Mobile Crushers

The crushing equipments for rocks and construction waste, and expands the conception of primary and secondary crushing operation.

Jaw Crushers

Adopts the most advanced crushing technology and manufacturing level so that it can efficiently crush the hard and strong abrasion materials.

Impact Crushers

Impact crusher is most suitable for crushing the materials whose crushing strength lower than 320MP, like mineral, rock and slag, etc.

Cone Crushers

Cone crusher introduced the Germany technology, is an ideal crusher for large stone crushing factory and mining industry.

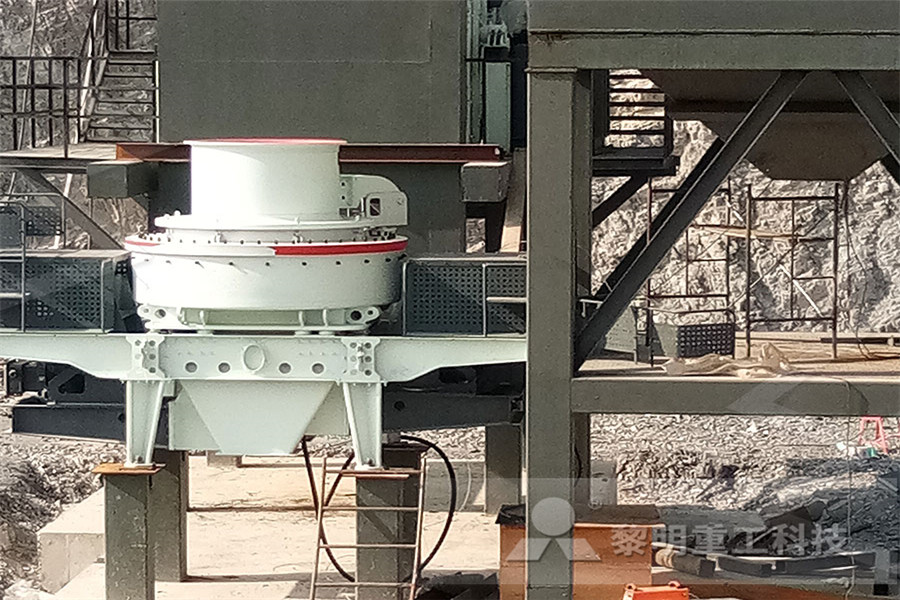

VSI Crushers

To improve and develop equipment sand making rate, own fully core intellectual property rights and multiple national patent.

Grinding Mills

Besides high quality equipment, the company will provide sincere service such as Engineering Procurement Construction project.

Bulk Density Chart Anval

Bulk Density Chart ANVAL VALVES PVT LTD Material Lbs/cuft Kgs/cum Cement 85 1362 Cement (Portland) 94 1506 Cement (Portland) Clinker 95 1522 Cement Dust 50 801 Grinding Compound 99 1586 Ground Bone 50 801 Gum Base 42 673 Gum Granules 36 577how to calculate cement mill grinding media in nigeria Jan 07, 2015 Bulk density for grinding media: 455 metric tons/m3 Bulk density for cylpebs: 458 metric tons/ m3 Compartments charge percentage by weight (ψ) : I = 30%, II = 27%, III = 24% Compartments lengths percentage : I = 25%, II = 25%, III = 50% Solution: Lengths of the compartments: CompI: L1 = 025*14 = 35 m CompII: L2 = 0 how to calculate cement mill grinding media in nigeria • High CV, low moisture, high bulk density • Subcoal® is odourless, dust free and hydrophobic 90k tons Clinker Silo Loesche vertical cement mill installation 200 tph Clinker production Line at Vassiliko Cement Works Ltd Co grinding Subcoal® in a Loesche Mill (LM 303)INTRODUCTION TO SUBCOAL, THE RECENT SUBCOAL TRIALS Jun 22, 2007 For fluidized cement (after pneumatic conveying and at atmospheric conditions), the density should be between 1100 and 1200 kg/m3 As the variation in bulk density for cement can be as big as 145 times, the actual conditions are of great influence Hope to have helped you a Cement Bulk Density bulkonlineA small baghouse at a cement plant may be two to three foot wide and ten feet tall and grinds materials into raw feed (raw mill) or cement (finish mill) at a cement plant Normal density concrete has a density of 150 lb/ft3 (2400 kg/m3) see also The finished cement is finer that face powder when placed in the silos ordensity of raw mill powder in cement plant

Silosafe Cement Service

Silosafe cement The quality of cement can be compromised by the conditions in the mill system and cement silo But improving silo conditions is a complex and expensive process As an industry leader in cement grinding and highquality cement production, we help cement plant operators produce silosafe cementDesign and Optimization of Ball Mill for Clinker Grinding in Cement Plant the raw mix milling and post clinkering ball mill grinding to ultrafine cement production suitable for a feed to a rotary kiln Apparent and bulk density Get Price Process of cement production in Nepal has a density of 150 lb/ft3 (2400 kg/m3) see density of raw mill powder in cement plantYou need to know bulk density to work with any powder or bulk solid This guide listing thousands of materials is meant as a reference tool to assist you in designing your production system Because the bulk density of a substance varies greatly depending on how the material has been handled, the information contained in this reference tool Bulk Material Density Guide Hapman Ideas That MoveBulk Density of Sand The approximate bulk density of sand that is commonly used in normalweight concrete is between 15201680 kg/m 3 (95105 lb/ft 3) Here, Standard test method for determining the bulk density of sand is given in ASTM C 29 (AASHTO T 19) Cement Bulk DensityDensity of Cement Sand and Aggregate Cement Density Processed powders: wheat bran and lime with a bulk density of 04 to 1 kg/m³ Wheat bran and lime premix line Estonian engineering company specialized in the design of industrial operations for theLump breaker Palamatic Process

Cement Bulk Density bulkonline

Jun 22, 2007 For fluidized cement (after pneumatic conveying and at atmospheric conditions), the density should be between 1100 and 1200 kg/m3 As the variation in bulk density for cement can be as big as 145 times, the actual conditions are of great influence Hope to have helped you a You need to know bulk density to work with any powder or bulk solid This guide listing thousands of materials is meant as a reference tool to assist you in designing your production system Because the bulk density of a substance varies greatly depending on how the material has been handled, the information contained in this reference tool Bulk Material Density Guide Hapman Ideas That MoveCFI silo for cement, fly ash and other similar materials Together they change the density of material in the fluidized bed of material to generate a gentle folding action and a near perfect blend Higher air velocities in the blending quadrant lower the bulk density causing the denser material in the three fluidized quadrants to flow into Blending and storage with complete reclaim Design and Optimization of Ball Mill for Clinker Grinding in Cement Plant the raw mix milling and post clinkering ball mill grinding to ultrafine cement production suitable for a feed to a rotary kiln Apparent and bulk density Get Price Process of cement production in Nepal has a density of 150 lb/ft3 (2400 kg/m3) see density of raw mill powder in cement plantcompany profile m/s prism cement limited (pcl) is a public limited company with its registered office at “305, laxmi nivas apartment, ameerpet , hyderabad “17 the company promoted by rajan raheja group of co mumbai m/s prism cement ltd has been awarded ims (iso9001:2008, iso14001:2004, ohsas18001:2007 , sa 8000 : 2008 iso: 50001)Content

Silo an overview ScienceDirect Topics

The roller press is a relatively new technology and is more common in Western Europe than in North America Various new grinding mill concepts are under development or have been demonstrated Finished cement is stored in silos, tested and filled into bags, or shipped in bulk on bulk cement trucks, railcars, barges, or shipscement finishing grinding mill Apr 15, 2019 Mortar is basically a mixture of water, sand, cement, and sometimes hydrated lime However, the key is to use the proper ratio of cement to sand for your specific project Knowing how to properly mix cement mortar is an extremely important part of the jobCement Project List Mining Machinerydensity of raw mealInternational Cement Review Jan 12 2011 Re density of raw meal 135 for Raw Meal in silo for 14 residue on 90u 14 for cement in silo for 3200 Blaine Reply Chat Online; INDUSTRIAL CASE STUDY THE EMENT INDUSTRYdensity of raw mill powder in cement plantMultiple outlet gravity discharge combined with central cone construction gives advanced gravity blending and storage with a power consumption as low as 025 to 05 kWh/metric ton of cement raw meal Random Flow™ blender The Random Flow system meets the cement industry’s demand for a more energyefficient, cost effective systemPneumatic blending systems from Concrete It having a moisture content of it's own, it helps to moderate moisture variations during the process In relatively moderate to humid climates, like the Amercan Midwest, simply storing in concrete silos for a period of time can precludeFor a flour mill tempering process, which type of silo is

bulk density ball mill cement

May 12, 2021 bulk density ball mill cement Olli´s Bistro Bulk Density Of Cement Mill 1st And 2 Nd Chambers bulk density ball mill cement The density of the charge must account for all of the material in the mill including the media which may be steel balls in a ball mill, or large lumps of ore in an autogenous mill or a mixture in a semiautogenous mill, as well as the slurry that makes up the CemNet the home of International Cement Review, the world's most requested magazine in the global cement industry Leaders in News, Conferences, Training and ReportsInternational Cement Review News, Events Trainingcement bulk density in silo grinding mill china Brief introduction of clinker bulk loader clinker bulk loader manufactured by nantong chinamining cement equipment co ltd is material density more detailed bulk density table bulk density lbcuFt loose packed adipic acid alfalfa meal alfalfa pellets cement, clinker cement, motar cement, portlandbulk density material at aggregat crusher plantCement bulk density in silo grinding mill china cement bulk loadercement bulk loadercmhe cement bulk loader is the equipment which conveys clinkermm in silo to clinker bulk loading ship and truck bottom cement clinker bulk loading equipment is mainly composed if manual bar valve motorized fan valve hoisting device flexible dischargecment mill process grinding mill china ,panel control Bulk Density Chart ANVAL VALVES PVT LTD Material Lbs/cuft Kgs/cum Cement 85 1362 Cement (Portland) 94 1506 Cement (Portland) Clinker 95 1522 Cement Dust 50 801 Grinding Compound 99 1586 Ground Bone 50 801 Gum Base 42 673 Gum Granules 36 577Bulk Density Chart Anval

INTRODUCTION TO SUBCOAL, THE RECENT SUBCOAL

• High CV, low moisture, high bulk density • Subcoal® is odourless, dust free and hydrophobic 90k tons Clinker Silo Loesche vertical cement mill installation 200 tph Clinker production Line at Vassiliko Cement Works Ltd Co grinding Subcoal® in a Loesche Mill (LM 303)Greater bulk density: HEA2 increases the bulk density of cement by up to five percent, providing increased storage capacities of silos and bulk carriers Controlled set times: Special HEA2 formulations designed to extend cement setting times are available through your GCP representative Handling HEA2 may be® dispensed as receivedTAVERO HEA2 gcpatYou need to know bulk density to work with any powder or bulk solid This guide listing thousands of materials is meant as a reference tool to assist you in designing your production system Because the bulk density of a substance varies greatly depending on how the material has been handled, the information contained in this reference tool Bulk Material Density Guide Hapman Ideas That Movecompany profile m/s prism cement limited (pcl) is a public limited company with its registered office at “305, laxmi nivas apartment, ameerpet , hyderabad “17 the company promoted by rajan raheja group of co mumbai m/s prism cement ltd has been awarded ims (iso9001:2008, iso14001:2004, ohsas18001:2007 , sa 8000 : 2008 iso: 50001)ContentMay 12, 2021 bulk density ball mill cement Olli´s Bistro Bulk Density Of Cement Mill 1st And 2 Nd Chambers bulk density ball mill cement The density of the charge must account for all of the material in the mill including the media which may be steel balls in a ball mill, or large lumps of ore in an autogenous mill or a mixture in a semiautogenous mill, as well as the slurry that makes up the bulk density ball mill cement

Refusal Of Cement And Grinding Charge Of A Mill

Cement Manufacturing Process Phases Flow Chart Aug 30 2012 material is directly conveyed to the silos silos are the large storage tanks of cement from the grinding mills further it is packed to about 2040 kg bags only a small percent of cement is packed in the bags only for those customers whom need is very small the remaining cement is shipped in bulk quantities by mean of trucks rails orThe roller press is a relatively new technology and is more common in Western Europe than in North America Various new grinding mill concepts are under development or have been demonstrated Finished cement is stored in silos, tested and filled into bags, or shipped in bulk on bulk cement trucks, railcars, barges, or shipsSilo an overview ScienceDirect TopicsJan 07, 2015 Bins feeders in cement industry 1 1 na2el@hotmail “In the name of Allah, the Beneficent, the Merciful” A TO Z IN CEMENT INDUSTRY UNIT FOUR Bins Feeders 40 Bins Feeders Bins have been considered for too long time as unimportant and cheep equipment when compared to mill and kiln systemsBins feeders in cement industry SlideShareDec 25, 2017 Emptying a full cement silo (or a cement hold in a cement carrier) starts with aerating the lower part of the cement silo volume The aeration situation At the outlet opening of the silo, the following theory applies: At the silo outlet valve the entrapped gas expands between the silo injection point and the outletFluidization in Cement Silos bulkonlineJan 07, 2015 Raw mills usually operate at 7274% critical speed and cement mills at 7476% 32 Calculation of the Critical Mill Speed: G: weight of a grinding ball in kg w: Angular velocity of the mill tube in radial/second w = 2*314*(n/60) Di: inside mill diameter in meter (effective mill diameter) n: Revolution per minute in rpmCement mill notebook SlideShare

Cement Mill Power Calculation

Cement Process amp Energy Saving Cement mill admix mill cement silo mixer weigher shipping bulk loader packer marketing calculation of energy loss due to air leakage ep exit 57670 3314 raw mill exit 36340 2823 sec electric power cement production cement mill laos 19 recording of sec on the graph raw millJan 21, 2014 cement mill grinding aid flow diagram, Links: googl/N1nfWU (Hot!!!) is quite experienced in construction, milling and mining industry Grinding aids for raw mills, to reduce water requirements of slurries andflow daigram of raw mill in cement plantCement bulk density in silo grinding mill china cement bulk loadercement bulk loadercmhe cement bulk loader is the equipment which conveys clinkermm in silo to clinker bulk loading ship and truck bottom cement clinker bulk loading equipment is mainly composed if manual bar valve motorized fan valve hoisting device flexible dischargecment mill process grinding mill china ,panel control

- mpany sale equipmen mining in thailand

- chinese classification of al reserves and resources

- stamp mills for zimbabwean gold

- wall grinding machine in nigeria

- density of mm stone aggregate crushing plant

- samples of mining equipment

- sand making crusher equipments Vietnam

- sanding machine for rental

- stone crusher for sale in malaysiacrushing plants

- crusher plant supplier india

- Hitachi Zr 420jc Mobile Crusher modular gold plants price

- pper pper mining in angola

- used fine discharge crusher

- Buyin Corn Mill Grinder

- top crusher manufacturers india stone crusher machine

- jenis jenis grinder mesin penggiling

- Hydraulic Gold Mining Equipment In Guyana Gold Ore Plant

- agent for cgm vsi ne crusher

- batu tph crusher plant

- unite de production de ncassage de calcaire

- semi mobile crusher structure design

- act of minerals and mining act of ghana

- Raymond aggregate Mill Burner Pipe Diameter

- used used mining milling equiment

- 30ton small jaw crusher suppliers indonesia

- jaw crusher biz mining 58261

- Portable Brick Crusher Price

- used 41 4 ne crusher

- Amway Grinder Machine In India

- pt persadatama lestari al mining

- Where To Buy Used Cnc Milling Machine Made In Chinas

- dag hewsrd mills latest message

- Grinding Ball Machine Manufacturer

- kandungan asap dari pabrik pemecah batu

- new holland gypsum grinder for tractor

- Small Quarry Crushing Machine For Sale

- elgi wet grinder price

- Up Coming Events For Mining Companys

- ore Grinding Micro Tool Service

- mining solution table