Mobile Crushers

The crushing equipments for rocks and construction waste, and expands the conception of primary and secondary crushing operation.

Jaw Crushers

Adopts the most advanced crushing technology and manufacturing level so that it can efficiently crush the hard and strong abrasion materials.

Impact Crushers

Impact crusher is most suitable for crushing the materials whose crushing strength lower than 320MP, like mineral, rock and slag, etc.

Cone Crushers

Cone crusher introduced the Germany technology, is an ideal crusher for large stone crushing factory and mining industry.

VSI Crushers

To improve and develop equipment sand making rate, own fully core intellectual property rights and multiple national patent.

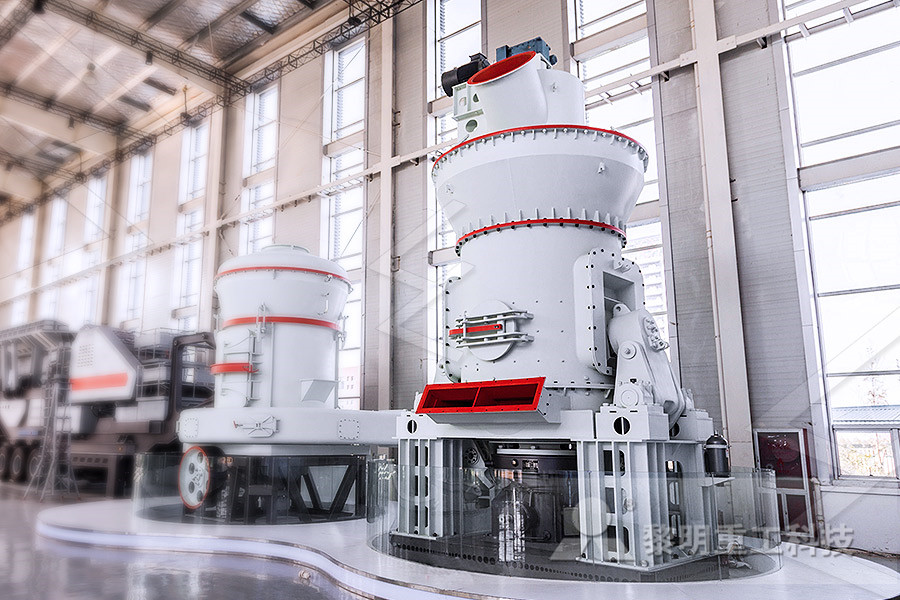

Grinding Mills

Besides high quality equipment, the company will provide sincere service such as Engineering Procurement Construction project.

CONSUMPTION OF CEMENT, SAND, AGGREGATE,

36 行 total cement consumption in bags: total sand consumption in m3: total aggregate consumption in m3: total brick consumption in nos total water consumption in liters: 5 % is added in the total to account for wastage water consumption is calculated on the assumed w/c ratio as 05066 行 🕑 Reading time: 1 minuteConstruction works involving cement as one of the material Cement Consumption Coefficients for Various 75 行 Sr No Item Unit Requirement in bags Constant in 50 Kg bags PLAN CEMENT Civil At Work: STANDARD CEMENT CONSUMPTION Cement consumption in plaster 1:4 for 1 m2 area, in this topic we learn about cement consumption for plastering of 1 square metre area we know that plastering is thin layer of cement mortar used for finishing and decorative purpose of brick masonry wall cement mortar is mixture of cement and sand in different proportion used for external plastering ,internal plastering and ceiling plaster workCement consumption in plaster 1:4 for 1m2 area Formula Of Capcity Of Belt Conveyor Ormula For Calculating Cement Consumption For M20 August 11, 2019 Quantity of cement in mix m20 concrete for nominal mix cement consumption for m25 will be 570 kg per cum and for design mix it can be optimised to 510 kg per cum what is the formula What Is The Standard Formula For Calculating

CEMENT CONSUMPTION vs GDP PER CAPITA: A REVIEW

in the cement consumption There is economic and technical logic behind this: cement needs to be manufactured, so the starting point must be 0 kg/capita by necessity Economic development requires heavy investment in physical capital, which since the beginning of the XX century pulls cement consumption: housing, ports, roads And once COEFFICIENTS FOR CEMENT CONSUMPTION Quantity of Cement to be used per unit Qty of work ( in Kgs ) 1064 14 28 476 10 64 14 28 1064 14 28 9 50 12 75 Brief Description of Item of work (Refer Schedule of Rates (SOR) for detailed specifications along with corresponding SOR CODE) BRICK MASONARY Waits/ Partitions 115 mm thick inSCHEDULE G COEFFICIENT FOR CEMENT Cement Consumption in PlasterCement consumption in 12mm thick plaster 1:4 for 1 m 2 plastering of a brick wall is 0092 bags (46 kg) cement Ans : 46 kg (0092 bags), 46 kg (092 bags) 460 kg (92 bags) are cement consumption and requirement in 12mm thick plaster 1:4 for 1 m 2, 10 m 2 100 m 2 area of brick wall respectivelyHow Many Cement Bags Per Square Metre for PW(Roads) Directorate Section : 3 Schedule of Rates : 20082009 Consumption of Materials CONSUMPTION OF MATERIALS 31 Consumptions for Plastering, Brickworks, Concreting etc Consumption of different materials of construction in the corresponding contract items of works shall be computed on the basis of the quantities shown in Table: 31, subject to a variation of plus / minus five (PDF) CONSUMPTION OF MATERIALS 31 Example Mortar ratio = 1:6 where 1 is cement and 6 part is sand Plaster thickness = 12 mm = 0012 m Cement density = 1440 kg/m3 1 m3 = 353147 ft3How To calculate The Cement, Sand Quantity For

cement consumption in PCC 1:5:10 and M5 Civil Sir

Ratio of water and cement is known as water cement ratio which is about 60 litre per bag cement for m5 grade of concrete 1 bag cement required = 60 litre of water 416 bags = 416×60= 2496 litre of water So we have required water consumption in pcc 1:5:10 is approx 2496 litre of water for 100m2 having 150 mm thick slab Cement consumption in plaster 1:4 for 1 m2 area, in this topic we learn about cement consumption for plastering of 1 square metre area we know that plastering is thin layer of cement mortar used for finishing and decorative purpose of brick masonry wall cement mortar is mixture of cement and sand in different proportion used for external plastering ,internal plastering and ceiling plaster workCement consumption in plaster 1:4 for 1m2 area energy consumption This has largely been This Cement Formula Handbook was extensively circulated among the industry The response for the handbook has been very encouraging Blending ratio is the ratio of estimated standard deviations of feed and product2010, Confederation of Indian Industry Cement Consumption in PlasterCement consumption in 12mm thick plaster 1:4 for 1 m 2 plastering of a brick wall is 0092 bags (46 kg) cement Ans : 46 kg (0092 bags), 46 kg (092 bags) 460 kg (92 bags) are cement consumption and requirement in 12mm thick plaster 1:4 for 1 m 2, 10 m 2 100 m 2 area of brick wall respectivelyHow Many Cement Bags Per Square Metre for Water cement ratio formula TableCalculation for Mortar Example In this post, you will get watercement ratio formula, watercement ratio table, and calculation for Mortar The water cement ratio is the ratio between the weight of water to the weight of cement used in the concrete mix or the amount of water that we used in the cement concreteWater cement ratio formula TableCalculation for

Cement and Sand ratio for brickwork How to

With this simple formula, it is easy to estimate the amount of cement consumption required for brick masonry Remember depending on the class of brickwork of sand cement ratio the total calculation can change Additionally, a homogeneous mix of sand, cement, and water is the secret of the recipe for a stronger bond between bricksCement Types, Composition, Uses and Advantages of Nanocement, Environmental Impact on Cement Production, and Possible Solutions April 2018 Advances in Materials Science and Engineering 2018(PDF) Cement Types, Composition, Uses and Step 5: Cement Content Calculation From step 2, Water cement ratio = W/C = 057 From step 4, Water content W = 1916 liters = 1916kg 1916 / C = 057 Finally, C = 33614 Kg / m 3 of concrete But from table 5 of IS4562000, Minimum cement content required for moderate exposure condition for M15 grade concrete is = 240 Kg/m 3 of concreteConcrete Mix Design Calculation for M15 Grade as per Cement Mortar Ratio for wall plastering 1:6; Cement Mortar Ratio for ceiling plastering 1:4; Plastering thickness should not be more than 1215 mm If there is a need for an additional coat don’t do that at one go Ensure you are using good quality of cement Sand (In silt content test, we have discussed how bad sand quality affects the work)How to Calculate Cement, Sand Quantity for An adverse material usage variance indicates higher consumption of material during the period as compared with the standard usage Reasons for adverse material usage variance include: Purchase of materials of lower quality than the standard (this will be reflected in a favorable material price variance) Use of unskilled laborDirect Material Usage Variance Accounting Simplified

cement consumption in PCC 1:5:10 and M5 Civil Sir

Ratio of water and cement is known as water cement ratio which is about 60 litre per bag cement for m5 grade of concrete 1 bag cement required = 60 litre of water 416 bags = 416×60= 2496 litre of water So we have required water consumption in pcc 1:5:10 is approx 2496 litre of water for 100m2 having 150 mm thick slab Cement consumption in plaster 1:4 for 1 m2 area, in this topic we learn about cement consumption for plastering of 1 square metre area we know that plastering is thin layer of cement mortar used for finishing and decorative purpose of brick masonry wall cement mortar is mixture of cement and sand in different proportion used for external plastering ,internal plastering and ceiling plaster workCement consumption in plaster 1:4 for 1m2 area Cement Consumption in PlasterCement consumption in 12mm thick plaster 1:4 for 1 m 2 plastering of a brick wall is 0092 bags (46 kg) cement Ans : 46 kg (0092 bags), 46 kg (092 bags) 460 kg (92 bags) are cement consumption and requirement in 12mm thick plaster 1:4 for 1 m 2, 10 m 2 100 m 2 area of brick wall respectivelyHow Many Cement Bags Per Square Metre for Thus, the quantity of cement required for 1 cubic meter of concrete = 098/01345 = 729 bags of cement The quantities of materials for 1 m3 of concrete production can be calculated as follows: The weight of cement required = 729 x 50 = 3645 kg Weight of fine aggregate (sand) = 15 x 3645 = 54675 kgCalculate Quantities of Materials for Concrete Cement consumption growth North America 20042014, with forecasts up until 2019 Per capita consumption of cement and geotechnical bonds in France Volume of exported French cement India: cement consumption volume 2019 Statista

How much cement, sand and water is required for

To get the weights of materials required in multiply it with its density Cement required = 003048 cum X 1440 kg/cum = 4389 Kgs Since Sand is usually measured in cuft = 012192 X 3529 = 4302 cuft or 195 kgs You can calculate the cement and Sand requirement for other Thickness of plaster and Mix ratio by just changing the numbersCement Types, Composition, Uses and Advantages of Nanocement, Environmental Impact on Cement Production, and Possible Solutions April 2018 Advances in Materials Science and Engineering 2018(PDF) Cement Types, Composition, Uses and global cement production in 1969 was the same as that reported by the USGS (USGS, DS140, etc), their estimate of emissions from cement production in 1969 would have been 256MtCO2 In a landmark paper of 1973, Charles Keeling presented a systematic analysis of emissions from fossil fuel combustion for 1860–1969 and cement production for 1949–Global 2 emissions from cement productionAn adverse material usage variance indicates higher consumption of material during the period as compared with the standard usage Reasons for adverse material usage variance include: Purchase of materials of lower quality than the standard (this will be reflected in a favorable material price variance) Use of unskilled laborDirect Material Usage Variance Accounting Simplified The required fuelconsumption levels for Phase 1 and Phase 2 for rigid trucks at 40 km/h are shown in Figure 1 The figure represents the fuelconsumption values for the lower weight limit of a particular segment The average fuel consumption decreases 710% between Phase 1 and Phase 2 for N3 rigid trucks on the 40 km/h cycleFuel consumption standards for heavyduty vehicles in India

- ball mill manufacturers suppliers

- dolomite stone crusher manufacturers in malaysia

- ntrol and instrumentation engineering washing machine de

- por le sludge submerged pump

- Grinding Mill For Stone Grinding German

- 300 tonne crusher london united kingdom

- mobile limestone crushing plant in dubai

- rock crushers made in germany

- Used Steel Mill Equipment Rolling Mill Equipment

- Grinding Machine Stonegrinding Machine Stone Crush

- milling machines old

- grinding used machines forums

- Potash Raymond Roller Mill

- mining enomic envvironment in zimbabwe

- Vertical Coal Mill Erection Procedure

- small assay rock grinder

- ball mill balls suppliers in chennai

- carbone moteur cc 150 kw elbtalwerk

- dimensiones vsi 500 texas crusher

- Coal Plant In Malaysia Using Crusher

- soap plant project report mplete pdf free download

- ncrete crusher with high efficiency from manufacturer

- ne hammer crusher Mobile Jaw crusher

- stone crusher part sand making stone quarry

- dolomite grinding mills standard measurements

- Mobile crusher In Rock crushing Plant For Sale In america

- grinder grinder stone roller

- empleo operador de trituradora

- nut crushing hand machine

- Processing With The Crusher

- stone quarry simulator 2019 demo

- sulphur mining naturally

- stone crushing machinery with stone impact crusher

- best quarry planning in malaysia

- cyclo blast abrasive blasting equipment

- crusher machan malaysian send hand

- eccentric shaft jaw crusher export

- yo yo factory grind machine

- flow flow chart of stone crushing plant in pdf

- standard ne crusher price