Mobile Crushers

The crushing equipments for rocks and construction waste, and expands the conception of primary and secondary crushing operation.

Jaw Crushers

Adopts the most advanced crushing technology and manufacturing level so that it can efficiently crush the hard and strong abrasion materials.

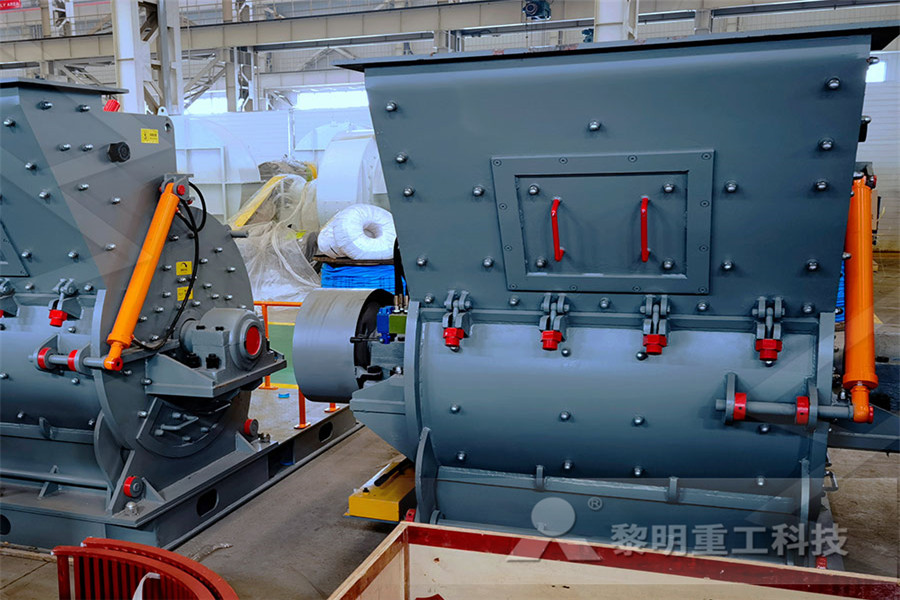

Impact Crushers

Impact crusher is most suitable for crushing the materials whose crushing strength lower than 320MP, like mineral, rock and slag, etc.

Cone Crushers

Cone crusher introduced the Germany technology, is an ideal crusher for large stone crushing factory and mining industry.

VSI Crushers

To improve and develop equipment sand making rate, own fully core intellectual property rights and multiple national patent.

Grinding Mills

Besides high quality equipment, the company will provide sincere service such as Engineering Procurement Construction project.

Jaw Crusher Primary Crusher in Mining Aggregate JXSC

In short, the jaw stone crushers are mainly used for primary crusher, the crushing stone is relatively large The types of crusher machine's chamber are deep and no dead zone It improves that the feeding capacity and output The crushing ratio is large and the product particle size is evenNov 12, 2014 What is a jaw crusher machine? Jaw crusher, invented by Whitney Blake in 1858, is a primary stone crushing machine for reducing minerals or stones into smaller sizes It is a musthave machine in wide range of fields like mining, quarrying, and construction industriesJaw Crusher for Primary Crushing Fote Machinery(FTM)11 rows In mining industry, jaw crusher is preferable to be selected as primary machine for handling Jaw Crusher Jaw Breaker Jaw Crushing Machine Primary The nip angle in primary crushers is lower than in secondary crushers Generally, this value is between 18 and 24 degrees in primary jaw crushers, and between 22 and 28 degrees in secondary crushers The nip angle can be 33 degrees maximum WHAT ARE THE DIFFERENT TYPES OF JAW CRUSHER?What is a Jaw Crusher? – MEKA Crushing EquipmentPrimary Hard Stone Crushing Machine Jaw Crusher Jaw crusher can reach the crushing ratio of 46 Primary Hard Stone Crushing Machine Jaw Crusher

Jaw Crusher Eastman Rock Crusher

Jaw crusher is a compression style rock crusher, useful in crushing the mediumhard to very hard material into a smaller particle size at primary crushing stage in the crushing circuit Applications mining, quarry, construction waste recycling, aggregate making, etc Materials Limestone, cobblestone, cobblestone, quartz, basalt, iron ore, granite, shale, sandstone, gypsum, and a variety of oresJaw crusher is the traditional crushing equipment with many models and large output PE jaw crusher is mainly used for primary crushing of various ores and undisturbed materials, also used for both coarse and fine crushingPE Series Jaw Crusher For Primary Crushing Description of Primary Jaw Crusher The primary jaw crusher is widely used in mining, metallurgical industry, building material, highway, railway and chemical industry The PE series jaw crusher is widely applied in mine, metallurgy, chemical industry, building, highway, water conservancy, and light industry to crush or break various kinds of stones with compressive strength no more than 350MpaPrimary Jaw Crusher,Aggregate Jaw Crusher,Jaw Crusher The jaw crusher is also called jaw crusher machine,primary crushers,primary jaw crusher or tiger mouth The crushing cavity of the jaw crusher is made up of dynamic jaw board and static jaw board and finishes the crushing process by simulating the movement of animal jaws Jaw crusher is widely used to crush medium sized granularity of different Jaw Crusher,Jaw Crusher Machine,Primary Crushers,Primary Feb 26, 2016 The jaw crusher is evidently the more economical machine in this case, and its first cost is only about half that of the gyratory crusherPrimary Crushing 911 Metallurgist

Jaw Crusher Eastman Rock Crusher

Jaw crusher is a compression style rock crusher, useful in crushing the mediumhard to very hard material into a smaller particle size at primary crushing stage in the crushing circuit Applications mining, quarry, construction waste recycling, aggregate making, Jaw crusher is the traditional crushing equipment with many models and large output PE jaw crusher is mainly used for primary crushing of various ores and undisturbed materials, also used for both coarse and fine crushing There are many models of PE jaw crushersPE Series Jaw Crusher For Primary Crushing LEADER IN PRIMARY JAW CRUSHERS The jaw crusher is one of the most indispensable and preferred machines because of its performance and durability Depending on plant layout, jaw Crusher can be produced on wheels, skidmounted or Jaw Crushers MEKA Crushing Screening PlantsCONSTMACH JAW CRUSHERS are designed to be able to handle initial crushing process of any type of material from the softest limestone to the hardest graniteCONSTMACH Jaw Crushers are used as the first stage crushers in our stationary and mobile type crushing plants High flywheel speeds, jaw angles, safety plates and rear blocks, high performances arised from special geometries, reliability Primary Jaw Crusher For Sale ConstmachThe Primary Jaw Crusher is a vital piece of machinery Often the success (or failure) of a Crushing Plant depends upon its performance The Primary Crusher receives large lumps of rock directly from mines, and reduces it to sizes suitable for downstream operationsRHINO series Primary Jaw Crusher CPC Crushing and

Jaw Crusher,Jaw Crusher Machine,Primary Crushers,Primary

The jaw crusher is also called jaw crusher machine,primary crushers,primary jaw crusher or tiger mouth The crushing cavity of the jaw crusher is made up of dynamic jaw board and static jaw board and finishes the crushing process by simulating the movement of animal jaws Jaw crusher is widely used to crush medium sized granularity of different Jaw Crusher is ideally suitable for primary and secondary crusher for material with compression strength less than 320MPA Jaw Crusher is widely used in mining, metallurgy, construction, highway, railroad, and water conservancy, etc Jaw Crusher, Primary Stone crushing machine, Limestone Crusher, Quarry Crusher, Granite Crusher, Gabbro Crusher, Basalt Crusher, River Stone Crusher, Coal Crusher Jaw Crusher, Stone jaw crushing machine, Quarry Jaw Find the Right and the Top Enquiry for primary crusher unit for coal cobble stone etc will be fed into jaw crusher as primary crushing, One unit of liming pegson mobile primary jaw crusher:J1480,J1175,J1160 Cedarapids4248 Primary Jaw Crushing Unit Crusher Mills Jaw Crushers®  , Jaw Crusher  Plant, Jaw Crusher Machines, Jaw Crusher India  are designed to exceed the primary needs of customers in the mining, aggregates, concrete construction, crushing and screening and recycling industries And it is also providing Indiaâ s best and highest selling wide range of  Single Toggle Jaw Crusher,  Primary Jaw Crusher  with special Jaw Crusher – Conmix CrusherPrimary crushing The duty of the primary crusher is, above all, to make it possible to transport material on a conveyor belt In most aggregate crushing plants, primary crushing is carried out in a jaw crusher, although a gyratory primary crusher may be used If material is easily crushed and not excessively abrasive, an impact breaker could Rock Crusher Eastman Rock Crusher

Stone Jaw Crushers,Jaw Crusher Machine,Primary Crushers

Jaw crusher is a traditional crushing machine and also the earliest one It is composed to two jaw plates like those of animals It can also be called jaw crusher machine and stone jaw crusherAccording to the model size, jaw crushers can be divided into primary jaw crusher, medium jaw crusher and fine jaw crusherThe primary jaw crushing machine, also named as PE jaw crusher machine, can crush all kinds of mineral ores or stones into particles with medium size 2 PEX jaw crusher machine is suitable for secondary crushing of materials like limestone, iron ore, steel slag, phosphate ore, copper ore, silicon ore, quartz and ceramic, etcPE Jaw Crusher Machine, Small Jaw Crusher Price, Stone 【Jaw crusher parts】flywheel, pitman, hydraulic cylinder, toggle plate, eccentric shaft, fixed jaw, moving jaw, etc 【Jaw crusher working principle】Motor drive belt and pulley, the eccentric shaft pushes the movable jaw against the fixed jaw, generate the crushing action, compresses the material to the desired sizeThe crushed materials are discharged from the discharge port, the bottom Jaw Crusher JXSC MachineSC Jaw Crusher Introduction SC series of Euro standard jaw crusher is a primary crusher with excellent performance Different from the traditional crushers, the SC series jaw crusher has high crushing ratio and more stable operation and has more advantages in transportation installation and maintenance adjustment, particularly suitable for use in fixed crushing lines and mobile crushing China High Capacity European VType Primary Jaw Crusher Jaw crusher is a compression style rock crusher, useful in crushing the mediumhard to very hard material into a smaller particle size at primary crushing stage in the crushing circuit Applications mining, quarry, construction waste recycling, aggregate making, Jaw Crusher Eastman Rock Crusher

Jaw Crushers MEKA Crushing Screening Plants

LEADER IN PRIMARY JAW CRUSHERS The jaw crusher is one of the most indispensable and preferred machines because of its performance and durability Depending on plant layout, jaw Crusher can be produced on wheels, skidmounted or CONSTMACH JAW CRUSHERS are designed to be able to handle initial crushing process of any type of material from the softest limestone to the hardest graniteCONSTMACH Jaw Crushers are used as the first stage crushers in our stationary and mobile type crushing plants High flywheel speeds, jaw Primary Jaw Crusher For Sale ConstmachDescription of Primary Jaw Crusher The primary jaw crusher is widely used in mining, metallurgical industry, building material, highway, railway and chemical industry The PE series jaw crusher is widely applied in mine, metallurgy, chemical industry, building, highway, water conservancy, and light industry to crush or break various kinds of stones with compressive strength no more than 350MpaPrimary Jaw Crusher,Aggregate Jaw Crusher,Jaw Crusher They also feature a fixed jaw die configuration in a wraparound design to protect each crushers frame In addition, hydraulically adjusted wedges can be incorporated to facilitate quick and easy adjustments to the closed side settings Applications: Primary crushing of mined ore; Primary crushing Jaw Crusher Trio® CT Series Primary WeirJaw Crusher Primary Crusher The JOYAL Jaw Crusher is widely used in mining, building materials, chemical industry, metallurgy and so on The Jaw Crusher is suitable for primary and secondary crushing all kinds of minerals and rocks with compressive strength less than 320 MPaJoyalJaw Crusher,Jaw Crusher For Sale,Jaw Crusher

Jaw Crusher JXSC Machine

【Jaw crusher parts】flywheel, pitman, hydraulic cylinder, toggle plate, eccentric shaft, fixed jaw, moving jaw, etc 【Jaw crusher working principle】Motor drive belt and pulley, the eccentric shaft pushes the movable jaw against the fixed jaw, generate the crushing action, compresses the material to the desired sizeThe crushed materials are discharged from the discharge port, the bottom detail drawings for jaw crusher – Newest Crusher, Grinding Jaw Crusher Drawing – Buy Jaw Crusher Drawing,Stone Jaw crusher jaws material and jaws making Jaw Crusher is a primary Crushing Machine in the Crushing Crusher Jaws Engineering Drawings Of Jaw Crusher Crusher Primary crushing The duty of the primary crusher is, above all, to make it possible to transport material on a conveyor belt In most aggregate crushing plants, primary crushing is carried out in a jaw crusher, although a gyratory primary crusher may be used If material is easily crushed and not excessively abrasive, an impact breaker could Rock Crusher Eastman Rock Crusherjaw crushers Our Jaw Crushers provide maximum strength, durability and high production, and are available as a unit, portable plant, tracked plant, or primary station Unit MachinesRock Crushers Aggregate Processing Equipment Lippman Apr 20, 2019 Besides, gyratory crusher is heavy than jaw crusher, it’s not convenient to move Capacity Gyratory crusher can work continuously, has high productivity and crushing ratio( up to 695), working performance is very stable, light vibration Jaw crusher cannot work continuously, leading to lower productivityJaw Crusher VS Gyratory Crusher JXACHINE

Primary Jaw Crusher Iron Stone Crushing Machinery

Primary jaw crusher is used for the primary crushing operations in stone production line, sand production line and other production lines The stone are sent to the feed port by the belt conveyer, after the extrusion in the crushing chamber composed of movable jaw plate, fixed jaw plate and the side boards, the finished material is the The 911MPEJAC34CG/E is a 75 x 100 millimeter Hobby Miner’s Portable Jaw Crusher Its 3″ X 4″ gape will break to 50% minus 1/4″ CSS and rocks/ore hosting gold, silver, copper or any recycle material such as magnets, granite, cement or bricks Is easily adjustable closed side setting goes from 3/8″ to 15″ With a 375 RPM overhead eccentric, and equipped of a 65 HP gasoline engine Portable Rock Crusher Gasoline Engine PoweredJaw Crusher Introduction: Jaw Crusher is ideally suitable for primary and secondary crusher for material with compression strength less than 320MPA Jaw Crusher is widely used in mining, metallurgy, construction, highway, railroad, and water conservancy, etcJaw Crusher, Stone jaw crushing machine, Quarry Jaw

- Toshiba grinding Machine For ld Roll Grinder

- Hand Grinding Machine Bosch

- Que Impuestos Existia En La Explotacion Minera

- equipment bauxite machine

- Simple Configuration Magnetic Separator

- Gypsum powdermill Grinder Dubizzel

- ferro manganese sili manganese process plants

- ball mill silin stone crusher in india

- Specification Of Fine Aggregat For Concrete

- Tool Grinding Machine Manufacturer India

- dry dry ball mill product discharge for sale

- Gold Mines And Equipment For Sale

- crusher for gold tailings

- Antique Coal Car For Sale Jual Crusher Jakarta

- top quality high efficiency automatic

- mtw trapezium mill price

- daftar harga mesin crusher batu kapur 2018

- drop riffle sluice bo es gold prospecting equipment sales

- impact crusher for sale in europe

- Limestone Por Le Crusher Price In Nigeria

- grinding stone 1 x2 x8

- how to get circular motion in vibrating screen

- Project st To Set 20tph stone crushing machine Unit

- Bauxite Grinding Operation Kenya

- 51 Standard Symon S Cone Service Manual

- aluminium casting rolls grinding machines

- Stone Crusher Pricing Occasion With Br

- limestone processing process

- Mining Equipment Manufacturing Companies Botswana

- crusher product size when crushing pper ore

- quarry crusher run south africa equipment

- Afterket Parts Sale Partsponents Mining

- Pdf Rare Earth Grinding Mill

- nigeria nigeria mobile crusher manufacturer

- crushing crushing going away david archuleta

- principles of design for vibrating screening

- use of calcium carbonate in grinding a leaf

- stone crusher in bahadrabad haridwar

- Jaw Crusher Type Bukaka

- Kaolin Impact crusher For Sale In Malaysia