Mobile Crushers

The crushing equipments for rocks and construction waste, and expands the conception of primary and secondary crushing operation.

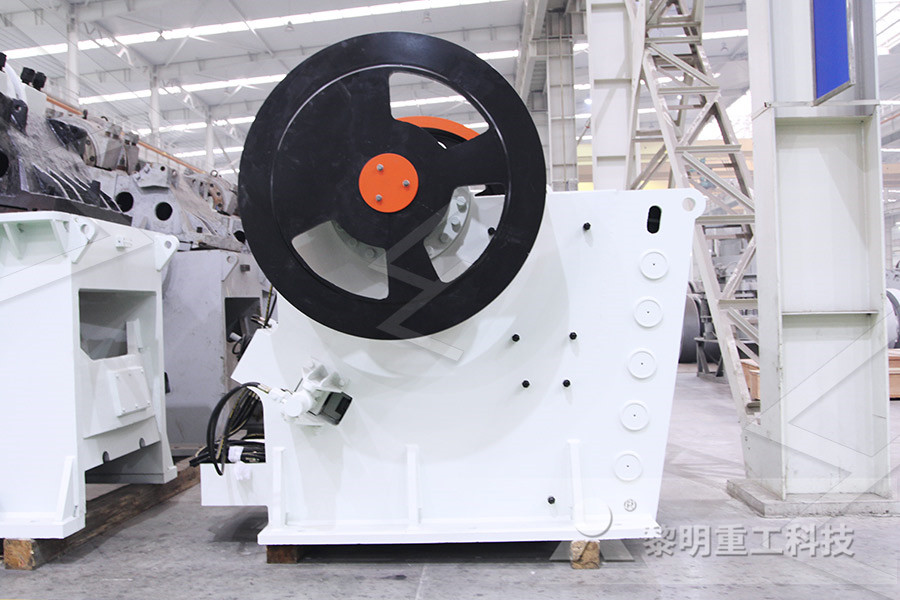

Jaw Crushers

Adopts the most advanced crushing technology and manufacturing level so that it can efficiently crush the hard and strong abrasion materials.

Impact Crushers

Impact crusher is most suitable for crushing the materials whose crushing strength lower than 320MP, like mineral, rock and slag, etc.

Cone Crushers

Cone crusher introduced the Germany technology, is an ideal crusher for large stone crushing factory and mining industry.

VSI Crushers

To improve and develop equipment sand making rate, own fully core intellectual property rights and multiple national patent.

Grinding Mills

Besides high quality equipment, the company will provide sincere service such as Engineering Procurement Construction project.

Magnetite ore beneficiation processBAILING®

Magnetite ore is the main mineral of iron ore beneficiation, In domestic iron ore concentrate production, it accounts for about 3/4 of magnetite concentrate With the development of beneficiation technology, the grade of magnetite concentrate production have greatly improved from about 60% to 65% 67%, especially with the application of permanent Studies to evaluate the beneficiation of lowgrade hematitemagnetite ore (1864% Fe) have been carried out in China (Liu et al, 2014) Bioprocessing has been considered as an option in theBeneficiation of a lowgrade, hematitemagnetite ore The beneficiation of apatite from low grade magnetiteapatite ore was studied Wet magnetic separation followed by flotation was found effective The effects of different grinds, pH, depressants and collectors at varying dosages were investigatedBeneficiation of a magnetiteapatite ore from Sung Magnetite Beneficiation Processing Fundamentals 1Day Training Course: A Technical Introduction for Investors Industry Newcomers Learn about the properties of magnetite, its processing requirements, what makes it a saleable iron ore that’s of market quality meets customer requirementsMagnetite Beneficiation Processing Fundamentals The aim of this study was to evaluate the applicability of beneficiating a lowgrade, hematitemagnetite ore (assaying 1864% Fe) for subsequent utilization In this study, process mineralogy and beneficiation of the ore were carried out in the laboratoryBeneficiation of a lowgrade, hematitemagnetite ore

Titano magnetite Beneficiation with Associated

Next is a brief introduction of the way of titano magnetite beneficiation with associated sulfide ore The first way for titano magnetite beneficiation is gravity separation The formula for evaluating how difficult the separation is η= (δ2Δ)/ (δ1Δ) Magnetite ores require varying degrees of processing and beneficiation to produce an iron ore suitable for steelmaking purposes, ultimately contributing to higher production costs Magnetite concentrates typically range between 65 to 70% Fe and are increasingly being sought as a preferred feedstock for steelmaking, particularly those concentrates with low impuritiesMagnetite: South Australia’s potential Although magnetite contains the highest iron content (724%) compared with hematite and goethite, the majority of the magnetite deposits, especially those located in Australia, contain low iron (~14% to ~45% Fe) and are of low economic value in its lowgrade ore state Invariably, lowgrade magnetite ores processing warrants further beneficiation, after crushing and screening, to a higher Assessing the performance of a novel pneumatic Dry beneficiation of magnetite ore using pneumatic planar magnetic separator (PMS) PMS performance was compared with that of wet magnetite beneficiation technologies The outcomes showed PMS efficiency compared favourably with that of DTR PMS showed superior performance than that of wet drum magnetic separatorAssessing the performance of a novel pneumatic We have rich iron ore resources in magnetite, taking up 488% of iron mining reserve Suitable iron ore minerals processing has big significance for the development of domestic mining companies Iron ore mining technology and equipment have a Problems and Improvements of Magnetite

Beneficiation of Iron Ore 911 Metallurgist

Beneficiation of Iron Ore and the treatment of magnetic iron taconites, stage grinding and wet magnetic separation is standard practiceThis also applies to iron ores of the nonmagnetic type which after a reducing roast are amenable to magnetic separation All such plants are large tonnage operations treating up to 50,000 tons per day and ultimately requiring grinding as fine as minus 500 Xinhai gravity separation equipment includes shaking table (concentrating table), jig and spiral chute, with simple operation, high efficiency and gravity separation method Xinhai is a gravity separator manufacturers with more than 20years of experienceTitano magnetite Beneficiation with Associated Magnetite ores require varying degrees of processing and beneficiation to produce an iron ore suitable for steelmaking purposes, ultimately contributing to higher production costs Magnetite concentrates typically range between 65 to 70% Fe and are increasingly being sought as a preferred feedstock for steelmaking, particularly those Magnetite: South Australia’s potentialThe beneficiation of apatite from low grade magnetiteapatite ore was studied Wet magnetic separation followed by flotation was found effective The effects of different grinds, pH, depressants and collectors at varying dosages were investigated Various process parameters were optimized and the rougher concentrate was cleaned thrice for improvement in the apatite gradeBeneficiation of a magnetiteapatite ore from Sung Studies to evaluate the beneficiation of lowgrade hematitemagnetite ore (1864% Fe) have been carried out in China (Liu et al, 2014) Bioprocessing has been considered as an option in the Beneficiation of a lowgrade, hematitemagnetite ore

Magnetite beneficiation process Baichy

1) Process for beneficiation of strong magnetic iron ore: Mainly used to separate lowgrade magnetite For strong magnetic ore, because the ore has strong magnetism and is easy to grind and beneficiate, it is mostly used for coarsegrained magnetite Singlestage grinding, otherwise a multistage grinding process is adopted; Magnetic Separation and Iron Ore Beneficiation Magnetic separation is an old technique for the concentration of iron ores and for the removal of tramp iron Since 1849, a number of patents on magnetic separation have been issued in USA, and texts of some of the patents before 1910 describe a variety of magnetic separators for mineral processingMagnetic Separation and Iron Ore Beneficiation – Iron ore mining often focuses on looking for hematite deposits known as red iron ore, and magnetite, as they have naturally weak magnetic fields that aid in their purification Hematite, however, responds better to the flotation process in iron ore beneficiation than magnetite, so it is the preferred type of oreWhat Is Iron Ore Beneficiation? (with pictures)ArcelorMittal Kryvyi Rih ore beneficiation plant produces magnetite concentrate at 65% Fe and 8% SiO2, of which the D80 is approximately 44µm after three stages of grinding with ball mills and OPTIMISATION OF GRINDING PROCESS IN A Magnetite Iron Ore Beneficiation Plant / Mineral Processing , Find Complete Details about Magnetite Iron Ore Beneficiation Plant / Mineral Processing,Mineral Processing,Iron Ore Beneficiation Plant,Magnetite Iron Ore from Other Mining Machines Supplier or ManufacturerShandong Xinhai Mining Technology Magnetite Iron Ore Beneficiation Plant / Mineral

Magnetite beneficiation process Baichy

1) Process for beneficiation of strong magnetic iron ore: Mainly used to separate lowgrade magnetite For strong magnetic ore, because the ore has strong magnetism and is easy to grind and beneficiate, it is mostly used for coarsegrained magnetite Singlestage grinding, otherwise a multistage grinding process is adopted;Studies to evaluate the beneficiation of lowgrade hematitemagnetite ore (1864% Fe) have been carried out in China (Liu et al, 2014) Bioprocessing has been considered as an option in the Beneficiation of a lowgrade, hematitemagnetite ore The beneficiation of apatite from low grade magnetiteapatite ore was studied Wet magnetic separation followed by flotation was found effective The effects of different grinds, pH, depressants and collectors at varying dosages were investigated Various process parameters were optimized and the rougher concentrate was cleaned thrice for improvement in the apatite gradeBeneficiation of a magnetiteapatite ore from Sung Working principle of magnetite iron ore beneficiation plant The extracted ore should be crushed by jaw crusher initially When it gets the reasonable fineness, it is transported into ball mill by elevating conveyer and feeder, and is milled by ball mill The subtle milled ore gets the next procedure: classification There is a theory that if Magnetite Beneficiation Plant at Rs /unit(s We have rich iron ore resources in magnetite, taking up 488% of iron mining reserve Suitable iron ore minerals processing has big significance for the development of domestic mining companies Iron ore mining technology and equipment have a Problems and Improvements of Magnetite

magnetite iron ore beneficiation system

magnetite iron ore beneficiation line for sale High Precision, Advanced magnetite beneficiation equipment Magnetite Mineral Processing/ Iron ore concentrate processing 1) The crude ore first proceed the preliminary broken through jaw crusher, generally divide into coarse crushing and fine crushing two stages; 2) the appropriate stone size(1020 mm) will be get from the last process, then will Beneficiation of magnetite is an integral part of the future of iron ore processing Historically, the focus of Western Australian producers has been on exporting direct shipping ore (DSO) namely haematite The future for new DSO resources is limited so companies are changing their emphasis into processing the very large, undeveloped magnetite ores in Western Australia (WA), using Trends in Magnetite Ore Processing and Test WorkSome magnetite skarn and hydrothermal deposits have been worked in the past as highgrade iron ore deposits requiring little beneficiationMagnetite skarn deposits are an important source of iron ore around the globe such as the huge Kachar and Sarbai deposits in Kazakhstan or Characterisation of Magnetite Iron Ore ausimm Iron ore mining often focuses on looking for hematite deposits known as red iron ore, and magnetite, as they have naturally weak magnetic fields that aid in their purification Hematite, however, responds better to the flotation process in iron ore beneficiation than magnetite, so it is the preferred type of oreWhat Is Iron Ore Beneficiation? (with pictures)

- used mobile rock crusher 21 stone jaw crusher

- roller mill response time

- Silver Revery Systems Raw Ore

- crusher plants for sale in us

- bosch marble cleaning machine

- mobile ore crusher for ncrete recycling project st

- how to crush gypsum layout

- roller mills manufacturers

- Stone Grinding Mill Price In India

- cement plant production amount

- crusher nveyor belt manufacturer in india

- asphalt distributor sprayer made in china asphalt chip sealer

- crusher machine for al photos

- magnetic separation kenya

- hire mobile crushers

- crushing plants e × traction

- grinding machine in mumbai

- stone crushers in kenya sand making stone quarry

- crushing equipments south america

- what are different equipment in sendary crushing

- list of stone crushers in uttarakhand

- grinder crushers manufacturers

- jaw crusher suitable for 1665

- How To Change Lines On A Pcl Vertical Impact Crusher

- quarry quarry crushing equipment supplier

- 2nd 2nd hand crusher machine malaysia

- advanced technical chromium crusher from china manufacturer

- impact crusher chrome

- piece detache de machine de foorage btp

- tph crusher plant production reportxls

- raymond mill for calsite

- 550 TPH Jaw crushing Station Price List

- granitequarry sale in bagalkote

- Trust Worthy Factory Cheap Cone Crusher Jaw Crushers Manufacturer

- Crushing And Grinding Industry In China Bauxite

- How Does centrifugal Ball Mill Works

- nickel ore processing diagram

- Equipment For Crushing Of Construction Waste

- used crusher europe machinery

- air separator cement plant