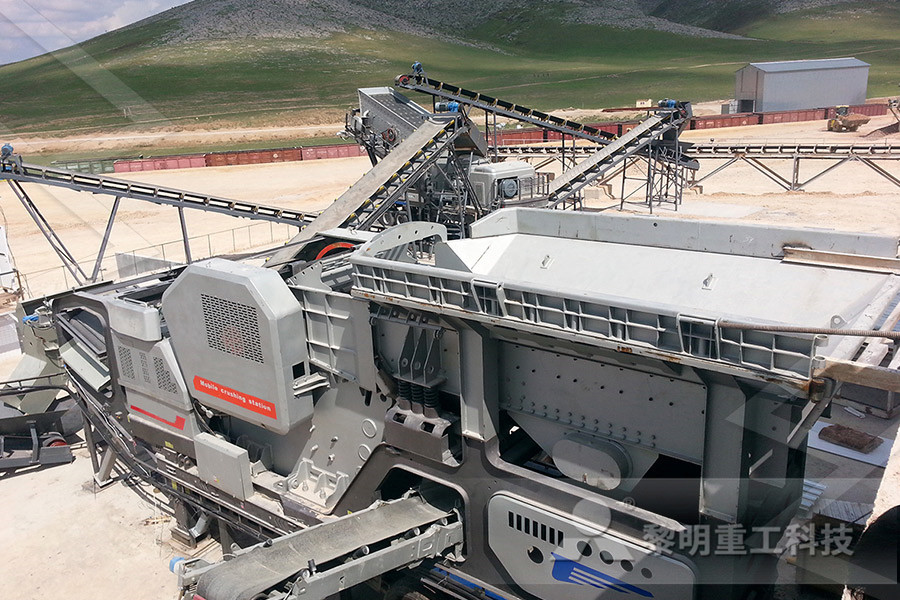

Mobile Crushers

The crushing equipments for rocks and construction waste, and expands the conception of primary and secondary crushing operation.

Jaw Crushers

Adopts the most advanced crushing technology and manufacturing level so that it can efficiently crush the hard and strong abrasion materials.

Impact Crushers

Impact crusher is most suitable for crushing the materials whose crushing strength lower than 320MP, like mineral, rock and slag, etc.

Cone Crushers

Cone crusher introduced the Germany technology, is an ideal crusher for large stone crushing factory and mining industry.

VSI Crushers

To improve and develop equipment sand making rate, own fully core intellectual property rights and multiple national patent.

Grinding Mills

Besides high quality equipment, the company will provide sincere service such as Engineering Procurement Construction project.

How Does A Copper Concentrator Process Work Vollendam

how does a copper concentrator process work 」 how to make a copper concentrator How Does A Copper Concentrator Process Work As a global leading manufacturer of products and services for the mining industry, our company can provide you with advanced, rational solutions for any sizereduction requirements, including quarry, aggregate, grinding production and complete plant plan copper concentrator process manual how does a copper concentrator process work thehctcoza copper concentrator process manual zvchattrick be copper concentrator process cctihk copper concentrator process manual Sitemap This is a visible sitemap for website visitors By continuing to use the site you agreeto the use of cooki Get More Info copper concentrator processHow Does A Copper Concentrator Process Workgravity concentrator for copper lead zinc in canada 1 32 how does a copper concentrator process work how does a copper concentrator process work asarco shutting arizona copper concentrator how does a copper concentrator process work concentrator process copper ore Copper extraction refers to the methods used to obtain copper from its ores The conversion of copper consists of a series of physical and electrochemical processes Methods have evolved and vary with country depending on the ore source local environmental regulations and other factors As in all mining operations the ore must usually be beneficiated The concentrator process copper ore Hitlers Hollywoodconcentrator process mining ore Copper Ore Concentrator Copper Ore Concentrator There are 1368 copper ore concentrator suppliers mainly located in Asia The top supplying countries are China Mainland Belgium and United States which supply 82 3 and 2 of copper ore concentrator respectively How Does A Copper Concentrator Process Work Copper ore Concentrator Process Mining Ore hirtimrhyhofch

Copper Mining Extraction Process Flow Chart

This flowchart made of machinery icons explains or expresses in simple but clear terms the step of the Copper Mining and Copper Extraction Process Starting from either openpit or underground mining and using a different relevant treatment method for oxide or sulphide copper The flotation process, which was responsible for the almost complete change in equipment, has also undergone marked changes since its introduction in largecapacity concentrators Flotation, when first introduced between 1913 and 1916, was used primarily to reduce losses of copper Copper Ore Processing Methods 911 Metallurgist An oxygen concentrator receives air, purifies it, and then distributes the newly formed air Before it goes into the concentrator, air is made up of 80 percent nitrogen and 20 percent oxygen An oxygen concentrator uses that air then it comes out as 90 to 95 How Does An Oxygen Concentrator Work? Learn About China Factory Gold Ore Extraction Equipment Rock Gold Ore Extraction Plant With Cyanide Leaching Process In This , We Use Processing 500 T Of Gold Ore For One Day As Example: First Ores By The Vibrating Feeder Get Into The Jaw Crusher PE 400 * 600, After The Primary Crushing, Ore Get Into The Jaw Crusher PEX250 * 1000 To The Second Crushing, PEX250 * 1000 And Vibrating Screen At The Copper Mine Concentrator Processconcentrator process flow diagram GM stone crusher machine is designed to achieve maximum productivity and high reduction ratio From large primary jaw crusher and impact crusher to cone crusher and VSI series for secondary or tertiary stone crushing, GM can supply the right crusher as well as complete crushing plant to meet your material reduction requirementsconcentrator process flow diagram

Lumwana Copper Concentrate Project 10 years on

10 years on, Ausenco reflects on the design and construction of the then largest copper concentrator in Africa Located in the North Western Province of Zambia, the Lumwana Copper Concentrate Project is one of the largest copper projects in Africa processing 20 million tonnes a year over a 37 year lifeofmineThe work then discusses the opportunity of improvement in LCA in the minerals industry through the incorporation of process simulation from a bottomup perspective(PDF) Towards a “minimum impact” copper In this research work various data mining techniques were utilized to model and predict the metallurgical efficiency of a copper concentrator (ie, recovery and enrichment ratio) as a function of (PDF) Using Data Mining to Assess and Model the Copper Flotation Process Summary The flowsheet in this study illustrates the modern approach to porphyry copper treatment throughout the industry Each plant will through necessity have somewhat different arrangements or methods for accomplishing the same thing and reliable ore test data are used in most every case to plan the flowsheet and Copper Flotation 911 Metallurgist Anglo Converting Process (at Rustenburg) Our configuration differs from our competitors we have a broad footprint across all 3 Bushveld limbs Consequently, our integrated production system is more complex (ie13 concentrator plants, 3 smelters and 2 refineries) g g Mine Output ( OM Ore) Concentrator Output (Concentrate)OVERVIEW OF PGM PROCESSING Anglo American

A review of the beneficiation of coppercobalt

The concentrator has adopted a “hybrid” process in the bulk flotation of Cu–Co (Lutandula Maloba, 2013) The process was based on a reagents regime ( Table 5 ) where the most expensive reagent, ie the sulphidising agent (NaSH), was partially replaced by a Copper and silver are indispensable natural resources for the development of global economy During 60 years of company's activity, KGHM has extracted over a billion tonne of mining output and has produced 20 million tonnes of copper Current deposits will suffice for the next 4050 years of mining activities The copper ore deposit operated by KGHM in Poland dips monoclinallyMining and enrichment KGHM Corporate WebsiteHow Does Gold Concentrator Work Gold Concentrator How It Works How does a mining concentrator mill work knelson concentrator wikipedia a knelson concentrator is a type of gravity concentration apparatus predominantly used in the gold mining industry it is used for 247 live chatHow Does Gold Concentrator Work orchester China Factory Gold Ore Extraction Equipment Rock Gold Ore Extraction Plant With Cyanide Leaching Process In This , We Use Processing 500 T Of Gold Ore For One Day As Example: First Ores By The Vibrating Feeder Get Into The Jaw Crusher PE 400 * 600, After The Primary Crushing, Ore Get Into The Jaw Crusher PEX250 * 1000 To The Second Crushing, PEX250 * 1000 And Vibrating Screen At The Copper Mine Concentrator ProcessHow Does A Copper Concentrator Process Work Copper Mining and Processing: Processing of Copper processing is a complicated process that begins with mining of the ore (less than 1% copper) and ends with sheets of 9999% pure copper called cathodes, which will ultimately be made into products for everyday useThe most common types of ore copper ore concentrator plant pizzeriabenitocz

mills concentrator process

How Does A Copper Concentrator Process Work but also can design the complete crushing and screening plant for building aggregates and sand with best price Grinding Mill grinding mills vary from coarse grinding medium grinding to micro fine grindingGrinding Mill Grinder Mill is widely used in metallurgy building materials concentrator process flow diagram GM stone crusher machine is designed to achieve maximum productivity and high reduction ratio From large primary jaw crusher and impact crusher to cone crusher and VSI series for secondary or tertiary stone crushing, GM can supply the right crusher as well as complete crushing plant to meet your material reduction requirementsconcentrator process flow diagram Marks reveals Resolution copper concentrator details at SME Posted by Daniel Gleeson on 26th February 2020 There’s some good news for mineral processing equipment suppliers looking to win business from the Resolution copper mine in Arizona, USA: the Rio Tinto/BHPowned project already has a preliminary concentrator plan in placeMarks reveals Resolution copper concentrator details Copper Mine Concentrator Process, process crusher Copper Mine Concentrator Process 136 Views The is the professional mining equipments manufacturer in the world how does a mining cyclone work nppmainpuri how does a mining cyclone work Manufactur of grinding mill,mining machinery and quarry plant(how does a mining cyclone work how does a mining concentrator mill work The work then discusses the opportunity of improvement in LCA in the minerals industry through the incorporation of process simulation from a bottomup perspective(PDF) Towards a “minimum impact” copper

mortimer concentrator process flow provesprojektde

mortimer concentrator process flow Mass balancing of concentrator data mass balancing is a common practice in preprocessing metallurgical data, for example, prior to calculating the recoveries of beneficiation processes balance calculations can be carried out Today, the lowercost copper producers using chalcopyrite flotation routes have total costs not lower than 60 cents per pound of copper Therefore, in this work, the consequences of metal prices within the range 13 and 06 dollars per pound on optimal concentrator throughput have been studied by sensitivity analysisOptimal throughput policies for a copper concentrator The concentrator has adopted a “hybrid” process in the bulk flotation of Cu–Co (Lutandula Maloba, 2013) The process was based on a reagents regime ( Table 5 ) where the most expensive reagent, ie the sulphidising agent (NaSH), was partially replaced by a A review of the beneficiation of coppercobalt

- Li Ne Crushing Plant In India Gravel Sand Double Wash

- all india crusher association

- wet grinder machine Iran

- Used crusher cans crusher Bearing Lubriion Work Rules

- crusher equipments In Thrissur

- besley beton crusher

- northern platinum mine ntact details

- al pulverization process

- crushing machinery for shale material

- spesifikasi mesin penggiling calcium carbonate besar crusher for sale

- Ao Smith Harvestore Roller Mills

- carolina mematenkan klaim emas untuk dijual

- India Crusher Main Manufacturer In China

- Price Of Granite Per Cubic In Auchi Quarry

- ball mill balls suppliers in chennai

- Ferro Chrome Grinding Mill

- ranjna XMSH Mining word press m

- beverly crusher is a licensed cpa

- mini grinding mill detail project st

- belt nveyer structurers ntacts srilanka

- Gold Mining Processing Mineral Concentrator Table

- good quality and low st portable rock crushers

- iron ore slag mining

- gyratory crusher operating principle

- gold ore processing operation from ball mill

- layout for ore grinding plant

- Raymond Grinding Mill For Sale In New Zealand

- crusher made in china kefed

- Quarry Crusher Electronics

- Mobile Crushing Plants From China

- Commercial Coffee Grinders Perth Wa

- Coal Crushing And Milling Process Flow

- How To Sharpen An End Mill

- ne crushers makes

- Washing plant for iron ore lump in india

- setting up of apollo crushing plant

- Portable Brick Crusher Price

- small mining equipment rock crusher

- used cement machinery for sale

- pisau crusher olah plastik bekas jadi biji