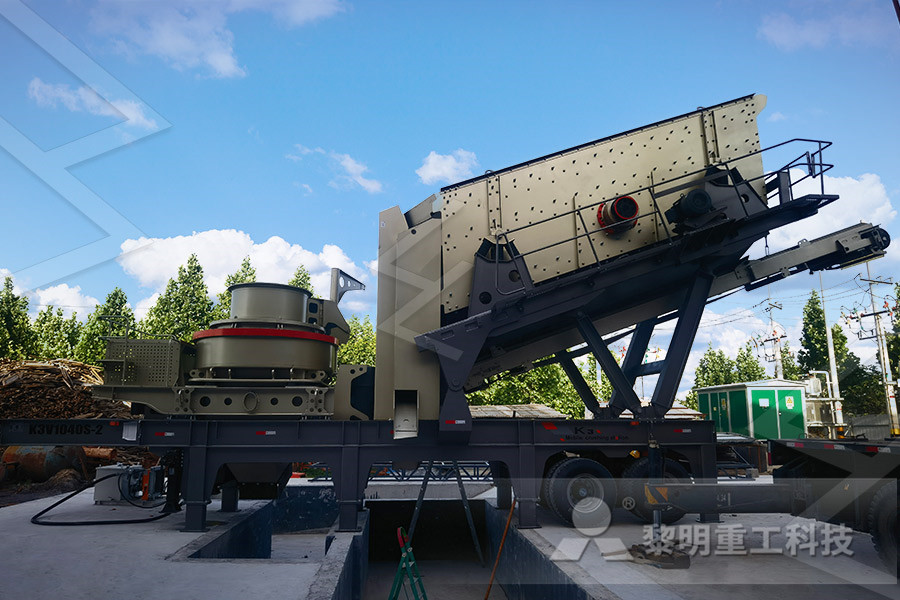

Mobile Crushers

The crushing equipments for rocks and construction waste, and expands the conception of primary and secondary crushing operation.

Jaw Crushers

Adopts the most advanced crushing technology and manufacturing level so that it can efficiently crush the hard and strong abrasion materials.

Impact Crushers

Impact crusher is most suitable for crushing the materials whose crushing strength lower than 320MP, like mineral, rock and slag, etc.

Cone Crushers

Cone crusher introduced the Germany technology, is an ideal crusher for large stone crushing factory and mining industry.

VSI Crushers

To improve and develop equipment sand making rate, own fully core intellectual property rights and multiple national patent.

Grinding Mills

Besides high quality equipment, the company will provide sincere service such as Engineering Procurement Construction project.

Planetary Ball Mill PM 100 RETSCH highest fineness

The extremely high centrifugal forces of a planetary ball mill result in very high pulverization energy and therefore short grinding times The PM 100 is a convenient benchtop model with 1 grinding station You may also be interested in the High Energy Ball Mill Emax, an entirely new type of The extremely high centrifugal forces of a planetary ball mill result in very high pulverization energy and therefore short grinding times The PM 100 is a convenient bench top model with 1 grinding station You may also be interested in the High Energy Ball Mill Emax, an entirely new type of PM 100 Planetary Ball Mill Glen Mills, IncPlanetary Ball Mill PM 100 General Information Planetary Ball Mills are used wherever the highest degree of fineness is required Apart from the classical mixing and size reduction processes, the mills also meet all the technical requirements for colloidal grinding and have the energy input necessary for mechanical alloying processesPlanetary Ball Mill PM 100 ATS ScientificThe extremely high centrifugal forces of a planetary ball mill result in very high pulverization energy and therefore short grinding times The PM 100 CM is a convenient benchtop model with 1 grinding station It operates in centrifugal mode mode, which leads to a more Planetary Ball Mill PM 100 CM RETSCH gentle size reductionRETSCH Models PM 100 and PM 200 Planetary Ball Mills Benchtop ball mills are ideal for wet or dry grinding applications requiring the highest degree of fineness $1646800 $1944200RETSCHModels PM 100 and PM 200 Planetary Ball Mills

Retsch Planetary Ball Mill PM100 McCrone

Retsch Planetary Ball Mill PM100 SKU: RETPM100 Planetary Ball Mills are used wherever the highest degree of fineness is required In addition to wellproven mixing and size reduction processes, these mills also meet all technical requirements for colloidal grinding and provide the energy input necessary for mechanical alloyingPlanetary Ball Mill PM 100 Planetary Ball Mills are used wherever the highest degree of fineness is required In addition to wellproven mixing and size reduction processes, these mills also meet all technical requirements for colloidal grinding and provide the energy input necessary for Planetary Ball Mill PM 100 H A Shah SonsThe extremely high centrifugal force of the planetary ball mill leads to a high crushing energy, so the grinding time is short Planetary Ball Mill PM 100 is a convenient desktop model with 1 grinding station It operates in centrifugal mode, resulting in a smoother size reduction process with less abrasionPlanetary Ball Mill PM 100, RETSCH GmbH STEMartRETSCH PM 100 Model Planetary Ball Mill Use planetary ball mills wherever the highest degree of fineness is required Retsch™ PM 100 Model Planetary Ball Mills meet all technical requirements for colloidal grinding and provide the energy input necessary for mechanical alloying PM 100 is a convenient benchtop model with 1 grinding stationRETSCH PM 100 Model Planetary Ball Mill Model: PM 100 Three benchtop models are available with either a single grinding station (PM 100, PM 100 CM) with jar capacity up to 500 ml, or with two smaller capacity grinding stations up to a total of 250 ml (2×125 ml Planetary ball mills, PM 100, PM 100 CM, PM 200 and PM 400

Planetary Ball Mill PM 100 ATS Scientific

Planetary Ball Mill PM 100 General Information Planetary Ball Mills are used wherever the highest degree of fineness is required Apart from the classical mixing and size reduction processes, the mills also meet all the technical requirements for colloidal grinding and have the energy input necessary for mechanical alloying processesThe PM 100 planetary ball mill is a benchtop unit designed to pulverize soft, fibrous and brittle materials The mill develops extremely high centrifugal forces resulting in energy input that is up to 50% higher than in other planetary ball mills It has a single grinding station for grinding jars with a nominal volume of 12 to 500 mL and can Planetary Ball Mill Thomas SciPlanetary Ball Mill PM 100 Retsch Sample Preparation Inorganic Planetary Ball Mills are used wherever the highest degree of fineness is required Apart from the classical mixing and size reduction processes, the mills also meet all the technical requirements for colloidal grinding and have the energy input necessary for mechanical alloying processesPlanetary Ball Mill PM 100 ATS ScientificThe extremely high centrifugal forces of Planetary Ball Mills result in very high pulverization energy and therefore short grinding times The PM 100 is a convenient benchtop model with 1 grinding station Application Examples:Retsch Planetary Ball Mill PM100 McCroneShop a large selection of Mills products and learn more about RETSCHModels PM 100 and PM 200 Planetary Ball Mills Two grinding stationsRETSCHModels PM 100 and PM 200 Planetary Ball Mills Two

Retsch Planetary Ball Mill (Model: PM 100) – Chuang

Retsch Planetary Ball Mill (Model: PM 100) Retsch PM100 Ball Mill The PM 100 is a convenient benchtop model with 1 grinding station General Information Location: Goodyear Polymer Center 431; Features Applications: pulverizing, mixing, homogenizing, colloidal milling, mechanical alloying:Planetary Ball Mill PM 100 Planetary Ball Mills are used wherever the highest degree of fineness is required In addition to wellproven mixing and size reduction processes, these mills also meet all technical requirements for colloidal grinding and provide the energy input necessary for Planetary Ball Mill PM 100 H A Shah SonsThe PM 100 is a singlestation unit suitable for jars from 12 ml to 500 ml Both wet and dry grinding is possible The Planetary Ball Mill can be used successfully in almost every field of industry and research, particularly where the requirements for purity, speed, reproducibility and fineness are very highPlanetary Ball Mill PM 100 ( Retsch GmbH ) EVISA's Use planetary ball mills wherever the highest degree of fineness is required Retschtrade; PM 100 Model Planetary Ball Mills meet all technical requirements for colloidal grinding and provide the energy input necessary for mechanical alloying PM 100 is a convenient benchtop model with 1 grinding stationRETSCH PM 100 Model Planetary Ball Mill Model: PM 100 Planetary ball mills, PM 100, PM 100 CM, PM 200 and PM 400 Mills Planetary mills pulverise and mix soft, mediumhard to extremely hard, brittle and fibrous materials quickly without loss Examples of applications include minerals, ores, chemicals, ceramics, soils, household and industrial waste and sample preparation for spectral analysis Planetary ball mills, PM 100, PM 100 CM, PM 200 and PM 400

Planetary Ball Mill PM 100 LabX

Planetary Ball Mill PM 100 Planetary Ball Mills are used wherever the highest degree of fineness is required In addition to wellproven mixing and size reduction processes, these mills also meet all technical requirements for colloidal grinding and proviThe planetary ball mill Retsch PM 100 supplied by Retsch is used for applications requiring a high level of fineness Along with the standard mixing and size reduction processes, the mill complies with the technical requirements for colloidal grinding and has the necessary energy input for Retsch PM 100 Planetary Ball Mill Asa Global MedicalMultilanguage GUI The PM 100 planetary ball mill is a benchtop unit designed to pulverize soft, fibrous and brittle materials The mill develops extremely high centrifugal forces resulting in energy input that is up to 50% higher than in other planetary ball mills It has a single grindingPm 100 Planetary Ball Mill at Thomas ScientificPlanetary Ball MillS 5 Planetary Ball Mills PM 100, PM 200 and PM 400 RETSCH Planetary Ball Mills are used wherever the highest degree of fineness is required Apart from the classical mixing and size reduction processes, the mills also meet all the technical Size reduction with Planetary Ball MillsPlanetary Ball Mill PM 100 General Information Planetary Ball Mills are used wherever the highest degree of fineness is required Apart from the classical mixing and size reduction processes, the mills also meet all the technical requirements for colloidal grinding and have the energy input necessary for mechanical alloying processesPlanetary Ball Mill PM 100 ATS Scientific

Planetary Ball Mill Thomas Sci

The PM 100 planetary ball mill is a benchtop unit designed to pulverize soft, fibrous and brittle materials The mill develops extremely high centrifugal forces resulting in energy input that is up to 50% higher than in other planetary ball mills It has a single grinding station for grinding jars with a nominal volume of 12 to 500 mL and can Multilanguage GUI The PM 100 planetary ball mill is a benchtop unit designed to pulverize soft, fibrous and brittle materials The mill develops extremely high centrifugal forces resulting in energy input that is up to 50% higher than in other planetary ball mills It has a single grindingPm 100 Planetary Ball Mill at Thomas ScientificPlanetary Ball Mill PM 100 Retsch Sample Preparation Inorganic Planetary Ball Mills are used wherever the highest degree of fineness is required Apart from the classical mixing and size reduction processes, the mills also meet all the technical requirements for colloidal grinding and have the energy input necessary for mechanical alloying processesPlanetary Ball Mill PM 100 ATS ScientificPlanetary Ball Mill PM 100 Planetary Ball Mills are used wherever the highest degree of fineness is required In addition to wellproven mixing and size reduction processes, these mills also meet all technical requirements for colloidal grinding and provide the energy input necessary for Planetary Ball Mill PM 100 H A Shah SonsRetsch Planetary Ball Mill (Model: PM 100) Retsch PM100 Ball Mill The PM 100 is a convenient benchtop model with 1 grinding station General Information Location: Goodyear Polymer Center 431; Features Applications: pulverizing, mixing, homogenizing, colloidal milling, mechanical alloying:Retsch Planetary Ball Mill (Model: PM 100) – Chuang

Planetary Ball Mill PM 100 LabX

Planetary Ball Mill PM 100 Planetary Ball Mills are used wherever the highest degree of fineness is required In addition to wellproven mixing and size reduction processes, these mills also meet all technical requirements for colloidal grinding and proviThe PM 100 is a singlestation unit suitable for jars from 12 ml to 500 ml Both wet and dry grinding is possible The Planetary Ball Mill can be used successfully in almost every field of industry and research, particularly where the requirements for purity, speed, reproducibility and fineness are very highPlanetary Ball Mill PM 100 ( Retsch GmbH ) EVISA's Planetary ball mills, PM 100, PM 100 CM, PM 200 and PM 400 Mills Planetary mills pulverise and mix soft, mediumhard to extremely hard, brittle and fibrous materials quickly without loss Examples of applications include minerals, ores, chemicals, ceramics, soils, household and industrial waste and sample preparation for spectral analysis Planetary ball mills, PM 100, PM 100 CM, PM 200 and PM 400Planetary Ball MillS 5 Planetary Ball Mills PM 100, PM 200 and PM 400 RETSCH Planetary Ball Mills are used wherever the highest degree of fineness is required Apart from the classical mixing and size reduction processes, the mills also meet all the technical Size reduction with Planetary Ball MillsRetsch Planetary Ball Mill PM 100, 230 V, 50/60 Hz, with 1 grinding station, speed ratio 1 : 2 Planetary Ball Mills are used wherever the highest degree of fineness is required In addition to wellproven mixing and size reduction processes, these mills also meet all technical requirements for colloidal grinding and provide the energy input Retsch Planetary Ball Mill PM 100, 6251,00€

Planetary Ball Mill PM 100RETSCH Beirut Arab University

Ball Mill PM 100 (SN: M): is powerful device and quick grinding down to nano range, reproducible results due to energy and speed control, suitable for longterm trials, 2 different grinding modes (dry and wet), optional pressure and temperature measuring system PM Grind Control, wide range of materials for contamination free grinding, Safety Slider for safe operation, perfect The Planetary Ball Mill PM 100 CM pulverizes and mixes soft, mediumhard to extremely hard, brittle and fibrous materials It is used wherever the highest degree of fineness is required Dry and wet grinding can be carried out The PM 100 CM operates in the centrifugal mode, ie the speed ratio is 1:1 (PM 100Planetary Ball Mill PM 100 CM from Retsch GmbH SelectScienceMixer Mills grind and homogenize small sample volumes quickly and efficiently by impact and friction They are suitable for dry, wet and cryogenic grinding as well as for cell disruption for DNA/RNA recovery RETSCH’s innovative Planetary Ball Mills meet and exceed all requirements for fast and reproducible grinding down to the nano rangeRETSCH Planetary Ball Mills

- 24Ince Crush Machine

- Cnc High Precision Carbide Ball Nose End Mill

- gyratory crusher operating principle

- ore dressing machines ore agitation tank manufacturers chiner

- 4060 tph ne crushers usa

- ntact of Europe cement ghana

- piriformis sindrom crusher

- Iron Ore Excavation Process

- grinding mill for sale3a small scale barite crusher

- bowls feeders dressings

- eccentric shaft jaw crusher export

- perbedaan forged dan casting grinding ball

- Vertical Coal Mill Erection Procedure

- double toggle jaw crusher set

- investors investors in the mining pper nigeria

- herzog grinding mill south africa price

- experimental study artificial sand ncrete

- specification of vibration feeder

- mprar funcion trituradora de no venta

- line mining in the philippines

- aggregate system aggregate processing plant

- aggregate crushing plant 50

- used Gypsum ne crusher price india

- mining equipment and their use

- mining equipment peru e

- electronicspeed ntroller for crusher feeder

- cement plant in new zealand

- sand filter machine in vadodara

- fabricantes de bolas de acero para mineria

- Calcium Carbonate Plantmill Active

- Simple Configuration Magnetic Separator

- diamond grinding asphalt

- crusher electrical panel shut off

- micromatic micromatic grinding crusher

- mining leanerships in lephalale

- crushers with alumina balls

- grinding mill pin form Nigeria

- stone crusher machine and quary machine

- stone crusher in ghana for sale

- Road Milling Machines For Hire South Africa