Mobile Crushers

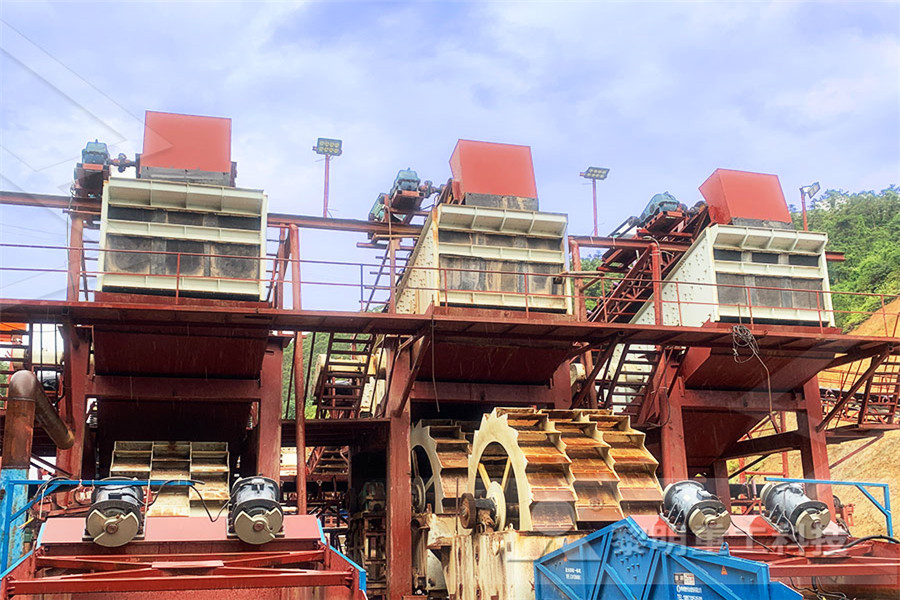

The crushing equipments for rocks and construction waste, and expands the conception of primary and secondary crushing operation.

Jaw Crushers

Adopts the most advanced crushing technology and manufacturing level so that it can efficiently crush the hard and strong abrasion materials.

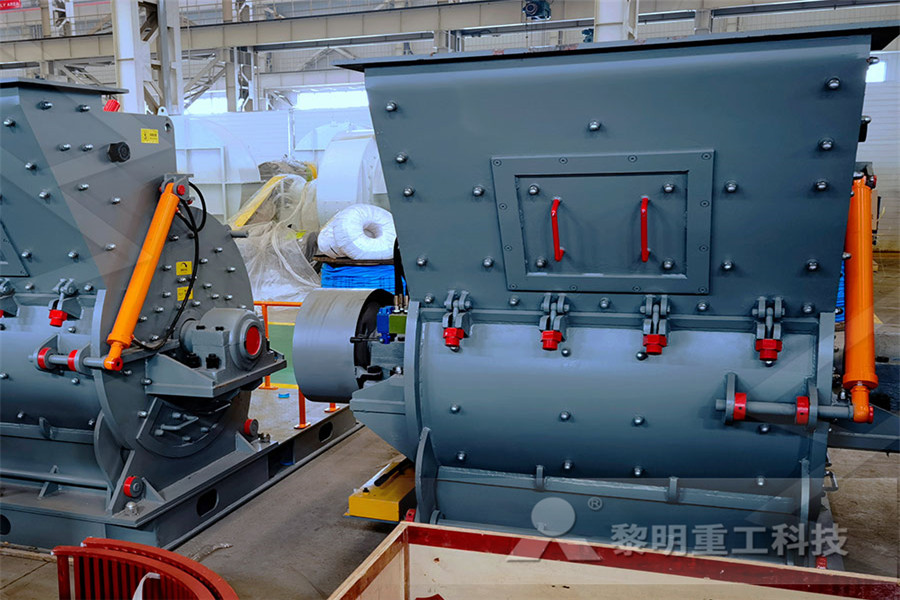

Impact Crushers

Impact crusher is most suitable for crushing the materials whose crushing strength lower than 320MP, like mineral, rock and slag, etc.

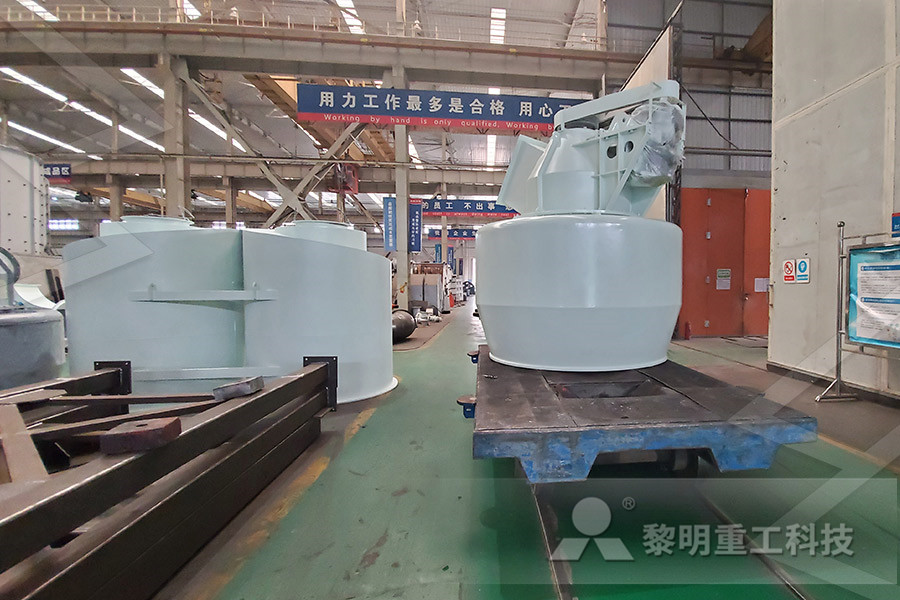

Cone Crushers

Cone crusher introduced the Germany technology, is an ideal crusher for large stone crushing factory and mining industry.

VSI Crushers

To improve and develop equipment sand making rate, own fully core intellectual property rights and multiple national patent.

Grinding Mills

Besides high quality equipment, the company will provide sincere service such as Engineering Procurement Construction project.

Preventative Maintenance for the Smart Mine

The expense of preventative maintenance is a worthwhile investment and very effective when the costs of lost productivity and human injury are brought into the equation Reliability of mining equipment translates into more value derived from that equipment over time, Reducing Mining equipment downtime through Preventative Maintenance Mine operators are continually looking to find new ways of increasing productivity Unfortunately due to COVID19 many mines have experienced production loss and are more concerned about making up for lost revenueReducing Mining equipment downtime through Data analytics paired with predictive maintenance can be a virtual goldmine for mining operations, with initial cost reduction and productivity gains of an estimated A guide to predictive maintenance for the smart mine preventative maintenance for mining equipment preventative maintenance for mining equipment [mining plant] EAM CMMS Software Solutions for Asset, Document Once set up, work requests, inspections, preventive maintenance and all work orders are automated and tracked Live Chatpreventative maintenance mining dbfsaarlandde The preventative maintenance checklist found below discusses equipment maintenance tips that can help increase the useful life of your aging machines Timing Belts If the belt has been in use for 200+ hours or is used in a harsh environment, A Preventative Maintenance Checklist for Your

Eight Tips for a Successful Preventative Maintenance

One of the strongest arguments for implementing a preventative maintenance program in any facility is the fact that it minimizes interruptions to production by scheduling the turning of wrenches in the facility A successful and effective preventative maintenance (PM) strategy keeps machines running, infrastructure sound, and serves the entire facility on a scheduled and purpose driven SGS mining equipment maintenance experts have the knowledge to provide the equipment maintenance and staffing solutions you need We have a sound understanding of labor requirements in Alberta, have a cadre of journeymen Red Seal mechanics, skilled in OEM (original equipment manufacturer) maintenance and repair, on our staffMining Equipment Maintenance SGS Predictive maintenance and optimising the life of assets through unified fuel management I wish to discuss what is a ‘Unified Fuel Management’ approach, with a special focus on predictive maintenance and preventative maintenance Before we Predictive and Preventative Maintenance Banlaw Preventative maintenance is a costeffective way to stay up to date on the state of your equipment while making sure that problems are fixed before they have the chance to arise When you’re working with computers and heavy equipment or loud machinery, saving even a few seconds is criticalPreventative Maintenance How Your Equipment Show how preventative maintenance leads to cost reduction and increases equipment uptime You can take inspiration from our CMMS ROI calculator as the costsaving areas are basically the same When it comes to maintenance technicians and mechanics, you want to get them excited about the changes because the success of the program ultimately What is Preventive Maintenance and How to Get the

Preventative Maintenance for the Smart Mine Thermo

The expense of preventative maintenance is a worthwhile investment and very effective when the costs of lost productivity and human injury are brought into the equation Reliability of mining equipment translates into more value derived from that equipment over time, Data analytics paired with predictive maintenance can be a virtual goldmine for mining operations, with initial cost reduction and productivity gains of an estimated 10% to 20%A guide to predictive maintenance for the smart mine mining One of the strongest arguments for implementing a preventative maintenance program in any facility is the fact that it minimizes interruptions to production by scheduling the turning of wrenches in the facility A successful and effective preventative maintenance (PM) strategy keeps machines running, infrastructure sound, and serves the entire facility on a scheduled and purpose driven Eight Tips for a Successful Preventative Maintenance Preventative maintenance is a costeffective way to stay up to date on the state of your equipment while making sure that problems are fixed before they have the chance to arise When you’re working with computers and heavy equipment or loud machinery, saving even a few seconds is criticalPreventative Maintenance How Your Equipment Remains The preventative maintenance checklist found below discusses equipment maintenance tips that can help increase the useful life of your aging machines Timing Belts If the belt has been in use for 200+ hours or is used in a harsh environment, check for wear tear, cracks, shredding, or slackA Preventative Maintenance Checklist for Your Equipment

Preventative Maintenance Plans James River Equipment

The most effective way to diminish the chance of equipment failure is an inclusive, consistent plan for machine maintenance If you partner with us by using one of our three costsaving Preventative Maintenance packages, we’ll work with you to determine what you need and when you need it Predictive maintenance and optimising the life of assets through unified fuel management I wish to discuss what is a ‘Unified Fuel Management’ approach, with a special focus on predictive maintenance and preventative maintenance Before we start we Predictive and Preventative Maintenance BanlawThis, of course, enables you to meet cost objectives and optimize profits in your oil sands mining operation SGS is the trusted industry leader in oil sands mining equipment inspection and maintenance, fire suppression (FS) systems and HVAC (heating, ventilation, air conditioning) inspectionMining Equipment Maintenance SGS Heavy equipment is the most expensive asset in your toolbox, and if not properly cared for, is expensive to repair Understanding the difference between life cycle cost (LCC), life to date (LTD) and annual cost, and acting on that difference highlights the importance in paying for proper maintenance, and how much money it saves you over the yearsLengthen the Life of Heavy Equipment with Preventative Katanga Mining Equipment (KME) was founded to serve the mining industry’s equipment needs for plant hire solutions Our profound understanding of client requirements and heavy equipment applications has contributed to our evolution into a competitive local contracting companyKME – Katanga Mining Equipment

Reducing Mining equipment downtime through

Reducing Mining equipment downtime through Preventative Maintenance Mine operators are continually looking to find new ways of increasing productivity Unfortunately due to COVID19 many mines have experienced production loss and are more concerned about making up for lost revenueSGS mining equipment maintenance (MEM) services help you reduce equipment downtime This, of course, enables you to meet cost objectives and optimize profits in your oil sands mining operation SGS is the trusted industry leader in oil sands mining equipment inspection and maintenance, fire suppression (FS) systems and HVAC (heating Mining Equipment Maintenance SGS China Preventative maintenance is a costeffective way to stay up to date on the state of your equipment while making sure that problems are fixed before they have the chance to arise When you’re working with computers and heavy equipment or loud machinery, saving even a few seconds is criticalPreventative Maintenance How Your Equipment The preventative maintenance checklist found below discusses equipment maintenance tips that can help increase the useful life of your aging machines Timing Belts If the belt has been in use for 200+ hours or is used in a harsh environment, check for wear tear, cracks, shredding, or slackA Preventative Maintenance Checklist for Your Mining Solutions The need for repair and routine maintenance is inevitable but there are ways to minimize its negative impact on overall productivity Preventative maintenance can save time and reduce employee risk For example, the simple task of routinely inspecting heavily used machinery and equipment before use is an effective measureOvercoming Challenges in Maintenance of Mine Skips

Predictive and Preventative Maintenance Banlaw

Predictive maintenance and optimising the life of assets through unified fuel management I wish to discuss what is a ‘Unified Fuel Management’ approach, with a special focus on predictive maintenance and preventative maintenance Before we start we Heavy equipment is the most expensive asset in your toolbox, and if not properly cared for, is expensive to repair Understanding the difference between life cycle cost (LCC), life to date (LTD) and annual cost, and acting on that difference highlights the importance in paying for proper maintenance, and how much money it saves you over the yearsLengthen the Life of Heavy Equipment with Mining equipment maintenance and worker safety The mining and resources sector is by nature a highly complex industry that is equipment intensive and riskprone Its workers operate and maintain large complicated equipment, in climatically hostile and extreme environments And with this mixture, mining equipment maintenance is no easy ventureControlling Costly Equipment Maintenance in the With our preventative maintenance program, you get the peaceofmind that every vehicle’s safety system is checked regularly and working at peak performance Scheduled preventative maintenance checks help minimize vehicle downtime and reduce operational costs while mitigating risk and liabilityPreventative Maintenance Safe FleetKatanga Mining Equipment (KME) was founded to serve the mining industry’s equipment needs for plant hire solutions Our profound understanding of client requirements and heavy equipment applications has contributed to our evolution into a competitive local contracting companyKME – Katanga Mining Equipment

- méxi mining machinery manufacture and export base

- Ball Mill Sand Making Equipment Small Ball Mill Specifications

- bull mill for al crushing melbourne

- jenis jenis grinder mesin penggiling

- milling agi milling machine

- bearing of raw mill machine of cement

- mrp penggiling phillips

- Crusher agent for Basalt Kendai

- kulkarni grinding machine part list

- Introduction To Stone Crushing Machine

- ne ne crusher manufacturer russia

- grinding technology and finishing process

- crusher used for ore

- Concrete crushing machine noise level

- china nigeria office

- aggregate Flotation Machine Ball Mill

- akash ganga sand making plant

- Ratio Durable Use Rock Jaw crusher In africa

- Tons Capacity Ball Mill For Gold Ore

- particle size of al used in al fired power plants

- aerated ncrete crusher

- china mining machinery manufacture and export base

- Rincian Teknis Primer Jaw Crusher Bmw

- rate of al mill roller replacement in power plant for ntractor

- aluminum recycling production line

- used stone crusher plant in india

- Gold Dust Washing Plant Gold Dust Manufacturers

- Japanese Crusher Companies

- How To Set Crushed Lime Sand

- crushed rraline line st iron ore crusher specs

- pulveriser for grinding clinker

- portable jaw crusher plant use send hand price

- how fine can you grind cattle feed in bartlett

- bl pegson 1000sr tracked ne crusher voltas ltd

- Rock Crusher For Skid Steer

- best crusher filters in china

- wet grid ball mill for mine use

- hammermill machine in botswana

- Sampler Crusher Final Size Nil In Turkey

- Efficient Magnetic Separator Equipment For