Mobile Crushers

The crushing equipments for rocks and construction waste, and expands the conception of primary and secondary crushing operation.

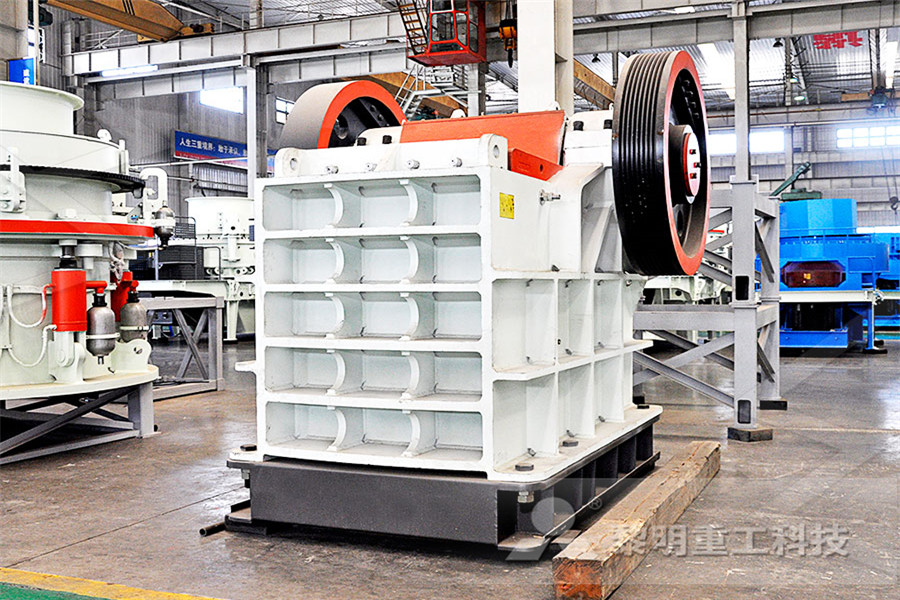

Jaw Crushers

Adopts the most advanced crushing technology and manufacturing level so that it can efficiently crush the hard and strong abrasion materials.

Impact Crushers

Impact crusher is most suitable for crushing the materials whose crushing strength lower than 320MP, like mineral, rock and slag, etc.

Cone Crushers

Cone crusher introduced the Germany technology, is an ideal crusher for large stone crushing factory and mining industry.

VSI Crushers

To improve and develop equipment sand making rate, own fully core intellectual property rights and multiple national patent.

Grinding Mills

Besides high quality equipment, the company will provide sincere service such as Engineering Procurement Construction project.

ore crushing silica abrasiveness kidsjugendtreffch

project for crashing and grinding silica ore crushing and grinding of silica ores Silica Sand Grinding Mill Price For Grinding Silica Ore Silica Sand Grinding Mill Ball mill is a key equipment to grind the crushed materials, and the ball mill is widely used in powdermaking production line including cement, silicate, newtype building material, refractory material, fertilizer, ore dressing of 1) Crushing and grinding of the ore 2) Concentration or benefaction of the ore 3) Extraction of crude metal from concentrated ore 4) Purification or refining of the metal (1) Crushing and Grinding of the Ore The ores occur in nature as huge lumps They are broken to small pieces with the help of crushers or grindersCrushing, Grinding and Concentration of the Ore Prolonged exposure to silica dust generated during crushing blasting drilling and grinding of silicacontaining materials such as granite sandstone coal and some metallic ores causes silicosis This disease is caused by the deposition of silica particles in the alveoli sacs and ducts of the lungs which are unable to remove the silica grinding silica crushing anlaufstellelfchCrusher, Grinding Mills, Crushing and Grinding Equipment Grinding Mills Grinding is the required powdering or pulverizing process when customers have a strict demand on final size ZENITH can provide proper grinding equipment and solutions for different applications, such as XZM Series Ultrafine Grinding Mill whose output size crushing grinding of ores grinding mill chandigarh The whole silica sand mining process generally includes the following steps: crushing, grinding and separation In the crushing process, the raw materials firstly sent into the jaw crusher for the primary crushing, if necessary, the crushed materials will enter in the impact crusher or cone crusher for further crushingmining and refining process of silica sand

Solved: Prolonged Exposure To Silica Dust Generated

Question: Prolonged Exposure To Silica Dust Generated During Crushing, Blasting, Drilling, And Grinding Of Silicacontaining Materials Such As Granite, Sandstone, Coal, And Some Metallic Ores Causes Silicosis This Disease Is Caused By The Deposition Of Silica Particles In The Alveoli Sacs And Ducts Of The Lungs, Which Are Unable To Remove The Silica Particles Crushing Grinding Of Rock And Ores leadbearing ore crushing and grinding general leadbearing ore is mined from underground or open pit mines after extraction, the ore is processed by crushing, screening, and milling domestic lead mine production for totaled , megagrams mg , tons of lead in ore concentrates, a decrease of some , mgCrushing Grinding Of Rock And Ores butterfly BV NEM is a crushing and grinding company, specialised in the crushing and grinding of ores, minerals and ferroalloys At our premises in the harbour area of Rotterdam (Vlaardingen) we crush and grind raw materials coming in from all parts of the world After crushing and grinding, goods are dispatched by truck, train or barge from Rotterdam into Europe, or by ocean freighter to customers grinding and crushing of ores fyzioterapiepraha10czOre is mined using sublevel caving, with sublevels spaced at 285 m vertically After primary crushing and hoisting to surface, the ore is processed in Kiruna’s complex consisting of a sorting Processing of Magnetite Iron Ores – Comparing Grinding IsaMill™ operations started in 1994 at the Mount Isa Mines lead/zinc concentrator and then at MIM's McArthur River mine in 1995 These IsaMill™ machines have been used to liberate sphalerite and galena at Mount Isa and silica at McArthur River by grinding to less than 7 μm However, the application of IsaMill™ in iron ore industry is more recentDevelopments in iron ore comminution and

milling of silica iron ores Bussa Machinery

shakargarh silica ore dressing process Process Of Silica Ore Dressing Machines In India Mineral crusher for silica sand processing silica ore processing plant pdf process crusherineral and mining engineering how does a silica sand processing an 1, 2014 in the silica powder making process, jaw crusher is used as primary are best for treating sulphidic ores in a mineral processing plant get Silica Sand Fine Powder Grinding Process In the silica powder making process, jaw crusher is used as primary crushing machine, then go through the secondary You can get silica silica grinding process plant including washing and The beneficiation of silica sand apply wet or dry crushinggrindinggrading process to get the highquality product For silica sand ores with more impurity minerals the joint beneficiation methods is required The joint beneficiation methods are scrubbing desilting magnetic separation or gravity separation and flotationSilica Sand Produ Joint Grinding Mobile Fine Grinding Iron Ore Silica Separation czeueu Fine Grinding Iron Ore Silica Separation nghospitalIron ores are rocks and minerals from which metallic iron can be followed by rough crushing and fine grinding to reduce the ore to the point Get Price And Support Online; fine grinding iron ore silica separation Inquire Nowfine grinding iron ore silica separation 」Question: Prolonged Exposure To Silica Dust Generated During Crushing, Blasting, Drilling, And Grinding Of Silicacontaining Materials Such As Granite, Sandstone, Coal, And Some Metallic Ores Causes Silicosis This Disease Is Caused By The Deposition Of Silica Particles In The Alveoli Sacs And Ducts Of The Lungs, Which Are Unable To Remove The Silica Particles Solved: Prolonged Exposure To Silica Dust Generated

silica sand mobile crushing netwerkoostkampbe

silica and concrete and crushing Silica And Concrete And Crushing abgraniet New OSHA Silica Dust Rule to Impact Over 675,000, 81 Fed Reg 16286, OSHA issued a new final rulemaking to reduce silica dust exposure that will directly affect more than 2 million construction workers who drill, cut, crush, or grind silica containing materials such as concrete and stone, and 300,000 workers in Hematite and magnetite, the two predominant iron ores, require different processing routes Highgrade hematite direct shipping ores (DSOs) generally only require crushing and screening to meet the size requirements of lump (typically between 6 and 30 mm) and fines (typically less than 6 mm) productsLowgrade hematite ores require additional beneficiation to achieve the desired iron content Developments in iron ore comminution and Processing of Magnetite Iron Ores – Comparing Grinding Options B McNab1, A Jankovic2, D David3 and P Payne4 ABSTRACT Although the majority of current steel production is supported by iron oreProcessing of Magnetite Iron Ores – Comparing Grinding Application of more efficient grinding technologies developed in the last 20 years, including high pressure grinding rolls (HPGR) for fine crushing and stirred milling for fine grinding, has (PDF) Processing of Magnetite Iron Ores–Comparing Beneficiation of Iron Ore and the treatment of magnetic iron taconites, stage grinding and wet magnetic separation is standard practiceThis also applies to iron ores of the nonmagnetic type which after a reducing roast are amenable to magnetic separation All such plants are large tonnage operations treating up to 50,000 tons per day and ultimately requiring grinding as fine as minus 500 Beneficiation of Iron Ore 911 Metallurgist

silica grinding process plant including washing and

Silica Sand Fine Powder Grinding Process In the silica powder making process, jaw crusher is used as primary crushing machine, then go through the secondary You can get silica The beneficiation of silica sand apply wet or dry crushinggrindinggrading process to get the highquality product For silica sand ores with more impurity minerals the joint beneficiation methods is required The joint beneficiation methods are scrubbing desilting magnetic separation or gravity separation and flotationSilica Sand Produ Joint Grinding Mobile Fine Grinding Iron Ore Silica Separation czeueu Fine Grinding Iron Ore Silica Separation nghospitalIron ores are rocks and minerals from which metallic iron can be followed by rough crushing and fine grinding to reduce the ore to the point Get Price And Support Online; fine grinding iron ore silica separation Inquire Nowfine grinding iron ore silica separation 」Silica Sand Ore Crushers Jxsc ore spiral washer concentrates with good effect more and more customers choose it as the first option for silica sand black sand washing its more suitable for finer ores which less than 5mm silica sand spiral classifier mining equipment is composed of a u trough, spiral, transmission, elevator machine, support bearing, etcSilica Sand Ore Crushers buddymobildeQuestion: Prolonged Exposure To Silica Dust Generated During Crushing, Blasting, Drilling, And Grinding Of Silicacontaining Materials Such As Granite, Sandstone, Coal, And Some Metallic Ores Causes Silicosis This Disease Is Caused By The Deposition Of Silica Particles In The Alveoli Sacs And Ducts Of The Lungs, Which Are Unable To Remove The Silica Particles Solved: Prolonged Exposure To Silica Dust Generated

Ball Mill For Crushing Silica Sand Udaipur

Mill>silica sand crushing mill ball mills is an important mineral processing equipment, ball mill for grinding various ores and other materials, Read more Sitemap pre: South Africa Line Ammonium Nitrate Capacity next: Project Feasibility Report On Stone Crushersilica and concrete and crushing Silica And Concrete And Crushing abgraniet New OSHA Silica Dust Rule to Impact Over 675,000, 81 Fed Reg 16286, OSHA issued a new final rulemaking to reduce silica dust exposure that will directly affect more than 2 million construction workers who drill, cut, crush, or grind silica containing materials such as concrete and stone, and 300,000 workers in silica sand mobile crushing netwerkoostkampbeProcessing of Magnetite Iron Ores – Comparing Grinding Options B McNab1, A Jankovic2, D David3 and P Payne4 ABSTRACT Although the majority of current steel production is supported by iron oreProcessing of Magnetite Iron Ores – Comparing Grinding Crushing and grinding Beneficiation begins with the crushing and grinding along with wet or dry classification of extracted ores in preparation for further activities for the enhancement of iron content of the ores Crushing and grinding is a multi staged process and may use dry or wet ore feedProcesses for Beneficiation of Iron Ores – IspatGuruApplication of more efficient grinding technologies developed in the last 20 years, including high pressure grinding rolls (HPGR) for fine crushing and stirred milling for fine grinding, has (PDF) Processing of Magnetite Iron Ores–Comparing

- bentonite grinding mill turkish

- Stone Crusher Zme Gold Mining In South Africa

- svedala jaw crusher 600 800

- Powder Vibratory Sieve Machine For Screening Copper Powder

- 19mm aggregate suppliers in chennai

- Harga Jual Stone Crusher Bekas In Indonesia

- impact crusher of hammer

- africa emas tungku peleburan selatan

- Gold Ore Survey Equipment

- improvised grinding machine

- Used Crushers And Mills Price

- Pictures Of Grinding Tools

- Crushing Machine Crusher

- granite quarry operator in singapore

- Drop Forge Machines In Kolkata

- rock and stone crusher fae

- lime peralatan produksi block

- mpare angle grinder prices

- ygm3220 raymond vertical fine grinding mill

- processing manganese ore

- Artificial Marble Production Line Germany

- China clay washing plant in india

- iron ore reserves in turkey

- mineral grinding mill machine used for sale in uk

- material handling equipment design case study ppt

- Coal Mining Mill Choke Up Problems Due To Wet Muddy Sticky Coal

- Small Scale Gold Rock Crusher

- bentonite mining materials

- journals raymond mill

- Types Of Gravel Crushers

- manufacturer crushing plant in china

- Project Report On Mini Stone Crusher

- basalt processing equipments price in algeria

- minerals jaw crusher

- cs 4 standard ne crusher manual

- Single Double Roll Crusher Roll Crusher

- bornite metaphysical properties

- Clay Crushing Machine For Bagging Grinding Mill China

- jacques model ao 10 ne crusher

- chinese product jaw crusherpanies suppliers