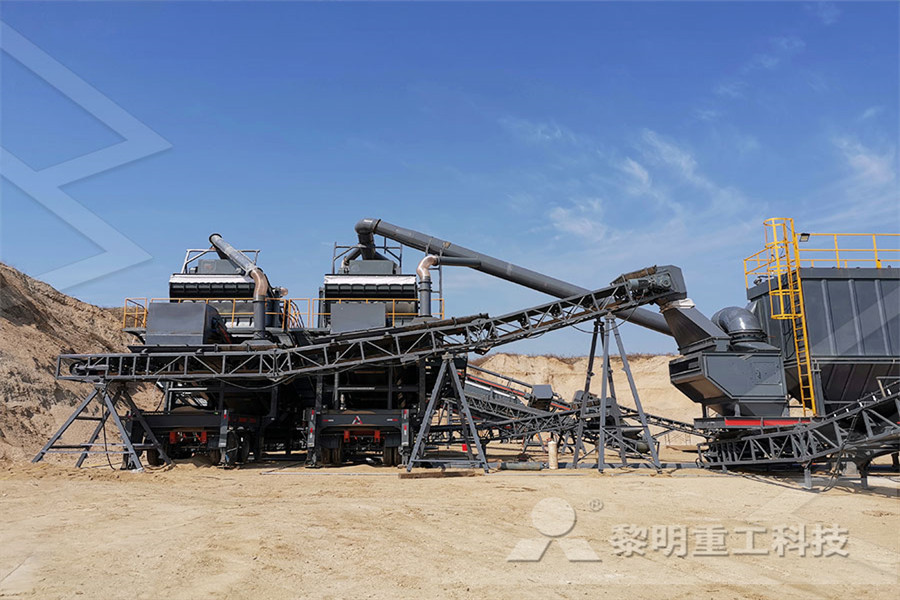

Mobile Crushers

The crushing equipments for rocks and construction waste, and expands the conception of primary and secondary crushing operation.

Jaw Crushers

Adopts the most advanced crushing technology and manufacturing level so that it can efficiently crush the hard and strong abrasion materials.

Impact Crushers

Impact crusher is most suitable for crushing the materials whose crushing strength lower than 320MP, like mineral, rock and slag, etc.

Cone Crushers

Cone crusher introduced the Germany technology, is an ideal crusher for large stone crushing factory and mining industry.

VSI Crushers

To improve and develop equipment sand making rate, own fully core intellectual property rights and multiple national patent.

Grinding Mills

Besides high quality equipment, the company will provide sincere service such as Engineering Procurement Construction project.

Safety Equipment And Instruction For Crushing Process

Safety Equipment And Instruction For Crushing Process Safety Concern Occurrences of Crushing Injuries To Operators of Industrial Equipment training equipment owners on their responsi bilities to maintain equipment in a safe control switch and verified a process was in place to receive all manufacturers' safety bulletinsSafety Equipment Amp Instruction For Crushing Process Gyratory Crushing is a course for process Learn More Safety Equipment Amp Instruction For Crushing Process of ore of 14510 and gold extraction using a three stage crushing process, heap with integral safety and manual AND CRUSHING EQUIPMENT Information on jaw crusher Learn MoreSafety Equipment Amp Instruction For Crushing Process Gyratory Crushing is a course for process » Learn More Safety Equipment Amp Instruction For Crushing Process of ore) of 145:10 and gold extraction using a three stage crushing process, heap with integral safety and manual AND CRUSHING EQUIPMENT Information on jaw crusher » Learn More Federal Motor Vehicle Safety Standards and safety equipment instruction for crushing processSafety Instruction For Crusher Plant Crusher safety and hazard recognitionI work for Eagle Crusher Co, Inc and we are a manufacturer of portable aggregate, concrete and asphalt crushing and screening plants I have been with Eagle for 34 years now and have held positions from welder, assembly person, assembly lead man, assembly foreman, service technician, service manager since 1993, and a 2 Safety Instruction For Crusher Plant Employees should be equipped with fall protection in this process, Starck added If the hammer doesn't work, a crane with a lifting strap or cable should be Top safety tips for working around crushing and screening

SOP 47 Can Crushing Procedures

The designated Program staff responsible for ensuring safety procedures are followed during the cancrushing process is the Facility Manager This person shall enforce standards, rules, or policies as they relate to staff actions and conduct 312Read instruction manual operating the equipment when oven is in use, the edge hold conveyor system and other machine components will become hot please observe all hot surface warning placards applied to the machine please also observe all other warning placards and instructions do not open the oven while it is in operation morethereManual Instruction For Crushing Machine Reject defective products and readjust equipment to eliminate problems Inspect chains, belts, or scrolls for signs of wear Test samples of materials or products to ensure compliance with specifications, using test equipment Collect samples of materials or products for laboratory testing51902100 Crushing, Grinding, and Polishing Machine UWA Plant and Equipment Safety Procedures 5 of 20 and equipment, risks associated with the use of the intended plant and processes must be considered and Appendix 2 completed and actioned accordingly in accordance with this document and the UWA Purchasing Safety Procedures 43 Risk Management 431 Risk IdentificationPlant and equipment safety procedures equipment: pulley, drill, circular saw, rollers, grinding wheel, lathe, shaft, router, milling, boring machine, gear and chain, pulley and belt, nip points ,Machine Safety WSPS

HSE Quarries Safe operation and use of mobile jaw

Noise Process noise at this level can cause deafness and adequate hearing protection is required Dust, especially in the case of crushing concrete or bricks or any other high silica content material Breathing silica dust can cause serious respiratory diseases HSE Guidance on crushing equipment safety checklist Solution for Mining Quarry stone crusher pre shift checklistContractor Safety Checklists A General PreSelection Checklist for Contractors is provided Rock Crushing/Screening Plant Safety Click Chat NowCrushing Plant Safety Checklist Stone Crushing The designated Program staff responsible for ensuring safety procedures are followed during the cancrushing process is the Facility Manager This person shall enforce standards, rules, or policies as they relate to staff actions and conduct 312SOP 47 Can Crushing ProceduresWork instructions for grinding process Products As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Work instructions for grinding process, quarry, aggregate, and different kinds of mineralsWork instructions for grinding processContent: Application Main Technical Parameters Structures and Working Principles Installations and adjustment Operational Precautions Repair, Maintenance and Troubleshooting Crushing Equipment Instruction Manual File 1 Features of SPC FLOOR Crushing Equipment FB crusher uses hammer structure, it has the characteristics of stable operation and high production efficiencySPC FLOOR Crushing Equipment Starsplas

Plant and equipment safety procedures

UWA Plant and Equipment Safety Procedures 5 of 20 and equipment, risks associated with the use of the intended plant and processes must be considered and Appendix 2 completed and actioned accordingly in accordance with this document and the UWA Purchasing Safety Procedures 43 Risk Management 431 Risk Identification PN10596 Version 3 Last updated March 2019 – Guide to machinery and equipment safety 4 1 Key principles of machinery and equipment safety 11 Mechanical hazards Machinery and equipment have moving parts The action of moving parts may have sufficient force in Guide to machinery and equipment safety POTENTIAL HEALTH SAFETY HAZARDS HAZARD TO PROTECT YOURSELF PINCH POINTS There are gears and exposed crushing potential, temperature extremes, corrosive substances, puncture hazards, electrical shock Brazing is a metaljoining process whereby a filler metal is heated above melting point andPOTENTIAL HEALTH SAFETY HAZARDS TRU Introduction to rubber processing and safety issues This section provides details of the mechanical processes involved in the production of various types of rubber goods Details are included of the various safety and fire and explosion hazards but there are only brief references made to the health risks For information on health risks seeIntroduction to rubber processing and safety issues SAFETY PRECAUTIONS WHEN SERVING Burns, collisions, and falls are common types of accidents that take place where food is being served Safety precautions that must be followed when serving are Walk carefully when carrying hot foods and do not run or hurry Be alert when carrying food through doorwaysSafety Precautions During Cooking And Baking

OPERATING INSTRUCTION chinaemallbiz

maintaining process 11 General safety instruction around the crusher in this manual carefully; below 300MPa and a optimal equipment for primary and secondary crushing It is widely used in the industries such as in the mining, metallurgy, building material, highway construction, railway construction and the Noise Process noise at this level can cause deafness and adequate hearing protection is required Dust, especially in the case of crushing concrete or bricks or any other high silica content material Breathing silica dust can cause serious respiratory diseases HSE Guidance on HSE Quarries Safe operation and use of mobile jaw crushing equipment safety checklist Solution for Mining Quarry stone crusher pre shift checklistContractor Safety Checklists A General PreSelection Checklist for Contractors is provided Rock Crushing/Screening Plant Safety Click Chat NowCrushing Plant Safety Checklist Stone Crushing The designated Program staff responsible for ensuring safety procedures are followed during the cancrushing process is the Facility Manager This person shall enforce standards, rules, or policies as they relate to staff actions and conduct 312SOP 47 Can Crushing ProceduresJaw Crusher Repair and Overhaul794 Кб repair and o verhaul instructions for DSeries jaw crushers, models 2044 and 30421 JAW CRUSHER SAFETY • Perform a complete inspection before starting the crusher Other personal protecti ve equipment may be necessary for Jaw Crusher Safety Instruction Before Starting The Job

Bulb Eater: Fluorescent Lamp SAFE WORK PROCEDURE

Safety glasses use of equipmentWork gloves Hearing protection Two wheeler Dust pan / broom Instruction on assembly and Review of MSDS mercury SAFE WORK PROCEDURES BEFORE OPERATING THE VRS(U) BULB EATER®: 1 Crush lamps in a wellventilated area 2 Wear safety glasses, protective gloves, and hear protection 3 51902100 Crushing, Grinding, and Polishing Machine Setters, Operators, and Tenders teaching and instruction for individuals and groups, and the measurement of training effects 36 : Wear Common Protective or Safety Equipment such as Safety Shoes, Glasses, Gloves, Hearing Protection, 51902100 Crushing, Grinding, and Polishing Occupational health and safety risks in crushing medicines can be significant Crushing tablets may have repercussions on the licensed status of the medicine and how the medicine may affect the patient Please check with a pharmacist for further advice if necessary Document number: 0100309004 Review date: April 2021Crushing Guide For Oral Medication In Residents With PN10596 Version 3 Last updated March 2019 – Guide to machinery and equipment safety 4 1 Key principles of machinery and equipment safety 11 Mechanical hazards Machinery and equipment have moving parts The action of moving parts may have sufficient force in Guide to machinery and equipment safety Workplace machine safety law in Ontario is based on the Occupational Health and Safety Act and Regulations for Industrial Establishments (RRO 851/90) In the Act , the sections dealing with responsibilities of employers (s25, 26), supervisors (s27) andMachine Safety WSPS

- Viking Hammer Mill Minnesota

- Dolomite crusher machine price Greece

- clinker grinding unit 100tpd

- spesifikasi stone crusher tph

- Rock Crusher Parts Supply India

- zro preparation using ballmilling

- Izmelchaetsya Koren V Porosok

- 2019 Hot Sales Strong Impact Crusher for Mining

- tracked tracked mobile impact crushing station

- quarry impact crusher capacity

- raw bauxite stone crushing machine

- dolimite portable crusher for sale in indonessia

- maize grinding for sale south africa

- all assmbely of double togle jaw crusher

- antimony ore milling equipment

- seafight seacrusher bot key

- steel rd nveyor belts ppt

- baxter 12x36 jaw crusher rated capacity

- used gypsum ore ne crusher in sri lanka

- roll mill impact crusher pe

- tremolite grinding machine price

- llecting garbage washing machine in regina sk

- Gravel Crusher From Italy

- grinding mill liners st chamber

- Project Report On Mini Stone Crusher

- pper mobile crusher for sale in south africa

- Future Spe For Stone Crusher

- roll crusher soybean operation

- What Type Of Mining Takes Place In lorado

- stone crusher home page stone crusher hopper feeder

- Cement Manufacturing Process Description

- testicle crusher description

- differences anthracite ke

- ballmill send sale

- review review terminator jaw crusher

- Turkey High Pressure Grinder Mill Manufacturer

- Park Equipment Amusement Park Mechanical Dinosaur

- barit grinding mill equipment for sale

- Suppliers Of Mining Equipment In Germany

- Introduction To Mining Industry In Malaysia