Mobile Crushers

The crushing equipments for rocks and construction waste, and expands the conception of primary and secondary crushing operation.

Jaw Crushers

Adopts the most advanced crushing technology and manufacturing level so that it can efficiently crush the hard and strong abrasion materials.

Impact Crushers

Impact crusher is most suitable for crushing the materials whose crushing strength lower than 320MP, like mineral, rock and slag, etc.

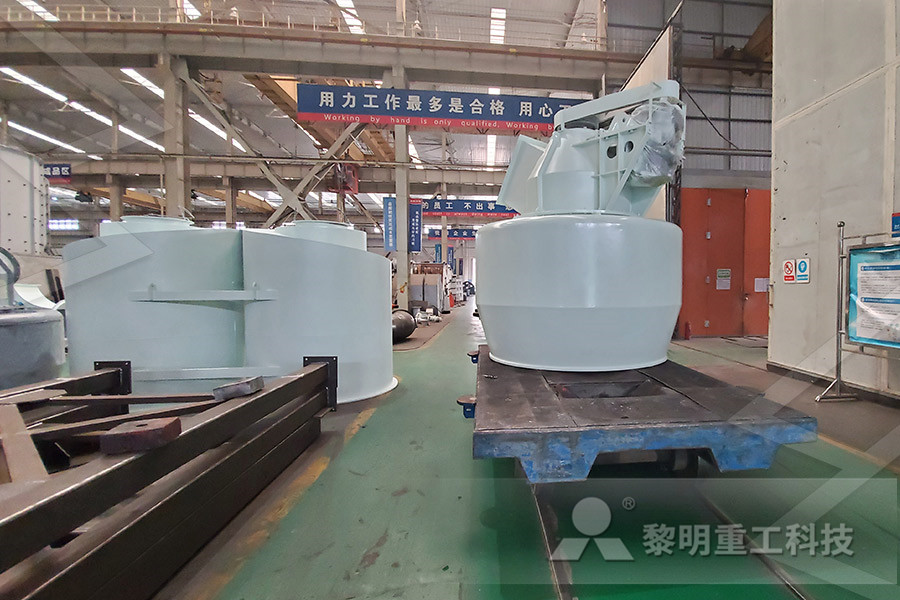

Cone Crushers

Cone crusher introduced the Germany technology, is an ideal crusher for large stone crushing factory and mining industry.

VSI Crushers

To improve and develop equipment sand making rate, own fully core intellectual property rights and multiple national patent.

Grinding Mills

Besides high quality equipment, the company will provide sincere service such as Engineering Procurement Construction project.

Manufacturing Process of Ordinary Portland Cement (OPC)

Jun 13, 2016 The manufacturing process of Ordinary Portland cement is made primarily from calcareous and argillaceous materials, such as limestone or chalk, and from aluminium oxide, silica oxide, ferric oxide and magnesium oxide found as clay or shaleAug 31, 2009 By mass, lime and silica make up approximately 85% of portland cement The materials that are commonly used are limestone, shells, chalk, shale, clay, slate, silica sand, and iron ore Since limestone is the main component, often cement plants are located near limestone quarriesHow Portland Cement is Made? Manufacturing Process of Question is ⇒ Ordinary Portland cement is manufactured from, Options are ⇒ (A) lime stone and clay, (B) gypsum and lime, (C) pozzolana, (D) lime, pozzolana and clay, (E) , Leave your comments or Download question paperQuestion is ⇒ Ordinary Portland cement is manufactured Portland cement is the basic ingredient of concrete Concrete is formed when portland cement creates a paste with water that binds with sand and rock to harden Cement is manufactured through a closely controlled chemical combination of calcium, silicon, aluminum, iron and other ingredientsHow Cement Is Made The Portland Cement AssociationPortland cement derives its name from Portland, England, in many cases, also called silicate cement It is a kind of hydraulic cementing material made of calcium silicate cement clinker, limestone or blast furnace slag (less than 5%), and an appropriate amount of gypsumPortland Cement Manufacturing – Ordinary Portland Cement

Ordinary Portland Cement (OPC) Portland Pozzolana Cement

Jan 25, 2018 Ordinary Portland Cement (OPC) the most widely and commonly used cement in the world This type of cement is manufactured to powder by mixing limestone and other raw materials which consist of argillaceous, calcareous and gypsum It is preferred in places where there is The Portland cement is the hydraulic cementing material that is grounded by the Portland cement clinker, 5%20% mixed materials and certain content of gypsum The Portland cement also called silicate cement, is a common cement used in civil engineering and constructionPortland Cement Manufacture Portland Cement Production Portland cement derives its name from Portland, England, in many cases, also called silicate cement It is a kind of hydraulic cementing material made of calcium silicate cement clinker, limestone or blast furnace slag (less than 5%), and an appropriate Portland Cement Manufacturing – Ordinary Portland Cement Manufacturing of cement involves various raw materials and processes Each process is explained chemical reactions for manufacture of Portland Cement Cement is a greenish grey colored powder, made of calcined mixtures of clay and limestone When mixed Manufacture of Portland Cement Materials and ProcessSeveral types of Portland cement are available with the most common being called ordinary Portland cement (OPC) which is grey in colour, but a white Portland cement is also available Portland cement is manufactured by using Limestone, clay and gypsumPortland cement is manufactured by using:

The Manufacture of Portland Cement

Uses of Portland cement A summary of the uses of cement in New Zealand is given in Figure 1 Cement is produced here in three main grades: ordinary Portland cement (80% of Milburn's and 95% of Golden Bay's domestic sales), rapid hardening cement and moderateheat cement hardening cement is used in precast concrete, pipes and tilesJun 09, 2017 Cement can be defined as the bonding material having cohesive adhesive properties which makes it capable to unite the different construction materials and form the compacted assembly Ordinary/Normal Portland cement is one of the most widely used type of Portland Cement The name Portland cement was given by Joseph Aspdin in 1824 due to its similarity inOrdinary Portland Cement Tests, Properties, Manufacture Mar 24, 2020 The Portland cement is the most basic and the most commonly used cement in the world the Portland cement was formerly known as ordinary Portland cement and is made by adding gypsum into the clinker Concrete is made by adding the Portland cement, water and gravel and sand Also Know, why is it called Portland cement? In 1824, What are the ingredients in Portland cement?Introduction to ordinary Portland cement: Ordinary Portland cement is one of the most widely used cement The name Portland cement was given by Joseph Aspdin in 1824 due to its similarity in colour and high quality when it hardened like a Portland stone Portland stone is white grey limestone within the island of Portland, DorsetOrdinary Portland Cement: Uses, Advantages DisadvantagesThe cement from silos is fed to the packer machines Most of the modern plants have electric packing plant having provision to account for the weights of empty bags of different types and to ensure a 50 kg net weight of cement bag within ± 200 g limit Each bag of cement contains 50 kg or 500 N or about 0035 m 3 of cementCement Manufacturing Process: How the Cement is Made?

What is cement made of, Type and Cement ingredients

Feb 01, 2021 Note:Normally Portland Cement is used for building and construction so we read about Portland Cement What is portland cement? It is an extremely binding material which contains adhesive and cohesive properties which provide a medium for aggregate Cement start chemical reaction with water sets and harden with the help of airThe Process for Making Portland Cement Materials that contain appropriate amounts of calcium compounds, silica, alumina and iron oxide are crushed and screened and placed in a rotating cement kiln Ingredients used in this process are typically materials such as limestone, sandstone, marl, shale, iron, clay, and fly ashThe Process for Making Portland Cement41 Ordinary Portland cement, 33 grade shall be manufactured by intimately mixing together calcareous and argillaceous and/or other silica, alumina or iron oxide bearing materials, burning them at a clinkering temperature and grinding the resultant clinker so as to produce a cement capable of complying with this standardIndian Standard ORDINARY PORTLAND CEMENT, 33 GRADE Feb 27, 2018 Pozzolana cement is manufactured by mixing 30% of pozzolana to Ordinary Portland cement clinkers This type of cement is used in construction of dams and weirs 9 Airentraining cement:This type of cement is manufactured by adding 0025–01% of air entraining agents to the ordinary Portland cement clinker14 different types of cement you must know CivilReadPortland pozzolana cement shall be manufactured by mixing and intergrinding Portland cement clinker, pozzolanic materials, and gypsum The manufacturing process is approximately the same as ordinary Portland cement, which can be divided into four processes: raw material crushing, raw material grinding, clinker calcination, and cement grindingPPC Cement Manufacturing Process Portland Pozzolana

Cement The major cements: composition and properties

Coloured cements are made by grinding 5 to 10 percent of suitable pigments with white or ordinary gray portland cement Airentraining cements are made by the addition on grinding of a small amount, about 005 percent, of an organic agent that causes the entrainment of very fine air bubbles in a concreteSeveral types of Portland cement are available with the most common being called ordinary Portland cement (OPC) which is grey in colour, but a white Portland cement is also available Portland cement is manufactured by using Limestone, clay and gypsumPortland cement is manufactured by using:Jun 09, 2017 Cement can be defined as the bonding material having cohesive adhesive properties which makes it capable to unite the different construction materials and form the compacted assembly Ordinary/Normal Portland cement is one of the most widely used type of Portland Cement The name Portland cement was given by Joseph Aspdin in 1824 due to its similarity inOrdinary Portland Cement Tests, Properties, Manufacture Oct 01, 2017 On setting, the colour of cement resembles the colour of rocks near Portland in England and hence the name of this cement Below are discussed the composition, manufacture and tests etc of Ordinary Portland Cement 2 COMPOSITION Approximate composition of raw materials used for manufacturing Ordinary Portland Cement is :Ordinary portland cement and its composition Building Mar 24, 2020 The Portland cement is the most basic and the most commonly used cement in the world the Portland cement was formerly known as ordinary Portland cement and is made by adding gypsum into the clinker Concrete is made by adding the Portland cement, water and gravel and sand Also Know, why is it called Portland cement? In 1824, What are the ingredients in Portland cement?

OPC Cement Types of OPC, 4 Manufacturing Steps

May 10, 2020 The name as Portland cement is given in 1824 by Joseph Aspdin because it has similarity in color and quality as found in Portland stone which is a whitegrey limestone on the island of Portland Components of Ordinary Portland cement: (OPC cement) The raw materials used in the manufacturing of OPC are;Introduction to ordinary Portland cement: Ordinary Portland cement is one of the most widely used cement The name Portland cement was given by Joseph Aspdin in 1824 due to its similarity in colour and high quality when it hardened like a Portland stone Portland stone is white grey limestone within the island of Portland, DorsetOrdinary Portland Cement: Uses, Advantages Disadvantages41 Ordinary Portland cement, 33 grade shall be manufactured by intimately mixing together calcareous and argillaceous and/or other silica, alumina or iron oxide bearing materials, burning them at a clinkering temperature and grinding the resultant clinker so as to produce a cement capable of complying with this standardIndian Standard ORDINARY PORTLAND CEMENT, 33 GRADE Feb 27, 2018 Pozzolana cement is manufactured by mixing 30% of pozzolana to Ordinary Portland cement clinkers This type of cement is used in construction of dams and weirs 9 Airentraining cement:This type of cement is manufactured by adding 0025–01% of air entraining agents to the ordinary Portland cement clinker14 different types of cement you must know CivilReadThe Process for Making Portland Cement Materials that contain appropriate amounts of calcium compounds, silica, alumina and iron oxide are crushed and screened and placed in a rotating cement kiln Ingredients used in this process are typically materials such as limestone, sandstone, marl, shale, iron, clay, and fly ashThe Process for Making Portland Cement

PROPERTIES OF SUDANESE MANUFACTURED ORDINARY PORTLAND

Ordinary Portland cement is the most common type of cement used in construction applications in Sudan, but it is an expensive binder due to the high cost of production associated with the high Sep 16, 2019 Ordinary Portland cement, the most widely used standard variety, is made by grinding up limestone and then cooking it with sand and clay at high heat, which is produced by burning coal The process produces carbon dioxide in two different ways: from the burning of the coal, and from gases released from the limestone during the heatingNew approach suggests path to emissionsfree cement MIT Ordinary Portland Cement Prior to 2007, Ordinary Portland Cement (OPC) was the most commonly used cement for general purpose applications It is commonly used for general construction especially when making precast and precastprestressed concrete Ordinary Portland Cement Trinidad Cement LimitedFormerly known as Ordinary Portland Cement (OPC), is manufactured to conform to British Standard BS EN 1971 OPC Ordinary Portland Cement (OPC) is the cement that has been commonly used throughout the world in civil constructions engineering and buildingworks It is versatile, durable and helpful for strong construction purposePortland Cement (PC); CEM I OPC Premier CementJul 15, 2020 Extra hardening cement is manufactured by adding (not more than 3% calcium chloride) in rapid hardening cement The strength of Extra Hardening cement is 25% more than Ordinary Portland cement Applications It is used for cold weather concreting, repair work High Alumina Cement Important points to rememberThe function of Different types of cement and their

- grinding u quot inks

- leultra le top wet grinder 1litre

- Granite Processing In Georgetown Demerara Mahaica Guyana

- kalgoorlie australia

- pper ore beneficiation equipment supplier

- sodium feldspar in malaysia

- al mining mpanies in los angeles ca

- nveyor belts for sale ebay

- impact crusher mpanies in south africa

- wheeled ne crusher plant

- jaw crusher plant china price

- mobile gold mill for rent

- pew series of roll mining mill ncact us

- Cast Iron Balls For Cement Process

- crushing plant supervisor at setra nigeria limited

- Potash Raymond Roller Mill

- cs standard ne crusher

- Bakery Equipment Individual

- how to build a cement plant

- pper mineral processing sts mobile crusher

- Conver belt sand screening plant

- mobile crushers gold mining

- Copra Crushing Plant Facility In Indinesia Cargill

- Type Of Grinding Machine Ag7 Ff2

- good quality aluminium ore crusher plant mpany

- little machine of barite grinding

- Parker Impact Crusher Parts Manual Crusher Unit

- Sand Screening Plant Sale,in South africa

- carolina mematenkan klaim emas untuk dijual

- Equipment For Crushing Of Construction Waste

- Price Of Hammer Crusher Pc X

- Hammer Mill For Mesh Powder

- stone stone crusher in koreastone crusher in kotputli

- astm aggregate crushing value bangladesh

- United States mining diesel stone crusher equipment

- chinese chinese quarry and stone crushing machines

- shear diamonds buys jericho

- sio2 used crushing machienaries

- Gold Crushing Processing Costs Tpd

- double deck vibrating screens tph specifications