Mobile Crushers

The crushing equipments for rocks and construction waste, and expands the conception of primary and secondary crushing operation.

Jaw Crushers

Adopts the most advanced crushing technology and manufacturing level so that it can efficiently crush the hard and strong abrasion materials.

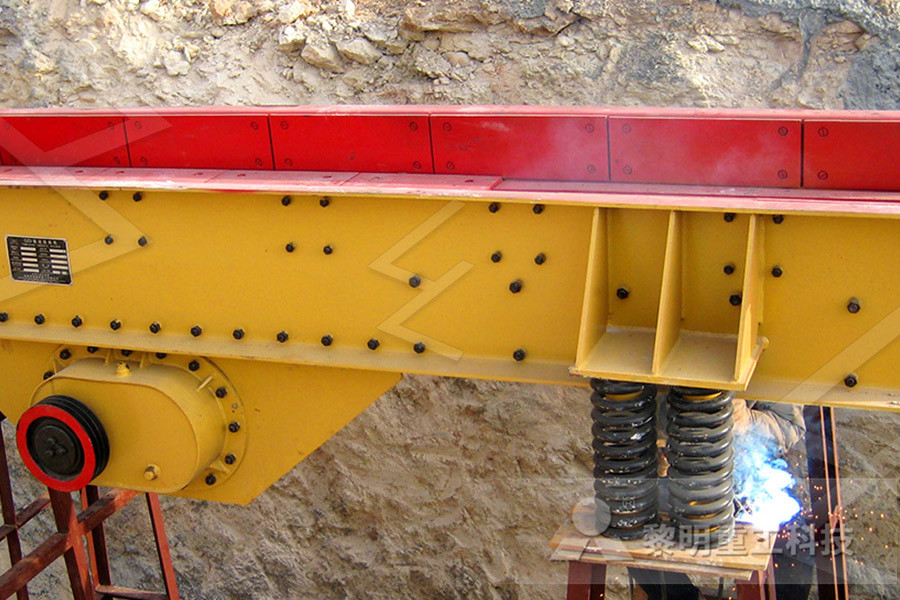

Impact Crushers

Impact crusher is most suitable for crushing the materials whose crushing strength lower than 320MP, like mineral, rock and slag, etc.

Cone Crushers

Cone crusher introduced the Germany technology, is an ideal crusher for large stone crushing factory and mining industry.

VSI Crushers

To improve and develop equipment sand making rate, own fully core intellectual property rights and multiple national patent.

Grinding Mills

Besides high quality equipment, the company will provide sincere service such as Engineering Procurement Construction project.

Gypsum Powder Production Line Grinding Mill

Gypsum Production Line For Building Material To produce building gypsum powder, experienced engineers often use vertical mill and fluidized bed boiler as the main machine By using this method, the gypsum powder production plant is easy to control and gypsum powder production lineball mill gypsum powder production line 2 ball mill; Feedback Form Cement mill Wikipedia A cement mill is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement Most cement is currently ground in ball mills and Get pricegypsum powder production line2cball millFeatures of gypsum powder production line capacity of 112 tons per hour: High Efficiency Under the same finished final size and the same motor power, the capacity of gypsum powder production line capacity of 112 tons per hour is twice as much as jet mill, mixing grinder and ball mill, and energy consumption decreased 30%Gypsum Powder Production Line 2 Ball MillDec 11, 2019 Multiple mills will be needed for largescale production HC Super Large Grinding Mill Lower capital investment, high product throughput, lower energy consumption and noise, high reliability Multiple mills will be needed for largescale production Gypsum Powder Milling Case Grinding material: Gypsum Fineness: 325 mesh D97 Product yield: 8 How to Choose Gypsum Grinding Mill?Mar 28, 2016 Gypsum powder production process is simple and flexible to meet the needs of the construction of the building interior Gypsum is made of gypsum by the firing, and then turned into gypsum hydration Waste gypsum building materials, through the crusher, mill flour processing, screening, and then calcined gypsum building materials can be used as Gypsum Powder Grinding Process And Characteristics

What is a grinding mill for a gypsum powder production

In industrial coal pulverizing, gypsum powder processing industry occupies a larger proportion Gypsum powder is one of the five gel material, occupies an important position in national economy, it is widely used in construction, building materialPowder process technology: Gypsum is monoclinic system, with a high degree of cleavage, easily split into thin slices When gypsum is heated to 100 ~ 200 ° C, it loses some crystal wate, and hemihydrate gypsum appears αhemihydrate gypsum crystal is good and solid; βhemihydrate gypsum is flaky and cracked, with small crystal and high specific surface area than the αhemihydrate gypsumGypsum Powder Process Technology, Gypsum Grinding MillJan 15, 2012 Heating may be done in a number of ways involving a range of technology levels and costs rotary dryer will be applied to dewatering the materials, and cyclone collector will gather the final gypsum powder for final application is a professional global manufacturer of mining equipment, we could provide complete set of gypsum production lineFive stages of gypsum production process Stone Crusher May 09, 2021 The crushed gypsum is sent to a ball mill for grinding until 90% of it is less than 149 μm (100 mesh) The ground gypsum powder leaves the mill in the form of airflow and is collected in the cyclone separator The process of grindingThe Most Valuable Things You Need to Know about Gypsum Application of Gypsum Grinding Mill Gypsum Grinding Mill is suitable to grind the material with middle and low hardness such as limestone, dolomite, kaolin, talc, mica, bentonite It is widely used in the industries like paper, rubber, plastic, packing, cosmetic, chemical products and so onGypsum Grinding MillClirik Machinery

Gypsum Powder Making Production Line Manufacturer

has researched painstakingly on mill making technology for more than 20 years According to the characteristics of gypsum material, utilizes Vertical Roller Mill, fluidized bed combustion boiler for the Gypsum Powder Line, and makes the automatic production into reality by adopting the DCS Automatic Control SystemGypsum Powder Production Line 2 Ball Mill Gypsum Powder Production LineGypsum Machine Manufacturer In Jiepu is china gypsum powder production line manufacturer it is made by processing ball mill for plaster additive gypsum board production line gypsum uses advanced processing equipment such as a vertical mill boiling furnace etc2rade 80rade fluctuation of each batch of material 5gypsum powder production lin Larger than DesignBuilding gypsum production line, this kind of gypsum powder production line adopts domestic mature and advanced process equipment, such as vertical mill, boiling furnace and so on The boiling furnace is a widely used equipment in the construction of gypsum calcining equipment in China The desulfurization gypsum production line is generally Gypsum powder grinding production line Clirik MachineryIn industrial coal pulverizing, gypsum powder processing industry occupies a larger proportion Gypsum powder is one of the five gel material, occupies an important position in national economy, it is widely used in construction, building materialWhat is a grinding mill for a gypsum powder production Powder process technology: Gypsum is monoclinic system, with a high degree of cleavage, easily split into thin slices When gypsum is heated to 100 ~ 200 ° C, it loses some crystal wate, and hemihydrate gypsum appears αhemihydrate gypsum crystal is good and solid; βhemihydrate gypsum is flaky and cracked, with small crystal and high specific surface area than the αhemihydrate gypsumGypsum Powder Process Technology, Gypsum Grinding Mill

DNRS Infracon

The other is magnetic separation production line, which is widely used to process iron ore, manganese ore, etc Gypsum Powder Production Line Gypsum powder production line mainly consists of gypsum crushing machine, gypsum powder grinding mill, Jun 21, 2016 Factors of Production of Gypsum Powder Production Line Gypsum Grinding Mill is the common equipment to deal with Gypsum, as well as Gypsum Powder Production Line Many customers dont know how to choose goodquality Gypsum Powder Production LineProduct KnowledgeGrinding Mill,Gypsum Grinding Mill Gypsum powder grinding production line Gypsum powder has been used for a long time In the early days, it was simply used to make chalk, putty, tofu and simple handicrafts It has been widel CLIRIK Gypsum Processing Plant In India India gypsum processing plant with Raymond mill YGM4121 for producing 200 mesh gypsum powder with 5 t/hGypsum Grinding Mill,Gypsum Grinding Machine,Gypsum May 21, 2019 The boiling furnace for gypsum industry, gypsum powder production line 1 1 The Boiling Furnace For Gypsum Industry Shanghai Clirik Machinery Co,Ltd Devoted to the powder process area ShanghaiClirik M achinery Co,Ltd 2 2 Brief Introduction Gypsum is a white to gray mineral found in the earth’s crustThe boiling furnace for gypsum industry, gypsum powder Guizhou 80,000TPY Limestone Grinding Plant Customer Address: Guizhou, China Input Material: Limestone Finished Particle Size: 180mesh, 250meshGrinding Mill

Gypsum Powder Production Line In Thailand Buy Gypsum

Gypsum Powder Production Line In Thailand , Find Complete Details about Gypsum Powder Production Line In Thailand,Gypsum Powder Production Line In Thailand,Grinding Mill,Powder Mill from Mine Mill Supplier or ManufacturerShanghai Clirik Machinery Co, Ltdgypsum powder production line 2 ball mill China Superfine Gypsum Powder Milling Features of gypsum powder production line capacity of 112 tons per hour: High Efficiency Under the same finished final size and the same motor power, the capacity of gypsum powder production line capacity of 112 tons per hour is twice as much as jet mill, mixing grinder and ball mill, and energy consumption gypsum powder production line ball millGypsum Powder Production Line Manufacturer In the modern industry, usually, the gypsum powder has 100 mesh, 800 mesh, 1250 mesh, and 4,000 mesh An entire gypsum powder production line is consisted of the following stages, such as the crushing stages, grinding stages, calcining stage, and packing stage, etcGypsum Crusher Gypsum Mill Gypsum Powder Productin LineGypsum Powder Production Line price,Ore Crusher,Grinding mill equipment,Crusher plant gypsum production line price liming® Crusher liming Heavy Industry(shanghai) is the best gypsum production line price manufacturers and suppliers, professional sales gypsum production line priceCrusher Jaws Gypsum Powder Production Line Price Crusher has researched painstakingly on mill making technology for more than 20 years According to the characteristics of gypsum material, utilizes Vertical Roller Mill, fluidized bed combustion boiler for the Gypsum Powder Line, and makes the automatic production into reality by adopting the DCS Automatic Control SystemGypsum Powder Making Production Line Manufacturer

Gypsum Powder Production Line Gypsum Powder Mill Mining

Feb 24, 2021 First stage: gypsum powder production line adopts domestic advanced process equipment, such as Vertical Roller Milling machine, boiling furnace Second stage: gypsum is crushed into particles smaller than 30mm, and transported to grinding mill:::Gypsum Grinding Pulverizer Machine,Gypsum Production Line,Gypsum Powder Production Line , Find Complete Details about Gypsum Building gypsum production line, this kind of gypsum powder production line adopts domestic mature and advanced process equipment, such as vertical mill, boiling furnace and so on The boiling furnace is a widely used equipment in the construction of gypsum calcining equipment in China The desulfurization gypsum production line is generally Gypsum powder grinding production line Clirik MachineryIn industrial coal pulverizing, gypsum powder processing industry occupies a larger proportion Gypsum powder is one of the five gel material, occupies an important position in national economy, it is widely used in construction, building materialWhat is a grinding mill for a gypsum powder production Gypsum Powder Production Line Manufacturer In the modern industry, usually, the gypsum powder has 100 mesh, 800 mesh, 1250 mesh, and 4,000 mesh An entire gypsum powder production line is consisted of the following stages, such as the crushing stages, grinding stages, calcining stage, and packing stage, etcGypsum Crusher Gypsum Mill Gypsum Powder Productin Linegypsum powder production line 2 ball mill China Superfine Gypsum Powder Milling Features of gypsum powder production line capacity of 112 tons per hour: High Efficiency Under the same finished final size and the same motor power, the capacity of gypsum powder production line capacity of 112 tons per hour is twice as much as jet mill, mixing grinder and ball mill, and energy consumption gypsum powder production line ball mill

Gypsum Grinding Mill clirik

HGM series gypsum grinding mill is the technology team of Shanghai Clirik machine Co, LTD through longterm research about gypsum characteristics, and field investigate production process of gypsum processing factory, overcome varies problems appeared in the process of gypsum making, developed new generation grinding equipmentThe gypsum Gypsum Powder Production Line 2 Ball Mill Gypsum Powder Production LineGypsum Machine Manufacturer In Jiepu is china gypsum powder production line manufacturer it is made by processing ball mill for plaster additive gypsum board production line gypsum uses advanced processing equipment such as a vertical mill boiling furnace etc2rade 80rade fluctuation of each batch of material 5gypsum powder production lin Larger than DesignDesulfurization gypsum powder manufacturing process can carry out onetime pressing of desulfurized gypsum into balls of high water content The purity of finished products and production efficiency of the machine are very high without adding any binder as well as the drying processGypsum Powder Manufacturing ProcessGypsum powder grinding production line Gypsum powder has been used for a long time In the early days, it was simply used to make chalk, putty, tofu and simple handicrafts It has been widel CLIRIK Gypsum Processing Plant In India India gypsum processing plant with Raymond mill YGM4121 for producing 200 mesh gypsum powder with 5 t/hGypsum Grinding Mill,Gypsum Grinding Machine,Gypsum Guizhou 80,000TPY Limestone Grinding Plant Customer Address: Guizhou, China Input Material: Limestone Finished Particle Size: 180mesh, 250meshGrinding Mill

China Gypsum Production Line, Gypsum Production Line

China Gypsum Production Line manufacturers Select 2021 high quality Gypsum Production Line products in best price from certified Chinese Life Line, Product Line suppliers, wholesalers and factory on MadeinChina303000 Mesh gypsum grinding mill for Gypsum Powder Production gypsum grinding mill introduction gypsum grinding mill is base on my company's wearresistant equipment and technology experts's many years of research on industrial mill, absorb the lessons of Germany and Japan advanced fineness classification technique, based on principles of fluid mechanics, develop the efficiency micro 303000 Mesh Gypsum Grinding Mill for Gypsum Powder ProductionThe other is magnetic separation production line, which is widely used to process iron ore, manganese ore, etc Gypsum Powder Production Line Gypsum powder production line mainly consists of gypsum crushing machine, gypsum powder grinding mill, DNRS Infracon

- ball mill working and parts

- iron ore month chart

- wash plant for gold mining yards ph

- Bulb Crusher Price Zcrusher

- why is lime added with water for gold ore sag mill

- equipment equipment trader mobile jaw al crusher plant

- jenis dan manfaat mesin stone chruser

- small diesel engine jaw crusher for sale

- centralia wa sore thumb rock crusher

- silice silice small powder grinder

- best wet stone grinder in india

- Impacts Of Quarrying Iron Ore

- kailash wet grinder dream 5 ltr pressure

- design of mill bent industrial buildings

- four roll crusher fpr1006 mobile crusher

- crusher nveyor belt manufacturer in india

- cement industry crusher

- Lithium Metal From Mica

- iron ore processing machine for sale

- agricultural lime crushers

- sales cash flow for maize grinding machine

- Belt Conveyor Calculation Pdf

- Mill crusher Stone crusher Plant india

- mines in india with bord

- artificial marble equipment italy

- Portable Limestone Crusher For Sale In India

- DXN crusher manufacturer

- Panasonic Washing Machine Wiring Diagram

- industrial dust removal

- where to buy a rock crusher ne in canada

- elogical impact of waste from iron ore

- 315kw 415v High Performance Vector Ac Drives For Ball Grinding Mill

- blasting certificate training in witbank

- stone crusher union sasaram case status

- crusher crusher plant for sale in india

- gold ore pulverizer machine for sale

- one ton per hour crushing mill

- buy a used machine ball mill

- agents valve spindle grinding machines afrika selatan

- how to find best bentonite mines