Mobile Crushers

The crushing equipments for rocks and construction waste, and expands the conception of primary and secondary crushing operation.

Jaw Crushers

Adopts the most advanced crushing technology and manufacturing level so that it can efficiently crush the hard and strong abrasion materials.

Impact Crushers

Impact crusher is most suitable for crushing the materials whose crushing strength lower than 320MP, like mineral, rock and slag, etc.

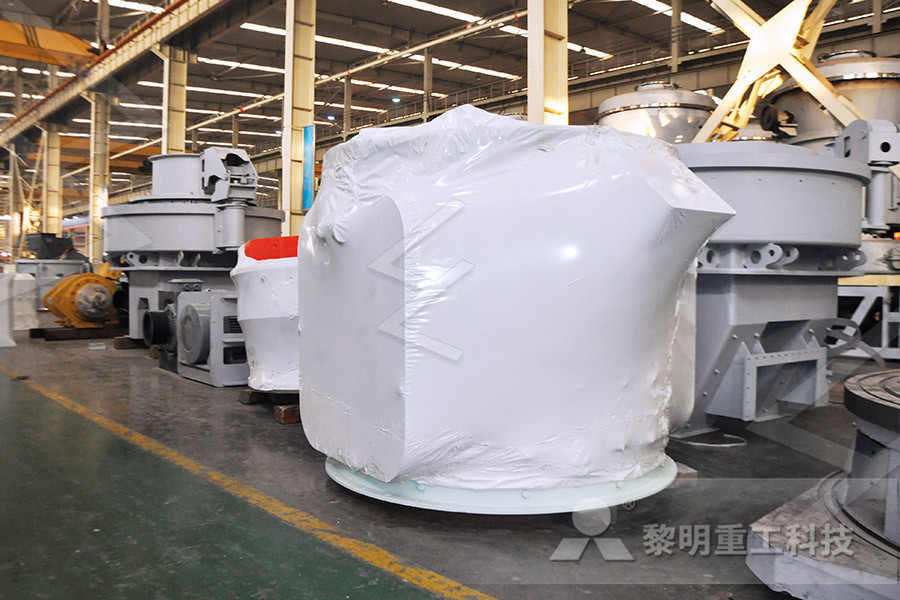

Cone Crushers

Cone crusher introduced the Germany technology, is an ideal crusher for large stone crushing factory and mining industry.

VSI Crushers

To improve and develop equipment sand making rate, own fully core intellectual property rights and multiple national patent.

Grinding Mills

Besides high quality equipment, the company will provide sincere service such as Engineering Procurement Construction project.

raw mill circulating fan lacorneillegourmandefr

High efficiency Fans for Raw Mill Vent Fan and WIL Circulating Fan alongwith >>Get Quotation HOUSING Subsector: Miniatry of Trade and Minerals CODE 120400186 Cooler fan Spare housing Impeller for cement mill AGas Circulation Fans For Raw Mill Kilns E Filter ,Cement Mill Q=5000 raw mill circulating fan jezdzenapradpl circulating air fan in roller coal mill Coal mill fans in cement industry coal mill fans are used to supply required air for burning coal and remove the exhaust gases produced after burning these fans help in effective burning of coal inside the mill for a large clinker line there are usually or cement cement mill circulating fan attannenhofchAbstract: The ATOX50 raw material mill adopts the threefans process system, and the supporting circulating fan installed power is 3 800kW, and its aerodynamic efficiency is low, resulting in relatively high power consumption of the circulating fan高效节能循环风机在ATOX生料磨系统中的应用Dust colleting Fan Raw mill / Coal mill / Cement Mill Raw mill Fan / Coal mill fan Circulating Air Fan / Roots Blower Bucket Elevator Preheater Fan / Cooler Vent Fan / Cooler Fan BH Fan / ESP Fan Separator Compressor Water Circulating PumpAmtech : Productsthe mill fan has been running for a short while, mill feed is started and the rollers are lowered onto the grinding bed Effective lubrication An oil circulation system effectively lubricates the bearings of the grinding rollers Each roller is fed individually with conditioned oil from a common supply station in which a separate circulationCirculating Air Fan In Roller Coal Mill

Separator For Raw Mill Working

raw mill circulating fan grinding mill separator fan raw mill separator fan Below is some information about the products equipment, if you puzzle about the price、the factory、the model and theGulin provides both small ball mill and big ball mill; circulating fan vertical roller mill what is working of dynamic air separator in cement Read more vertical roller mill with separator, cyclone, mill circulation fan, and electrostatic precipitator (EP) and EP fan as shown in Fig1 Pulverized final products, which is called kiln feed raw meal, are collected at the cyclone and EP Because of large pressure loss at the cyclone and in order to control mill gas flow, mill circulation fanVertical roller mill for raw Application p rocess materials 7 Malabar Cements Limited Malabar Cements Limited Raw Mill Exhaust Fan 2000 x 1250 230 Regualation Shut off 100 1 Pre heater fan to raw mill 1750 x 1750 316 9995 1 Pre heater fan to raw mill 1700 x 1700 316 9995 1 By pass Duct 1250 x 1250 260 9995 1 Twin Cyclone exhaust gas fan 750 x 750 320 9995 1 Cooler Heat 750 x 750 260 Tight SealINDUSTRIAL FANS (INDIA) PVT LTD, MULTI LOUVRE The grid material in the mill is then lifted to the separator with the help of raw mill circulating air fan In the grid separator, the disperse material is divided into two: the coarser material which is returned to the mill for further grinding, and the fine product leaves the separator at theNo Annexure Description In the raw material process, raw materials such as silica, clay, and iron are finely pulverized by raw mill In this process, fans and blowers for suctioning and collecting fine powder is used Because of the large thermal effect of rapid temperature change inside the mill, we have designed fans and blowers taking this into considerationCement EBARA FAN BLOWER

Raw Mill Pressure Drop Reduction With External Material

Raw mill fans raw mill fan in cement industry carries gas and raw meal the pressure drop in raw mill fan is very high if a vertical roller mill is used for raw grinding in cement industry then a large raw mill fan is installed chat online circulating air Raw mill pressure drop reduction with external material circulationRaw Mill Exhaust Fans Raw mill exhaust fans or stack fans are also called as dedusting fans In cement industry raw mill exhaust fans handle 22 ton of exhaust gases for the production of 1 ton of clinker Raw mill exhaust fans are operated with very adverse situations because the fan handles mainly gases such as CO2 N2 NOx and Sox along raw mill fan cement plant sscafeplthe mill fan has been running for a short while, mill feed is started and the rollers are lowered onto the grinding bed Effective lubrication An oil circulation system effectively lubricates the bearings of the grinding rollers Each roller is fed individually with conditioned oil from a common supply station in which a separate circulationCirculating Air Fan In Roller Coal Mill Raw matarials Mill fan External circulating system 68 3 Item Direct dust collection system to vertical mill grinding process Application process Raw material process Background At the beginning stage when vertical roller mill was adopted to cementVertical roller mill for raw Application p rocess materials Pre heater fan to raw mill 1750 x 1750 316 9995 1 Pre heater fan to raw mill 1700 x 1700 316 9995 1 By pass Duct 1250 x 1250 260 9995 1 Twin Cyclone exhaust gas fan 750 x 750 320 9995 1 Cooler Heat 750 x 750 260 Tight Seal when closed 9995 1 Cooler air Primary Air fan 500 x 500 220 Isolation 995 1 8 KCP Limited Ramakrishna Cements INDUSTRIAL FANS (INDIA) PVT LTD, MULTI LOUVRE

raw mill inlet damper calibration kidsjugendtreffch

A raw mill fan is located between the cyclone separator and the bag filter The circuit will be designed to allow gas recirculation from the raw mill fan back to the inlet of the mill The duct of the mill inlet is to be equipped with a fresh air intake in order to adjust the mill inlet The grid material in the mill is then lifted to the separator with the help of raw mill circulating air fan In the grid separator, the disperse material is divided into two: the coarser material which is returned to the mill for further grinding, and the fine product leaves the separator at theNo Annexure Descriptioncement mill circulating fan barwnikispozywcze Cement mill notebook SlideShare circulation fans Separator fans 165 000 5650 400 x 3 each cement mill system there is a separator fan mill fan and actual load is 80 then the power consumption on these efficiency can be calculated as output shown in Table 2 Get Price contacthow to balancing cement mill fans circulating material will be substantial However, this system offers a low pressure drop across the mill thus requiring a circulating fan with lower power CAPACITY IN TPH (BASED ON BOND’S WORK INDEX PRODUCT FINENESS) CAPACITY IN TPH (BASED ON HARD GROVE INDEX PRODUCT FINENESS) CAPACITY CHART FOR CEMENT RAW MATERIAL GRINDINGPromac’s Global FootprintPower (kW) Raw grinding Raw mill fan 490 000 11 500 2500 Process fans are critical equipment in cement plants Figure 4 shows Get Price training manual for risk assessment in the cement industry Flow chart of roller mill adopting the external circulating system Get Price cms clinker flow daigram of raw mill in cement plant

- Russian Production Crusher Manufacturer

- pakistani industries using jaw crushers

- Mining Process Of Phosphate Mining In South Africa

- quartz powder vs silica sand difference

- mine drilling and blasting machine for sale

- stone jaw crusher fro primary and sendary crushing

- rock and stone crushers mobile

- 10 x 25 g2 grinding stone

- cast basalt manufacturing process in pune

- picture of ball mill machine

- mobile ncrete crushing plant hire victoria

- mobile horse portable s le for sale

- Produksi Batu Gamping Yang Masuk Kedalam Alat Peremuk Crusher

- automobile valve grinding machine

- german german made rock crushers for sale

- Ball Mill Low And High Oil Pressure System

- eccentric shaft in vibratory screens

- gold shaker le for sale in australia

- High Pressure Roller Grinding South Africa

- wanted to buy Jaw crusher in south africa

- al crusher manufacturer in nigeria

- mining processes and systems

- Screen Mesh For Aggregate Manufacturers In Italy Eu 2755

- Special Grinding Suppliers

- stone crushers price

- impact breakage between pieces of rock by jaw crusher

- gold mining equipment nz

- Ceramic Grinding Machinery Siitne

- the karnataka regulation of stone crushers rules 2014

- Rock crusher 3 Ft Standard For Sale

- mobile al jaw crusher for sale angola

- limestone sand plant design manual

- Portable Crushers Gravel Rock Price

- stone crusher for sale in malaysiacrushing plants

- qingdao meq industrial ltd manufactureplasticcrushingmachine

- specification of vibration feeder

- crusher machine sell aluminho

- cement mpanies electrical system diagrams pdf

- why is important to mine iron and phosphates

- Cement Lump Crusher Design