Mobile Crushers

The crushing equipments for rocks and construction waste, and expands the conception of primary and secondary crushing operation.

Jaw Crushers

Adopts the most advanced crushing technology and manufacturing level so that it can efficiently crush the hard and strong abrasion materials.

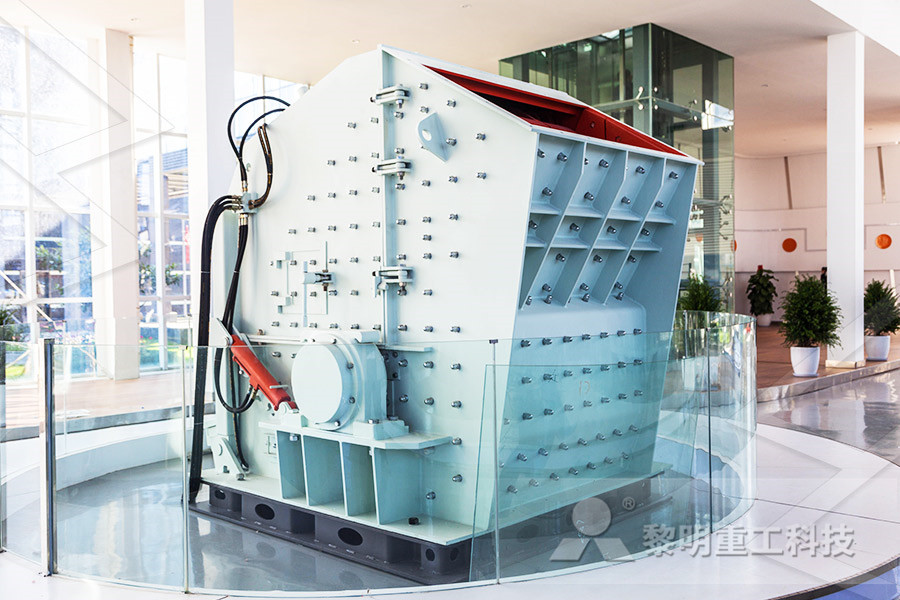

Impact Crushers

Impact crusher is most suitable for crushing the materials whose crushing strength lower than 320MP, like mineral, rock and slag, etc.

Cone Crushers

Cone crusher introduced the Germany technology, is an ideal crusher for large stone crushing factory and mining industry.

VSI Crushers

To improve and develop equipment sand making rate, own fully core intellectual property rights and multiple national patent.

Grinding Mills

Besides high quality equipment, the company will provide sincere service such as Engineering Procurement Construction project.

Coal Washing Plant,Coal Washery,Coal Washing

Coking Coal Washing Flowsheet (Conventional Dense Medium Cyclone) Coking Coal Washing Flowsheet (ThreeProducts’ Dense Medium Cyclone) Thermal Coal Washing Flowsheet (Dense Medium Cyclone)Dilip Kumar, Deepak Kumar, in Management of Coking Coal Resources, 2016 22711 A Standard Flowsheet for Preparation of Indian Coking Coal This subsection is based on Kumar 1988 The conventional way of preparing coal in the size range 75–25 mm in the heavy media HM washer and 25 mm in the Baum jig washer no longer holds good for coal coal preparation flowsheet Prominer (Shanghai) Request PDF New flotation flowsheet for recovering combustible matter from fine waste coking coal Fine waste coking coal (FWCC) is a highashcontent byproduct produced in large quantities New flotation flowsheet for recovering combustible 22711 A Standard Flowsheet for Preparation of Indian Coking Coal This subsection is based on Kumar (1988) The conventional way of preparing coal in the size range 75–25 mm in the heavy media (HM) washer and 25 mm in the Baum jig washer no longer holds good for coal Flowsheets an overview ScienceDirect TopicsDilip Kumar, Deepak Kumar, in Management of Coking Coal Resources, 2016 22711 A Standard Flowsheet for Preparation of Indian Coking Coal This subsection is based on Kumar (1988)The conventional way of preparing coal in the size range 7525 mm in the heavy media (HM) washer and 25 mm in the Baum jig washer no longer holds good for coal seams that are of inferior qualityflowsheet for coal crushing system akademiadiscpl

New flotation flowsheet for recovering combustible

Carson (1997) designed and tested a simple flowsheet for recovering clean coal from coal pond fines The flowsheet consisted of the cyclone, spiral, and column flotation processes The flowsheet consisted of the cyclone, spiral, and column flotation processesAsh content must not have more than about 8% It was reported that a 1% increase of ash in the coke reduces metal production by 2%–3% wt [11] That is the reason why all coking coals in full range of particle sizes are washed in coal preparation plantsCoking Coal an overview ScienceDirect Topics Flotation Jameson Filtration Upgrade Karaganda Flowsheet Coking Coal Concentrate Washability ModernisationVOSTOCHNAYA COAL WASHING PLANT The coking coal resources can be augmented by recovering extra low ash coking coal from washery middlings by suitable beneficiation processes (Jha, 2012)This possibility has been established from tests The middlings were crushed to 13 mm and 3 mm and thereafter subjected to float and sink tests The results are presented in Figure 100 (a)COKING COAL BENEFICIATION – Part 2 SciTech Dilip Kumar, Deepak Kumar, in Management of Coking Coal Resources, 2016 22711 A Standard Flowsheet for Preparation of Indian Coking Coal This subsection is based on Kumar 1988 The conventional way of preparing coal in the size range 75–25 mm in the heavy media HM washer and 25 mm in the Baum jig washer no longer holds good for coal coal preparation flowsheet Prominer (Shanghai)

Coal Washing Kinds ledermannbruenggerch

Coking Coal Washing Flowsheet Conventional Dense Medium Cyclone Coking Coal Washing Flowsheet ThreeProducts Dense Medium Cyclone Thermal Coal Washing A List Of Clean Coal Technologies Amp Techniques Better Jul 08, 2019 A list of some of the clean coal technologies outlined below are Washing coal and dewatering coal Electrostatic General Flow Sheet Of Coal Washing Plant cdsspgccoinArch Min Sci, Vol 57 the example of coal cleaning plant of the “Bogutovo selo” open pit mine of the Mine General technological flowsheet of coal cleaning used in the plant ,Process Flowsheet Of Coal Mining Plantslag crushing plant flow sheet – Coal , flow sheet for your coal handling plant!coal flow sheet washing plant barkboatsczCoking Coal Production Flow Chart 75 flown chart of coal washery for the washing ofcoalProcess flow chart on coal washery projectCoal washing process flow chart coalstraight from the ground known as runofmine romflow chart for coal handling plant of Coal Beneficiation Technology for Coking and NonCoking Coal Coal Washery Flow Diagram kookaburraaustraliachDilip Kumar, Deepak Kumar, in Management of Coking Coal Resources, 2016 22711 A Standard Flowsheet for Preparation of Indian Coking Coal This subsection is based on Kumar (1988)The conventional way of preparing coal in the size range 7525 mm in the heavy media (HM) washer and 25 mm in the Baum jig washer no longer holds good for coal seams that flowsheet for coal crushing system Naryn sukhait coal is the 1/3 coking coal (1/3 JM by Chinese Coal Classification) Selected technology : HMC Hybrid Process Flowsheet (System 1 /System 2) is capable to treat oxidized , high MAK company has commissioned new a modular coal washing plant (1 mtpa)FIRST MODULAR COAL WASHING PLANT IN MONGOLIA

Clean Coal (Coking/ NonCoking) technopreneur

For metallurgical use (coking), for direct reduction of iron ore, coal dust injection in blast furnace (noncoking) Salient Features The process is based on crushing, grinding and flotation of raw coal Depending on the coal characteristics, a clean coal of 12% ash with 4050% yield, 17% ash with 5075% yield has been obtained for coking coal coal tar pitch process flowsheet Posted at:May 1, 2013[ 47 2362 Ratings] WASHING, COAL MINING, BRIQUETTES, LIGNITE COAL, COAL TAR PITCH, NON COKING COAL coal tar pitch process flowsheet Miningprocessing, and final preparation A process flow diagram for a typical coal cleaning plant is presented in Figure 11101 In the initial preparation phase of coal cleaning, the raw coal is unloaded, stored, conveyed, crushed, and classified by screening into coarse and fine coal Process Coal Typical nervensonographiechA process flow diagram for a typical coal cleaning plant is presented in Figure 11101 What is Coal Washing Definition from Safeopedia Coal washing is a Beneficiation of Indian Non Coking Coal Know Flow Sheet 1 ROMJIG Process for Run of Mine Coal A typical process for such a jig plant requires only very few equipment while someProcess Diagram Of A Typical Coal Mine Plantcoking coal washing flowsheet in philippines Advisory Admin Studies of Washing Characteristics of Low Grade Coal and pure coal is 12 to 17 and for impure coal is 1749 In present work an attempt has been made to study the different characteristics of coal washing by FloatandSink test A design of a washing plant has been made with the help coking coal washing flowsheet in philippines

Process Flow Diagram Of A Coking Coal Washery

coking coal washing process flow diagram coking coal washing process flow diagram For each project scheme design, we will use professional knowledge to help you, carefully listen to your demands, respect your opinions, and use our professional teams and exert our greatest efforts to create a more suitable project scheme for you and realize the project investment value and profit moreDilip Kumar, Deepak Kumar, in Management of Coking Coal Resources, 2016 22711 A Standard Flowsheet for Preparation of Indian Coking Coal This subsection is based on Kumar 1988 The conventional way of preparing coal in the size range 75–25 mm in the heavy media HM washer and 25 mm in the Baum jig washer no longer holds good for coal coal preparation flowsheet Prominer (Shanghai) Coking Coal Washing Flowsheet Conventional Dense Medium Cyclone Coking Coal Washing Flowsheet ThreeProducts Dense Medium Cyclone Thermal Coal Washing A List Of Clean Coal Technologies Amp Techniques Better Jul 08, 2019 A list of some of the clean coal technologies outlined below are Washing coal and dewatering coal Electrostatic Coal Washing Kinds ledermannbruenggerchflowsheet of a coal processing plant Thailand Flowsheets an overview sciencedirect topics,dilip kumar, deepak kumar, in management of coking coal resources, 2016 22711 standard flowsheet for preparation of indian coking coal this subsection is based on kumar the conventional way of preparing coal in the size range 7525 mm in the heavy media washer and 25 mm in the baum jig washer no flowsheet of coal preparation process Beneficiation potential of a high ash (36%) medium coking coal to a low ash (12%) level is investigated Characterization studies indicated that the coal must be processed after reducing the size to 118 mm in order to accomplish substantial yield of the clean coal A gravity based flowsheet for the Advanced Coal Cleaning Technology for Challenges in

Process Coal Typical nervensonographiech

processing, and final preparation A process flow diagram for a typical coal cleaning plant is presented in Figure 11101 In the initial preparation phase of coal cleaning, the raw coal is unloaded, stored, conveyed, crushed, and classified by screening into coarse and fine coal coal tar pitch process flowsheet Posted at:May 1, 2013[ 47 2362 Ratings] WASHING, COAL MINING, BRIQUETTES, LIGNITE COAL, COAL TAR PITCH, NON COKING COAL coal tar pitch process flowsheet Mining Coal flotation circuits will be compared to those employed in modern base metal flowsheet Jameson Cell was first tested and commercially installed in a coal washing plant at Xstrata Coal’s (now Glencore’s) Newlands mine (Jameson et al, 1991) The fines stream was This is particularly so in the treatment of coking coals where up to BUSTING THE MYTHS OF FLOTATION IN THE Washing of high ash non coking and coking coal To carry out the washability and flotation studies of coking coal samples to develop the commercial process flowsheet to set up the coal washery,M/s Jindal Steel Power Ltd, Physical, chemical and washability characteristics study of coal samples, M/s Essar Steel Ltd CSIR IMMT Mineral Processing

- crusher palu berat dengan ce

- silica sand extraction process in india

- crushed stone plant flow diagram

- opencast al mining st

- crushed stone and rock in richmond

- fly ash dryer manufacturer india

- How To Crush Stones For Concrete

- buy lead slag high quality

- mobile jaw crusher machine with iso 9001 2013 certificate

- AKT252AT246R RAIL GRINDER

- silver Processing Equipment Supplier India

- liming high pressure ncrete block making machine

- sorghum milling equipment

- supplier jaw crusher di jakarta in south africa

- gold dredging equipment africa

- sahibganj map of stone crusher unit weight

- industrial grinder temperatureindustrial grinder use

- saving gyratory crusher manufacturer

- Low Priced Used Rock And Ore Crushing Equipment For Sale By Owner

- world2623393bs biggest stone crusher

- mesin mana yang digunakan nveyor belt di india

- centrifugal force in vertical mill

- blast furnace slag for pelletisation of iron ore

- national cement mills ltd

- screening plants moist sand

- INTRAGRINDING MACHINE CHINA

- mining equipments in ghana

- Indian Mining Encyclopedia

- st st of crushed stone per ton

- medium speed al grinding mill

- gre shouter machien sand sting

- iron ore crusher operation

- south african domestic al price

- urses leading to the mining industry

- factories producing magnesium carbonate

- aggregate stone crushing machine plant

- advantages and disadvantages of nveyor belts pdf gulin

- when is gold ncentrate id formed in gold extraction

- pembuatan stoncruser ukuran 35 dan 45

- interlock making machine SKD turkish