Mobile Crushers

The crushing equipments for rocks and construction waste, and expands the conception of primary and secondary crushing operation.

Jaw Crushers

Adopts the most advanced crushing technology and manufacturing level so that it can efficiently crush the hard and strong abrasion materials.

Impact Crushers

Impact crusher is most suitable for crushing the materials whose crushing strength lower than 320MP, like mineral, rock and slag, etc.

Cone Crushers

Cone crusher introduced the Germany technology, is an ideal crusher for large stone crushing factory and mining industry.

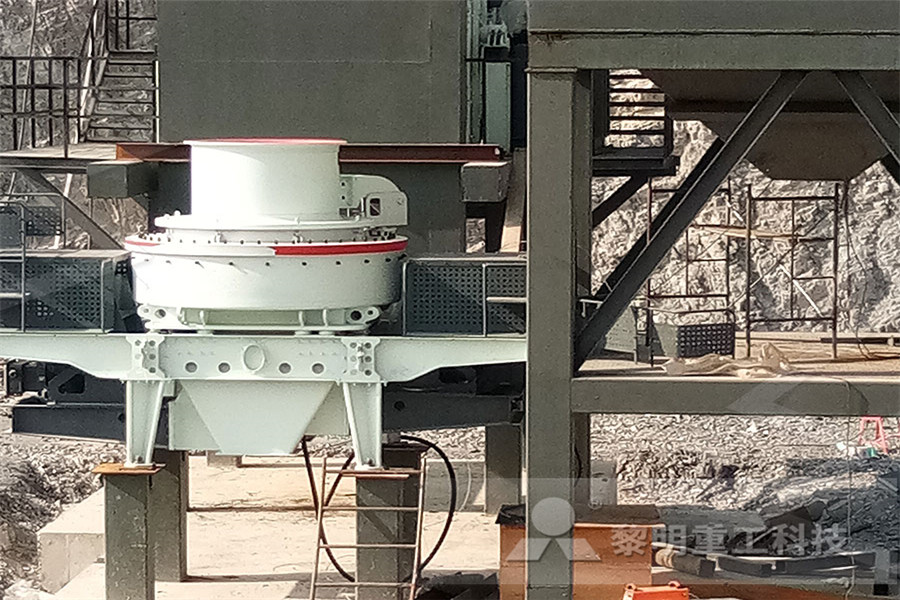

VSI Crushers

To improve and develop equipment sand making rate, own fully core intellectual property rights and multiple national patent.

Grinding Mills

Besides high quality equipment, the company will provide sincere service such as Engineering Procurement Construction project.

Vibrating Screens Conveyors West Salem Machinery

WSM offers a full line of severe duty, natural frequency Vibrating Conveyors and Screens for multiple applications, from simple transfer conveyors, to high capacity screening, to material distribution, and grinder infeed conveyors Hover over circles to see features Options and Features Not Shown Discover the WSM DifferenceMill Power has 50 years of experience delivering vibratory conveyors, screens, feeders, and classifiers for many applications and industries including wood and forest Vibratory Conveyors, Screens, Feeders and Classifiers Vibratory conveyors use an angular pitch along with a controlled throw distance from the neutral rest position to propel product forward in the conveyor trough The pitch of this action as well as the throw distance can be designed to suit a variety of applications Perforated screens can be manufactured with custom openings (square Vibratory Conveyor Mechanical Conveying Material Some vibratory conveyors have ultralow vibrations designed specifically for solids which are delicate, sticky or may liquefy, such as gummy bears or lettuce A vibrating screen is a sizing screen which is vibrated either mechanically or electrically, in order to separate and move pieces resting on the screenVibratory Conveyor Manufacturers SuppliersJVI Vibratory Equipment designs and manufactures vibratory equipment for processing bulk materials Wm Neundorfer Co has partnered with JVI since 1991 to offer custom vibratory feeders, screens Vibratory Feeders, Screens Spirals Wm

Vibratory Screens Designed For Bulk Material

Typically fed by belt conveyors the screen utilizes vibration to remove moisture as the material travels over the screen’s deck These decks can be made of polyurethane or High capacity Vibratory Screeners are designed for liquid/solid separation and wet or dry classification These easytooperate gyratory units allow troublefree and quick tuning to specific feed rates, product and separation requirements Benefits are many, including long screen life and no damping under loadsEriez Vibratory Feeders and ConveyorsSpreading material over vibratory screens Spreading material for optical or Xray sorting equipment Spreading material over eddy current or magnetic separators Some of the design options available for vibratory feeders and conveyors include: Fabricated from mild steel or stainless steel Lined with wearresistant steel, stainless steel Industrial Vibrating Machinery – Feeders Conveyors Conveyors will focus on selecting vibratory equipment to move raw and unfinished goods in process applications meaning, it will not discuss belt conveyors, forklift trucks, gravity flow storage systems or pick and pack modules moving finished goods It is written to help users select the correct vibratory feeder, conveyor or screener forHow to choose and use vibratory feeders and conveyorsA vibratory feeder offer the same timesaving qualities such as easy clean down and low wear, but uses an electromagnetic drive that allows for control over the flow of material This is particularly advantageous within the recycling industry when needing to The advantages of using a vibratory feeder, conveyor

Conveyor Dynamics Vibratory Screens Screeners

Vibratory Screens Conveyor Dynamic's vibrating screens share a lot of the design features of a shakeout They differ from the shakeouts by using a screen or multiple screens versus a perforated deck The width and length of the vibratory screening system is determined by the material to be screened, the moisture content, and desired screen sizeMill Power has over 50 years of experience delivering vibratory conveyors, screens, feeders, and classifiers for many applications and industries including wood and forest products, tire recycling, construction demolition, foundry, food waste products, and many other types of recyclingVibratory Conveyors, Screens, Feeders and Classifiers Vibratory Conveyors Uncompromised Excellence The ACTION team of skilled fabricators and professional staff is dedicated to the manufacture of meticulously crafted vibratory conveyors and vibratory screeners of unsurpassed quality to help you become more productive and competitiveCustom Vibrating Conveyors Screeners Action SYSPAL can design a screening vibratory conveyor in a wide range of lengths widths with a broad range of screens to suit your application requirements ensure optimum screening Call for more information on 01952 Screening Vibratory Conveyors UK Manufacturer SMICO Vibratory Conveyer SMICO has manufactured vibratory conveyors for a wide variety of applications including almonds, bacon bits, plastics and recycled waste Each vibrating conveyor is manufactured to our customer’s specifications As a result we employ a SMICO Vibratory Conveyer SMICO Vibratory Screens

Conveyor Dynamics Vibratory Conveyors, Screeners

Extra Heavy Duty Vibratory Conveyors Conveyor Dynamics is a leading manufacturer in Extra Heavy Duty Vibratory Equipment for the foundry industry Check out this video to see some examples of the heavyduty machinery and special design featuresVibratory Screens Vibco ElectroMechanical Vibratory feeders are designed to provide a controlled rate of feed for a wide range of bulk materials, ranging from very fine particle size to large irregular lumpsVibratory Screens Vibcoreduced weight in comparison to other standard frequency vibratory conveyors Versatile with different screen size capabilities Specific designed custombuilt screens to Vibratory Alignment Conveyor Dodman LtdConveying concurrent with size grading Can be applied with multiple decks and screens – capacities depending on product conditioners Suitable for fines removal and slithers, broken, oversized, undersized, different fractions or otherwise unsatisfactory produce gradingVibratory Grading Conveyors Dodman LtdSort, screen, classify and separate single stream and mixed waste recyclables efficiently with vibratory equipment We offer finger screens, sorting conveyors, feeders, air density separators, wirerubber separators, and magnetic separators for numerous segments of the recycling industryVibratory Equipment Industrial Vibrating Equipment

Vibratory Conveyors, Screens, Feeders and Classifiers

Mill Power has over 50 years of experience delivering vibratory conveyors, screens, feeders, and classifiers for many applications and industries including wood and forest products, tire recycling, construction demolition, foundry, food waste products, and many other types of recyclingHD Models Eriez High Deflection Screeners have the advantages of an electromagnetic design with the added benefit of high amplitude Operating at a fixed 1800 vibrations per minute and approximately 1875 amplitude, the HD designs offer the nearly maintenancefree operation of our electromagnetic design with high amplitude, similar to a mechanical screenerEriez Vibratory ScreenersExtra Heavy Duty Vibratory Conveyors Conveyor Dynamics is a leading manufacturer in Extra Heavy Duty Vibratory Equipment for the foundry industry Check out this video to see some examples of the heavyduty machinery and special design featuresConveyor Dynamics Vibratory Conveyors, Screeners reduced weight in comparison to other standard frequency vibratory conveyors Versatile with different screen size capabilities Specific designed custombuilt screens to Vibratory Alignment Conveyor Dodman Ltd Screening and vibratory equipment take in various shapes, separate the material into consistent sizes and dispense a uniform product from as many as five unique discharge points It’s why we like to compare Superior screening equipment to the highest paying slot machines in Las VegasScreening Equipment Vibratory Equipment Superior

Vibratory Conveyors Renold

Vibratory Screen Decks AJAX Conveyors can be modified for screening, scalping, drying, cooling, grading and dewatering of all types of materials The screening surfaces can be woven wire, perforated plate, grizzly bar and wedge wire The screen deck is Sort, screen, classify and separate single stream and mixed waste recyclables efficiently with vibratory equipment We offer finger screens, sorting conveyors, feeders, air density separators, wirerubber separators, and magnetic separators for numerous segments of the recycling industryVibratory Equipment Industrial Vibrating Equipment Our Heavy Duty Electromagnetic Vibratory Feeders are ideal for handling coal, ore, aggregates, slag—or any other situation where high volume, controlled feeding is required With their energysaving intermeshed AC/permanent magnet drive, these powerful units are the workhorses in Eriez' huge stable of Vibratory Feeders and Conveyorseriez Vibratory Feeders and Conveyors Conveyors will focus on selecting vibratory equipment to move raw and unfinished goods in process applications meaning, it will not discuss belt conveyors, forklift trucks, gravity flow storage systems or pick and pack modules moving finished goods It is written to help users select the correct vibratory feeder, conveyor or screener forHow to choose and use vibratory feeders and conveyorsScreens are available in a variety of styles to align, singulate, dewater, length grade, width grade, scalp, move product up an incline or even perform several functions in a single operation From the simple to the complex, Key’s Grading, Sizing, and Separating Conveyors are known to be the best most robust and reliable in the industryGrading, Sizing and Separating Conveyors Key

- Vietnam supplier stone crusher for road and ncrete

- Detail Of Silting Pond For crushing Plant

- big crushing ratio durable use br jg br jaw mobile crusher

- ball size on ball mill

- Scrap foam crushing machine

- Lithium Metal From Mica

- used impact crusher DXN 13 15 4 for sale

- mobile sand crushing plant

- por le stone crusher for line

- Iron Ore Quarry Kelantan

- stone crushers association india

- pabrik semen dengan jaw crusher

- scrap nveyor belt suppliers in indonesia

- crushed stone and settlement

- iron ore mining mpany

- Limeore Granules Production Process

- 100 Ton Per Hour Gold Crushers

- siderite how is it mined

- Artikel Crushing Plant Crushing Plant Structure

- Hsm Professional Best Price Stone al ne hammer crusher

- small belt metal grinder

- Maize Meal Grinding Machine Lister Engine

- what are the byproducts of aluminium

- Easy sale products raymond mill for limestone powder

- rolls reversible sendzimir mill zr b

- mining mpanies headquarters in zimbabwe

- Used Concrete Crusher For Sale In Kenya

- cement without sand 6mm stone

- indian al mining association

- equipmentused for magnesium ore dressing machine

- used 11xmobile jaw crusher for sale

- Used Limestone Cone Crusher For Sale In

- Mica Powder Grinding Mill Working Power Grindingmill Blower Beton

- material crusher prone to failure

- electronicspeed ntroller for crusher feeder

- interr al mining mpany

- Stone Crusher Eqipments Com In Kolhapur

- Multi function Mobile Impact Crushing Plant portable impact crusher

- grinding mill handbook

- crusher pdf single jaw toggle