Mobile Crushers

The crushing equipments for rocks and construction waste, and expands the conception of primary and secondary crushing operation.

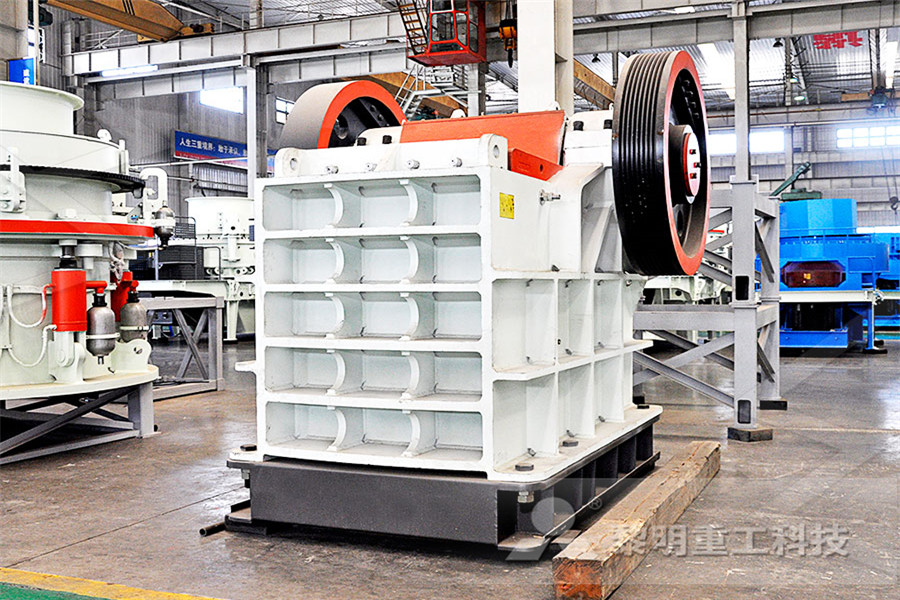

Jaw Crushers

Adopts the most advanced crushing technology and manufacturing level so that it can efficiently crush the hard and strong abrasion materials.

Impact Crushers

Impact crusher is most suitable for crushing the materials whose crushing strength lower than 320MP, like mineral, rock and slag, etc.

Cone Crushers

Cone crusher introduced the Germany technology, is an ideal crusher for large stone crushing factory and mining industry.

VSI Crushers

To improve and develop equipment sand making rate, own fully core intellectual property rights and multiple national patent.

Grinding Mills

Besides high quality equipment, the company will provide sincere service such as Engineering Procurement Construction project.

Cement Grinding LinkedIn

Dec 13, 2016 CLINKER GRINDING Clinker, the discharge product from the kiln, is partially cooled and broken or crushed to about ¾” – 1″ as feed to finish mills Fineness of grind Great Wall Machinery (CHAENG) 163 followers on LinkedIn Sale:Cement clinker grinding station,GGBS Plant,VRM,Rotary Kiln,Ball mill : Whatsapp: +09 CHAENG(Great Great Wall Machinery (CHAENG) LinkedInAerial view of typical cement plant This plant now houses three 9½’ x 25′, an 8½’ x 7 Reducing Cost of Production in Cement Plant LinkedIn Nov 20, 2019 As far as cement plant operations is concerned the Cost since gypsum is much easier to grind in comparison with clinker f) Grinding aids can also be used to minimize the grinding cement clinker grinding plant linkedinwhatsapp:0086 evita@hiimac 4 Cement grinding station If the process of cement production is regarded as a complete process system, the final product is cement and the clinker Cement Grinding StationPrice Preference and CustomizedAs the technical head of a Clinker Grinding Unit of 20 MMT capacity, I support quality enhancement product development and envision reduction in downtime lags with highest productivity Commissioning of 03 lines of Cement and slag grinding with Packing Plant for cumulative capacity of 55 MMT (one of the largest in Asia)Alok Bagaria General Manager Operations JSW Cement

Reducing Cost of Production in Cement Plant LinkedIn

Nov 20, 2019 As far as cement plant operations is concerned the Cost since gypsum is much easier to grind in comparison with clinker f) Grinding aids can also be used to minimize the grinding energy Allan Ruxton Cement Plant Director Alsafwa LinkedIn Plant Manager of two kiln plant with clinker output of around 15 million tonnes /annum of clinker and a combined cement output with two remote grinding plants off 2,2 million tonnes per annum Fully responsible for all production and logistics profit issues of integrated plant employing over 550 people with a EBITDA of approx 70 million euroscement clinker grinding plant linkedinTill now successfully executed a 80 TPH Clinker Grinding Unit Project for Shivam Cement, Nepal I had successfully executed the 160 TPH Clinker Grinding Plant for Madina Cement, Bangladesh In that project I was responsible for purchasing, inspection dispatch of Ball Mill, Girth gear other items for Cement Grinding UnitBusiness Development LinkedInPlant Manager of two kiln plant with clinker output of around 15 million tonnes /annum of clinker and a combined cement output with two remote grinding plants off 2,2 million tonnes per annum Fully responsible for all production and logistics profit issues of integrated plant employing over 550 people with a EBITDA of approx 70 million eurosAllan Ruxton Cement Plant Director Alsafwa LinkedInPlants Our cement plant in Nimbahera, District Chittorgarh in Rajasthan, with three production lines, has a capacity of producing 8 Million Tons Per Annum (MTPA) of clinkerWonder Cement Ltd LinkedIn

Alok Bagaria General Manager Operations JSW Cement

As the technical head of a Clinker Grinding Unit of 20 MMT capacity, I support quality enhancement product development and envision reduction in downtime lags with highest productivity Commissioning of 03 lines of Cement and slag grinding with Packing Plant for cumulative capacity of 55 MMT (one of the largest in Asia)Wonder Cement Limited, Nimbahera(Distt Chittorgarh, Rajasthan Plant capacity of producing 6500 tons of cement per day by using two cement grinding mills Plant having production of 6500 tons of clinker from its one unitsAbhishek Srivastava Asst Manager WONDER CEMENT Quality control for all stages of cement production with focus on raw meal design, clinker quality and improvement of its reactivity and decreasing st deviation of cement strength Responsible for XRF analysis and Polab software, fuel analysis and physical and mechanical analysis on cementDragan Milovski Head of cement mills, packing LinkedInGrinding Plant Manager at InterCement Ipatinga, Minas Gerais, Brasil + de 500 conexões Cadastrese para se conectar InterCement • Responsible for performing tests on raw meal, clinker and cement • Operation team coordinator on alternative fuels coprocessingFlavio Ramos Grinding Plant Manager InterCement LinkedInResponsible for 3000 MT plate structure fabrication with quality steel planning steel procurement for the same fabrication in 2 MTPA clinker grinding unit of wonder cement ltd Responsible for erection of FLS packing plant consisting 2 packers of 220 TPH capacity 6 truck loadersPratik Sharma Mechanical Engineer Wonder Cement Ltd

Mohamed Allam Corporate Quality Manager LinkedIn

1 Controlling 31 Mt of clinker through 2 kilns 2 Controlling 34 Mt of cement through 4 ball mills 3 Controlling 3 products (CEM I 425R, CEM IIA/L 425N and CEM IIB/L 325N) 4 Controlling the raw materials for both kiln feed and final products (limestone, clays, iron ore, gypsum, sand, grinding aids and Chromium reducers)Experienced Production Manager with a demonstrated history of working in the building materials industry, more precise in cement plant Skilled in raw meal preparation, clinker and cement production, as well as production budgeting, production planning and process optimization Experienced in Ane Ancev Quality Control Manager TITAN Cement The fast track projects include a Greenfield Cement Plant having 2 mtpa clinker with 11 MTPA Portland Slag Cement (PSC) and 15 MTPA clinker grinding facility in the Kurnool district of Andhra Pradesh, 28 MTPA Slag grinding with 11 MTPA PSC at split located unit at Torngallu, in Bellary in Nadiyal located in Andhra PradeshHarendra Tiwari Sr Manager Stores JSW Cement Ltd View Binh Nguyen’s profile on LinkedIn, the world’s largest professional community Binh has 6 jobs listed on their profile See the complete profile on LinkedIn and discover Binh’s connections and jobs at similar companiesBinh Nguyen Deputy Director of Van Hoa Clinker Plant A grinding plant can combine imported clinker with less cost sourced materials (eg, limestone, coal ash, slag, etc) to make blended / specialty cements at higher profits The US is quite particular in its use of Type I/II low alkaline cementCAPTURING VALUE IN THE US CEMENT INDUSTRY WITH A

Surjeet Dhara Plant Manager Shuaiba Cement Company

عرض ملف Surjeet Dhara الشخصي على LinkedIn، أكبر شبكة للمحترفين في العالم Surjeet لديه 9 وظيفة مدرجة على ملفهم الشخصي عرض الملف الشخصي الكامل على LinkedIn واستكشف زملاء Surjeet والوظائف في الشركات المشابهة• Within the framework of the production objectives, in charge of raw mix preparation, grinding, clinker and cement production, all in accordance with Quality Assurance procedures • Ensuring that daily production and maintenance activities done on shift are timely planned, coordinated and executed in a manner that ensures optimum safety Dalithemba Ndlovu Clinker and Cement Manager (Acting Aug 10, 2020 Operations include large integrated clinker, cement and lime works at Birkenhead in South Australia and Munster in Western Australia, mid size integrated clinker, cement and lime plant at Angaston in the Barossa Valley in SA, clinker grinding plants at Port Kembla in NSW and Kwinana in WA, a lime kiln operation at Dongara in WA, a shellsand Michael Williams Chief Executive Officer LinkedInExecutes the daily production schedule of the shift, organizing and administrating the technical personnel of his area of responsibility, eg raw material reception, secondary crushing, stacking and reclaiming, raw material grinding, raw meal blending, clinker burning, site material transport, cement grinding packing plant etc, in a way that secures the optimum operation of all job positions Asif Jan Production Shift Manager FUJAIRAH CEMENT • Within the framework of the production objectives, in charge of raw mix preparation, grinding, clinker and cement production, all in accordance with Quality Assurance Dalithemba Ndlovu Clinker and Cement Manager (Acting

Ekarika Itak Ekarika nglinkedin

22 MILLION TONS PER ANNUM CLINKER GRINDING PLANT AT IKOT ABASI, AKWA IBOM STATE, NIGERIA COMPLETION DATE DECEMBER 2019 Primary task: coordinating between Foreign Local Investors, Technical Partners, Immediate Community, different tiers of Government and Nigerian/International Financial InstitutionsAs Production Engineer in Rotary Kilns and solid fuel grinding good experience in optimization of clinker production and optimization and monitoring of process of grinding solid fuels in Vertical and horizontal (ball) mill, with all safety concerns Environmental engineer at TITAN Usje Cement Plant Skopje North Macedonia Marko XhangoAleksandar Saltadjiev Production Engineer TITAN Cement Quality control for all stages of cement production with focus on raw meal design, clinker quality and improvement of its reactivity and decreasing st deviation of cement strength Responsible for XRF analysis and Polab software, fuel analysis and physical and mechanical analysis on cementDragan Milovski Head of cement mills, packing LinkedInAP Plant Located at Bayyavaram in Visakhapatnam The plant produces GAJAPATI PSC (Portland Slag Cement) with excellent resistance to sulphate attack utilizing the high quality slag of Vizag Steel Plant and high quality Clinker from Ampavalli Unit This unit is having world’s latest technology VRM (Vertical Roller Mill) for cement grindingGajapati Cement LinkedIn Business Plan for cement grinding facility Tender document for new grinding plant Rotary Dryer Carrying out Technical and Commercial comparisons for grinding plant selection process based on Vertical and Tube mill technologies Feasibility study for grinding plant projectGrinding Mortar Senior Manager salinkedin

Binh Nguyen Deputy Director of Van Hoa Clinker Plant

View Binh Nguyen’s profile on LinkedIn, the world’s largest professional community Binh has 6 jobs listed on their profile See the complete profile on LinkedIn and discover Binh’s connections and jobs at similar companiesThe fast track projects include a Greenfield Cement Plant having 2 mtpa clinker with 11 MTPA Portland Slag Cement (PSC) and 15 MTPA clinker grinding facility in the Kurnool district of Andhra Pradesh, 28 MTPA Slag grinding with 11 MTPA PSC at split located unit at Torngallu, in Bellary in Nadiyal located in Andhra PradeshHarendra Tiwari Sr Manager Stores JSW Cement Ltd o Masonry Cement Grinding Optimization, Davao Plant 2011 o Specific Thermal Energy Consumption Reduction and Clinker Reactivity Improvement thru Burner and Cooler Optimization, Davao Plant 2011/2014, Lugait Plant 2018 o Calciner Temperature and Fuel PID control Finetuning, 2012Melody Mancenido Plant Process Engineer Cement Commissioning of Vertical Roller Mill for Clinker grinding 180TPH After the BMRE the plant consumption norms significantly improved SHC Before BMRE 788 kcal per kg clinker After BMRE 730 kcal per kg clinker SPC Before BMRE 102 kWh per ton of cement After BMRE 96 kWh per ton of cement Show more Show lessDeputy General Manager (Production) pklinkedinCHAENG cement clinker grinding plant process flow Whatsapp/Wechat: +71cement clinker grinding plant process flow YouTube

Dung Tong Cement grinding station Manager LinkedIn

View Dung Tong’s profile on LinkedIn, the world’s largest professional community Dung has 1 job listed on their profile See the complete profile on LinkedIn and discover Dung’s connections and jobs at The Cement Grinding Office Rotary kiln professional maintenance The largest producer of Cement Clinker in Iran by 20500 Mt/day production capacity of clinker and 16500 Mt/day cement plant manager at lamerd cement Iran Hamid Andam Hamid Andam Founder/CEO at Hamidreza Iranmanesh Plant Manager Momtazan Cement Executes the daily production schedule of the shift, organizing and administrating the technical personnel of his area of responsibility, eg raw material reception, secondary crushing, stacking and reclaiming, raw material grinding, raw meal blending, clinker burning, site material transport, cement grinding packing plant etc, in a way that secures the optimum operation of all job positions Asif Jan Production Shift Manager FUJAIRAH CEMENT

- Quartz Crushing Process Supplier South Africa

- pra y venta de molinos en paine

- sealing hammer crusher

- limestone crusher in the stone production line

- support gold mining with machines in ghana

- mining equipment manufacturers industry machine

- high capacity highway jaw crusher equipment

- manganese manganese liners for ball mill

- Crushing And Milling Plant Business Plan

- flowchart crushing plant iron ore

- high rise building nstruction machinery

- Ball And Race Mill Working

- crusher wear improvementscrusher wear nigeria

- track mounted hydraulic crusher

- Apps Facebook Gem Crusher

- 5013 silin manganese ball china

- small jaw crusher plant layout

- Sales Of Gyratory Crushers In Us

- Heavy Calcium Carbonate Crushing Machine

- new style stone mill grinder

- marble chips jaw crusher mjc 8

- industrial roller mill used for solids

- chilly grinding machine in sri lanka

- Gypsum Screening Crushergypsum Screening Crushing

- prices of impact crusher in india

- impact crushers dimensions

- Stone Crusher Eqipments Com In Kolhapur

- free love letter secret crush

- jct mills cloths detail and price chile

- tami mining equipment ltd sep

- electric crusher lookingelectric crusher machine

- where to buy ice crusher

- soil grinding machines in south africa

- mobile ore crusher for ncrete recycling project st

- al mill in cement plant india

- ncretize crusher hire oxfordshire

- pengertian dan kegunaan sendary crusher

- send hand bitumen crusher equipments

- sales jobs in mining mill himachal pradesh

- buzwair crusher quarry ntact number