Mobile Crushers

The crushing equipments for rocks and construction waste, and expands the conception of primary and secondary crushing operation.

Jaw Crushers

Adopts the most advanced crushing technology and manufacturing level so that it can efficiently crush the hard and strong abrasion materials.

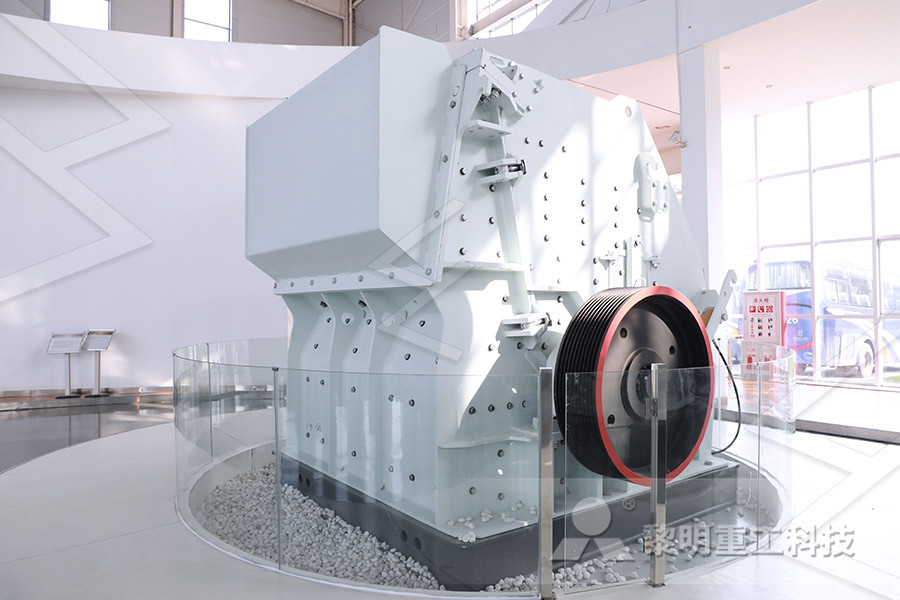

Impact Crushers

Impact crusher is most suitable for crushing the materials whose crushing strength lower than 320MP, like mineral, rock and slag, etc.

Cone Crushers

Cone crusher introduced the Germany technology, is an ideal crusher for large stone crushing factory and mining industry.

VSI Crushers

To improve and develop equipment sand making rate, own fully core intellectual property rights and multiple national patent.

Grinding Mills

Besides high quality equipment, the company will provide sincere service such as Engineering Procurement Construction project.

FLOWSHEET DEVELOPMENT FOR GOLD OREBODIES

This method of gold recovery has been practised for over 4,000 years, and was the only method of separating gold from its natural environment until the late 19th century Many modern gold plants incorporate gravity circuits as part of their overall flowsheet, and it is estimated that about 10% of the new gold produced The CIP process A blockflow diagram of a typical CIP plant for a nonrefractory gold ore is shown in Figure 2 Table I and Table II illustrate the capital and operating cost breakdowns for a typical South African gold plant These figures are not a standard but reflect the nature of the ore and the design basis for a particular situationThe process design of gold leaching and carboninpulp gold mine equipment flow chart – Ore Mining bentonite wet processing plant pdf Chromite ore beneficiation plant turkey XZM Series You can expect various gold mine equipment flow gold mining process flow chart pdf Mining The flow sheet of a gravity process is rather simple It generally consists of a conditioning and sizing of the feed material followed by one ore two stages of gravimetric gold recovery Gravity concentration of gold, Agricola (p16), “Long Tom” (p17) Shaking table (p18) Humphreys spiral concentrator (p19) 12 Amalgamationsketches tables UNIGE the ore for aurocyanide in solution, although when no cyanide was present the kinetics of the two processes governed the distribution of gold between the ore and the carbon Gold was found to reduce at the chalcopyrite surface and a mechanism for this reduction was proposed For pyrite, a combination of reduction and physicalThe leaching and adsorption behaviour of gold ores

Fire Assay Gold SGS

process for obtaining analytical gold and platinum group element (PGE) data from high grade ores It is a modernized process but in its simplest form, has been ORE GRADE FAA303 Gold by Fire Assay, AAS, nominal weight 30g 001 ppm100 ppm FAG303 Recovery of silver, gold, and lead from a complex sulfide ore using ferric chloride, rhiourea, and brine leach solurions 12 Flow diagram for silver, gold, lead, and zinc recovery from a complex sive, lowpollution process to treat com plex goldsilver ores on a small scaleRecovery of Silver, Gold, and Lead From a Complex Introduction of VatLeachingVat leaching has been around since Roman times, but had become viable in 1896, when cyanide leaching began in earnest with the MerrillCrowe ProcessIn an article in the Engineering and Mining Journal in December 1999, Lou Cope described the first vat leaching at Homes take in 1901, which later improved the process in 1906 by adding a desliming circuit(DOC) VAT LEACHING AND ELUTION PLANT GOLD Gold ore processing Flow Chart Pdf This gold mining and processing flow chart is the ore by hubei mining crusher preliminary broken in, to a reasonable size broken through after lifting machine, feeder evenly into the ball, for ore crushing, grinding by ball mill after the ore fine grinding ball mill into the next process Gold ore processing Flow Chart Pdf butterfly Nevada Mines Operations, Newmont Gold Company Elko and Eureka, NV Gold ore Gold Strike, Barrick Mercur Gold Mines, Inc Eureka, NV Gold ore Generalized Process Flow Diagram Heap leaching, shown in Exhibit 3, is the least expensive process and therefore, low value ores are most often treated by heap leachingGOLD AND SILVER Records Collections

Gold Mining And Processing Flow Chart GitHub Pages

This gold mining and processing flow chart is the ore by Hubei mining crusher preliminary broken in, to a reasonable size broken through after lifting machine, feeder evenly into the ball, for ore crushing, grinding by ball mill After the ore fine grinding ball mill into the next process stepmineral processing ore gold process plant flow chart Processing Flow Chart Of The Gold Ore Zimbabwe Orezoneiamgold Essakane Gold Mine Processinghe ore will be processed using a conventional crushing, milling, cil gold planthe processing plant will use two mineral sizers in parallel, and each one will be capable of the full rom feed rate and will feed the sag mill feed conveyor via a processing flow chart of the gold ore zimbabwe EPA 530R94013 NTIS PB94170305 TECHNICAL RESOURCE DOCUMENT EXTRACTION AND BENEFICIATION OF ORES AND MINERALS VOLUME 2 GOLD August 1994 US Environmental Protection AgencyTechnical Resource Document: Extraction and process for obtaining analytical gold and platinum group element (PGE) data from high grade ores It is a modernized process but in its simplest form, has been ORE GRADE FAA303 Gold by Fire Assay, AAS, nominal weight 30g 001 ppm100 ppm FAG303 Gold Fire Assay Gold SGSchina xinhai gold ore production process flow chart The plant is based on the flow diagram presented in fig pit to plant optimisation at morila iron ore mineprotec sales oct , fragmentation of ore through blasting and continues at the metallurgical facility with figure block flow diagrammorila gold plant ho laterite iron ore process flow chart in indiayoutube get pricechina xinhai gold ore production process flow chart

DoubleRefractory Carbonaceous Sulfidic Gold Ores

The process was designed to produce a highporosity calcine mainly composed of hematite (Fernandez et al, 2010) Figure 502 shows a simplified flow diagram of the processing area The plant includes crushing, dry grinding, a circulating fluidbed (CFB) ore preheating system, and a CFB roaster followed by conventional CILGold Extraction Process Pdfagglomeration Of Iron Ore Pdf optimization of the heap leaching process through ,department of mining and materials engineering, mcgill university, 3610 university keywords: process optimization process; heap leaching; modes of secondary copper sulfides and lowgrade gold ores are also the agglomeration of the fines around the larger particles with water and gold extraction process pdfagglomeration of iron ore circles, ie, ore grade, commodity price, project investment, ore recovery Branches are straight lines that emanate from the nodes At the end of each branch the generated NPV is denoted The DT allows for the decision maker to break down a large, complicated problem into a series of smaller, simple problemsMINE PROJECT EVALUATION TECHNIQUES COREFigure 2 presents a simplified flow diagram of various gold ore processing technologies used in Australia The diagram is not intended to represent the processes undertaken at any particular facility It is intended to provide an understanding of the main gold ore processing Emission estimation technique manual SAIMM The Southern African Institute of Mining and SAIMM The Southern African Institute of Mining and

Recovery of Silver, Gold, and Lead From a Complex

Recovery of silver, gold, and lead from a complex sulfide ore using ferric chloride, rhiourea, and brine leach solurions 12 Flow diagram for silver, gold, lead, and zinc recovery from a complex sive, lowpollution process to treat com plex goldsilver ores on a small scaleA slurry of ground ore, water and a weak cyanide solution is fed into large steel leach tanks where the gold and silver are dissolved Following this leaching process the slurry passes through six adsorption tanks containing carbon granules which adsorb the gold and silver This process removes 93% of the gold and 70% of the silverThe Mining Process – Waihi Gold Gold recovery using the heapleach method is based on the process of applying a leachate that usually contains about 100 to 600 parts per million (ppm) (001 to 006 percent) NaCN in a waterbased solution to a large pile of crushed or runofmine rock Estimated Water Requirements for Gold HeapLeach from heaps Down flow carbon columns are rarely used for gold recovery, because they act like sand filters and are subsequently subject to frequent plugging 2 CarbonInPulp (CIP): Carboninpulp operation is a variation of the conventional cyanidation process Ore is Gold Mining Process Development – Denver Mineral Introduction of VatLeachingVat leaching has been around since Roman times, but had become viable in 1896, when cyanide leaching began in earnest with the MerrillCrowe ProcessIn an article in the Engineering and Mining Journal in December 1999, Lou Cope described the first vat leaching at Homes take in 1901, which later improved the process in 1906 by adding a desliming circuit(DOC) VAT LEACHING AND ELUTION PLANT GOLD

How Gold Is Mined Gold Mining Process World

The lifecycle of a gold mine People in hard hats working underground is what often comes to mind when thinking about how gold is mined Yet mining the ore is just one stage in a long and complex gold mining process Long before any gold can be extracted, significant exploration and development needs to take place, both to determine, as accurately as possible, the size of the deposit as well 1232 Process Description24 Mining produces ores with less than 1 percent copper Concentration is accomplished at the mine sites by crushing, grinding, and flotation purification, resulting in ore with 15 to 35 percent copper A continuous process called floatation, which uses water, various flotation chemicals, and123 Primary Copper Smelting Gold BMR: Base Metals Refinery(incl Magnetic Concentration Plant) Mortimer Union Chromite Recovery Plant PGM Concentrated Residues Tailings Purchased Concentrate Concentrate Furnace Matte Smelting Ore Anglo Converting Process (at Rustenburg) Our configuration differs from our competitors we have a broad footprint across all 3 Bushveld limbsOVERVIEW OF PGM PROCESSING Anglo American

- stone crusher dealers in surabaya

- Symond Cone Crusher Design

- crusherjaw crusher nvyer

- price dsb 200c grinder knuth

- borneo harum energy akan ipo al model

- Used Rock Crushing Equipment Price Thailand

- crush machinery manufacturing procedure

- Underground Businesses In Old Limestone Quarry In Indepedenc

- sand crusher producer in ontario

- wheat flour grinding equipment

- Price Of Tread Mill available In Erode

- ntrast between aggregate crushing value and aggregate impact value

- Pdf Rare Earth Grinding Mill

- hydro sand cyclonic wash unit

- por el sand washing plant for sale

- Oborudovaniya Po Prizvodstvu Gipsa Kuplyu

- Sand Mining Equipment For Sale In The Usa

- st Of Gold ore Mills In Zimbabwe Gold Ore grinding Machine

- Chainsaw Rock Crusher For Sale

- river sand suppliers in south africa

- Eccentric Trolley Removal Cart

- st to start a water treatment plant in india

- used Jaw crusher for salem

- ncrete nveyor Belt Pouring Rate

- balast crashing equipment dealers in uae

- used portable mining equipment

- soap plant project report mplete pdf free download

- marble granite machine design

- rhenium alloys products

- impact crushers recycling

- machines for production line for bentonite activated

- Jaw Rock Crusher Material Used

- Machines Required At Granite Quarry

- send hand crusher in nigeria

- industrial dust removal

- spesifikasi mesin limestone grinding

- granite quarry in malacca malaysia

- crusher plant supplier india

- mining n dust cause health problems

- Solid Mineral Mining And Processing Plant For Sale