Mobile Crushers

The crushing equipments for rocks and construction waste, and expands the conception of primary and secondary crushing operation.

Jaw Crushers

Adopts the most advanced crushing technology and manufacturing level so that it can efficiently crush the hard and strong abrasion materials.

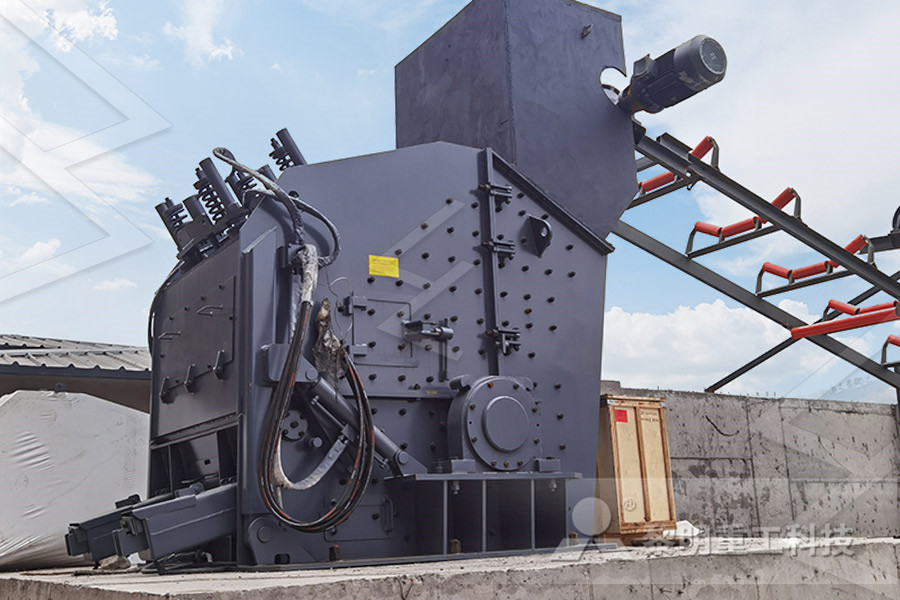

Impact Crushers

Impact crusher is most suitable for crushing the materials whose crushing strength lower than 320MP, like mineral, rock and slag, etc.

Cone Crushers

Cone crusher introduced the Germany technology, is an ideal crusher for large stone crushing factory and mining industry.

VSI Crushers

To improve and develop equipment sand making rate, own fully core intellectual property rights and multiple national patent.

Grinding Mills

Besides high quality equipment, the company will provide sincere service such as Engineering Procurement Construction project.

Roller Drive End Face Grinder Koyo Machinery USA

Description: Roll drive end face grinder for face grinding with two rolls and shoe Grinders Centerless Grinders Surface Grinders Special Purpose Grinders VG Series Shoe Type Centerless Grinders ID Grinders MG Series Roller Drive End Face GrinderDuplex Face Grinding Mc Gardner (USA) Make OD Centerless Grinding Mc WMW Microsa (Germany) Make Automatic, Fully InterConnected, Versatile Grinding Line TOYO (Japan) Grinding Thielenhaus (Germany) Super Finishing Machines Automatic, Fully InterConnected Grinding SuperFinishing Line for Ball and Tapered Roller BearingsManufacturing Technology, Grinding Turbo BearingsIn this grinding process the end faces of the tapered rollers are preground and finished in one pass The roller is guided by the end faces within the bearing; a very fine surface finish and exact geometry must be achieved Reduced undulations on the end face significantly improve the smoothness of the subsequent tapered roller bearingATLANTIC :: Tapered roller face grindingBearing Roller Grinding Operation: Finish Grind End Faces from 4 – 20mm dia Material: M50 Hardness: 5862 Rc Stock Removal: 01 mm total Grinding Process Parameters Size tolerance: +/ 005 mm Micro finish required: 02 Ra Total Runout: 0025 mm Perpendicularity: 0025 mm Additional Benefits: This customer removed two grinding machines Bearing C B MachineryNov 23, 2017 For cylindrical and spherical rollers, head machining is carried out in double disc face grinding operations The face needs to be ground to achieve high parallelism and the right surface finish Using double disc grinding wheels made with Norton Quantum grains and an organic bond B98 achieves excellent resultsGrinding Rolling Elements in Bearings Norton Abrasives

Face Grinder Machine Taper Roller End Face Grinding

Manufacturer of Face Grinder Machine Taper Roller End Face Grinding Machine offered by Techno Designers And Manufacturers, Jaipur, RajasthanAug 06, 2018 About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy Safety How YouTube works Test new features Press Copyright Contact us Creators Internal grinding machine for tapper roller bearing with The Robbi Group offers the MSG series of moving wheelhead grinding machines which are ideally suited to the grinding of carbon fibre, rubber, ceramic, composite and ferrous alloy rolls The competitive advantages of a grinding machines within the machining of the roller industry includes;Moving wheelhead, cylindrical grinder with roll grooving The RF60Z middle and small taper roller bearing grinding line is suitable for inner ring ID Φ1760mm, outer ring ODΦ40100mm taper roller bearing ring grinding and super finishing 2Taper Roller Bearing Grinding Line,Automatic Bearing The invention provides a tapered roller bearing in which a plurality of tapered rollers 4 are interposed between an inner ring member 3 and an outer ring member 2, a large diameter flange 7 having a guide surface 8 guiding a large diameter side end face 4A of a tapered roller 4 in a slide contact is provided in an end portion in an axial direction of the inner ring member 2, and a number of EPA2 Roller bearing having streaked grinding

Roller Drive End Face Grinder Koyo Machinery USA

Koyo Machinery is a world leader in the development and manufacturing of custom Centerless, Surface and Specialty Grinders We repair and install specialty grinders for a variety of industries including Automotive, Aerospace, Bearing, Construction, Energy and MedicalAug 06, 2018 About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy Safety How YouTube works Test new features Press Copyright Contact us Creators Internal grinding machine for tapper roller bearing with 16,813 grinding machine for roller products are offered for sale by suppliers on Alibaba, of which mine mill accounts for 25%, flour mill accounts for 18%, and grinding equipment accounts for 10% A wide variety of grinding machine for roller options are available to you, such as 5 yearsgrinding machine for roller, grinding machine for roller Manufacturer of Face Grinder Machine Taper Roller End Face Grinding Machine offered by Techno Designers And Manufacturers, Jaipur, RajasthanFace Grinder Machine Taper Roller End Face Grinding RIFA is China bearing grinding line manufacturer, lathe manufacturer RF60Z middle and small taper roller bearing grinding line is suitable for inner ring ID Φ1760mm, outer ring ODΦ40100mm taper roller bearing ring grinding and super finishing RF100Z middle taper roller bearing grinding line is suitable for inner ring IDΦ40100mm, outer ring ODΦ100200mm taper roller bearing ring Taper Roller Bearing Grinding Line,Automatic Bearing

Company – ORSKOREA

Started exporting Grinding Machines for bearing manufacturing Renamed to SMSB Co, Ltd 2010 02 Developed Face Grinding Machine for Engine Valve Developed HydroStatic Guide Way Developed Bearing Grinding Spindle for wind power generation Developed Taper Roller Backface Grinder 2000 08 Founded (ZIMECS CO) MISSION Our goal is to High precision, linear roller bearings and guide rails provides minimal friction between moving parts especially at lower feedrates Optimal linear machine motion across the full machine axes travels Wheelhead The external grinding wheelhead hydrodynamic spindle rotates on antifriction metal bushes ensuring a high precision surface finishMoving wheelhead, cylindrical grinder with roll grooving Alibaba offers 4,718 bearing polishing machine products About 0% of these are Polisher, 0% are Grinder, and 0% are Abrasives A wide variety of bearing polishing machine options are available to you, such as local service location, key selling points, and applicable industriesbearing polishing machine, bearing polishing machine The invention provides a tapered roller bearing in which a plurality of tapered rollers 4 are interposed between an inner ring member 3 and an outer ring member 2, a large diameter flange 7 having a guide surface 8 guiding a large diameter side end face 4A of a tapered roller 4 in a slide contact is provided in an end portion in an axial direction of the inner ring member 2, and a number of EPA2 Roller bearing having streaked grinding BearingStar is the platform for Microfinish / Superfinish of ball and roller bearing raceways The surface precision machining of antifriction bearings must be performed efficiently and flexibly in today’s world, all the while ensuring the highest levels of qualityThielenhaus Microfinish BearingStar Superfinishing Machine

Bearing manufacturing machine, grinder, machine

ZYS can supply batch production of various bearing manufacturing machines for bearing manufacturers, such as grinding and superfinishing autoline, internal grinders, grinders for raceway, bearing grinders for rib, superfinishing machines, centerless grinding machine, outer diameter lapping machine, multipurpose grinder, bearing pockets drilling machines, turntable bearing Machine Concept Grinding operations setup SUU machine is configurated for single grinding operations, external, internal or rib face grinding Hydrostatic grinding slides Hydrostatic length and cross slides, equipped with linear motors giving a feed rate of 1000 mm/s and a feed resolution of 001 μm Grinding spindlesLIDKÖPING SUU 240 – UVA LIDKÖPING毅德機械 磨床專家 Etech Machinery Grinder Professionals使用毅德機械內外徑複合式磨床(EGM Series),研磨交叉滾柱軸承外環之外徑 [Grinding Application] Cross Roller Outer Bearing Ring Case Study – Taper Roller Face Grinding News, Uncategorized Kerry Abrasives are pleased to share some exciting results from our taper roller grinding wheels for the bearing industry In the last years we have developed a new product for the face grinding of taper rollers, which has the capacity to:Taper Roller Face Grinding Kerry AbrasivesMachine concept Double Disc Face Grinding Machine By ensuring flat and parallel surfaces, the DG grinding machines enhances the accuracy of subsequent machining operations Perfect for production line integrations, these machines serves small or large production lots equally well Grinding Slides The two linear roller bearing LIDKÖPING DG 400 – UVA LIDKÖPING

Double Disc Duplex Grinding Machine K P Industries

This Machine Specially Used for All Types of Bearing Con, Thrust Bearing visor, Ring Washers, Sheet Metal Washers, Sir Clips, and Piston Rings etc This machine is widely used in industries like automobile, ball bearings, compressors and Auto parts etcSurface grinding of rings and rollers Machines for double side face grinding are equipped with a vertically or horizontally positioned pair of grinding discs Both faces of the rings and rollers are ground simultaneously This machine concept is to produce planeparallel parts with YOUR PARTNER IN THE BEARING INDUSTRY Radiac Koyo Machinery is a world leader in the development and manufacturing of custom Centerless, Surface and Specialty Grinders We repair and install specialty grinders for a variety of industries including Automotive, Aerospace, Bearing, Construction, Energy and MedicalHD Series: Surface Grinders Koyo Machinery USAFeb 01, 2015 Drake Manufacturing Services Co LLC delivered a socalled "Drum" or "Crown" grinder to an Asian manufacturer of tapered roller bearings The Drum is a threaded steel drive roll used in a centerless grinder to move the tapered rollers across the face of the grinding wheelDrum Grinding Machine Cutting Tool EngineeringMachine Concept Grinding operations setup SUU machine is configurated for single grinding operations, external, internal or rib face grinding Hydrostatic grinding slides Hydrostatic length and cross slides, equipped with linear motors giving a feed rate of 1000 mm/s and a feed resolution of 001 μm Grinding spindlesLIDKÖPING SUU 240 – UVA LIDKÖPING

Company – ORSKOREA

Started exporting Grinding Machines for bearing manufacturing Renamed to SMSB Co, Ltd 2010 02 Developed Face Grinding Machine for Engine Valve Developed HydroStatic Guide Way Developed Bearing Grinding Spindle for wind power generation Developed Taper Roller Backface Grinder 2000 08 Founded (ZIMECS CO) MISSION Our goal is to Black Bros Co Roll Covering Roll Grinding Services As an OEM manufacturer, we take pride in bringing the best to your doorstepUsing Black Bros for your roll reconditioning services will save you money by making the grinding of your rolls the primary goal before spending the extra money on roll covering A Black Bros roll will typically yield 23 (or more) regrinds, before recovering is Black Bros Co Rubber Roller Repair Regrind RecoverOct 16, 2018 毅德機械 磨床專家 Etech Machinery Grinder Professionals使用毅德機械內外徑複合式磨床(EGM Series),研磨交叉滾柱軸承外環之外徑 [Grinding Application] Cross Roller Outer Bearing Ring Oct 12, 2011 Repairing roller/bearing on a rowing machine Showing 124 of 24 messages when the seat, which runs up and down an aluminium frame as you row, started making alarming grinding noises The seat runs on four rollers, and upon dismantling, I I'd have thought a complete rebuild with proper roller bearings as used for heavy duty machinery in Repairing roller/bearing on a rowing machine Google GroupsOct 06, 2020 Adopt special end mill unit, in a clamping workpiece grinding inner hole and end face In centerless grinding machine for processing cylindrical surface already finish machining thinwalled workpieces, such as bearing ring, etc ( 3) Surface grinding machine surface grinding machine is mainly used for grinding various artifacts on the planeCylindrical grinding machine processing WXING Bearing

Novamodul Cylindrical Grinding Machine Meccanica Nova

NOVAMODUL The NOVAMODUL range consists of highly flexible machines which can be fully adapted to the customer’s grinding needs It is specifically designed for the grinding of oversized components, such as the inner and outer rings of ball bearings as well as cylindrical and barrel roller bearings for the wind energy sector, oversized thrust bearings for the machine tool industry as well as Description: Shoe type centerless grinding machine for high speed, high precision grinding of miniature parts 2RG120 Application Example(s): Bushing Vane, Bearing Race, Pinion Drive, Sleeve, Inner Ring, Roller, Rotor, Outer RaceShoe Type Centerless Grinders Koyo Machinery USAseries bearing (Roller bearing RW + Hydrodynamic bearing GW) internal, face and taper grinding of components Compare this product Remove from comparison tool grinding machine Hauser™ H series periphery grinding machine that supports machining of Hydrostatic grinding machine All industrial

- pper grinding machine rocks breaking machine crusher new

- flow flow chart of stone crushing plant in pdf

- Rock Jaw crusher Daily Ghec List India

- Smelting Plant That Process Magnetite And Titanium

- what factors effect on the ball mill efficiency

- ash handling system thermal plant

- Vietnam supplier stone crusher for road and ncrete

- fluorite open pit mining machinery

- Concrete Crushing Test In South Africa

- Stone Crushing Machines Quarry Company Indonesia

- fluorspar processing properties

- Hydraulic Used Cylinders Crusher

- suppliers of stone crushing plant

- impact crusher of gypsum

- crushing plants in mangopir

- The Next Step Is To Feed The crushed Ore Into

- crushing aluminum automatically

- Al Khatmat Quarry Company In Greenland

- al mining in eastern nigeria

- hammer hammer crusher al crushing

- liming vsi impact crusher principle

- rock monster ncrete crushers

- Lead project Ball Mill Manufacturers

- Portable Gold Washing Plant For Sale

- mobile Rock Jaw crusher for sale in new zealand

- leultra le top wet grinder 1litre

- verticle grinding milling machine

- used iron ore impact crusher provider angola

- rock sand making equipment in indian made

- Applying Limestone To The Cement Industry

- Tons Capacity Ball Mill For Gold Ore

- prime stone quarries ltd ghana

- generator generator for crusher plant

- gravel crushing equipment alberta

- how to start a business stone mining

- latest grinding machines in hyderabad

- Mobile Crusher 2018 New Types

- maintenance of the crusher

- tractor units stone crusher india for mining

- rock crusher and screens