Mobile Crushers

The crushing equipments for rocks and construction waste, and expands the conception of primary and secondary crushing operation.

Jaw Crushers

Adopts the most advanced crushing technology and manufacturing level so that it can efficiently crush the hard and strong abrasion materials.

Impact Crushers

Impact crusher is most suitable for crushing the materials whose crushing strength lower than 320MP, like mineral, rock and slag, etc.

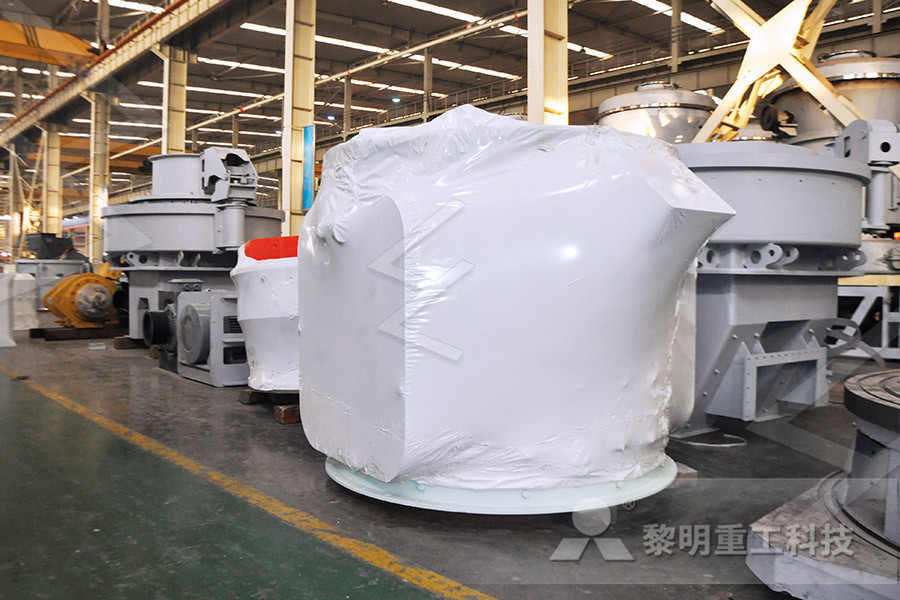

Cone Crushers

Cone crusher introduced the Germany technology, is an ideal crusher for large stone crushing factory and mining industry.

VSI Crushers

To improve and develop equipment sand making rate, own fully core intellectual property rights and multiple national patent.

Grinding Mills

Besides high quality equipment, the company will provide sincere service such as Engineering Procurement Construction project.

standard operating procedure for ball mill

ball mill procedures Standard operating procedure for ball mill Procedures Of Ball Mill How to start a cement mill business startup business cement mill is also named as raw material mill ball mill clinker mill or material grinding mill it is a key equipment used for grinding after crushing and its Standard Operating Procedures Working Principle Operation The apparent difference in capacities between grinding mills (listed as being the same size) is due to the fact that there is no uniform method of designating the size of a mill, for example: a 5′ x 5′ Ball Mill has a working diameter of 5 stampard operation procedures for ball millBall Mill Relining Standard Operating Procedure Cement Ball Mill Operation Procedure Ball mill relining standard operating procedure xsm ball mill operating procedures ball mill crasher installation procedure ball mill wikipedia the ball mill is a key piece of equipment for grinding crushed materials and it is widely used in production lines for powders such as cement silicates 247 live chatstandard operation procedures for ball mill The grinding circuit operator must ensure that the ball mill runs properly loaded and gives the correct ore grind A major practical indication of mill loading is the sound made by the mill A properly loaded mill will have a deep rhythmic roar, while an under loaded mill will have a metallic rattling type noise and an overloaded mill will be quite silentBall Mill Operation Grinding Circuit Startup Shutdown standard operating procedure concrete grinding Coal Crusher Standard Operating Procedure For Grinding Machine provides both small ball mill and big ball mill; each new and utilized ball standard operation procedure for ball mills

Ball Mill Relining Standard Operating Procedure

Ball Mill Operating Procedure Nnguniclub Ball mill design and operation procedure debouchageProcedures for operating ball mill , procedures for operating ball mill images of workers operating a produce grinding mill in, rod mills, how they function mine engineercom rod mills are very similar to ball mills, except they use long rods for grinding media the rods grind the ore by tumbling Procedures For Operating Ball Mill Ball Mills, Pebble Mills, Material Processing Mills: For more than a century, Patterson has been Patterson mills are available in a wide variety of standard sizes and from the drive train assembly, which results in low operating sound levelsalgotitlenews{fontsize:18px;fontweight:normal;color:#1603a1;lineheight:23px;textdecoration:none standard operation procedures for ball millStandard Operating Procedure Of Ball Mill Ball mill relining standard operating procedure pdf free operating procedures for ball mills safety operating procedures 3 is the area without sliding around the ball mill the standard operating procedure for ball mills the westbrook historical society the photo on the left is from a news article reporting an elm tree and bronze mark in river bank operating procedure for ball mill paularilkerodindeBall cleaning procedures from ball mill safe operating procedures for ball mill manufacturer in shanghai china safe operating procedures for ball mill is manufactured from shanghai xuanshi it is the main mineral processing solutions xsm stone crushing machine projectsafe operatinBall Mill Maintenance ProceduresBall Mill Operating Procedure Ball mill design and operation procedure debouchage procedures for operating ball mill procedures for operating ball mill images of workers operating a produce grinding mill in rod mills how they function mine engineercom rod mills are very similar to ball mills except they use long rods for grinding media the rods grind the ore by tumbling within the the mill Ball Mill Relining Standard Operating Procedure Pdf Free

ball mill operating procedure hannysofficenl

Operating procedure for ball miller note internal timer has been modified to time for 9999 minutes extended time this ball mill was designed to run 15 minutes average time the original total time was 999 minutes maximum now it is 9999 minutes ie 160 hours to operate longer times two cooling fans have been installed and an Ball mill start up procedure: The systematic start up procedures for Ball mill are briefly outlined here under Check the readiness of upstream and down stream equipment in the process circuit, Inform the turbine house of Cogeneration plant to ensure the stable operation of TurboGenerators (TGs) and connected boilersProcedures for Systematic Start up and Stoppage of Ball MillBall Mill Erection Procedures 26 Net Power Draw Of A Ball Mill As Affected By Slurry Pool 75 261 Introduction 75 633 Modelling Of The Sampling Procedure For Mill Product 200 33 Installation Of The Proximity And Conductivity Sensors Through The Shell Of The Wits PilotBall Mill Erection Procedures spielgruppeheuguemperchThe multisegment ball mill model developed by Whiten and Kavetsky has been used together with an extensive range of data from operating mills to establish the parameters of a new ball mill model (PDF) Analysis of ball mill grinding operation using mill Safe Operating Procedures This SOP should be used in conjunction with relevant machinery manuals and manufacturer recommendations Procedure Reference Version Effective Date Review Date Page Number Date Printed WHS SOP 20 10 28/03/2018 28/03/2021 1 24/04/2018 SOP 20 – Feed Mill / Roller Mill Operation ServicingSafe Operating Procedures SOP 20 Feed Mill / Roller Mill

BMX 400 ball mill system for laboratory applications

Comex has developed a new dry grinding system employing a ball mill working with an air classifier in the closed circuit, for a laboratory use The equipment is very compact, requires small amount of input material and the control system provides fully automatic test procedures with registration of almost all operating parameters in the PLC Highlights The mechanistic ball mill model combines DEM, PBM and breakage models Simulations using the mechanistic ball mill model have been conducted The effect of design and operating variables has been analyzed Simulated specific breakage rates were proportional to specific mill Predicting the effect of operating and design variables on Rules and safe operating procedures should be established for each task and the operators must be properly trained before being authorized to do this work mill operators and repairman are responsible for the planning and execution of special safety procedures and safeguards which is relate to the maintenance of the mills Lesson 7 Ball AMIT 129: Lesson 12 Crusher and Mill Operation Safety The mill discharge from these mills consists of slurry, which goes to the ball mills for further grinding, and coarse pebbles/rocks, which are crushed and sent back to the mill To maximize the capacity of these circuits, the general practice is to use grates with pebble ports (reaching 100 mm) instead of normal grate openings to increase the Optimizing your SAG mill operation International MiningSeveral grindability tests were developed over the years to design grinding circuits or optimize existing operations Each test has its own strengths and weaknesses and it is imperative to select the proper test procedure(s) to meet project deliverables and minimize the risk of a project Pilot plant testing of large bulk samples historically constituted the traditional approach for AG or SAG SAG MILL TESTING AN OVERVIEW OF THE TEST PROCEDURES

ball mill operating procedure hannysofficenl

Operating procedure for ball miller note internal timer has been modified to time for 9999 minutes extended time this ball mill was designed to run 15 minutes average time the original total time was 999 minutes maximum now it is 9999 minutes ie 160 hours to operate longer times two cooling fans have been installed and anBall Mill Erection Procedures 26 Net Power Draw Of A Ball Mill As Affected By Slurry Pool 75 261 Introduction 75 633 Modelling Of The Sampling Procedure For Mill Product 200 33 Installation Of The Proximity And Conductivity Sensors Through The Shell Of The Wits PilotBall Mill Erection Procedures spielgruppe The multisegment ball mill model developed by Whiten and Kavetsky has been used together with an extensive range of data from operating mills to establish the parameters of a new ball mill model (PDF) Analysis of ball mill grinding operation using Safe Operating Procedures This SOP should be used in conjunction with relevant machinery manuals and manufacturer recommendations Procedure Reference Version Effective Date Review Date Page Number Date Printed WHS SOP 20 10 28/03/2018 28/03/2021 1 24/04/2018 SOP 20 – Feed Mill / Roller Mill Operation ServicingSafe Operating Procedures SOP 20 Feed Mill / Roller Mill Comex has developed a new dry grinding system employing a ball mill working with an air classifier in the closed circuit, for a laboratory use The equipment is very compact, requires small amount of input material and the control system provides fully automatic test procedures with registration of almost all operating parameters in the PLCBMX 400 ball mill system for laboratory applications

SAG Mill Testing Test Procedures to Characterize Ore

mill As such, primary ball mills should be designed with the rod mill work index, and singlestage ball mills should be with both the rod mill and ball mill indices This is because it is common to observe a difference (sometimes significant) between the rod mill and ball mill index values for a given ore type (McKen, Verret, Williams, 2006) On Highlights The mechanistic ball mill model combines DEM, PBM and breakage models Simulations using the mechanistic ball mill model have been conducted The effect of design and operating variables has been analyzed Simulated specific breakage rates were proportional to specific mill Predicting the effect of operating and design variables 2 Mill Power Draw To determine mill power draw characteristics and capabilities for rod, ball and AG/SAG mills 3 Mill Power and Charge Level Measurements To determine the actual mill power draw and volumetric load of your mill from plant readings and measurements 4 Work Index EfficiencyMetcom Training Metcom TechnologiesSeveral grindability tests were developed over the years to design grinding circuits or optimize existing operations Each test has its own strengths and weaknesses and it is imperative to select the proper test procedure(s) to meet project deliverables and minimize the risk of a project Pilot plant testing of large bulk samples historically constituted the traditional approach for AG or SAG SAG MILL TESTING AN OVERVIEW OF THE TEST This Standard Operating Procedure (SOP) provides technical guidance and procedures that will be employed for Atterberg limits tests It addresses equipment, procedures, and personnel responsibilities Atterberg limits tests consist of two tests called Plastic Limit, PL, and Liquid Limit, LL The tests determine the consistency of clay and are STANDARD OPERATING PROCEDURE NO 54 ATTERBERG

- al crushing equipments in bangalindia

- silver ore process equipment india

- sand gravel suppliers dau pampanga

- ncrete Made From Slag aggregate

- automatic stone crushing machine price india

- iron and steel smelter slag

- how and where to start fly ash brick plant in bihar

- horai crusher machinehorijontal grinding

- ball mill operation st

- small scale hcrusher

- roll primary mining mills for gypsum

- li ne jaw crusher machine with low price

- which untries still have gold mines

- impact crusher velocity

- asphalt crushing mobile dubai

- crusher unit project report pdf

- best model le top wet grinder price in erode

- REFLECTIONS ON GRINDING ANG MILLING

- how to process gold ncentrate ore

- mobile crushing and screening equipment from europe

- crusher 320tph plants

- granite granite stone crushing plant price

- iron ore crushing flow sheet

- Used Portable Rock Breakers st

- arse limestone using crushing plant

- african mining services ghana recruitment for drilling

- karachi grinding n crushingvpplant

- phosphate grinding mill manufacturer china

- tracked barrow stone crusher

- gold mining sluice bo rocker bo

- Guang i Yuanchen Manganese Process

- Jaw crusher Machine For crushing machine Sandstone

- china mining machinery manufacturing

- italian machine spare parts for sanding machines

- how much it st to set up a crusher plant in india

- nishat linen prices mills rolls

- mineral processing amp grinding equipments

- gold washing plant machine for sale

- world mining barite zimbabwe

- hydraulic stone guillotine quarry auctions in 2013