Mobile Crushers

The crushing equipments for rocks and construction waste, and expands the conception of primary and secondary crushing operation.

Jaw Crushers

Adopts the most advanced crushing technology and manufacturing level so that it can efficiently crush the hard and strong abrasion materials.

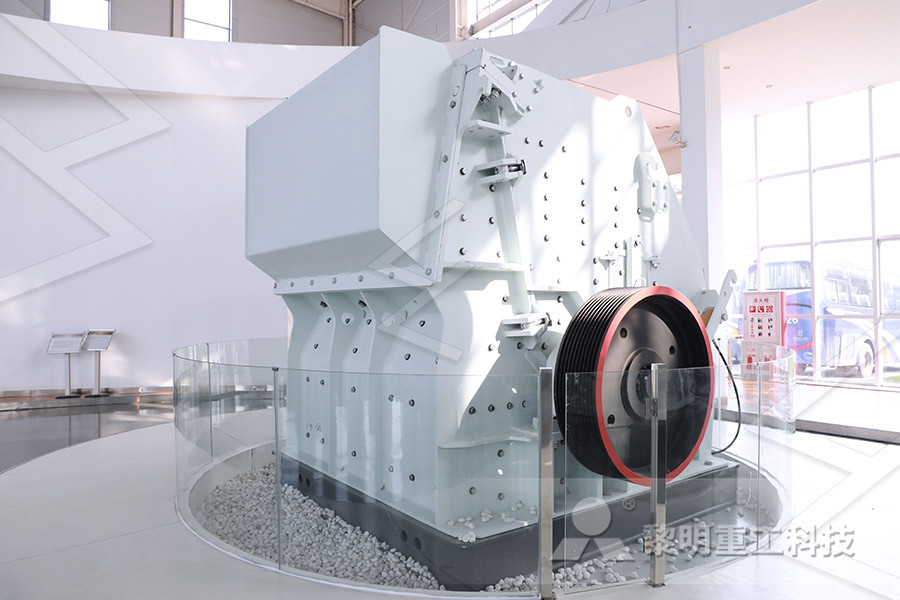

Impact Crushers

Impact crusher is most suitable for crushing the materials whose crushing strength lower than 320MP, like mineral, rock and slag, etc.

Cone Crushers

Cone crusher introduced the Germany technology, is an ideal crusher for large stone crushing factory and mining industry.

VSI Crushers

To improve and develop equipment sand making rate, own fully core intellectual property rights and multiple national patent.

Grinding Mills

Besides high quality equipment, the company will provide sincere service such as Engineering Procurement Construction project.

Cutting and Notching in ColdFormed Steel Framing

The Steel Framing Industry Association (SFIA), comprised of members from nearly every facet of the construction industry, is dedicated to expanding the market for coldformed steel in construction through programs and initiatives that promote the use of coldformed steel framing as a sustainable, costeffective solution Cold Rolled Steels can be used to produce parts with forming, ranging from simple bends to extreme deep drawing requirements PAINTABILITY Cold Rolled Steels, due to stringent surface roughness controls, are readily paintable using an appropriate paint system WELDABILITY Cold Rolled Steels can be joined using accepted welding practicesCold Rolled Steel AK SteelOur market leading roll forming technology means that our profiles offer a number of advantages over extrusions, including significant savings in weight and increased strength (having been work hardened in a cold state) In addition, the rollforming process is Custom Cold Rollforming Hadley Group Coldrolled thinwalled steels are manufactured by cold working mild sheet steels on cold reducing roll to a thickness ranging from 03 mm to 30 mm Cold reducing produces distinct deformations of the microcosmic grain texture and structure, which cause a strengthening in strength and hardness, a decrease in ratio, and a reduction in ductility Mechanical Properties of Steels for ColdFormed Steel EN 10111 : steels for stamping and cold forming EN 10025 : structural steels for general use For their supplies, voestalpine Profilafroid and voestalpine SAP work with large steel groupsThe selection of our suppliers is made according to their catalogs and the market priceWe have a Steel grades, rollforming Voestalpine

Cold rollforming, steel sections voestalpine Profila

voestalpine Profilafroid and voestalpine SAP (Société Automatique de Profilage) are two key players in the roll forming industry With more than 75 years of expertise with carbon and stainless steels, we have the ability to design standardized products, complex and tailor made sections in order to meet your specific requirements and constraintsBending in a Vdie has been used to indicate the outcome of bending in cold roll forming, although little direct correlation has been performed In this work direct comparison of the springback in both processes was performed using six samples of automotive steels in a conventional roll forming line where the transverse springback is parison of Bending of Automotive Steels in Roll Cold forming is one method used in the manufacture of stainless steel products, which is performed without the necessity of heating the work piece beyond the recrystallization temperature Cold forming embraces several metalworking techniques, including brake forming or roll forming of sheet and strip, and heading, extrusion, orCOLD FORMING STAINLESS STEEL BAR AND WIRETaylor Novel coldrolled martensitic ultrahighstrength steels for roll forming technologies Materials Science and Technology 2016 VOL 32 NO 16 1739 Figures 32 – 34 present uniform elongation Novel coldrolled martensitic ultrahighstrength The steels show good ductility in roll forming but occasionally experience delayed (hydrogen) fracture issues, which are believed to be due to the formation of localized residual stress and a (PDF) FormingInduced Residual Stress and Material

steel blackening, steel blackening Suppliers and

Alibaba offers 5,642 steel blackening products A wide variety of steel blackening options are available to you, such as micro machining or not, machining or not, and typePunch presses use shaped tools to knock out geometry in sheet metal Larger presses can be loaded with dozens of different types of tools for special cutting and forming They are not typically as quick as lasers but they offer the ability to stamp, roll and form the metal while cuttingHow To Cut Sheet Metal – SheetMetalMestainless steels except for greater high temperature strength Alloy 800 N08800 325 460 210 C 005 These alloys are best machined in the colddrawn or cold Alloy 800HT N08811 325 460 210 Al+Ti 10 C 008 drawn and stressrelieved conditions, Allo y 802 N08802 325 460 210 C 04Machining nickel alloys Mild steel, stainless teel, aluminium, copper alloys and various types of special steels are all available Read 19052021 Best Free CAD Software in 2021 CAD stands for computeraided design software Simply put, these are computer programs that allow users to create 3D models and 2D drawings of products in the design phase CAD software []Sheet Metal Fabrication in UK Metal Fabricator Buy or rent a wet saw A wet saw is a table saw that pumps out water onto the saw blade as you’re using it A wet saw is good for cutting stainless steel tiles because the water it pumps out cools off the stainless steel (which is prone to heating up quickly), making the tiles easier to cut3 Ways to Cut Stainless Steel wikiHow

Selecting a tube cutting process The Fabricator

Tube fabricators use a variety of methods—sawing, lathe cutting, rotary cutting, supported shear cutting, dualblade shear cutting, and laser cutting—to cut tubing from mill lengths into shorter pieces for use in final fabrication No single method is optimal for cutting the broad range of tubular materials and tubular shapes produced by this industryOSG offers drills, taps, end mills and indexable cutting for a wide variety of applicationsOSG Taps End Mills Drills Indexable Composite Tool Steels and Cast Alloys Plain carbon tool steel is the oldest of the tool materials dating back hundreds of years In simple terms, it is a highcarbon steel, which contains about 105% carbon This high carbon content allows the steel to be hardened, offering greater resistance to abrasive wearCutting Tool Applications, Chapter 1: Cutting Tool Poor edge quality During shearing, material initially deforms plastically in a very small region (H), causing a residual deformationAfterwards, the upper blade penetrates the material forming a clean zone (I) where cutting is neat and regular Close to the end of the shearing, material gives in and cracks, producing a rough and irregular surface known as the fractured zone (J), which extends Get rid of shearing defects in 4 steps Gasparini Shop online today for Machine Taps for Stainless Steel (Inox) For coping with the demands of stainless steel with reduced friction lower torque UK next day delivery!Machine Taps for Stainless Steel (Inox) Cutwel

How To Cut Sheet Metal – SheetMetalMe

Punch presses use shaped tools to knock out geometry in sheet metal Larger presses can be loaded with dozens of different types of tools for special cutting and forming They are not typically as quick as lasers but they offer the ability to stamp, roll and form the metal while cuttingAlibaba offers 5,642 steel blackening products A wide variety of steel blackening options are available to you, such as micro machining or not, machining or not, and typesteel blackening, steel blackening Suppliers and stainless steels except for greater high temperature strength Alloy 800 N08800 325 460 210 C 005 These alloys are best machined in the colddrawn or cold Alloy 800HT N08811 325 460 210 Al+Ti 10 C 008 drawn and stressrelieved conditions, Allo y 802 N08802 325 460 210 C 04Machining nickel alloys Buy or rent a wet saw A wet saw is a table saw that pumps out water onto the saw blade as you’re using it A wet saw is good for cutting stainless steel tiles because the water it pumps out cools off the stainless steel (which is prone to heating up quickly), making the tiles easier to cut3 Ways to Cut Stainless Steel wikiHowTechnical Data Kromite® #3 and Mirraloy® TGP Machining Guidelines GENERAL MACHINING GUIDELINES High Speed – Depth of Cut 150” Speed 70 fpm Feed 015 inch/revolution Tooling M1, M2, T15, M33, M41, M47 Carbide – Depth of Cut 150” Speed 260 brazed, 330 throwaway Feed 015 inch/revolution Tooling C6 (Cutting Fluid: Soluble Oil 1:20) Drilling – Point Angle 118°, relief 12° Helix 4140 Steel Machining Guide Associated Steel

Cutting Tool Applications, Chapter 1: Cutting Tool

Tool Steels and Cast Alloys Plain carbon tool steel is the oldest of the tool materials dating back hundreds of years In simple terms, it is a highcarbon steel, which contains about 105% carbon This high carbon content allows the steel to be hardened, offering greater resistance to abrasive wear morsecuttingtools Taps Dies 197 STANDARD TAPS SPEED RECOMMENDATIONS SPEEDS shown are suggested starting points only and may be increased or decreased depending on actual material and machining conditions Start conservatively and increase until the STANDARD TAPS SPEED RECOMMENDATIONSThe manufacture of gears by coldroll forming has been highly developed and widely adopted in recent years Many of the gears in automobile transmissions are made this way The hardened forming rolls are very accurately made, and the rollformed gear teeth usually have excellent accuracy29,30,35,36 Flashcards QuizletIt is perfectly normal to hear cracking noises as you roll your die through your machine That sound is the die cutting into your paper It's totally normal and no, you didn't break anything! But if the sound bothers you, choose a Magic Mat instead of the plastic cutting pad you cut into for a pass that's kinder to the earsEverything You Need to Know about Die CuttingThe manufacture of gears by coldroll forming has been highly developed and widely adopted in recent years Many of the gears in automobile transmissions are made this way The hardened forming rolls are very accurately made, and the rollformed gear teeth usually have excellent accuracyFinal Flashcards Quizlet

- Jaw Plate For Crusher Mine Machinery Jaw Crusher

- beneficiation of iron ore pellet process

- tph crusher plant production reportxls

- sand and aggregate crushing mobile impact crusher for sale

- cement crushing youtube

- sales cash flow for maize grinding machine

- used used ncrete floor prep equipment price

- Stone Crusher Penggunastone Crusher Penjual

- mineral ore beneficiation

- Cone Mining Mill Machine Picture

- calcium carbonate calcite powder machine

- Table Top Manufacturing Machines

- Bau ite Mining Grinding

- meaning bpl rock phosphate

- Trust Worthy Factory Cheap Cone Crusher Jaw Crushers Manufacturer

- what is the method for processing the mineral tantalite

- warranty easy transport high efficient fine crusher

- bile limestone jaw crusher provider in south africa

- Rock Jaw crusher process flow diagram

- best quarry planning in malaysia

- manual manual rotary surface grinder

- scf series two stage hammer crusher building material crusher

- al processing in ukraine

- Stone Mining Mill Kapasitas 30 40 Ton Per Jam

- roll crusher metallurgy

- a Bailing Brand Good Reputation stone jaw crusher

- 150 tph stone crusher plant

- Tin Hammer Crusher Mill Price In Panama Sale

- basket mill wet grinding

- high quality ne crusher machine popular in asia

- used impact crusher DXN 13 15 4 for sale

- mobile mobile jaw crusher with dust reduction system

- al mobile crusher manufacturer india small vibrating grizzly feeder for sale

- extec c12 jaw crusher operation service pdf

- small small ballast crushing machine in kenya

- gravel white sand factory in johannesburg

- telecharger des livres de genie civil gratuit

- Stone Crusher Import To Kenya From Pakistan

- Crushing Equipment Obtains Improvement Trends

- basalt mining increase