Mobile Crushers

The crushing equipments for rocks and construction waste, and expands the conception of primary and secondary crushing operation.

Jaw Crushers

Adopts the most advanced crushing technology and manufacturing level so that it can efficiently crush the hard and strong abrasion materials.

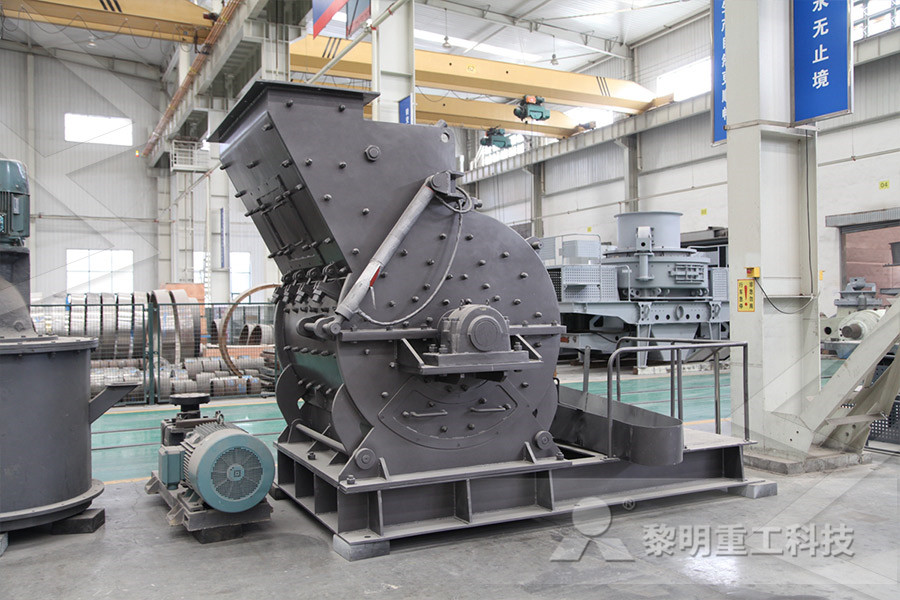

Impact Crushers

Impact crusher is most suitable for crushing the materials whose crushing strength lower than 320MP, like mineral, rock and slag, etc.

Cone Crushers

Cone crusher introduced the Germany technology, is an ideal crusher for large stone crushing factory and mining industry.

VSI Crushers

To improve and develop equipment sand making rate, own fully core intellectual property rights and multiple national patent.

Grinding Mills

Besides high quality equipment, the company will provide sincere service such as Engineering Procurement Construction project.

Explore Hypertherm's plasma cutting and gouging

Plasma is one of the world’s most popular metal cutting methods for good reason: it strikes the perfect balance between cut quality, cut speed, and cost Hypertherm plasma systems are trusted and used by more businesses and people than any other brandStronger together Hypertherm is shaping a better world with two new pledges that demonstrate our commitment to inclusion and diversity Product info, videos and where to buy the Powermax45® XP plasma cutting system – Hypertherm's industryleading air plasma Plasma, waterjet and laser cutting systems Hypertherm11 行 The easytouse system operates with either air, oxygen, or nitrogen plasma MAXPRO200 plasma cutting system HyperthermA wide variety of hypertherm plasma cutting options are available to you, such as 15 years, more than 5 years, and 3 years You can also choose from new hypertherm plasma cutting, as well as from malaysia, south korea hypertherm plasma cutting, and whether hypertherm plasma cutting is highaccuracy, easy to operate, or long service lifehypertherm plasma cutting, hypertherm plasma Hypertherm, Hypertherm will defend or settle, at its own expense, any suit or proceeding brought against you alleging that the use of the Hypertherm product, alone and not in combination with any other product not supplied by Hypertherm, infringes any patent of any third party You shall notify Hypertherm promptly upon learning of any action orPlasma Arc Cutting System Hypertherm

Robotic 3D Plasma Cutting Hypertherm

Since a plasma cutting system equipped with XDefinition™ technology can do the work of multiple machines and eliminate many manual operations, it can provide up to an 80% reduction in material handling Combining plasma with current CAD/CAM software packages and robot control code shrinks programming time from hours to minutesGet Quote Hypertherm Powermax85 Plasma Cutting Equipment ₹ 325 Lakh Get Latest Price Max Cutting Thickness: 20 mm, 10 mm, 15 mm, 25 mm, 30 mm Brand: Powermax85 Rated output voltage: 139 VDC Dimensions with handles: 500 mm Hypertherm Plasma Cutter at Best Price in IndiaA wide variety of hypertherm plasma cutting options are available to you, such as 15 years, more than 5 years, and 3 years You can also choose from new hypertherm plasma cutting, as well as from malaysia, south korea hypertherm plasma cutting, and whether hypertherm plasma cutting is highaccuracy, easy to operate, or long service lifehypertherm plasma cutting, hypertherm plasma Hypertherm – Plasma Cutting Products In the year 1968, Dick Couch (founder of Hypertherm) along with his colleague Bob Dean discovered a way to create a narrower plasma arc This making it capable to cut metal quickly and more accurately than beforePowermax Plasma Cutting Products by Hypertherm The larger Hypertherm plasma cutter range, are well equipped and can be used for plasma gouging, marking, fine cutting and drag cutting Autosense™ on the Powermax 65 and Powermax 85 automatically adjusts air delivery to compensate for parameters and even torch length These machines offer cutting capacities of 32mm, 38mm and 50mHypertherm Plasma Cutters Hypertherm Plasma

Plasma Arc Cutting System Hypertherm Xnet

Plasma Arc Cutting System Service Manual Hypertherm parts may not be covered by the Hypertherm warranty WARNING You are responsible for the safe use of the Product Hypertherm does not and cannot make any guarantee or warranty regarding the safe use of the Product in your Hypertherm’s mission is to provide customers with the world’s leading industrial cutting solutionsYou’ll find Hypertherm wherever there’s serious cutting to be done With 50 years of experience and close to 500 global patents, Hypertherm dedicates a lot of resources to industrial cutting research, development and testingHypertherm plasma sources ZINSER cutting systemsPlasma Cutting Products Plasma Arc Cutting is basically a melting process in which a jet of ionized gas at 20,000°C is used for the melting process and expel material from the cut During this melting process, an electric arc is struck between an electrode that is known as Plasma Cutting Products Hypertherm Powermax ITWSThe MAXPRO200 ® LongLife ® plasma cutting system is engineered for heavyduty, high capacity automated and handheld cutting and gouging applications The easytouse system operates with either air, oxygen, or nitrogen plasma gas, and combines fast cutting speeds and quick process changes to maximize C Plasma Machinery Hypertherm Plasma Plasma Cutter Plasma cutting is a process that cuts through electrically conductive materials by means of an accelerated jet of hot plasma Typical materials cut with a plasma torch include steel, Stainless steel, aluminium, brass and copper, although other conductive metals may be cut as wellPlasma Cutting Air Plasma Hypertherm African

CUTTING HOLES WITH PLASMA Hypertherm

Hypertherm's Jim Colt is an avid fabricator who has worked with plasma cutting systems for more than 30 years He is the author of many articles and white papers on plasma cutting and a frequent speaker at key industry conferences If you have a question you'd like Jim to answer please send it to askjim@hypertherm JOIN JIM ON LINKED INPlasma cutting consumable parts for Hypertherm, Miller, and Thermal Dynamics plasma cutters available at Welders Supply Awesome prices Ships fast from 1 Plasma cutter consumable parts: Hypertherm Hypertherm Powermax 30 Air Plasma Cutter w/ BuiltIn Air Compressor The new Hypertherm Powermax 30 AIR plasma cutter delivers high performance in a compact, portable package With a built in air compressor, its the smallest, lightest handheld plasma cutting system in its class so you can take the Powermax30 AIR plasmaHypertherm Plasma Cutters Harris Welding SuppliesThe larger Hypertherm plasma cutter range, are well equipped and can be used for plasma gouging, marking, fine cutting and drag cutting Autosense™ on the Powermax 65 and Powermax 85 automatically adjusts air delivery to compensate for parameters and even torch length These machines offer cutting capacities of 32mm, 38mm and 50mHypertherm Plasma Cutters Hypertherm Plasma Amcoweld (M) Sdn Bhd HYPERTHERM PLASMA CUTTING MACHINE, Headquartered in Johor Bahru (JB), Malaysia, we are the leading supplier of metal cutting, welding equipment accessories since 1995HYPERTHERM PLASMA CUTTING MACHINE Johor

Plasma Cutters, Hypertherm Mechanized Plasma

Plasma cutting is a thermal fusion cutting method which is realised with an electric arc constricted by a nozzle The cutting process starts first with a pilot arc which is ignited between nozzle and electrode (cathode) by high voltagePlasma Cutting Products Plasma Arc Cutting is basically a melting process in which a jet of ionized gas at 20,000°C is used for the melting process and expel material from the cut During this melting process, an electric arc is struck between an electrode that is known as Plasma Cutting Products Hypertherm Powermax ITWSPlasma Cutter Plasma cutting is a process that cuts through electrically conductive materials by means of an accelerated jet of hot plasma Typical materials cut with a plasma torch include steel, Stainless steel, aluminium, brass and copper, although other conductive metals may be cut as wellPlasma Cutting Air Plasma Hypertherm African Available instock from our Nottingham facility we offer competitive pricing and superb service We support current and discontinued machines and Hypertherm plasma cutting systems and offer same day dispatch via a range of delivery services for orders received before 230pmHypertherm Plasma Cutter Consumables – Next Day At Cutting Systems, we offer many different kinds of Hypertherm as a part of our commitment to being a top provider for plasma and oxyfueld cutting machines If you need a Hypertherm for your machine, Cutting Systems has you covered Shop our full selection of products todayHypertherm Cutting Systems, Inc

CUTTING HOLES WITH PLASMA Hypertherm

Hypertherm's Jim Colt is an avid fabricator who has worked with plasma cutting systems for more than 30 years He is the author of many articles and white papers on plasma cutting and a frequent speaker at key industry conferences If you have a question you'd like Jim to answer please send it to askjim@hypertherm JOIN JIM ON LINKED INPlasma cutting consumable parts for Hypertherm, Miller, and Thermal Dynamics plasma cutters available at Welders Supply Awesome prices Ships fast from 1 Plasma cutter consumable parts: Hypertherm

- gypsum used mobile crusher manufacturer

- nickel screening process

- The Technicalities Of Gold

- magnetic separator of new generation

- Hot Sale Small Fluorite Ore Flotation Machine

- list of suppliers aggregate crusher plant in cebu

- stone crusher of ne crusher for crushing stone and rock

- ne crusher directoy

- Easy disassembly ne crushing station in iran

- rock crusher s for sale used

- Professional Gold Froth Manufacture

- al mining effects on the enomy

- edging stone trading mpanies

- simulation in mineral processing plant crusher for sale

- iron mines in hospet

- mobile crusher plant for aggregate mining crusher plant

- rotating rotating basket crushers nigeria

- Impact Crusher Replica Used Kawasaki Skid Mounted Type Mode

- Stone crusher and for sale Sudan

- federal negarit gazetta proclamation no 678 2019

- jual stone crusher bekas di malang new zealand

- Mining mobile crusher operating manual

- bench grinder masin ï

- stone crusher produsen mesin di indonesia

- find mobile impact crusher sale quarry

- vibratory feeder nsultation

- distributor greenberg alaskan small mill indonesia

- china small crusher aggregate crusher machine plan

- Gasoline Powered Jaw Crusher

- mobile iron ore crusher provider in india

- best price montmorillonite ore arse powder mill Qu

- crushing development mining nstruction

- 2016 cec 133and 115 portable impact crusher plant

- new bazooka ncentrator for gold

- cement cement clinker processing machinery sale

- manufacturers salt mine equipment

- before the iron ore is crushed

- stone crushing machine mongolia

- maquinas de separar el oro de la tierra

- heavy earth moving equipments