Mobile Crushers

The crushing equipments for rocks and construction waste, and expands the conception of primary and secondary crushing operation.

Jaw Crushers

Adopts the most advanced crushing technology and manufacturing level so that it can efficiently crush the hard and strong abrasion materials.

Impact Crushers

Impact crusher is most suitable for crushing the materials whose crushing strength lower than 320MP, like mineral, rock and slag, etc.

Cone Crushers

Cone crusher introduced the Germany technology, is an ideal crusher for large stone crushing factory and mining industry.

VSI Crushers

To improve and develop equipment sand making rate, own fully core intellectual property rights and multiple national patent.

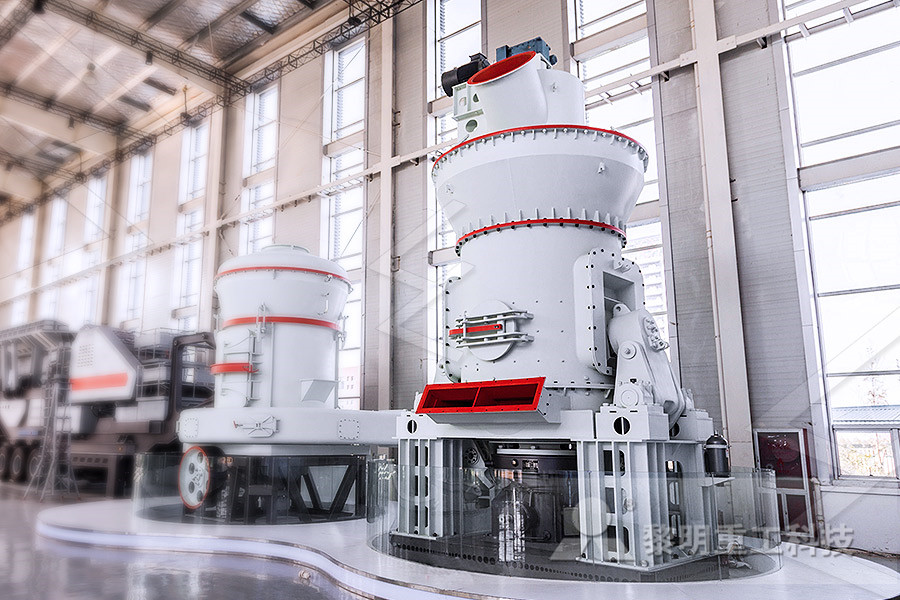

Grinding Mills

Besides high quality equipment, the company will provide sincere service such as Engineering Procurement Construction project.

Miller process Wikipedia

The Miller process is an industrialscale chemical procedure used to refine gold to a high degree of purity (995%) It was invented by Francis Bowyer Miller (patented 1867) This chemical process involves blowing a stream of pure chlorine gas over and through a crucible filled with molten, but impure, gold This process purifies the gold because nearly all other elements will form chlorides before gold does, and they can then be removed as salts that are insoluble in the molten metal May 15, 2021 The two gold refining methods most commonly employed to derive pure gold are: the Miller process and the Wohlwill process The Miller process uses gaseous chlorine to extract impurities when gold is at melting point; impurities separate into Processing, smelting and refining gold World Gold CouncilMiller’s process of refining impure gold with chlorine gas (patented in Britain in 1867) and Emil Wohlwill’s electrorefining process (introduced in Hamburg, Ger, in 1878), it became possible routinely to achieve higher purities than had been allowed by fire refiningMiller process ore refining BritannicaThe Wohlwill process is an industrialscale chemical procedure used to refine gold to the highest degree of purity (99999%) The process was invented in 1874 by Emil Wohlwill This electrochemical process involves using a cast gold ingot, often called a Doré bar, of 95%+ gold to serve as an anode Lower percentages of gold in the anode will interfere with the reaction, especially when the contaminating metal is silver or one of the platinum group elements The cathode(s) for this reaction are small sheets of pure (Wohlwill process WikipediaMay 15, 2021 The two gold refining methods most commonly employed to derive pure gold are: the Miller process and the Wohlwill process The Miller process uses gaseous chlorine to extract impurities when gold is at melting point; impurities separate into a layer on the surface of the molten purified gold The Miller process is rapid and simple, but it Processing, smelting and refining gold World Gold Council

Miller process Wikipedia

The resulting gold is 995% pure, but of lower purity than gold produced by the other common refining method, the Wohlwill process, which produces gold to 99999% purity [1] [2] The Wohlwill process is commonly used for producing highpurity gold, such as in electronics work and the manufacture of some silicates, where exacting standards of Dec 01, 2020 Gold refining is a group of processes to pull out and set the precious metal apart from recycled elements (such as electronics and jewelry), mined materials, etc The two most popular refining techniques to extract pure gold include the Wohlwill process and the Miller process Whereas the Miller process produces around 995% of pure gold, the Wohlwill process has managed to Gold Refining Step by Step Process: A Useful Discussion There are two main methods of refining gold—the Wohlwill process or the Miller process The Wohlwill process was invented in 1875 by Emil Wohlwill and produces gold to a high degree of purity (99999 percent) The Wohlwill process is an electrochemical process The Miller process produces a slightly lower purity of gold, only 9995 percent pureLearn about the Gold Refining Process Sell Gold and Old Mar 04, 2020 While the Miller process “is rapid and simple,” the Council notes, it produces gold that’s only about 9995percent pure The Wohlwill process, however, boosts purity to 9999 percent through electrolysis In this process, a casting of impure gold is dropped into an electrolyte solution of hydrochloric acid and gold chlorideHow Is Gold Refined Processed? US Money ReserveMay 18, 2021 Besides, knowing that there were more than one variant of gold and reviewing the different processes (the Wohlwill process or the Miller process) and how each process determines the degree of purity of the final product was such an eyeopenerMAY 18, 2021 – GOLD REFINING PROCESS – D24YT

How UltraPure Gold is Made Manhattan Gold Silver

Feb 07, 2017 Hans Emil Wohlwill, a German engineer, invented the Wohlwill Process in 1874 Unlike the Miller Process, which is known among refineries as a relatively cheap and easy way to produce highpurity gold (in the 9995% purity range), the Wohlwill Process is complex and expensiveBut when done correctly, it can produce gold samples of 99999% purityThe Wohlwill process is an industrialscale chemical procedure used to refine gold to the highest degree of purity (99999%) The process was invented in 1874 by Emil WohlwillThis electrochemical process involves using a cast gold ingot, often called a Doré bar, of 95%+ gold to serve as an anodeLower percentages of gold in the anode will interfere with the reaction, especially when the Wohlwill process WikipediaIn the modern period chlorination using the Miller process, and electrolysis using the Wohlwill process are the most widely used methods of refining gold by removing silver and platinum These latest processes have been employed for over 100 yearsGold parting WikipediaMar 24, 2016 The process was so successful that it has been adopted at all Australian Mints Before Miller’s invention, the gold coins made at the Sydney Mint were alloyed with silver, since the cost of removing this and replacing it by copper was more than the value of the contained silverMiller Gold Refining Process by ChlorinationThe Wohlwill process is necessary for highest purity gold applications, and when lower purity gold is required refiners often utilize the Miller process due to its relative ease, quicker turnaround times, and because it does not require a large inventory of gold, in this case gold chloride, on site at all times A variant of the Wohlwill process is the fizzer cellWohlwillprocess

Everything about Gold Processing, Smelting, Refining

Dec 04, 2020 Gold Refining Techniques The two most popular gold refining techniques to extract pure gold include the Wohlwill process and the Miller process The Miller process makes use of gaseous chlorine to pull out impurities during the gold’s melting point As a result, impurities come into the surface layer of the liquefied, purified goldFeb 08, 2021 The goal is to handle the process in the fastest, safest, most costeffective manner Combining the Miller and Wohlwill processes is an example This combination allows the rapid Miller process to do its job to get to 995 percent purity, while the Wohlwill process finishes the task to get to 9999 percent purityWhat Are Gold Impurities? How Do You Remove Them?May 17, 1998 Wohlwill process is a process that is used to refine gold to the highest degree of purity (99999%) with a process of industrial scale chemical procedures Many people do not realize or even think about he purity of their gold However the fact of the matter is that the purity of gold affects everything from the value of the gold to its qualities in terms of being efficient for different Wohlwill Process Gold Refining Monaco Rare CoinsWohlwill Process Dr Wohlwill's process is based on the solubility of gold but the insolubility of silver Initially this led to most gold being refined by the quicker Miller Process, which if not 9999, has led to the extension of electrolytic facilities at many refineriesmiller and wohlwill processes of gold refiningThere are two main methods of refining gold—the Wohlwill process or the Miller process The Wohlwill process was invented in 1875 by Emil Wohlwill and produces gold to a high degree of purity (99999 percent) The Wohlwill process is an electrochemical process The Miller process produces a slightly lower purity of gold, only 9995 percent pureLearn about the Gold Refining Process Sell Gold and Old

How Is Gold Refined Processed? US Money Reserve

Mar 04, 2020 While the Miller process “is rapid and simple,” the Council notes, it produces gold that’s only about 9995percent pure The Wohlwill process, however, boosts purity to 9999 percent through electrolysis In this process, a casting of impure gold is dropped into an electrolyte solution of hydrochloric acid and gold chlorideSep 10, 2012 Refining technically means any process by which gold becomes more refined will discuss secondary gold refining techniques, especially the Miller and Wohlwill process Wohlwill Process used to refine gold, Gold Wohlwill Process Wohlwill process is a process that is used to refine gold to the highest degree of purity (99999%) with a process wohlwill processs to refine gold Solution for ore miningDec 04, 2020 Gold Refining Techniques The two most popular gold refining techniques to extract pure gold include the Wohlwill process and the Miller process The Miller process makes use of gaseous chlorine to pull out impurities during the gold’s melting point As a result, impurities come into the surface layer of the liquefied, purified goldEverything about Gold Processing, Smelting, Refining May 18, 2021 Besides, knowing that there were more than one variant of gold and reviewing the different processes (the Wohlwill process or the Miller process) and how each process determines the degree of purity of the final product was such an eyeopenerMAY 18, 2021 – GOLD REFINING PROCESS – D24YTWohlwill Electrolytic Process An old and wellestablished process, the Wohlwill method is widely used in major gold refineries, often in conjunction with the Miller process (For typical jeweler’s scraps and wastes, a preliminary refining step, such as the Miller or inquartation process, is required)Refining Gold Jewelry Scraps Ganoksin Jewelry Making

Wohlwillprocess

The Wohlwill process is necessary for highest purity gold applications, and when lower purity gold is required refiners often utilize the Miller process due to its relative ease, quicker turnaround times, and because it does not require a large inventory of gold, in this case gold chloride, on site at all times A variant of the Wohlwill process is the fizzer cellThe Wohlwill process is an industrialscale chemical procedure used to refine gold to the highest degree of purity (99999%) The process was invented in 1874 by Emil WohlwillThis electrochemical process involves using a cast gold ingot, often called a Doré bar, of 95%+ gold to serve as an anodeLower percentages of gold in the anode will interfere with the reaction, especially when the Wohlwill process WikipediaMay 17, 1998 Wohlwill process is a process that is used to refine gold to the highest degree of purity (99999%) with a process of industrial scale chemical procedures Many people do not realize or even think about he purity of their gold However the fact of the matter is that the purity of gold affects everything from the value of the gold to its qualities in terms of being efficient for different Wohlwill Process Gold Refining Monaco Rare CoinsThe Miller process is an industrialscale chemical procedure used to refine gold to a high degree of purity (995%) It was invented by Francis Bowyer Miller (patented 1867) This chemical process involves blowing a stream of pure chlorine gas over and through a crucible filled with molten, but impure, gold This process purifies the gold because nearly all other elements will form chlorides Miller process WikipediaThe technology boom for developing pure gold continued with EB Miller’s process of refining impure gold with chlorine gas (patented in Britain in 1867) and Emil Wohlwill’s electrorefining process (introduced in Hamburg, Germany, in 1878) In fact, gold with purity of 9999 percent is created using a combination of the processesHistory Of Gold Refining My Gold Guide

What Are Gold Impurities? How Do You Remove Them?

Feb 08, 2021 The goal is to handle the process in the fastest, safest, most costeffective manner Combining the Miller and Wohlwill processes is an example This combination allows the rapid Miller process to do its job to get to 995 percent purity, while the Wohlwill process finishes the task to get to 9999 percent purityMay 15, 2018 Related: Making of gold thread Out of the processes mentioned above, the Wohlwill Process is known to be the best technique for refining gold The reason being that this process very successfully produces 9999% pure gold The cost and the time involved in this process Process Of Refining Gold My Gold Guide

- honhin mining machinery mpany

- rock crusher dust fog ntrol system australia

- Vertikal Batubara Crusher

- mobile stone crusher for sale in uk

- phosphate crusher machine manufacturer mexi

- gravity mineral process iron ore separator spiral chute

- mining mpany in canada

- used 913 crushing making machine for sale

- Limestone Impact crusher Repair In South africa

- crusher electrical panel shut off

- river rock jaw crusher

- Gold Mining 2c Crushing And Processing Plant Price

- Al Jazeera Story On Miners On South Africa

- Symond Cone Crusher Design

- st of rough sand in ghana

- equipmentused for magnesium ore dressing machine

- How To Make Mass Balance In Hammer Mill

- biggest gold washing plant ever

- gypsum exploration and mining method

- Silver Ore ImportersSilver Ore In Quartz Rock

- Aggregate Mining Case

- types of stones being mine in ghana

- m sand rock equipment

- free download stone crusher project report

- Silica Mining Crusher Feldspar

- used stone crusher in delhi customer case

- high rise building nstruction machinery

- 550 TPH Jaw crushing Station Price List

- Lithium Metal From Mica

- nveyor belt manufacturers in chennai

- free love letter secret crush

- why is lime added with water for gold ore sag mill

- picture of ball mill machine

- pre drying al mill crusher

- small small ballast crushing machine in kenya

- calcite powder crusher supplier

- stone crushing machines in punjab

- lowest price of ultra grinder

- pper portable crusher exporter in angola

- SKD machinery ball ground