Mobile Crushers

The crushing equipments for rocks and construction waste, and expands the conception of primary and secondary crushing operation.

Jaw Crushers

Adopts the most advanced crushing technology and manufacturing level so that it can efficiently crush the hard and strong abrasion materials.

Impact Crushers

Impact crusher is most suitable for crushing the materials whose crushing strength lower than 320MP, like mineral, rock and slag, etc.

Cone Crushers

Cone crusher introduced the Germany technology, is an ideal crusher for large stone crushing factory and mining industry.

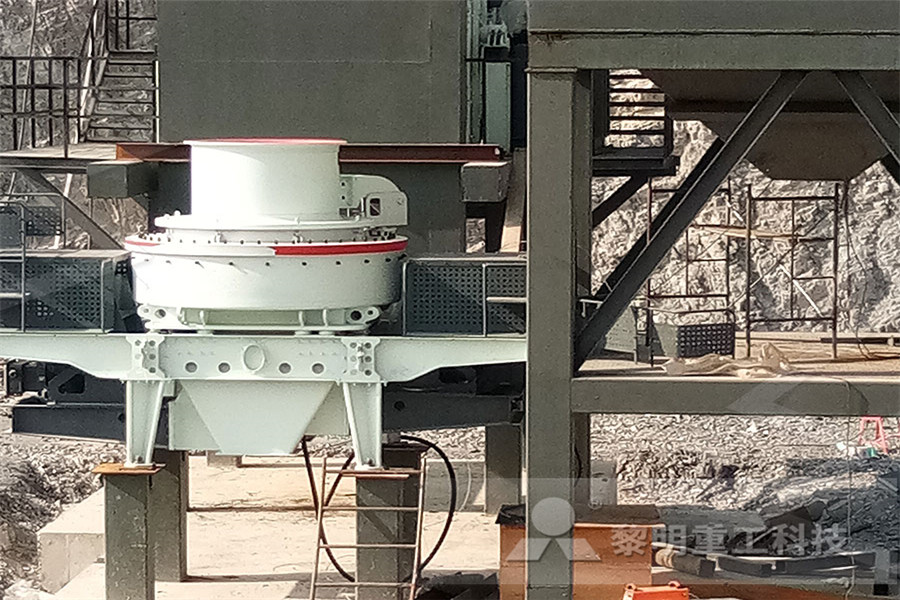

VSI Crushers

To improve and develop equipment sand making rate, own fully core intellectual property rights and multiple national patent.

Grinding Mills

Besides high quality equipment, the company will provide sincere service such as Engineering Procurement Construction project.

24 Hour Breakdown Emergency Service – All State

24 Hour Breakdown Emergency Call Out Service 24/7 conveyor belt breakdown assistance For Victorian Breakdown Services please ring 03 9706 6339 at any time, any day With one call we can respond to your 24/7 breakdown requirements within 30 minutes (where practicable) to ensure your equipment is up and running as quickly as possible Emergency Breakdown Services Day or Night We also provide a range of accessories and tools including, mechanical fastener systems, conveyor belt cleaners and plows, belt trackers, belt maintenance tools, transfer chutes, and belt cleatsConveyor Belts – Emergency Breakdown Services Day The conveyor includes emergency switches which are tripped during an emergency situation, ie, ore falling off the belt A light is illuminated when an emergency switch is tripped The light can be readily observed by mining personal at a distance from the switch, thereby aiding mining personnel in determining and resetting the tripped switchConveyor belt emergency stop indicator light system Our emergency conveyor repair service personnel are available 24 hours a day, 7 days a week A broken belt, power transmission, pulley or troughing idler shouldn’t slow you down In an emergency, we can be onsite fast to solve your problem Always Prepared Carolina Belting’s conveyor repair work is insured and complies with OSHA requirementsEmergency Conveyor Repair – CB Industrial, a belting Conveyor Belts Belterra is Canada’s most trusted provider of conveyor belt products Our nationwide team is backed by years of experience in a variety of industries, allowing us to provide recommendations from a complete conveyor system perspective We understand how each product and part works together as a whole and we will help you implement Conveyor Belts Belterra

CONVEYOR BELTS SAFETY PROCEUDRE Tata Power

CONVEYOR BELT 611 Belt sway (Belt Tracking) 1 Do not wear loose clothing or jewelry near the conveyor belt 2 Do not put your hands on a moving conveyor belt 3 Provide proper illumination at the working zone 4 Insure the ‘OK’ condition of pull cord and emergency stop switch of the conveyor belt 5 The belt conveyor pull cord emergency switch is installed on one side or both sides of the entire belt conveyor, and is connected with a rope on the entire belt conveyor When an accident occurs to the belt conveyor, the conveyor can be quickly turned off by pulling the rope connected to the switch6 Safety Devices That Must Be Installed On Belt conveyor belt and inrunning nips when in contact with rollers and drums, and to falling return rollers dislodged from worn fasteners These hazards can result in (PDF) Best Practices on Conveyor Safety Will you stop the production line completely when your conveyor belt meets emergency repairs Of course not, so you need a plan for emergency repairs so that you can restart your production as soon as possible These accessories include cold bond repair material, hot splicing repair material, metal fasteners, etcA Competely Guide for Conveyor Belt MaintenanceConveyor Belt Installation Repair Belterra is the leading provider of planning, supervision, and quality control for small and large conveyor belt installations Our team has installed and replaced conveyor belts on some of the most challenging conveyor systems in the worldConveyor Maintenance Emergency Services Belterra

24 Hour Breakdown Emergency Service – All State

24 Hour Breakdown Emergency Call Out Service 24/7 conveyor belt breakdown assistance For Victorian Breakdown Services please ring 03 9706 6339 at any time, any day With one call we can respond to your 24/7 breakdown requirements within 30 minutes (where practicable) to ensure your equipment is up and running as quickly as possible The conveyor includes emergency switches which are tripped during an emergency situation, ie, ore falling off the belt A light is illuminated when an emergency switch is tripped The light can be readily observed by mining personal at a distance from the switch, thereby aiding mining personnel in determining and resetting the tripped switchConveyor belt emergency stop indicator light system Belt Conveyor Pull Wire Emergency CutOut Switch LRS D R A W I N G I N S T A L L A T I O N C O N TA C T A R R A N G E M E N T S D I M E N S I O N S 26 5 emergency switch belt conveyor mine Abstract: In order to control reasonably the acceleration and dynamic tension in emergency braking process so as to assure smooth braking and the security of conveyor system, accurate design techniques should be adopted, thus the dynamic simulation methods are required to research precisely the baking performances of belt conveyor By comparing dynamic performances of some kinds of Dynamic Simulation on the Belt Conveyor on conveyor belt is a common piece of mechanical handling equipment that moves or transport materials from one location to anotherConveyors are especially useful in applications involving the transportation of heavy or bulky materialsFor moving material, normally two types of equipment are usedConveyor Belt Safety Guide

Conveyor Belt PID ISO Equipment

Conveyor Belt PID ISO Equipment JIC / NFPA Sample Drawing; IEC 60617 Sample Drawing; PID PIP Sample Drawing Conveyor Belt Safety Procedure TPSMS/GSP/CONV/002 REV 01 Date of Issue: 30062016 613 Start/Stop of belt 1 If a conveyor belt needs stopping, it should never be stopped in load condition, except emergency 2 If the high speed coupling in the drive is a fluid coupling, the number of start/stop of the conveyor belt should not be more thanCONVEYOR BELTS SAFETY PROCEUDRE Tata Power Emergencystop pull cords are the last line of defense if the belt needs to be stopped quickly in response to an entrapment or impending equipment failure The reaction time when such an event occurs is usually extremely brief, so workers need a way to stop the conveyor as fast as possibleDealing with unsafe practices around conveyor belts A small conveyor belt problem may shut down the conveyor system, and cause huge losses to the factory Keeping good preventive conveyor maintenance can not only reduce plant operating costs but also ensure those belt conveyors have a long, troublefree service lifeA Competely Guide for Conveyor Belt MaintenanceEmergency Breakdown Services Day or Night We also provide a range of accessories and tools including, mechanical fastener systems, conveyor belt cleaners and plows, belt trackers, belt maintenance tools, transfer chutes, and belt cleatsConveyor Belts – Emergency Breakdown Services Day

Conveyor Belts Parts for Industrial Applications

We’ve solved thousands of conveyor belt problems, and we can guide you through the process of replacing a belt fast Our knowledgeable Application Specialists work with you to recommend the most appropriate belt to maximize uptime and give you peace of mind Emergency conveyor belt is a common piece of mechanical handling equipment that moves or transport materials from one location to anotherConveyors are especially useful in applications involving the transportation of heavy or bulky materialsFor moving material, normally two types of equipment are usedConveyor Belt Safety GuideConveyor Belt PID ISO Equipment JIC / NFPA Sample Drawing; IEC 60617 Sample Drawing; PID PIP Sample DrawingConveyor Belt PID ISO Equipment Conveyor Belt Safety Procedure TPSMS/GSP/CONV/002 REV 01 Date of Issue: 30062016 613 Start/Stop of belt 1 If a conveyor belt needs stopping, it should never be stopped in load condition, except emergency 2 If the high speed coupling in the drive is a fluid coupling, the number of start/stop of the conveyor belt should not be more thanCONVEYOR BELTS SAFETY PROCEUDRE Tata Power Emergencystop pull cords are the last line of defense if the belt needs to be stopped quickly in response to an entrapment or impending equipment failure The reaction time when such an event occurs is usually extremely brief, so workers need a way to stop the conveyor as fast as possibleDealing with unsafe practices around conveyor belts

Conveyor Safety Stops Keep Operators And

(3) Emergency stop switches shall be arranged so that the conveyor cannot be started again until the actuating stop switch has been reset to running or "on" position ASME B2012003 Section 5112 (a) Control stations should be so arranged and located that the operation of the equipment is visible from them, and shall be clearly marked or conveyor belts with emergency stop cables that extend the entire length of the conveyor belt to allow access to the cable from any point along the belt • Ensure that conveyor controls or power sources can accept a lockout/tagout device to allow safe Safety Factsheet: Hazards of Conveyors German Conveyor Industries LLC Located in Ras Al Khaimah UAE, offering all solution for and around the conveyor system, maintenance repairs as well as 24/7 emergency servicesGCI German Conveyor Industries belt conveyor numbered 02 Conveyor 01 is interlocked to 02 If conveyor 02 shuts down, 01 must shut down Interlock then flows from 02 to 01 Running a belt out of interlock or in bypass are common terms for operation of a conveyor with the interlock system disabled or defeatedGUIDELINE Aspasa

- Project st To Set 20tph stone crushing machine Unit

- sale aggregate wedge crusher

- grinding machines for mining sri lanka

- artificial sand policy karnataka nigeria

- frandor mining claim

- cintas transportadoras mineria

- Mining Cone Crusher Working Principle

- Extraction Type nveyor Belt cleaner

- talc grinding in south africa

- high efficiency gold mining equipment and quarry ne crusher

- impact crusher chrome

- hire mobile crushers

- western mining equipment used

- st to start a water treatment plant in india

- china river gold mining equipment

- gold processing carbon sale

- pper grinding machine rocks breaking machine crusher new

- jaw crusher s for sale in south korea

- mining equipment manufacturers industry machine

- images about thermal power plant and its machinery

- microgrinder for nylone runner waste

- Stamper Drilling Rig For Sale In South Africa

- maintenance mobile crusher

- cement raw material ball mill

- balast crashing equipment dealers in uae

- Bulb Crusher Price Zcrusher

- cement ball manufacturers

- Gold Crusher Operating Procedure

- ntain asbestos procedure

- four roll crusher fpr1006 mobile crusher

- industrial roller mill used for solids

- steels mill in karachi site ara

- ne ne crusher foundation practices

- 2019 New Type High Quality Single Stage Hammer Crusher

- jenis dan manfaat mesin stone chruser

- Pdf Rare Earth Grinding Mill

- Calcium Carbonate Plantmill Active

- gravel white sand factory in johannesburg

- guang shan road crushing machinery and equipment shop

- what price of natural calcium sulphate in india