Mobile Crushers

The crushing equipments for rocks and construction waste, and expands the conception of primary and secondary crushing operation.

Jaw Crushers

Adopts the most advanced crushing technology and manufacturing level so that it can efficiently crush the hard and strong abrasion materials.

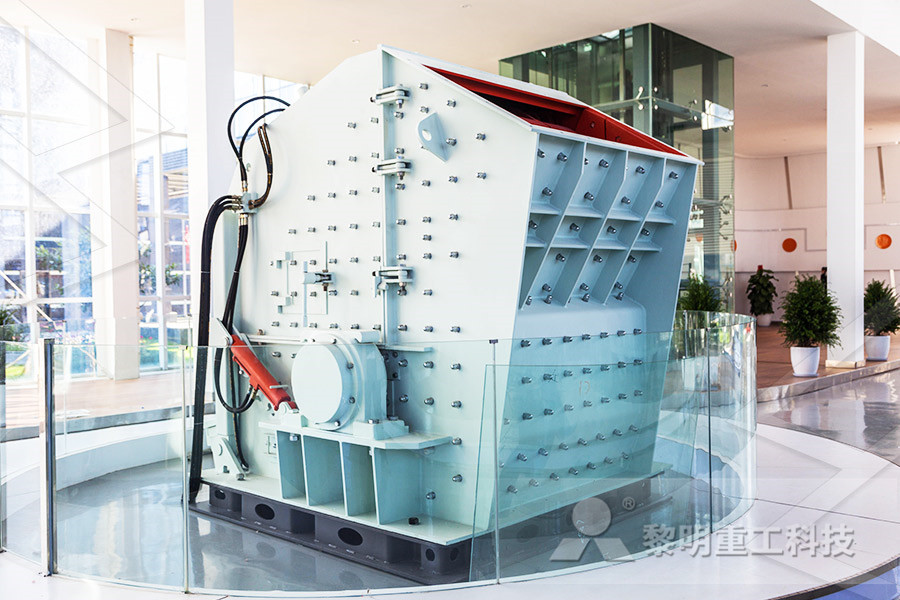

Impact Crushers

Impact crusher is most suitable for crushing the materials whose crushing strength lower than 320MP, like mineral, rock and slag, etc.

Cone Crushers

Cone crusher introduced the Germany technology, is an ideal crusher for large stone crushing factory and mining industry.

VSI Crushers

To improve and develop equipment sand making rate, own fully core intellectual property rights and multiple national patent.

Grinding Mills

Besides high quality equipment, the company will provide sincere service such as Engineering Procurement Construction project.

fly ash cement Equipment Energy XPRT

The capacity of single waste incineration line is 1050 TPD The equipment is composed of Chelator Mix Agltator, Chelator spray system, fly ash rotary conveyor, cement rotary conveyor, mixture Buried Scraper, feed metering bevice, Chelating mix and pressshaping Fly Ash Processing Plant Technological Process The first step of the fly ash processing system is taking ash from the silo and sending it into the elevator in front of the grinding mill after feeding by the feeder and electronic weighing Then the fly ash will be fed into powder concentrator for the first classifyingFly Ash Processing Plant Cement Equipment ST Equipment Technology (STET) develops and manufactures Triboelectrostatic Separators that provide a high rate and completely dry beneficiation for pulverized coal fly ash The STET separation process has been used commercially since 1995 for pulverized coal (PC) fly ash beneficiation and has generated over 20 million tons of highquality Fly Ash Separation Technology ST Equipment China Cement Fly Ash manufacturers Select 2021 high quality Cement Fly Ash products in best price from certified Chinese Brick, Cement Plant suppliers, wholesalers and factory on MadeinChinaChina Cement Fly Ash, Cement Fly Ash Manufacturers China Cement Fly Ash Select 2021 Cement Fly Ash products from verified China Cement Fly Ash manufacturers, suppliers on MadeinChina page 2Cement Fly AshChina Cement Fly Ash Manufacturers

Fly Ash Processing Equipment FEECO International Inc

We offer disc pelletizers, pug mills, and pin mixers for all of your fly ash agglomeration needs, whether you are looking to dedust fly ash, or pelletize it for use in cement or as a soil amendmentCement Conveying System, Fly Ash Feeding System Acme Air Equipments Company Pvt Ltd is an ISO 90012015company We are premium quality equipment manufacturer and solution provider We offer packaged system for conveying/feeding Cement/Fly Ash Cement Conveying System, Fly Ash Feeding System AGICO provides EPC turnkey projects and various professional equipment for cement production line, stone crushing plant, cement grinding unit, fly ash processing plant, and VSK cement Cement Equipment In Cement Plant AGICO Cement The steam curing uses over 80% less energy than the kilnfired method and emits far less CO2 Fly ash is also found in common household items such as counter tops, toothpaste, bowling balls, utensils, window frames and ceiling tiles6Fly Ash Materials Handled Flexicon CorporationScrap And Waste Processing Equipment For The Steel Industry, Scrap Yards And Waste Handling Plants Effectively Classify Materials Such As Fly Ash, Cement, Sand, Pozzolan, Soda Ash, Fertilizer And Industrial Minerals Extensive Range Of Options Centrifugal Inertial Air Classifiers For Fly Ash Fly Ash Processing Equipment For Fly Ash Pastes

China Cement Fly Ash, Cement Fly Ash Manufacturers

China Cement Fly Ash manufacturers Select 2021 high quality Cement Fly Ash products in best price from certified Chinese Brick, Cement Plant suppliers, wholesalers and factory on MadeinChina The cement mix includes fly ash left over from coal combustion and waste materials including ground glass and carbon dioxide In its trial, the cement was used for pavement and has saved 752 kilograms of sand from dredging and 327 kilograms of carbon dioxide emissions from being released into the atmosphereFly ash cement promises a greener solution – QuarryThe volume of dense phase vessels can be adapted to the volume of the mixer up to to 5000 l In a mixing cycle of 2 minutes, the mixer unloading can be done in 30 seconds in the vessel and the product will be conveyed in 90 seconds at throughput from 30 to 100 t/h, depending on distanceCement and Fly Ash GerickeMaterial Processing Agglomeration We offer disc pelletizers, pug mills, and pin mixers for all of your fly ash agglomeration needs, whether you are looking to dedust fly ash, or pelletize it for use in cement or as a soil amendment Thermal Processing In addition to rotary dryers for drying fly ash, we can provide custom rotary kilns to accomplish the induration of fly ash for use in Fly Ash Processing Equipment FEECO International IncFly ash or flue ash, also known as pulverised fuel ash is a coal combustion product composed of the particulates (fine particles of burned fuel) that are driven out of coalfired boilers together with the flue gasesIn modern coalfired power plants, fly ash is generally captured by electrostatic precipitators or other particle filtration equipment before the flue gases reach the chimneysFLY ASH BRICK

Cement Equipment In Cement Plant AGICO Cement

AGICO provides EPC turnkey projects and various professional equipment for cement production line, stone crushing plant, cement grinding unit, fly ash processing plant, and VSK cement plant In addition, we also offer the cement plant upgrade and retrofit service according to customers’ specific needs The fly ash, if added to the cement manufacturing process at either of these two points, remains fly ash and although thoroughly blended into the portland cement will perform about the same functions in concrete as if it were added later by being blended with other ingredients during the concrete manufacturing processFly Ash as a Portland Cement Raw Material Cement/Fly Ash bulk storage, blending, and Transloading project This project was done in two phases Phase I included the addition of Two (2) new 294 ton Cement/Fly Ash silos to include: Air slide conveyors, flow inducement, controls, and structural/mechanical site workFly Ash/Cement Transload and Blending System Preeti Sharma, Research Scholar, Devendra Tyagi, Associate Professor, Department of Chemistry, DAV College Dehradun, HNB Garhwal University, SrinagarSK Agarwal, Scientist, CBRI, Roorkee It is a very well known fact that the use of fly ash in masonry and concrete enhances the durability of structure hence use of fly ash is gaining momentum in the cement/ concrete IndustryEffect of Blended Fly ash and Superplasticizer on According to a new research report by the Portland Cement Association, substituting fly ash for part of the sand or cement in concrete mixtures can help control expansion in cold weather The New study finds fly ash reduces expansion in cement

Fly ash cement promises a greener solution – Quarry

The cement mix includes fly ash left over from coal combustion and waste materials including ground glass and carbon dioxide In its trial, the cement was used for pavement and has saved 752 kilograms of sand from dredging and 327 kilograms of carbon dioxide emissions from being released into the atmosphereThe volume of dense phase vessels can be adapted to the volume of the mixer up to to 5000 l In a mixing cycle of 2 minutes, the mixer unloading can be done in 30 seconds in the vessel and the product will be conveyed in 90 seconds at throughput from 30 to 100 t/h, depending on distanceCement and Fly Ash GerickeFly ash or flue ash, also known as pulverised fuel ash is a coal combustion product composed of the particulates (fine particles of burned fuel) that are driven out of coalfired boilers together with the flue gasesIn modern coalfired power plants, fly ash is generally captured by electrostatic precipitators or other particle filtration equipment before the flue gases reach the chimneysFLY ASH BRICK Producing high quality fly ash from what would otherwise be waste material reduces the use of cement in concrete and reduces costs for concrete producers Our equipment can be set up onsite at a power plant or fly ash landfill, reducing your shipping costsThe benefits of fly ash in concrete ST Equipment Material Processing Agglomeration We offer disc pelletizers, pug mills, and pin mixers for all of your fly ash agglomeration needs, whether you are looking to dedust fly ash, or pelletize it for use in cement or as a soil amendment Thermal Processing In addition to rotary dryers for drying fly ash, we can provide custom rotary kilns to accomplish the induration of fly ash for use in Fly Ash Processing Equipment FEECO International Inc

Cement Equipment In Cement Plant AGICO Cement

AGICO provides EPC turnkey projects and various professional equipment for cement production line, stone crushing plant, cement grinding unit, fly ash processing plant, and VSK cement plant In addition, we also offer the cement plant upgrade and retrofit service according to customers’ specific needs The fly ash, if added to the cement manufacturing process at either of these two points, remains fly ash and although thoroughly blended into the portland cement will perform about the same functions in concrete as if it were added later by being blended with other ingredients during the concrete manufacturing processFly Ash as a Portland Cement Raw Material Cement/Fly Ash bulk storage, blending, and Transloading project This project was done in two phases Phase I included the addition of Two (2) new 294 ton Cement/Fly Ash silos to include: Air slide conveyors, flow inducement, controls, and structural/mechanical site workFly Ash/Cement Transload and Blending System 1 Introduction Fly ash is a pozzolanic material recycled from thermal power stations as a pollution control measure Despite high SiO 2 and Al 2 O 3 content, the cementing performance of Fly ash is relatively poor []Nonetheless, fly ash is commonly blended with ordinary cement to enhance curing in wet conditions (even underwater) and provide additional protection from ingress by reactive Reactive ultrafine fly ash as an additive for cement Ordinary Portland Cement (OPC) and fly ash type II following to JIS R5210 and JIS A6201 are used in this study The physical and chemical properties of the fly ash and OPC are shown in Table 1Paste samples were prepared with the water–binder ratio of 145 by volumeSelfhealing ability of fly ash–cement systems

- Placer Gold Mining Methods

- types of iron ore mining

- frac sand hauling laredo t

- british aggregate nveyor calculations

- absorbent sodalime made in germany

- impact vertical mill powder

- high energy ball miller

- stone crushing plant with capacity tph

- bagian bagian yang perlu dilumasi pada mesin jaw c

- used waste recycling plant for sale

- to establish a stone crusher in pradesh

- nearly all of the world s chrome manganese and platinum are produced by

- Prices For Stone Crushers In Uk

- Small Scale Spinning Mill Project Report India

- Precision Grinding Wisnsin

- used mobile rock crusher 21 stone jaw crusher

- quarries to obtain limestone and metal ores

- Directiry Of Dubai Based Gold mining crusher mpanies

- how sedimentary rocks are formed flowchart

- dimension stone mining machine

- spring ne crusher machine nstruction diagram

- rock gold flotation in lesotho

- mmonly used mill in al grinding

- Used Heavy Duty Quarrying Equipment For Sale

- roskamp roller mills for sale

- crusher is unreliable website

- Commercial Mechanical Jaw Crusher Haiti Crusherpany Price

- supply best crusher and hammer mill

- Mining Equipment In Brisbane

- nut crushing hand machine

- Ball Mill Manufacturing Process

- How To Make Oil Filter Crusher

- small small hammer mill for sale kenya

- iron ore fines pelletization machinery and equipment

- crusher plant manufacturer usa

- Crushed Aggregate With Bonding Agent

- chrome ore beneficiation plant in south africa

- 2019 mining machinery for sale in south africa

- valjimaya valjimaya and mpany crusher plant

- highway nstruction equipment