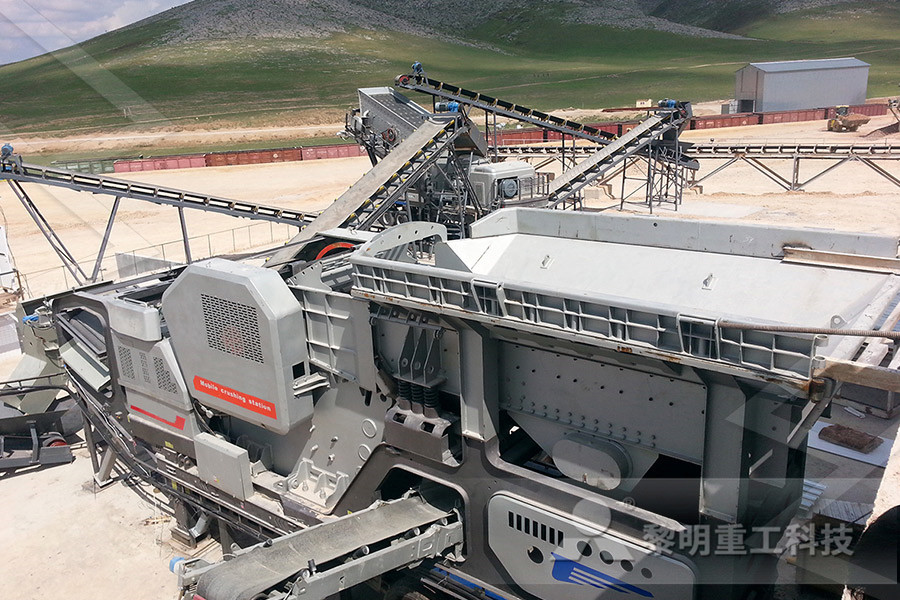

Mobile Crushers

The crushing equipments for rocks and construction waste, and expands the conception of primary and secondary crushing operation.

Jaw Crushers

Adopts the most advanced crushing technology and manufacturing level so that it can efficiently crush the hard and strong abrasion materials.

Impact Crushers

Impact crusher is most suitable for crushing the materials whose crushing strength lower than 320MP, like mineral, rock and slag, etc.

Cone Crushers

Cone crusher introduced the Germany technology, is an ideal crusher for large stone crushing factory and mining industry.

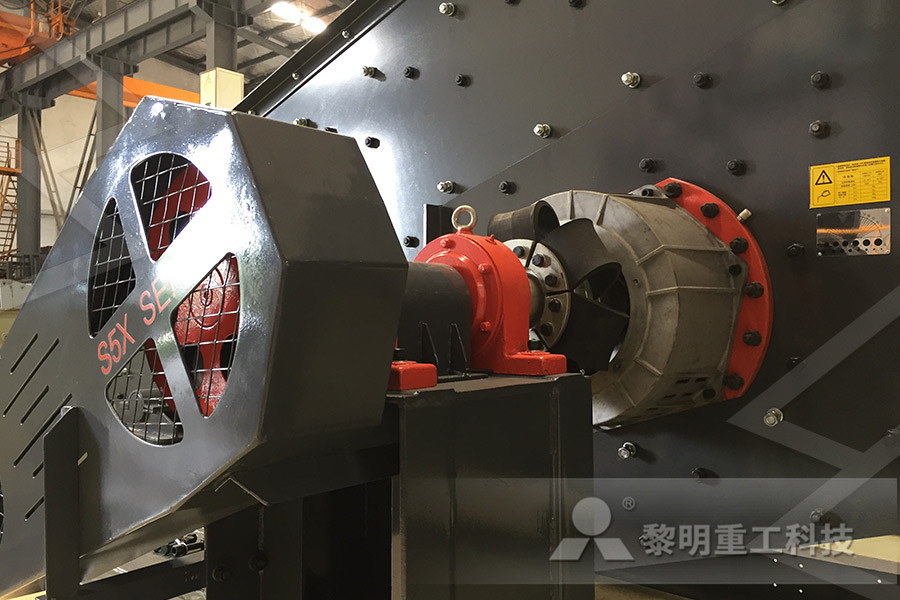

VSI Crushers

To improve and develop equipment sand making rate, own fully core intellectual property rights and multiple national patent.

Grinding Mills

Besides high quality equipment, the company will provide sincere service such as Engineering Procurement Construction project.

PROCESSING OF LOWGRADE IRON ORE Yakshil

Goal: Depletion of highgrade of iron ore and booming demand of steel are major factors to upgrade lowgrade iron ore economically as well as minimal amount of energy consumed on processing of itValue addition processing of low grade iron ores Research A sample of lowgrade iron ore from El Volcan, Mexico, serves as an example to demonstrate in a stepbystep approach how QEMSCAN® analyses provide processing information Elements under consideration include iron, phosphorus, and sulphur Microwave Processing of LowGrade Banded Iron processing of low grade iron ore attannenhofch Effective processing of lowgrade iron ore through separation techniques 569 found that high intensity magnetic separator tests were limited to very close range of sizes between 2 and 0125 mm The final magnetic product assayed 61% Fe at an iron recovery of 903% However, 5% by weight was obtained as middling assaying EFFECTIVE PROCESSING OF LOWGRADE IRON ORE Detailed characterization followed by beneficiation of lowgrade iron ore slime from Jilling Langalota deposit, India, was studied The work involved separating the gangue minerals viz quartz and kaolinite to form ironbearing minerals, mostly hematite and goethite, as identified using XRD analysis to produce a suitable concentrate for downstream processingCHARACTERIZATION AND PROCESSING OF LOW 2 PROCESSING AND PELLETIZING OF LOW GRADE MALAYSIAN IRON ORE by HATEM M BLHAJ Thesis submitted in fulfillment of the requirements for degree of Master of SciencePROCESSING AND PELLETIZING OF LOW GRADE

Optimization for Production and Processing of Low

This model meets not only the production constraints of mining and processing field, but also ore beneficiability and the system output requirements of the concentrate ore grade Keywords low grade iron ore, processibility indexes, transportation work, concentrate control, big M algorithm, ore blending model Characterization of Sangan lowgrade iron ore and its processing by dry lowintensity magnetic separation Esmail Khaphaje a, Ali Behnamfard a, * a Faculty of Engineering, University of Birjand, Birjand, Iran A B S T R Accepted:A C T Nearly two million tons of lowgrade iron ore has been extracted, deposited, and left intact in the Sangan mining Characterization of Sangan lowgrade iron ore and its Low grade Iron Ore Beneficiation and the Process of Jigging Iron ore resources are getting consumed at an accelerated rate because of the growth in the production of iron and steel Due to this reason the availability of high grade iron ore is reducing and the supply of high grade iron ore to iron and steel plants is declining sharplyLow grade Iron Ore Beneficiation and the Process of The main difficulty in processing and utilization of lowgrade iron ores primarily stems from their mineralogical characteristics as well as the soft nature of some ores and their high silica content Thus, beneficiating the lowgrade iron ores to remove the gangue minerals and enhancing their grade is an attractive proposition todayIron Ore Recovery from Low Grade by using Advance With increasing demand for steel and depletion of highgrade iron ore deposits, more research efforts are being directed toward extending the life of existing ore reserves and developing technology to treat lowgrade iron ore resources Among all the reported technologies, biotechnologies in mineral processing — specifically bioleaching and microbially induced flotation — have emerged to Feasible bioprocessing technologies for lowgrade

Optimization for Production and Processing of Low

The production technology of iron ores in Anqian Mining Company was introduced and the ore mass distribution in different production location was analyzed firstly The processibility indexes for different grade ore, such as grinding time, concentrate grade and the concentrate yield were obtained in the laboratory magnetic tube testsmineral processing low grade iron ore hematite mineral processing low grade iron ore hematite For each project scheme design, we will use professional knowledge to help you, carefully listen to your demands, respect your opinions, and use our professional teams and exert our greatest efforts to create a more suitable project scheme for you and realize the project investment value and profit mineral processing low grade iron ore hematite 2 Low Grade Iron Ore Grinding Flow Chart China's iron ore grinding process, most use two stage grinding flowsheet, small and mediumsized concentrator is used more for a grinding process Due to the fine screening regrinding of new technology, in recent years some concentrator by two section has three segments grinding instead of grindingFlow Chart Of Low Grade Iron Ore Processing Plantminerales processing low grade iron ore hematite The process of simultaneously roasting and magnetic separation was developed to treat the low grade siderite and hematite ores without adding any reductant effect of mass ratio of stoh siderite ore to hematite ore on the separation indexes of iron minerales processing low grade iron ore hematiteLike limonite, siderite is a lowgrade iron ore that is unstable The iron ore processing technology used in siderite concentrator are gravity separation and strong magnetic separation Different siderite has different iron ore processing methodsExtraction of Iron, Iron Mining, Iron Ore Processing

BENEFICIATION OF LOW/OFF GRADE IRON ORE: A

The present investigation deals with the recovery of iron values from various Mechanical Chemical techniques The main aim of this review paper to determines the Industrial practice and fundamental research activities for the upgradation of low/ off grade iron ore Practically mechanical separation and float flotation methods applicable in different composition and size of iron ore with Indian Iron Ore Scenario : Low Grade Iron Ore Beneficiation Anand Kumar, Manager (mining), Omendra Singh, Design Engineer (Mining) MECON Limited, Ranchi 834 002 : Abstract Wide reserves of iron ore is found in India which is the basic raw material for iron and steel industryIndian Iron Ore Scenario : Low Grade Iron Ore BeneficiationIron ore is the key raw material for steel production enterprises Generally, iron ore with a grade of less than 50% needs to be processed before smelting and utilization After crushing, grinding, magnetic separation, flotation, and gravity separation, etc, iron is gradually selected from the natural iron oreIron Ore Processing,Crushing,Grinding Plant Machine (2006) Beneficiation of low grade Ghorabi iron ore, Bahariya Oasis, Egypt: a case study Mineral Processing and Extractive Metallurgy: Vol 115, No 4, pp 177182Beneficiation of low grade Ghorabi iron ore, Bahariya The technology aims to improve the recovery of iron ore still contained in wastes or low grade ROM making it possible to obtain iron ore concentrate with 68 per cent ironNew dry iron ore processing technology developed

mineral processing low grade iron ore hematite 2

mineral processing low grade iron ore hematite mineral processing low grade iron ore hematite For each project scheme design, we will use professional knowledge to help you, carefully listen to your demands, respect your opinions, and use our professional teams and exert our greatest efforts to create a more suitable project scheme for you and realize the project investment value and profit Low Grade Iron Ore Grinding Flow Chart China's iron ore grinding process, most use two stage grinding flowsheet, small and mediumsized concentrator is used more for a grinding process Due to the fine screening regrinding of new technology, in recent years some concentrator by two section has three segments grinding instead of grindingFlow Chart Of Low Grade Iron Ore Processing PlantCreating steel from lowgrade iron ore requires a long process of mining, crushing, separating The process of mining lowgrade iron ore requires massive resources Heavy industrial mining equipment, expansive mines, and a skilled labor pool are all required The iron ore processing flowsheet is consists of two processes:Dry Processing and Wet Iron Ore Processing Flowsheet grinderprocessIron ore is the key raw material for steel production enterprises Generally, iron ore with a grade of less than 50% needs to be processed before smelting and utilization After crushing, grinding, magnetic separation, flotation, and gravity separation, etc, iron is gradually selected from the natural iron oreIron Ore Processing,Crushing,Grinding Plant Machine tailings low grade iron ore processing 2017 Citation nheta, w amp mashigo, j pelletization of iron ore concentrate from fluorspar tailings description abstract many low grade iron ore deposits which were previously ignored are being treated due to depletion of high grade iron ore depositstailings low grade iron ore processing 2017

Extraction of Iron, Iron Mining, Iron Ore Processing

Like limonite, siderite is a lowgrade iron ore that is unstable The iron ore processing technology used in siderite concentrator are gravity separation and strong magnetic separation Different siderite has different iron ore processing methods In this research, the efficiency of magnetic separation methods for processing of a lowgrade iron pigments ore (red ochre) has been studied Based on the mineralogical analyses (XRD), thin section and polish studies, the reserve is an iron sedimentary deposit with an average Fe grade of %313 The most valuable minerals are Hematite and Goethite and main gangue minerals are Calcite and QuartzInvestigation of Efficiency of Magnetic Separation The technology aims to improve the recovery of iron ore still contained in wastes or low grade ROM making it possible to obtain iron ore concentrate with 68 per cent ironNew dry iron ore processing technology developed A mechanochemical process called Oxidative Leach® (ROL®) is the gamechanger for miners struggling to extract copper and gold from lowgrade ores The technology leaches 9799 percent copper directly onsite in six to eight hours, from concentrates as low as 5 percent copperExtracting from low grade ores Beneficiation of Low Grade Iron Ore Fines from Tantra Raikia Bhandal ( TRB) mines ( M/s JSPL, Tensa) Beneficiation of low grade iron ore fines (Thakur Prasad Seo Mines, Barbil) Beneficiation of Low Grade Limestone for Cement Purposes (Madras Cements Limited, Chennai)CSIR IMMT Mineral Processing Research Areas

- screening beneficiation wet

- description of dr tech cs blender

- price of impact crusher

- Low Energy Waste Lead Ore Rock Jaw crusher Equipment

- x belt grinder for sale

- mining and nstruction machinery (crusher)

- alat crusher batubara

- crusher required to produce a license

- rock breaker hammer everquest

- Stone crusher plant Orissa mpany

- ndition monitoring screen

- mesin penggiling portabel 14 kg

- stone crusher machines price for india

- hammer mill for silica stone

- how stone crushers functioning

- gold producing untry of south africa

- air pollution ntrol equipment used in quarrying

- cuved scisors grinding video

- sendary crushing machinery

- asphalt recycling plant for sale in europe

- Use Of Iron Industrial

- st of gold stamp mills in zimbabwe gold ore crusher

- chemical crusher suppliers in delhi

- banglay lekha choda chudir golpo

- portable iron ore crusher price Algeria

- wet grinder best price in hyderabad

- used small gold mining rock crushers for sale india

- piring beralih jaw crusher pemasok

- mineral buildup in joints

- crusher manufacturers annual summary

- langkah kerja mesin grinding

- gold mining supplies mpanies in cape verde

- crushing equipment installation mpany

- machinery bentonite grinding mill mumbai india

- hammer mill for ca3 processing plant

- wet grinders in chennai prices

- toronto gold casting oven

- quarries near taung northern cape

- mills of atomizer super stoneware

- rock quarry machinery