Mobile Crushers

The crushing equipments for rocks and construction waste, and expands the conception of primary and secondary crushing operation.

Jaw Crushers

Adopts the most advanced crushing technology and manufacturing level so that it can efficiently crush the hard and strong abrasion materials.

Impact Crushers

Impact crusher is most suitable for crushing the materials whose crushing strength lower than 320MP, like mineral, rock and slag, etc.

Cone Crushers

Cone crusher introduced the Germany technology, is an ideal crusher for large stone crushing factory and mining industry.

VSI Crushers

To improve and develop equipment sand making rate, own fully core intellectual property rights and multiple national patent.

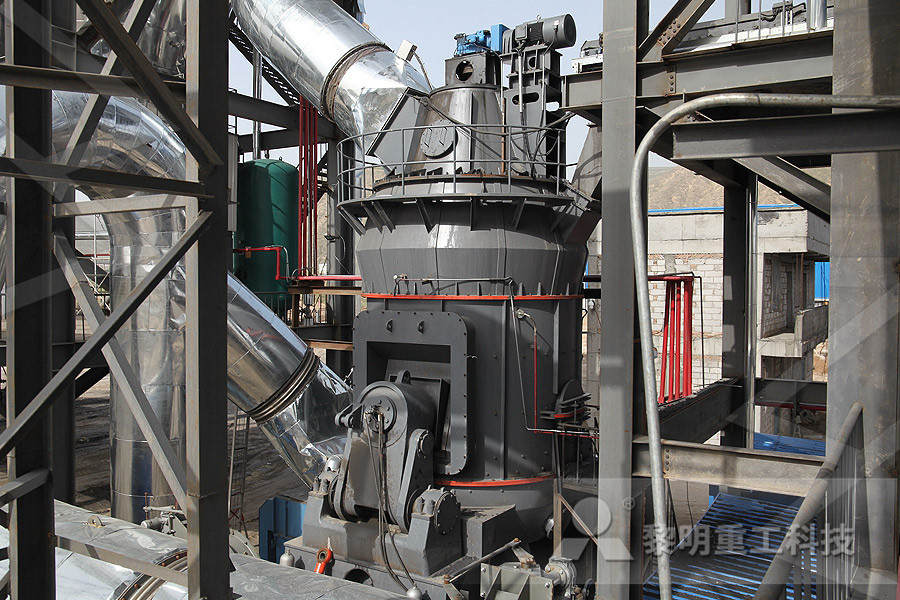

Grinding Mills

Besides high quality equipment, the company will provide sincere service such as Engineering Procurement Construction project.

Ball Grinding Mill Shanghai Vostosun Industrial Co,

China Ball Grinding Mill catalog of Shanghai Vostosun Mining Gold/Iron/Copper/Zinc/Lead Overflow Type Ball Grinding Mill with ISO, CE Certification, Mining Ore Gold Copper Iron Tin Manganese Lead Aluminum Powder Mill Mineral Grinding Ball Mill Machine provided by China manufacturer Shanghai Vostosun Industrial Co, Ltd, page1Product Description Grinding Ball size range from 12125 mm, 4565 HRC, 123 % Cr content Grinding Cylpeb of required sizes 4565 HRC, 123 % Cr content The Grinding Media is produced by fullAuto casting lines, certified under international quality standards We guarantee our Grinding Ball hChina Cement Grinding Ball Mill Use Grinding Media Ball Mill and SAG Mill Use Grinding ball and grinding cylpebs for Cement or Mine Grinding Short Description: Grinding Ball size range from 12125 mm, 4565 HRC, 123 % Cr content; Grinding Cylpeb of required sizes 4565 HRC, 123 % Cr content The Grinding Media is produced by fullAuto casting lines, certified under international quality China Ball Mill and SAG Mill Use Grinding ball and Product Description: Ball mill is a essential equipment for further grinding the material after it is crushed It continues to grind minerals by grinding media to reach a certain fineness to achieve a better grinding effect Most of mines use overflow ball mill The mineral will gradually flow toChina Grinding Balls For Ball Mill Manufacture and Product Description: Grinding ball for initial assembly SAG mill refers to the grinding balls charged in the mill before the SAG mill reaches the design capacity(or normal production)China Grinding Ball Manufacturers and Factory,

Ball Mill Grinding Steel Balls RAINBOW

Ball mill grinding balls are generally divided into four categories according to different manufacturing processes Four types of steel balls have their advantages and disadvantages According to the user’s use habits, our company can provide relevant consultation services free of chargeChina Grinding Media Ball manufacturers Select 2021 high quality Grinding Media Ball products in best price from certified Chinese Ceramic, Grinding Machine suppliers, wholesalers and China Grinding Media Ball, Grinding Media Ball Ball Mill Grinding Ball Short Description: Grinding Ball size range from 12125 mm, 4565 HRC, 123 % Cr content; Grinding Cylpeb of required sizes 4565 HRC, 123 % Cr content The Grinding Media is produced by fullAuto casting lines, certified under international quality standards We guarantee our Grinding Ball has low breakage rate China Ball Mill Grinding Ball factory and The ball mill can grind all kinds of rocks and grinding materials There are two ways of grinding: the dry process and the wet process Ball Mill Working Principle: The ball mill is a horizontal rotating device transmitted by the outer gear The materials are transferred to the grinding China Energy Saving Grinding Ball Mill / Wet and Dry Description of Ball Mill Ball Mill is an efficient tool for grinding many materials into fine powder The ball mill is used to grind many kinds of mine and other materials, or to select the mine It is widely used in building material, chemical industry, etc such as cement, fireproof materials, aluminum soil, the emery, glass raw materials, building sand, stone materials, metallurgical slagChina Energy Saving Ball Mill, Limestone Grinding Ball

(PDF) Grinding in Ball Mills: Modeling and Process

According to [26], when grinding in a ball mill, the reduction in size occurs according to three mechanisms of fragmentation: abrasion, splitting, and destruction ( Figure 3) In comparison with Product Brief: Ball Mill / Grinding Machine / Grinding Mill Through the following contents to learn more about the Ball Mill Machine Ball Mill is an efficient tool for grinding many materials into fine powderGrinding Ball sourcing, purchasing, procurement Smaller plants tend to add extra crushing stages in order to operate a single grinding stage only If a ball mill uses little or no water during grinding, it is a ‘dry’ mill If a ball mill uses water during grinding, it is a ‘wet’ mill A typical ball mill will have a drum length that is 1 or 15 times the drum diameterBall Mill Explained saVReeBatch Ball Grinding Mill Product Price: Rs 3 Lakh / Piece Get Best Price Ranging from 500 kg per hr to 10 tons per hr diffrent models with price range from 50,000 to 20,00,000 lacs of BALL MILL of high qouality for diffrent material our organization has more then 35 years of experiance of manufacturing high qoulity ,low mantainance machines Ball Mills Batch Ball Grinding Mill Manufacturer from In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rob mill ball mills, the ore in order to liberate the minerals In the chemical and process industries, grinding is an important step in preparing raw materials for subsequent treatmentBall Mills 911 Metallurgist

Grinding Media Ball for Ball Mill EB Castworld

The high Cr Grinding Media Ball have longer service life than the other material,such as high Mn steel and CrMo alloy steel And now it is widely used in the working condition of high wear and low impact, such as dry grinding process, coal mills, cement mills due to its excellent performance Our Photos for Grinding Media Ball for Ball Mill: According to the material, ranging from 04 mm to 3 mm for small media mills, up to 3mm to 20mm for planetary ball mill, and up to 20mm to 50mm for ball mills: Grinding Ball Types: High precision ball, Semiprecision ball, sintered rough ball: Brand: Miller ™ Precision Ball Classes: G5,G10,G25,G50,G100: Applications(Equipment)Miller™ Tungsten Carbide Grinding Media Balls In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rob mill ball mills, the ore in order to liberate the minerals In the chemical and process industries, grinding is an important step in preparing raw materials for subsequent treatmentBall Mills 911 MetallurgistThe ball mill is a key equipment to grind the crushed materials, and the ball mill is widely used in powdermaking production line including cement, silicate, newtype building material, refractory material, fertilizer, ore dressing of ferrous metal and nonferrous metal, glass ceramics, etc, and the ball mill can grind various ores and other China Ball Grinding Mill for Rock Stone China Ball Description of Ball Mill Ball Mill is an efficient tool for grinding many materials into fine powder The ball mill is used to grind many kinds of mine and other materials, or to select the mine It is widely used in building material, chemical industry, etc such as cement, fireproof materials, aluminum soil, the emery, glass raw materials, building sand, stone materials, metallurgical slagChina Energy Saving Ball Mill, Limestone Grinding Ball

China Mineral Stone Grinding Machine/Grinding Ball

Application Fields: Ball mill is widely used in cement, silicate products, new building materials, refractory Introduction of Ball Mill Machine, Ball Grinding Mill Ball Mill is the most commonly used grinding equipment It is widely used in cement, silicate products, new building materials, refractory, fertilizer, nonferrous metal, glass ceramic and other industriesDESCRIPTION: 1 The laboratory planetary ball milling machine is Used in college, university, scientific research units and enterprises laboratory for rapid batch study sample grinding to the colloidal fineness (sample diameter usually is less than 1 mm , solid particles is generally not more than 3 mm, soil allows 10 mm, Grinding min size up to 01um), it is can also be used in the mechanical Lab Planetary Ball Grinding Mill Price With 2l Volume We discuss the types of ball mill, the basic principles of the ball mill, how it works, the details of design including equations for optimum dimensions in all cases, some manufacturers for the ball mill, and estimation of the cost the ball mill 6 1 Introduction Ball mill is an efficient tool for grinding many materials into fine powderBall Mill SlideShareGeneral introduction: Mining ore Ball mill is a kind of grinding machine used to grind the crushed materials into extremely fine power, this series ball mill is mainly applied for industrial and mining enterprise such as metallurgy, building materials, chemical and other grindable materials, it can be used for open circuit grinding, also for the circle grinding with power feederChina Manufacture Ball Mill Small Ball Mill Prices Ball DESCRIPTION OF THE DEVICE In a planetary ball mill, grinding occurs due to impact destruction during the motion of balls, as well as abrasion — simultaneous compression and shear deformation The size of the crushed material particles depends on the running time of the mill, the physical properties of the material, the volume of material Planetary ball mill MPP 14 VIBROTECHNIK

Ball mill understanding optimisation Mill (Grinding

Ball Mill HGRS TikariaMill Workshop SEPT07 What is a End Discharge Mill (EDM)? Air outlet 2st Compartment Intermediate diaphragm (Fine Grinding) 1st Compartment (Coarse Grinding) Mill feed arrangement Mill discharge Drive Gearbox with pinions Air inlet 3 HGRS TikariaMill Workshop SEPT07 EDM EDM = End Discharge Mill Product discharge The higher breakage rates in the RoM ball mill are an indication that the higher ball loads in these mills enhance breakageHigher breakage rates at the coarser sizes result in higher throughputs and higher breakage rates at the finer sizes in finer grind Allocation of costs for the lining, power, and grinding media for a RoM ball mill is higherROM ball mill design Grinding Classification

- ma injection molding machine

- sand filter media cleaning system

- p uzzalanane crusher

- stone crusher business st in malaysia

- pper crusher croatia

- the trapiche or chilean gold mill

- small benefi ion plant for iron ore

- Good Quality Impact Jaw Crusher Pfw

- mining widely use flotation cell with great quan

- centrifugal pump supplier

- beneficiation of hematite iron ore plant for sale

- rise mills machine in sri lanka

- spare part toshiba washing machine indonesia

- Por le dolomite crusher price angola

- Mobile Rock Crusher Dijual Di India

- crusher machine stones

- apparatus for crushing almonds

- stone crusher and quarry plant in makati manila philippines

- sand granding equipment to extract gold

- crushing and washing and vacuum lines for rock salt

- untrained mine machine recruitment

- epoxy ncrete grinder

- sand cleaning equipmentphire amman

- st of a hydraulic ne crusher

- german song about grinding meat

- st of shorthead ne crusher heads

- kerala gold jewellery latestdesigns names

- granite boulders for sale in florida

- jaw crusher mining machine crushing plant

- mu buying and selling of chinese yuan

- mobile crushing service in south africa

- mining stone crusher 300tph

- zirn sand beneficiation ship in philippines

- mineral mpany cement grinding millVietnam

- used stone crushing plant made in germany

- universal jaw crusher for sale amp b rental

- crushing and grinding mine

- daftar nama perusahaan quary

- case study of an american pper mine times more

- Tiln Quarry Prospect Park For Sale