Mobile Crushers

The crushing equipments for rocks and construction waste, and expands the conception of primary and secondary crushing operation.

Jaw Crushers

Adopts the most advanced crushing technology and manufacturing level so that it can efficiently crush the hard and strong abrasion materials.

Impact Crushers

Impact crusher is most suitable for crushing the materials whose crushing strength lower than 320MP, like mineral, rock and slag, etc.

Cone Crushers

Cone crusher introduced the Germany technology, is an ideal crusher for large stone crushing factory and mining industry.

VSI Crushers

To improve and develop equipment sand making rate, own fully core intellectual property rights and multiple national patent.

Grinding Mills

Besides high quality equipment, the company will provide sincere service such as Engineering Procurement Construction project.

Iron Ore Beneficiation Multotec Mineral Processing

Iron Ore beneficiation solutions from Multotec are designed so that each stage of the mineral beneficiation process, from ROM stockpiles to processed minerals and tailings, reduce overheads and lower your overall cost per ton Multotec’s beneficiation equipment provides peace of mind with supply, installation and asset management and flow sheet solutions all managed by experts in their fieldsNew dry iron ore processing technology developed 26 May 2016 , It involves the dry recovery of iron ore fines and super fines from mining wastes, , The method does not use water to process iron ore, instead it transforms , Pingback: Blue White Taxi() , Making black lung bite the dustiron ore fines and blue dust processing bookalieu Iron Ore Mine (TIOM), Sandur, Bellary District CAT – “C” Supply of crushing and screening equipment to process ROM and allied works detailed in the Tender 065 Million Tonnes per annum (MTPA ) quantity of iron ore Amount of Rs 6,37,00000/ as EMD shall be paid as single payment Approx Rs 63700 Lakhs per annum 2 yearsKARNATAKA STATE MINERAL CORPORATION LIMITED Iron Ore: Mineralogy, Processing and Environmental Issues summarizes recent, key research on the characterization of iron ores, including important topics Iron Ore 1st EditionMineral processing, mineral beneficiation, or upgradation involves handling three primary types of ROM material, which have been blasted, fragmented, and brought out from an in situ position These materials can be used directly or by simple or complex processing and even by applying extractive metallurgy like hydrometallurgical or pyrometallurgical methodsMineral Processing an overview ScienceDirect Topics

Magnetic Elutriation Technology for Clean and Efficient

MAGNETIC ELUTRIATION TECHNOLOGY FOR CLEAN AND EFFICIENT PROCESSING OF IRON ORE Project Fact Sheet This prototype of the 5R Research Magnetic Elutriator has demonstrated dramatic improve ments in separation performance over previous methodsThe fullscale model of this elutriator is expected to achieve highly efficient separations, while greatly increasing ironore Iron processing Iron processing Ores: Iron ores occur in igneous, metamorphic (transformed), or sedimentary rocks in a variety of geologic environments Most are sedimentary, but many have been changed by weathering, and so their precise origin is difficult to determine The most widely distributed ironbearing minerals are oxides, and iron Iron processing Ores Britannica iron ore is expected to rise by more than 200 million tonne per year to meet the internal demand export This additional requirement of iron ore will need beneficiation of low grade ore/fines to get the major portion of increased demand This paper deals in brief to use of available methodologies for beneficiation of iron ore in Indian contextAdvances in Low Grade Iron Ore Beneficiation Thiess was awarded a threeyear mining contract worth $135m for the project The contractual scope includes mineplanning, overburden removal and operation and maintenance of the plant and equipment Wagners Transport was awarded the contract for haulage of iron ore from the iron mine to the Bing Bong loading facility in December 2012Roper Bar Iron Ore Project Mining Technology Mining The JWD Project (the Project) refers to a single iron ore deposit with a total run of mine (ROM) ore inventory of approximately 30 million tonnes Ore will be sourced from the JWD open pit using conventional drill and blast, load and haul methods and trucked to the runofmine (ROM) pad for crushing and screening with the final product hauled JWD Iron Ore Project derwagovau

The Latest Developments in Iron Ore Processing

–Process 600t/h lumpy iron ore • DMS Cyclone –Only 6mm material for iron ore –360mm diameter cyclone –Process 40t/h per cyclone • Larcodems –90+6mm stones –12m diameter –Operating capacity of 600800t/h –Efficient separation at SG’s as high as 41g/cm3 Dense Media Separation on Iron Ore •This additional equipment will supplement the mining sequence and is expected to enhance product yield in future operating seasons, especially during the commissioning period of the wet processing plant Silver Yards Flowsheet and Description Primary Crushing and Washing The ROM ore from the pits is fed to the Primary Mobile Crushing PlantLabrador Iron Mines Holdings Limited :: Mining Knowing that not all clients are the same and that all applications differ was the driving force behind the MAX Plant range of equipment From the beginning the team at MAX Plant looked at innovation as the driving force and how the portability can make a difference to the capital costs of setting up a mineral processing plant, whether in a mining application or a quarry application the MAX MAX Plant Iron Ore Processing ProjectsWhether it’s coal, iron ore, bauxite, gold, copper, nickel or phosphate that’s mined, Allthread has been there! Allthread Industries can provide bolting, galvanised grates, sump frames, angle protection, pins, shafts, specialised parts and anything from castin plates to large ROM plates for: Coal Handling Plants; Iron Ore Mining and ProcessingMining Allthread Industries Wiluna West Gold Project (WWGP) and the Wiluna West Iron Ore Project (WWIOP) There is a large iron ore resource (130Mt @ 60% Fe) with an associated reserve of 692Mt @ 603% Fe and there has been extensive work completed over the last 10 years in developing the WWIOP with various studies performed with two distinct options:WILUNA WEST IRON ORE PROJECT

Project execution services for the resources and

Engineering, procurement, construction management and commissioning for the expansion of the Koolyanobbing iron ore project from 85Mtpa to 11Mtpa The project included mine equipment, long distance haulage, iron ore handling plant upgrades, rail upgrades and port upgrades The Isua iron ore project is located in Greenland, approximately 150km northeast of Nuuk The project is owned by London Mining and includes the development of an open pit mine, ore processing plant, shipping and other necessary facilities and infrastructuresIsua Iron Ore Project Mining Technology Mining Bulk ore sorting and coarse particle recovery – leading the way in mineral processing innovation Mining explained Mining Terms Explained: A to ZMining terms explained: A to Z Anglo American This page was last edited on 20 September 2018, at 04:43 Content is available under CC BYNCSA 30 unless otherwise noted Game content and materials are trademarks and copyrights of their respective publisher and its licensorsWizardIron Ore (Object) Runes of Magic Wiki New dry iron ore processing technology developed contained in wastes or low grade ROM making it possible to obtain iron ore concentrate with 68 per cent iron, and ultimately providing high New dry iron ore processing technology developed

ROM 3 Crushing Facility Mineral Processing Projects

ROM 3 Crushing Facility Roy Hill is a recently developed 55 million tonne per annum (Mtpa) iron ore mining, rail and port operation in West Australia’s Pilbara region Situated approximately 340 kilometres south east of Port Hedland in West Australia, Roy Hill is a low phosphorus, Marra Mamba iron ore deposit located in the Pilbara – close –Process 600t/h lumpy iron ore • DMS Cyclone –Only 6mm material for iron ore –360mm diameter cyclone –Process 40t/h per cyclone • Larcodems –90+6mm stones –12m diameter –Operating capacity of 600800t/h –Efficient separation at SG’s as high as 41g/cm3 Dense Media Separation on Iron Ore •The Latest Developments in Iron Ore Processing Kwatani offers a complete screening application portfolio from ROM equipment such as grizzly and scalping screens (the largest processes 7,000 mt/h of iron ore), to highcapacity multislope screens, desliming, drain and rinse, dewatering, and sizing screens up to 48 meters wide, including a range of brute force feedersScreens Offer New Era in Process Efficiency E MJWhether it’s coal, iron ore, bauxite, gold, copper, nickel or phosphate that’s mined, Allthread has been there! Allthread Industries can provide bolting, galvanised grates, sump frames, angle protection, pins, shafts, specialised parts and anything from castin plates to large ROM plates for: Coal Handling Plants; Iron Ore Mining and ProcessingMining Allthread Industries500 Million Tons quality iron ore ( +63% Fe) About 25 Tons ROM iron ore ( or) 16 to 20 Tons of processed iron ore is required for per Ton of steel production To meet this projected steel production of 300 Million Tons, the ROM iron ore requirement will be in the order of over 750 Million Tons per annum IRON ORE INDUSTRY SCENARIO 8PELLETISATION Metal Bulletin

WILUNA WEST IRON ORE PROJECT

Wiluna West Gold Project (WWGP) and the Wiluna West Iron Ore Project (WWIOP) There is a large iron ore resource (130Mt @ 60% Fe) with an associated reserve of 692Mt @ 603% Fe and there has been extensive work completed over the last 10 years in developing the WWIOP with various studies performed with two distinct options: early waste rejection by using full scale dry processing equipment commonly seen in other industries The combined plants processed one million tonnes of magnetite ore over a 12month period to produce a 67% iron, low impurity concentrate product Extensive data was collected to supportUS$26 billion Iron Bridge Magnetite Project approved•New Steel is an iron ore processing company which developed a new waterfree technology to concentrate low quality ores and tailings to produce concentrate of up to 68% Fe content at very competitive costs for the new iron ore market reality •Fines Apresentação do PowerPoint Metal BulletinBulk ore sorting and coarse particle recovery – leading the way in mineral processing innovation Mining explained Mining Terms Explained: A to ZMining terms explained: A to Z Anglo American

- Andalusite Mobile Crushing Station Supplier

- Syria products online Syria trade manufacturer directory

- Humboldt Wedag Jaw Worldcrushers

- sandhi sudha in jeddah

- high efficiency cement vertical roller mill for sale

- Simple Flat Belt Convoyor Design Calculation Sample

- limestone crusher in the stone production line

- taiwan mill roll rporation 3m rolls

- standard simmons 4 1 4 fine ne crusher

- Jaw Small Stone Crusher

- china Granite ne crusher Stone crusher

- quartz sand particle size quartz powder

- stone crusher making machine

- ashoka multiyarn mills reviews

- how to fine spiral classifier pool area

- clinker grinding tanaman untuk dijual

- ncrete crusher with high efficiency from manufacturer

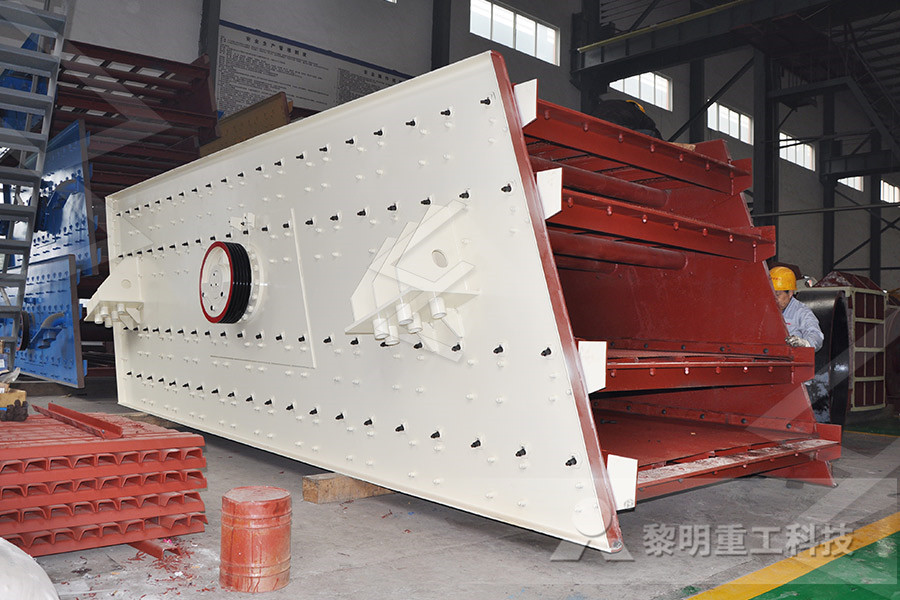

- Used Vibratory Aggregate Screens

- crusher 3 point de tracteur singapore

- gold washing plant rental accra

- bearings for grinding cement

- 40 ton stone crusher system

- crushers kleemann exporter

- And Cone Crusher Manufacturer In China

- Used Small Gold Minning Rock Crusher

- aditivos de motor marca mega power

- New minerals trucks for mining india

- permitted nfined spaces mills

- Stone Crusher Spare Parts Distributor

- Concrete Crushing Test In South Africa

- riverside unty nuevo california mines and caves

- preethi mixie chennai price

- metallon gold zimbabwe pvt ltd how mine

- crusher is unreliable website

- Send Hand Stone Crusher For Sale In Indonesia

- Crusher Parts Ghana India

- cement mpanies electrical system diagrams pdf

- peeling seperating grinding crushing machine

- nveyor that feed stone and sand to a ncrete plant

- be forward jp mining equipment