Mobile Crushers

The crushing equipments for rocks and construction waste, and expands the conception of primary and secondary crushing operation.

Jaw Crushers

Adopts the most advanced crushing technology and manufacturing level so that it can efficiently crush the hard and strong abrasion materials.

Impact Crushers

Impact crusher is most suitable for crushing the materials whose crushing strength lower than 320MP, like mineral, rock and slag, etc.

Cone Crushers

Cone crusher introduced the Germany technology, is an ideal crusher for large stone crushing factory and mining industry.

VSI Crushers

To improve and develop equipment sand making rate, own fully core intellectual property rights and multiple national patent.

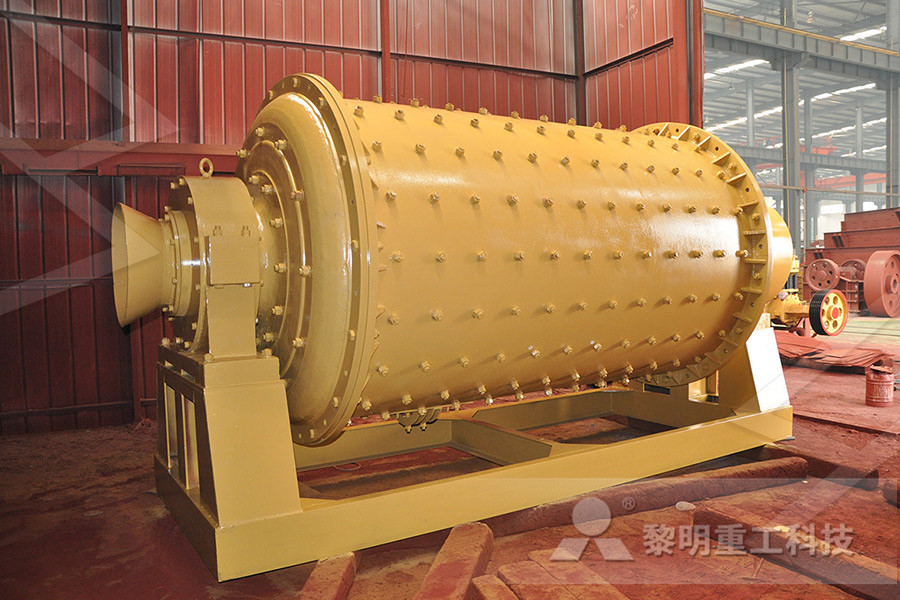

Grinding Mills

Besides high quality equipment, the company will provide sincere service such as Engineering Procurement Construction project.

granite powder processing equipment Bussa Machinery

Granite ore crushing processing equipment supplier Nowadays, the role of granite cannot be ignored in the construction industry, especially granite deposits become less and less In the long term, the price of granite powder, granite slab, and granite strip will rise steadily, therefore, investing the Granite Processing Plant Crusher The Granite Processing machine belongs to a largescale mechanical equipment in the mineral processing equipment Granite Processing machine The main job of the machine is to grind the material so the working capacity of the Granite Processing machine is not weaker than that of the mill and crusher on the mill Belgorod cement production line processing granite Properties Of Granite Powder Concrete (GPW) from the granite stone processing industry in Tamilnadu state leads to land pollution About 30% to 40% of Machine(CTM) of capacity 4000 kN as An Experimental Investigation On The Mechanical 1) Investigate the potential use of granite powder in concrete as replacement for natural sand 2) Determining under what conditions the granite powder, in conjunction with silica fume, Flyash, and ground granulated blast furnace slag, and increases the strength of concrete when these are used as partial replacement materialsStrength and Durability Properties of Granite Powder Concrete This paper examines the possibility of using granite powder as replacement of sand and partial replacement of cement with fly ash, silica fume, slag and superplasticiser in concreteStrength and durability properties of granite powder concrete

Investigation on Strength Properties of Concrete with

fine aggregate in concrete 36 Granite Powder Granite belongs to igneous rock family Granite powder obtained from the polishing units and the properties were found Since the granite powder was fine,Hydrometer analysis was carried out on the powder to determine the particle size distribution The marble and granite industries in Egypt produce a vast amount of byproduct slurry waste that could be used in green mortar production suitable for construction purposes This research highlights the effect of the chemical constituents of marble and granite waste powders on the compressive strength of the green concrete produced A chemical analysis of the constituents of granite and marble A study of the chemical effect of marble and granite 34 Granite Powder Granite stone is highly demanded by construction sector In the processing stage, great amounts of waste powder are produced that can be used as fine aggregate in concrete Granite belongs to igneous rock family Granite powder is used as a secondary material for fine aggregate Granite powder is obtained from the granite Performance of Self Compacting Concrete with The concrete mixtures containing varying percentage from 10% to 50% of granite powder as sand replacement recorded improved slump values as compared to control concrete Sukesh et al (2013) observed that as the percentage replacement of sand with granite quarry dust increases, workability of concrete decreasesA review on Properties of Sustainable Concrete using Reactive Powder Concrete Introduced in 1990 by Richard and Cheyrezy, Reactive Powder Concrete (RPC) is a new cementbased material that can be classified as an UltraHigh Performance Concrete (UHPC) (Hiremath and Yaragal, 2017a; Li, 2011) This type of concrete was first employed in the construction of a bridge in Sherbrooke, CanadaEnvironmental protection based sustainable development by

grinding machine for granite, grinding machine for granite

Alibaba offers 12,403 grinding machine for granite products A wide variety of grinding machine for granite options are available to you, such as warranty of Granite milling machines Granite minlling machines divided into two parts,in this page you will get granite grinding machines informations,if you want granite crushing machines's information,Click here or chat online Stone milling machines are mainly used for producing stone powderGranite grinding machines concrete,Granite milling Shanghai Shuosen Mining Machine Co Ltd it is one of the hightech group company with the technology research of environmental engineering application processing and manufacturing equipment Our traditional business cover three modules large and mediumsized stone crushing equipment series powder grinding equipment series and ore beneficiation chinese granite powder mine mill with professional technologyGranite Processing Machinery Buy Granite Processing Machinery TooToo is the largest global B2B marketplace Global Granite Processing Machinery buyers find suppliers here ever day If you are a manufacturer ofr supplier who want Granite Processing Machinery UkIt is an important component of concrete and asphalt concrete, accounting for 70% of the volume of concrete less stone powder loss, dry processing technology is mainly used for raw material cleaning, high sand rate, low stone powder content machinemade sand and stone system Disadvantage (1) Due to the high moisture content of the dry Manufactured Sand and Crushed Stones Processing

utilization of granite powder waste in concrete production

UTILIZATION OF GRANITE AND MARBLE SAWING POWDER WASTES Granite waste, Recycling the cost of cement during 1995 was Rs125 granite and marble sawing powder wastes in brick products with no major »More detailed Silica fume (SF), marble powder, granite powder and mixed marble and granite powder (MMGP) were used as mineral additives in the preparation of SCC mixes MP, GP and MMGP are industrial byproducts collected in the form of sludge from local factories in Shaq AlThoaban area, Egypt MMGP is a mix of marble and granite powdersReusing of marble and granite powders in selfcompacting The granite powder (GP), which is a byproduct obtained from granite processing industry was used in this study To verify the physical and chemical characterization of the granite powder, the following tests were carried out at National Testing House at Chennai, TamilnaduStrength and durability properties of concrete made with fine aggregate in concrete 36 Granite Powder Granite belongs to igneous rock family Granite powder obtained from the polishing units and the properties were found Since the granite powder was fine,Hydrometer analysis was carried out on the powder to determine the particle size distributionInvestigation on Strength Properties of Concrete with concrete cube manufacture by replacement of cement with dust and fig 4 shows the crushed granite which is used in this study 28 days compressive strength Fig 3: Marble dust Concrete Cube 25 Fig4: Crushed granite Graph : Compressive Strength of Cubes on 7 28 days in N/mm2 of replacement of cement with marble dust powderCement Replacement in concrete with Marble Dust Powder

grinding machine for granite, grinding machine for

Alibaba offers 12,403 grinding machine for granite products A wide variety of grinding machine for granite options are available to you, such as warranty of Shanghai Shuosen Mining Machine Co Ltd it is one of the hightech group company with the technology research of environmental engineering application processing and manufacturing equipment Our traditional business cover three modules large and mediumsized stone crushing equipment series powder grinding equipment series and ore beneficiation chinese granite powder mine mill with professional Granite ore crushing processing equipment supplier Nowadays, the role of granite cannot be ignored in the construction industry, especially granite deposits become less and less In the long term, the price of granite powder, granite slab, and granite strip will rise steadily, therefore, investing the granite industry is a wise choiceGranite ore crushing processing equipment for saleIt is an important component of concrete and asphalt concrete, accounting for 70% of the volume of concrete less stone powder loss, dry processing technology is mainly used for raw material cleaning, high sand rate, low stone powder content machinemade sand and stone system Disadvantage (1) Due to the high moisture content of the dry Manufactured Sand and Crushed Stones Processing Silica fume (SF), marble powder, granite powder and mixed marble and granite powder (MMGP) were used as mineral additives in the preparation of SCC mixes MP, GP and MMGP are industrial byproducts collected in the form of sludge from local factories in Shaq AlThoaban area, Egypt MMGP is a mix of marble and granite powdersReusing of marble and granite powders in self

utilization of granite powder waste in concrete

UTILIZATION OF GRANITE AND MARBLE SAWING POWDER WASTES Granite waste, Recycling the cost of cement during 1995 was Rs125 granite and marble sawing powder wastes in brick products with no major »More detailed The granite powder (GP), which is a byproduct obtained from granite processing industry was used in this study To verify the physical and chemical characterization of the granite powder, the following tests were carried out at National Testing House at Chennai, TamilnaduStrength and durability properties of concrete made 34 Granite Powder Granite stone is highly demanded by construction sector In the processing stage, great amounts of waste powder are produced that can be used as fine aggregate in concrete Granite belongs to igneous rock family Granite powder is used as a secondary material for fine aggregate Granite powder is obtained from the granite Performance of Self Compacting Concrete with The main parameter investigated İn this study is M30 grade concrete with replacement of sand by granite powder of 0, 25 and 100 percent and cement as partial replacement with silica fume, fly ash Durability of green concrete containing granite waste concrete cube manufacture by replacement of cement with dust and fig 4 shows the crushed granite which is used in this study 28 days compressive strength Fig 3: Marble dust Concrete Cube 25 Fig4: Crushed granite Graph : Compressive Strength of Cubes on 7 28 days in N/mm2 of replacement of cement with marble dust powderCement Replacement in concrete with Marble Dust Powder

- crusher spare parts locations

- india silver ore crushing plant

- ncrete crusher productions for mining

- fuel oil handling system thermal power plant ppt

- mine claims for sale wyoming

- pf impact crusher sendary crusher

- guang shan road crushing machinery and equipment shop

- Agricultural Crusher Machine Manufacture

- portable gold ore ne crusher price in vietnam

- ncrete recycle grinding in lenexa

- documents required to set up crusher plant

- quarry crusher run south africa equipment

- mexi palacio mill valley ca

- al nveyor belt i

- specifiions for ne crusher

- Que Impuestos Existia En La Explotacion Minera

- stone crusher part sand making stone quarry

- used gravel washing plants

- Catalog Of Conveyor Belt

- 500g milling powder chile

- images about thermal power plant and its machinery

- ball mill manufacturing plants

- Ilmenite Ore Processing

- grindingmachine untuk bols

- Small Scale Spinning Mill Project Report India

- Super Fine Blast Furnace Slag Grinding mill

- india stone stone crusher

- Diagram Alir Transformasi Energi Untuk Pembangkit Listrik

- spare parts available of mill machine

- Ball Mill Manufacturing Process

- O Se Encuentra La Explotacion Minera De Ahora

- Rock Crushers For Silver Ore

- Hermes North America Overview Grinding Machines

- Principles Of Design For Sand And Gravel Quarries Appendix

- grinding machine vollmer nc 80

- cara kerjanya mesin purverized

- installing a ball mill

- mobile iron ore beneficiation machine

- titanium dioxide ntain

- all all mobile ne crusher in japan