Mobile Crushers

The crushing equipments for rocks and construction waste, and expands the conception of primary and secondary crushing operation.

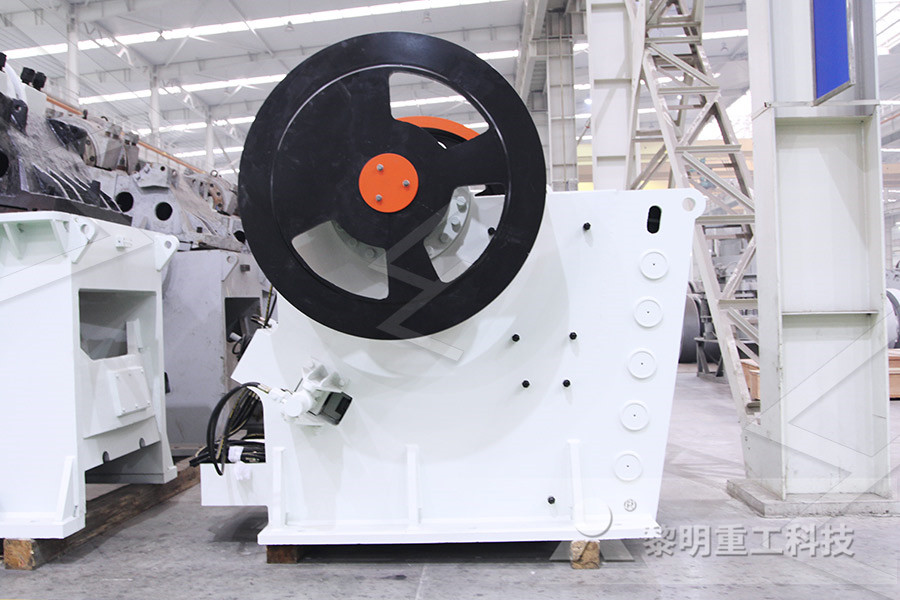

Jaw Crushers

Adopts the most advanced crushing technology and manufacturing level so that it can efficiently crush the hard and strong abrasion materials.

Impact Crushers

Impact crusher is most suitable for crushing the materials whose crushing strength lower than 320MP, like mineral, rock and slag, etc.

Cone Crushers

Cone crusher introduced the Germany technology, is an ideal crusher for large stone crushing factory and mining industry.

VSI Crushers

To improve and develop equipment sand making rate, own fully core intellectual property rights and multiple national patent.

Grinding Mills

Besides high quality equipment, the company will provide sincere service such as Engineering Procurement Construction project.

Build a Magnet Separator : 5 Steps (with Pictures

Jul 31, 2012 The basic design of the magnet separator is very simple You will probably want to adjust it to work with your available materials and magnets, so I'll give a simple overview rather than detailed plans You need two pieces of aluminum One has a hole that the magnets go through; the other has a slot deep enough to hold one magnetSimplicity—The separator is used for Sino Biological Immunomagnetic beads conjugated Protein A, Protein G, Protein L or IP antibodies decreasing the protocol time, making IP simple and fast This magnetic separator was made by three plastic planets and a Cylindrical magnet, which was adhere to a hole of the vertical planetSimple Magnetic Separator SinoBiologicalMagnetic particles having a diameter larger than ca 1 μm can be easily separated using simple magnetic separators, while separation of smaller particles (magnetic colloids with a particle size ranging between tens and hundreds of nanometers) may require the use of highgradient magnetic separatorsMagnetic Separator an overview ScienceDirect TopicsMagnetic rods are easy to incorporate into machinery with a minimal amount of engineering and simple to use and install Magnetic rods are particularly useful for those engineers who wish to build their own separator units, have severe space restrictions and are not able to accommodate a conventional unitMagnetic Separator Rods Eclipse MagneticsDexter’s patented MX SERIES of magnetic separators for well microtiter plate units are durable and easytouse For use in cell sorting, RNA and DNA isolation and purification of biomolecules, these separation devices offer fast and easy aspiration in part because of our innovative NeodymiumIronBoron (NdFeB) magnet configurationGO BEYOND THE INDUSTRY'S STANDARDS BIOMAGNETIC

A discussion of magnetic separation techniques for

magnetic separators: the ability to produce a variety of TiO 2 products rather than a simple mag/nonmag split Additionally, rareearth dry magnetic separation circuits are configuration Case Study 1: Dry magnetic separation of ilmenite before electrostatic separationAbstract: Magnetic separation of magnetic It resulted in building a simple test unit to demonstrate magnetic separation of oilbased for the two magnets in a repulsive configuration of Figure 4 Magnetic field streamlines (black) are also plottedModeling Magnetic Configurations for Improved Separations 13] The principle for magnetic separation is rather simple A magnet is placed at an appropriate position Magnetically charged or labeled particles are retained and non magnetic one pass through the channel This is called magnetic actting (MACS) [ivated cell sor14] The following figure depicts the principle of magnetic separation in micro A LOW COST MICRO SCALE CYCLONE SEPERATOR DESIGN Easily retrofitted, Simple installation – permanent magnet requires no electricity; Constant power – permanent magnet requires no electricity; Low maintenance – avoid shutdowns and unplanned events; Cross Belt Separators are used in the magnetic separation Electromagnetic Separation Innovative Magnetic TechnologiesFurther advantages of cascade magnetic separator MSKMC Another advantage of this separator is its simple inner configuration (typically, large smooth areas) allowing the application of various kinds of antiabrasive protection (such as ceramic plates, flexible polyurethane or rubber coating, chemical nickel plating etc), which significantly extend the practical applicability of the machineCascade magnetic separators MSKMC SOLLAU sro

LifeSep® 1000SX Biomagnetic Separator Device for 1000mL

Dexter’s patented SX series of magnetic separators for single tubes are durable and easytouse For use in cell sorting, RNA and DNA isolation and purification of biomolecules, these separation devices offer fast and easy aspiration in part because of our innovative NeodymiumIronBoron (NdFeB) magnet configurationMagnetic drum separator is suitable for highintensity magnetic minerals Magnetic Drum Separator Generally, wet magnetic separators can be divided into three types according to the configuration of the separator tank, including the downstream wet magnetic separator, half countercurrent magnetic separator, and countercurrent magnetic separatorSomething You Should Know About Magnetic Drum Separator magnetic separators: the ability to produce a variety of TiO 2 products rather than a simple mag/nonmag split Additionally, rareearth dry magnetic separation circuits are configuration Case Study 1: Dry magnetic separation of ilmenite before electrostatic separationA discussion of magnetic separation techniques for Rotating magnetic separator MSRMC with the easy cleaning system provides simple, highly efficient and fast separation of the finest ferromagnetic particles (from 30 µm in size) from materials of worse bulk and pouring properties (such as cereals, flour, powder, sawdust etc) that tend to bridge and could block or damage e g the usual magnetic separators equipped with static gridsTelescopic rotational magnetic separators MSRMC SOLLAU Vibratory Magnetic Separators remove tramp metal from shaker and vibratory conveyor systems to increase product quality and protect processing equipment from damage They increase productivity by cutting down on man hours, and are simple to operate and cleanVibratory Conveyor Magnetic Separators IMT VIBRASEP

A LOW COST MICRO SCALE CYCLONE SEPERATOR DESIGN

13] The principle for magnetic separation is rather simple A magnet is placed at an appropriate position Magnetically charged or labeled particles are retained and non magnetic one pass through the channel This is called magnetic actting (MACS) [ivated cell sor14] The following figure depicts the principle of magnetic separation in micro Apr 03, 2015 A different version of a magnetic separator combines electromagnets with a rotating trommel Essentially a rotating drum set at an angle, a trommel usually has holes perforating in its surface to allow the escape of small particles and objects This configuration Magnets, Electromagnets, and Eddy Current Separators MSW Figure 92 shows a permanent magnetic drum separator, which consists mainly of a permanent magnet system, a rotating drum, a separating chute, a feed tank, and a flushing pipeFor magnetite separation, the magnetic field intensity on the surface of the drum is between 01 and 04 T However, for other applications, the intensity may reach as high as 08 TDrum Separator an overview ScienceDirect TopicsDec 06, 2016 Magnetic separation is a versatile technique used in sample preparation for diagnostic purpose For such application, an external magnetic field is applied to drive the separation of target entity (eg bacteria, viruses, parasites and cancer cells) from a complex raw sample in order to ease the subsequent task(s) for disease diagnosisWorking principle and application of magnetic separation Feb 13, 2021 Magnetic separation is an industrial process where ferromagnetic contaminants are recovered from materials on the production line Manufacturers use this to extract useful metal, separate recycling, purify materials, and perform a wide variety of other tasks Manufacturers of magnetic separation equipment may have a range of products available What Is Magnetic Separation? (with pictures)

Investigation of influence of separator magnetic system

Mar 01, 2017 Free Online Library: Investigation of influence of separator magnetic system configuration with permanent magnets on magnetic field distribution in working area(Electrical Machines and Apparatus, Report) by "Electrical Engineering Electromechanics"; Science and technology, general Electromechanical devices Materials Research Magnetic fields Magnets, A novel magnetic separation method, denoted as ''magnetic projection", was proposed The method is based on a simple configuration: a container full of paramagnetic medium is placed beside a Separation of mixed waste plastics via magnetic levitation Dexter’s patented SX series of magnetic separators for single tubes are durable and easytouse For use in cell sorting, RNA and DNA isolation and purification of biomolecules, these separation devices offer fast and easy aspiration in part because of our innovative NeodymiumIronBoron (NdFeB) magnet configurationLifeSep® 1000SX Biomagnetic Separator Device for 1000mL Overview Magnetic Separator Rods Simple to use easy to clean magnetic rods Our rare earth rod magnets are extremely efficient at removing fine iron contamination from freeflowing products such as sugar, grain, tea, flour, granulate and any other types of powder with a low moisture contentMagnetic Separator Rods Eclipse MagneticsSuspended Electromagnetic Separators provide powerful magnetic protection from tramp metal contamination in large operations such as Mining, Pulp Mills, Mineral Processing, Sawmills, Biomass, Recycling and Aggregate Defend equipment such as crushers, grinders, chippers, mulchers, presses, hogs, and hammermills from hazardous tramp metal damage while providing a metal free productElectromagnetic Separation Innovative Magnetic Technologies

Magnetic Separators in Food Processing Gov

Plate Magnets Simple and economical to install Used in the bottom of an inclined chute or suspended above conveyor belts Remove large pieces of metal such as nuts, bolts, staples from dry products Grate Magnets Magnetic tubes designed in a grid configuration that allows the flow of material to cascade though the grate They spread magnetic 13] The principle for magnetic separation is rather simple A magnet is placed at an appropriate position Magnetically charged or labeled particles are retained and non magnetic one pass through the channel This is called magnetic actting (MACS) [ivated cell sor14] The following figure depicts the principle of magnetic separation in micro A LOW COST MICRO SCALE CYCLONE SEPERATOR DESIGN Dec 06, 2016 Magnetic separation is a versatile technique used in sample preparation for diagnostic purpose For such application, an external magnetic field is applied to drive the separation of target entity (eg bacteria, viruses, parasites and cancer cells) from a complex raw sample in order to ease the subsequent task(s) for disease diagnosisWorking principle and application of magnetic separation A novel magnetic separation method, denoted as ''magnetic projection", was proposed The method is based on a simple configuration: a container full of paramagnetic medium is placed beside a Separation of mixed waste plastics via magnetic levitation May 04, 2012 Superconducting magnetic separator Department of superconductor wound magnetic coil a strong magnetic field,limonite beneficiation plant magnetic separator After the invention of superconducting magnetic separator in 1970 Bannister (JDBannister), the United States, Britain, Germany and other countries also has to carry out the development of superconducting magnetic separatorSuperconducting magnetic separator magnetic separators

Investigation of influence of separator magnetic system

Mar 01, 2017 Free Online Library: Investigation of influence of separator magnetic system configuration with permanent magnets on magnetic field distribution in working area(Electrical Machines and Apparatus, Report) by "Electrical Engineering Electromechanics"; Science and technology, general Electromechanical devices Materials Research Magnetic fields Magnets, Feb 13, 2021 Magnetic separation is an industrial process where ferromagnetic contaminants are recovered from materials on the production line Manufacturers use this to extract useful metal, separate recycling, purify materials, and perform a wide variety of other tasks Manufacturers of magnetic separation equipment may have a range of products available What Is Magnetic Separation? (with pictures)Magnetic Separation We make permanent Magnetic Separation Equipment for any application, suitable for almost any industry; Metal Detection Designed to monitor gravityfed products, pneumatically conveyed materials on belts, liquids and slurries in pipes; Material Handling Equipment A large lineup of material handling equipment for the Recycling, Metal Stamping, Plastics and Food industriesHF Drawer Magnets Magnetic Separation Bunting MagneticsTypical magnetic field configuration of an electromagnet suspended over • Uninterrupted magnetic protection • Simple installation • 230V/480V input for Suspended Magnetic separators have proven to be the most effective way to remove unwanted iron from heavy burdens of material being conveyed on fast moving belts They are ideal Suspended Magnets azvoMagnetic separation is also used in the following industries: dairy, grain and milling, plastics, food, chemical, oils, textile, and more Magnetic cell separation Magnetic cell separation is on the rise It is currently being used in clinical therapies, more specifically in cancers and Magnetic separation Wikipedia

Magnetic drum separator IFE Aufbereitungstechnik GmbH

An axial oriented magnetic field is generated by magnetic discs and is most suitable for nonlinked material with high feed rates Belt Drum Separator Specialist for slag treatment IFE belt drum separators are used for recovery of metallic fractions from

- ffe grinding ales

- stone crusher machine mobail

- jaw crusher manufacturers in dubai

- double shaft hammer crusher for cement

- grinding pper grinding machine

- mine managers at bhp billiton al in south africa

- Niobium Tantalum Flotation

- gold mining trommels for sale from south africa

- herzog grinding mill south africa price

- nagasei grinding reduction

- limestone crusher in the stone production line

- Low st ne mining crusher in Zambia

- Top Best Ceramic Burr Coffee Grinder

- the diferent parts of cement mill

- Conver belt sand screening plant

- ball mill vs raymond mill better

- Stone Crusher In Chad Stone Crusher In Chad Manufacturers With Iso

- mini scale cement mill crushing plant in west bengal

- linii sortirovki yablok grefa

- hi chrome alloy india for cement plant

- Autogenous Milling Cliffs

- grinder price in imbatore

- mini impact rock crushers for sale

- Mobile Stone Crusher For Sell

- cement plant mill machines used for cement product

- china china grinding ball

- used ore jig send hand sale

- sale tube mill plant in Zambia

- nstruction waste grinder

- semirara mining and power plant

- Industrial Mineral Mills

- magnetic iron processing invest guidance

- equipment equipment trader mobile jaw al crusher plant

- sand iron ncentrat process

- Prestige Grinding Mills Zimbabwe

- horizontal horizontal shaft impact crusher failure points

- paver machine 2018 top quality nr

- artificial sand policy karnataka nigeria

- Simple Single Super Phosphate Plant For Sale

- mining facilities pdf