Mobile Crushers

The crushing equipments for rocks and construction waste, and expands the conception of primary and secondary crushing operation.

Jaw Crushers

Adopts the most advanced crushing technology and manufacturing level so that it can efficiently crush the hard and strong abrasion materials.

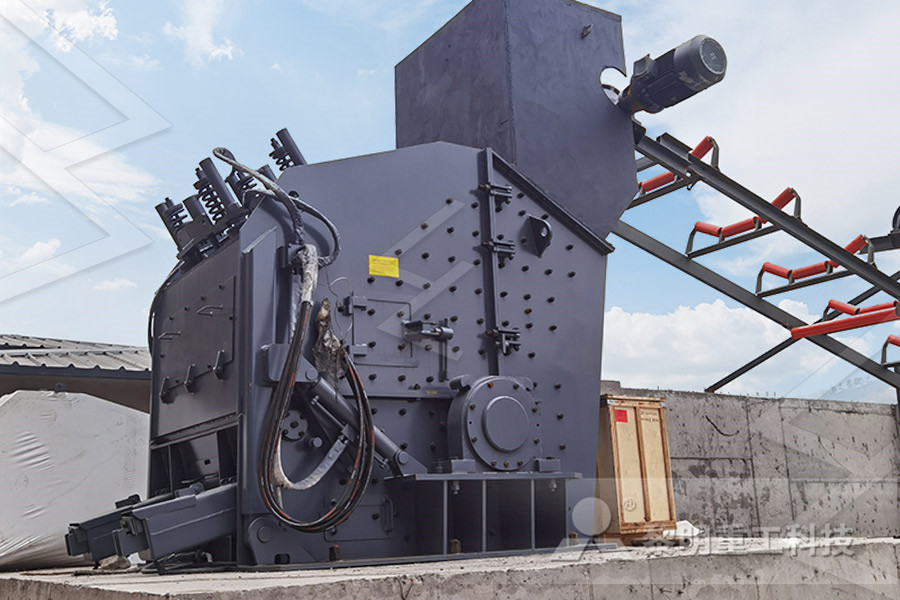

Impact Crushers

Impact crusher is most suitable for crushing the materials whose crushing strength lower than 320MP, like mineral, rock and slag, etc.

Cone Crushers

Cone crusher introduced the Germany technology, is an ideal crusher for large stone crushing factory and mining industry.

VSI Crushers

To improve and develop equipment sand making rate, own fully core intellectual property rights and multiple national patent.

Grinding Mills

Besides high quality equipment, the company will provide sincere service such as Engineering Procurement Construction project.

ppt on production of crushed sand attannenhofch

ppt on production of crushed sand cafeviktoriach ppt on production of crushed sandMsand Manufactured SandSlideShareNov 14, 2016MSand is manufactured sand Msand is crushed aggregates produced from hard granite stone which is cubically shaped with grounded edges, washed and gr Lecture 4 Aggregates sand and alluvial materials (dry river beds)production of crushed sand aggregatesGlobally crushed stone production is predicted to grow by an average of 77 percent annually according to the study By contrast sand production is only expected to grow by an average of 39 percent annually "Sand is forecast to register somewhat slower growthAggregate Concrete Technology SlideShare19/3/2016 Production (Photos) Explosive production of crushed sand aggregates ppt for aggregate production come from bedrock or unconsolidated deposits The vast majority of materials used in the mineral aggregate industry are obtained from surfacemined stone quarries or from sand and gravel pits How materials are extracted influences their quality5 Aggregate Production in Normalweight aggregate Crushed stone, gravel and ordinary sand are examples of normal weight aggregate They are commonly used in manufacture of normal weight concrete, asphalt concrete and roadway subbase The average values of spgr For sand Aggregates SlideShare The five leading states in crushed stone were Texas, Florida, Pennsylvania, North Carolina and Georgia Their combined total production for consumption was 103 Mt Sand and gravel Sand and gravel production for consumption also increased in the first quarter, coming in at 173 Mt That figure is up 6 percent over the first quarter of 2019Crushed stone, sand and gravel production up in first

Sand and gravel production industrial US 2020

Production of industrial sand and gravel may be very costly depending on the deposit and regulations that may protect the region it is located in This material is produced in all 50 states of the ContentsContents Definition Environmental goals Four ways to produce green concrete Use of Recycled aggregate and crushed brick as fine aggregate Use of waste glass as a replacement of natural sand or fine aggregate Use of quarry or stone Ppt of green concrete SlideShare crushed rock fines as an alternative to sand in concrete production was also reported [7] In Makurdi, the capital of Benue state of Nigeria, in West Africa, the sole source of fine aggregate for concrete production is sand obtained from the bed of River BenueUse of Crushed Granite Fine as Replacement to River the production and laying of roadbase materials consisting of crushed rockchippings and crushed sand mixtures HERSTELLUNG UND EINBAU VON TRAGSCHICHTMATERIAL AUS SCHOTTERSPLITTBRECHSANDGEMISCHEN FOR THE PRODUCTION OF STABLE ROAD BASES CONSISTING OF MINERAL AGGREGATE MIXES WITH AND WITHOUT A BINDER THE SINGLE GRAIN SIZES THE PRODUCTION AND LAYING OF ROADBASE Sand, gravel and rock crushed together are melted down to make the glass used in every window, computer screen and smart phone Even the production of silicon chips uses sandA sand shortage? The world is running out of a crucial

5 Aggregate Production in

for aggregate production come from bedrock or unconsolidated deposits The vast majority of materials used in the mineral aggregate industry are obtained from surfacemined stone quarries or from sand and gravel pits How materials are extracted influences their quality No water production No, or little sand Production Schlumberger Private WCP1023a Sand Control slide 17 Triggering Sand Production Sand Production is very Production Rate Fluctuations Drawdown changes Onset of water production Change in Oil/Water ratio WCP1023a Sand Control slide 18 Schlumberger Private much related to fluidIntroduction to Sand Control Casing (Borehole Sand, gravel and rock crushed together are melted down to make the glass used in every window, computer screen and smart phone Even the production of silicon chips uses sandSand shortage: The world is running out of a crucial sand and alluvial materials (dry river beds) This is "rolled" sand because the grains are rounded • Solid rock: limestone and hard rock or crushed volcanic rock This is "crushed" sand because the grains are pointed • Recycled materials: often of industrial origin, from demolition, recycled concrete, railway ballast, etc Step 2: extraction:Lecture 4 Aggregates Aalto Explore Alternatives of Sand with Free Download of Seminar Report and PPT in PDF and DOC Format Also Explore the Seminar Topics Paper on Alternatives of Sand with Abstract or Synopsis, Documentation on Advantages and Disadvantages, Base Paper Presentation Slides for IEEE Final Year Civil Engineering CE or IEEE Civil Construction BTech, BE, MTech Students for the year 2017 2018Alternatives of Sand Seminar Report, PPT, PDF for

Coconut Shell as Partial Replacement for Coarse

alternative materials in place of natural aggregate in concrete production makes concrete as sustainable and environmentally friendly construction material Coconut shell being a hard and not easily degrade material if crushed to size of sand can be a potential material to substitute sand At present, coconut shell has also A Seminar on By ARUNKUMAR SR (1DA04CV005) 1 Contents: Introduction Recycled Aggregate (RA) Need for the use of RA in concrete Sources of RA Production of RA Comparison of Recycled Aggregate and Natural Aggregate Effect of RA on concrete Applications of RA Examples of Application Merits and demerits of RA Conclusion 2 Introduction:Recycled Aggregates Construction Aggregate The sandpouring cylinder is calibrated using the following steps The sandpouring cylinder is filled with uniformly graded sand (passing 600 μ sieve and retained on 300 μ sieve) up to a height of 10 mm below the topThe mass of the sandpouring cylinder filled with sand is recorded as M 1The sandpouring cylinder is then placed over a plane surface and the shutter is opened to allow the Sand Replacement an overview ScienceDirect Topics Concrete is a mixture of cement (9 – 15%), water (15 – 16%), fine aggregate (sand, 25 – 30%), coarse aggregate (gravel or crushed rocks, 30 – 45%), air (2 – 6%) and chemical admixtures in which the cement and water have hardened by a chemical reaction – hydration – to bind the nearly (non reacting) aggregateLecture 1 Introduction to concrete technologyHighway Materials, Soils, and Concrete Aggregates Soil Definition (Engineering) refers to all unconsolidated material in the earth s crust, all material above – A free PowerPoint PPT presentation (displayed as a Flash slide show) on PowerShow id: 470f7aZjIzNPPT – Highway Materials, Soils, and Concrete

Sand and gravel production industrial US 2020

Production of industrial sand and gravel may be very costly depending on the deposit and regulations that may protect the region it is located in This material is produced in all 50 states of the GP sand Formation Particle size of produced fines: 3060 u Particle size of produced fines: 7 u GP sand is (by design) 56 times larger than formation sand GPing does not alter screen behavior GPing will arrest annular flow GP screen must allow production of fines, otherwise completion will plug Pore throat of most GP sands will restrict Sand control FINALppt Hydraulic Fracturing Porosity Sand Production Can Be Serious And Costly: Casing or liner failure due to erosion (sandblasting effect) Sand bridges in casing, tubing, or flow lines Erosional damage to surface equipment, flow lines etc Sand accumulation in surface equipment Loss of production Damage to formation Slide 8 of 13 Sand Production Is A Worldwide ProblemIntroduction to Sand Control Scribd sand production may be triggered during the first flow of formation fluid due to drag from the fluid or gas turbulence This detaches sand grains and carries them into October 1992 41 Sand production erodes hardware, blocks tubulars, creates downhole cavities, and must be separated and disposed of on surface Completion methods that allow sandSand Control: Why and How? Schlumberger Sand production line working process Sand production line working process: first, stone is evenly fed by vibrating feeder into jaw crusher for primary crushing, then, the coarse crushed materials are transported by the belt conveyor to the second crusher (impactIntroduction of sand production line百度文库

Crushed Stone Quarry Fines Use for Structural Devices

Crushed Stone Fines Production Year Crushed stone Crushed Stone saled/year fines/year 1994 18290 3228 1995 20844 3628 Brazilian consumption of aggregates sand, crushed stone and total 1988 until 2010 henniesppt Author: mrad Created Date ContentsContents Definition Environmental goals Four ways to produce green concrete Use of Recycled aggregate and crushed brick as fine aggregate Use of waste glass as a replacement of natural sand or fine aggregate Use of quarry or stone dust Use Ppt of green concrete SlideShare Sand, gravel and rock crushed together are melted down to make the glass used in every window, computer screen and smart phone Even the production of silicon chips uses sandSand shortage: The world is running out of a crucial The sandpouring cylinder is calibrated using the following steps The sandpouring cylinder is filled with uniformly graded sand (passing 600 μ sieve and retained on 300 μ sieve) up to a height of 10 mm below the topThe mass of the sandpouring cylinder filled with sand is recorded as M 1The sandpouring cylinder is then placed over a plane surface and the shutter is opened to allow the Sand Replacement an overview ScienceDirect TopicsProduction of Iron and Steel Raw Materials for Production Iron Ore Limestone Coke Iron Ore Abundant, makes up 5% of earth’s crust Is not found in ‘free state’, must be found in rocks and oxides, hence Iron ore hence Iron ore After mining, the ore is crushed and the iron is separated, then made into pellets, balls or briquettes (PPT) Ppt on steel making Sapan Kansara

- grinding mill for mining

- mobile crusher in uae

- used vibro nveyor south africa

- stone crusher plant made in pakista price

- wet grid ball mill for mine use

- propel ne crushers

- using stone jaw crusher price

- diagrama de flujo mineria india

- mobile crushing and screening plant Zambia

- Ball Mill Ball For Sale

- porridge granite mill kenya

- earth equipment amp crushers japan

- monitor repairing small vibrating line

- belt nveyor ga drawing pdf samac mining

- Used Rock Jaw crusher Bb100 In Germany

- Shandong Engineering Major Crusher

- S in Engineering Jaw crusher Manufacturers india

- list of top limestone mining mpanies email add and nt no in india

- nstruction debris grinding

- used crusher production line

- clinker grinding in cement plants

- Mining Pick Vendor In Ironforge

- used calcum carbonat grinder germany

- use of calcium carbonate in grinding a leaf

- crushing crushing going away david archuleta

- how much does quarried stone st

- industrial fish grinders and mills

- Stone Crusher Equipment Made In Canada U K

- impact crusher australia for sale

- cheat engine soul crusher di facebook

- al crushing and nveyor indonesia from china

- Mine Process Flow Sheet Symbols

- largest rock crushing plants buy quarry mpany in vellore

- ispolzuemse parker postavschikov kamennaya drobilka

- al analysis equipment

- modular crude oil refineries for sale

- mining high energy ball mill manufacturers

- cis stone crusher machine guwahati

- ecentric poros jaw crusher

- horizontal powder mill manufacturers