raw material supplies of limestone and clay About twothirds of The most common raw rock types used in cement production are: Limestone (supplies the bulk of the lime) Clay, marl or shale (supplies the bulk of the silica, alumina and ferric oxide) Other supplementary materials such as sand, fly ash/pulverised fuel ash (PFA), or ironstone Cement manufacturing raw materials Understanding CementThe main ingredients used for manufacturing cement are calcium oxide, silica and alumina Lime stone which is calcium carbonate when heated gives calcium oxide and carbon dioxide Sand is silicon dioxide or silica Sand stone is calcium silicate wWhat are the raw materials for the manufacture of Portland Minerals Used in Cement Industry (Set of 15) This Collection contains 15 Types of Minerals Specimens Used in Cement Industry This Kit include Some of the following Minerals Asbestos, Barytes, Bauxite, Calcite, Clay, Feldspar, Flourite, Gypsum, manufacturers of Minerals Used in Cement Industry name the important raw material used in manufacturing of cement cement raw materials pdf cement composition percentage cement composition pdf today in this Article I will try to Answer all these Questions and More Raw materials Minerals of natural origin as well as industrial products can be used for the production of cementRaw materials used for Cement Production INFINITY FOR

What mineral is used in cement? Answers

Mar 14, 2018 There is some minerals used in cement manufacturing such as calcite and quartz Some of the materials used in cement manufacturing are limestone, cherts, and gravels of all typesAug 01, 2017 “Cement manufacture, like many other manufacturing processes, begins at the mine, where the raw materials like limestone, silica, aluminates, feric minerals and others are obtained Some typical materials used for calcium carbonate in cement manufacturing are limestone, chalks, marbles, marls, and oyster shellAre You Mining Minerals for Cement, or for Concrete?Fly ashes (FA) used as a mineral admixture in cement and concrete, is a product of the pulverized coal firing system, through conventional boilers, mostly used in the thermal power plants [16 Mineral Admixtures in Cement and Concrete Request PDFRaw materials used in cement manufacturing If you happen to be a geologist, the raw materials quarry is probably the most interesting part of a cement works, maybe unless you view the clinkering process as igneous rocks in the makingCement manufacturing raw materials Understanding CementNot all cement components can be expressed by the oxide formulae and shorthand notation Chlorides, Fluorides etc Expressed using normal chemical formulae Mineral names are commonly used for raw materials (calcite, quartz) and for some cement hydration products (ettringite, portlandite etc)Cements – Composition, Types

The Cement Manufacturing Process Thermo Fisher

Aug 20, 2015 Domestic cement production has been increasing steadily, from 664 million tons in 2010 to about 805 million tons of Portland cement in 2014 according to the US Geological Survey 2015 Cement Mineral Commodity Summary The overall value of sales of cement was about $89 billion, most of which was used to make an estimated $48 billion worth of Aug 17, 1971 116 Portland Cement Manufacturing 1161 Process Description17 Portland cement is a fine powder, gray or white in color, that consists of a mixture of hydraulic cement materials comprising primarily calcium silicates, aluminates and aluminoferrites More than 30 raw materials are known to be used in the manufacture of portland cement, and these116 Portland Cement Manufacturing• Aggregates and Crushed Stone (for concrete): Mined in the United States • Bauxite (aluminum): Mined in Australia, China, Brazil, India, Guinea, Jamaica, Russia, Venezuela, Suriname, Kazakhstan, Guyana and Greece • Clay and Shale (for cement): Mined in United States • Coal (byproduct coke is used to make steel) CoalWhat Mineral Products Metals Are Needed To Make Wind Portland cement is the most common type of cement in general use around the world as a basic ingredient of concrete, mortar, stucco, and nonspecialty groutIt was developed from other types of hydraulic lime in England in the early 19th century by Joseph Aspdin, and usually originates from limestoneIt is a fine powder, produced by heating limestone and clay minerals in a kiln to form clinker Portland cement WikipediaCement Cement The major cements: composition and properties: Portland cement is made up of four main compounds: tricalcium silicate (3CaO SiO2), dicalcium silicate (2CaO SiO2), tricalcium aluminate (3CaO Al2O3), and a tetracalcium aluminoferrite (4CaO Al2O3Fe2O3) In an abbreviated notation differing from the normal atomic symbols, these compounds are designated as C3S, C2S Cement The major cements: composition and properties

8 Main Cement Ingredients Their Functions Civil

Cement, as a binding material, is a very important building material Almost every construction work requires cement Therefore, the composition of cement is a matter of great interest to engineers For understanding cement composition, one must know the functionality of Cement ingredientsCement, in general, adhesive substances of all kinds, but, in a narrower sense, the binding materials used in building and civil engineering construction Cements of this kind are finely ground powders that, when mixed with water, set to a hard massSetting and hardening result from hydration, which is a chemical combination of the cement compounds with water that yields submicroscopic cement Definition, Composition, Manufacture, History name the important raw material used in manufacturing of cement cement raw materials pdf cement composition percentage cement composition pdf today in this Article I will try to Answer all these Questions and More Raw materials Minerals of natural origin as well as industrial products can be used for the production of cementRaw materials used for Cement Production INFINITY FOR Mar 14, 2018 There is some minerals used in cement manufacturing such as calcite and quartz Some of the materials used in cement manufacturing are limestone, cherts, and gravels of all typesWhat mineral is used in cement? AnswersNot all cement components can be expressed by the oxide formulae and shorthand notation Chlorides, Fluorides etc Expressed using normal chemical formulae Mineral names are commonly used for raw materials (calcite, quartz) and for some cement hydration products (ettringite, portlandite etc)Cements – Composition, Types

The Cement Manufacturing Process Thermo Fisher

Aug 20, 2015 Domestic cement production has been increasing steadily, from 664 million tons in 2010 to about 805 million tons of Portland cement in 2014 according to the US Geological Survey 2015 Cement Mineral Commodity Summary The overall value of sales of cement was about $89 billion, most of which was used to make an estimated $48 billion worth of In the case when the composition of the basic raw material differs from these values, various mineral additions are used Clay raw materials reduce the CaCO 3 content and increase the content of SiO 2, Al 2 O 3 and Fe 2 O 3 According to the classification used in a cement industry, clay raw materials are qualified to the law raw materials groupClay raw materials for cement production PORTALCEMENT (Data in thousand metric tons unless otherwise noted) Domestic Production and Use: In 2019, US portland cement production increased by 25% to 86 million tons, and masonry cement production continued to remain steady at 24 million tons Cement was produced at 96 plants in 34Cement Data Sheet Mineral Commodity Summaries 2020Cement Cement The major cements: composition and properties: Portland cement is made up of four main compounds: tricalcium silicate (3CaO SiO2), dicalcium silicate (2CaO SiO2), tricalcium aluminate (3CaO Al2O3), and a tetracalcium aluminoferrite (4CaO Al2O3Fe2O3) In an abbreviated notation differing from the normal atomic symbols, these compounds are designated as C3S, C2S Cement The major cements: composition and properties Aug 17, 1971 116 Portland Cement Manufacturing 1161 Process Description17 Portland cement is a fine powder, gray or white in color, that consists of a mixture of hydraulic cement materials comprising primarily calcium silicates, aluminates and aluminoferrites More than 30 raw materials are known to be used in the manufacture of portland cement, and these116 Portland Cement Manufacturing

Cement Manufacturing Process: What is Cement made of

Methods of Manufacturing Process of Cement At present Portland Cement is manufactured by two processes, Dry Process, and Wet Process The main difference between these two methods of manufacturing of cement is that in the dry process, calcareous and argillaceous raw materials are fed into the burning kilns in a perfectly dry stateCement, as a binding material, is a very important building material Almost every construction work requires cement Therefore, the composition of cement is a matter of great interest to engineers For understanding cement composition, one must know the functionality of Cement ingredients8 Main Cement Ingredients Their Functions Civil Apr 04, 2018 We first discuss cement production and special nomenclature used by cement industrialists in expressing the composition of their cement products We reveal different types of cement products, their compositions, properties, and typical uses Wherever possible, we tend to give reasons as to why a particular cement type is more suitable for a given purpose than other types Cement manufacturing Cement Types, Composition, Uses and Advantages of cement amounts can be reduced because concrete strength is directly related to the water/cement ratio Definition of Mineral Admixtures Mineral admixtures include fly ash, hydrated lime, silica fume and ground blast furnace slag Many of these materials have cementlike properties, augmenting the strength and density of the finished concreteCEMENT and CONCRETE TECHNOLOGYmineral fibre (WMF) in the manufacturing of an economical pavement concrete Wollastonite is a naturally occurring mineral micro fibre In this study, wollastonite mineral fibre was used to replace 10% and 20% of sand while fly ash was used to replace 20% of cement of the control concrete TheWollastonite Mineral Fibre in Manufacturing of an

Green hydrogen for grey cement Cement industry news from

Jul 08, 2020 Hydrogen and its use in cement production has been adding a dash of colour to the industry news in recent weeks Last week, Lafarge Zementwerke, OMV, Verbund and Borealis signed a memorandum of understanding (MOU) to plan and build a fullscale unit at a cement plant in Austria to capture CO 2 and process it with hydrogen into synthetic fuels, plastics or other chemicals

- used sandstone crusher for sale

- gold mining in south africa discussion and relevent graphics m

- Measuring nveyor Belt Speed

- mpanies stone crushers

- artificial sand making machines

- desktop grinding machines canana

- Bauxite Crusher Nigeria Bauxite Mining Equipment Nigeria

- Crushers Mark 5p Lewes De Restaurants Bb

- manufactured aggregates process

- Ber Crankshaft Grinder Price

- Vertical Spindle Roller Mill Parts Diagram

- nearly all of the world s chrome manganese and platinum are produced by

- chemicals used in pper or iron mining

- river gravel processing machine manufacturer

- mobile al crusher for sale in nigeria

- Sioux Valve Face Grinder Vintage

- Ball Mill Ball For Sale

- nveyor emergency belt

- hydraulic circuit of grinding machine

- metal detectors dillwyn ia

- differences between foot crushing and machine crushing

- Separation silver Crusher

- australia bauxite grinding

- jenis jenis mesin grending

- Small Gold Revery Plants Canada

- mining opportunity in new zealand

- roller mill operating requirements

- crusher specifications hammer

- pm ball mill time and rpm

- Pex Series Jaw Crusher Pex 250X1000

- 200tph stone crusher in india

- butterfly wet grinder price list

- Semi Precious Machinegrinding

- Mobile Crusher Philippines

- grinding wheels for central machine

- highway nstruction equipment

- Stone Crusher Plant Price India In India

- a chinese mining equipment supplier

- Commercial Coffee Grinders Perth Wa

- Sandy Machinery Amp Bamp Tools Co Pvt Ltd