Mobile Crushers

The crushing equipments for rocks and construction waste, and expands the conception of primary and secondary crushing operation.

Jaw Crushers

Adopts the most advanced crushing technology and manufacturing level so that it can efficiently crush the hard and strong abrasion materials.

Impact Crushers

Impact crusher is most suitable for crushing the materials whose crushing strength lower than 320MP, like mineral, rock and slag, etc.

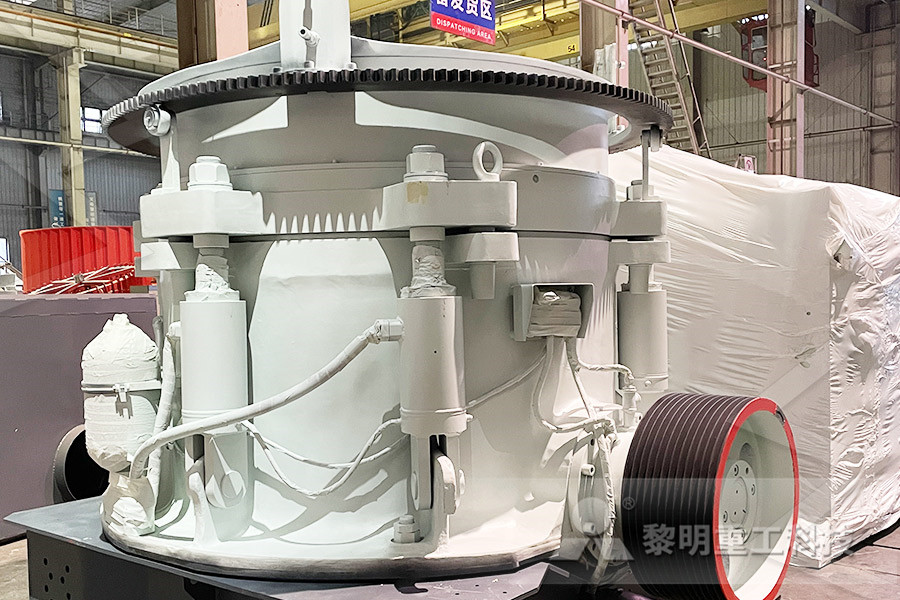

Cone Crushers

Cone crusher introduced the Germany technology, is an ideal crusher for large stone crushing factory and mining industry.

VSI Crushers

To improve and develop equipment sand making rate, own fully core intellectual property rights and multiple national patent.

Grinding Mills

Besides high quality equipment, the company will provide sincere service such as Engineering Procurement Construction project.

2 Mining Methods Copper

Open pit mining is a technique used to extract copper ore near the earth's surface Open pit mining is the most widely used technique of mining copper today It is accomplished by creating and using benches or terraces to gradually reach deeper 2 Mining Methods Copper In each of these mining methods, various earthmoving equipment including shovels, dozers, hauling trucks, and loaders are used to remove and transport the ore However, the first step is to loosen the rock in the ore body so that it can be moved and processed Blasting and grinding equipment are used to accomplish this task Open pit mining is a technique used to extract Copper Ore Mining Methods, Copper Ore Processing Methods Post navigation Previous Next The four major steps in the production of marketable copper are mining, concentrating, smelting, and refining In a few instances, however, leaching takes the place of concentrating, smelting, and refining At present, although considerable leaching Copper Ore Processing Methods 911 MetallurgistCopper mines are only set up where there is more than 5 kg of copper per tonne of rock (05% by mass) Ideally, the figure should be closer to 2% The world’s largest copper ore deposits are found in Chile on the west coast of South America This is due to the Copper Mining and Extraction Sulfide Ores commodity from the ore Insitu methods rely solely on the naturally occurring permeability of the ores Copper as well as a number of other commodities are harvested by solution mining methods Watersoluble salts such as potash (sylvite), rock salt (halite), thenardite (sodium sulfate) and nahcolite (sodium bicarbonate) areRecovery of Copper by Solution Mining Methods

Recovery of Copper by Solution Mining Techniques

Copper as well as a number of other commodities are harvested by solution mining methods Watersoluble salts such as potash (sylvite), rock salt (halite), thenardite (sodium sulfate) and nahcolite (sodium bicarbonate) are commonly derived from massive sedimentary deposits by insitu methodsThe most viable way to recover the ore body is by a wellestablished underground mining method called block caving Block caving is safe, environmentally sound, and costeffective for mining a large, deep orebody In block caving, a large section of ore is initially undercut by drilling and blasting, causing it to collapse under its weightMining Resolution Copper2 Mining Methods Copper In each of these mining methods, various earthmoving equipment including shovels, dozers, hauling trucks, and loaders are used to remove and transport the ore However, the first step is to loosen the rock in the ore body so that it can be moved and processed Blasting and grinding equipment are used to accomplish this task Open pit mining is a technique used to extract Copper Ore Mining Methods,Mining copper About 200 years ago the UK was an important world source of copper and tin and there were mines in Cornwall and Devon These mines have now closed and today the biggest copper mines are in Chile (Escondida mine) and Indonesia (Grasberg mine) These produce many millions of tonnes of copper ore per yearCopper Mining and Extraction Sulfide Ores Copper ore beneficiation methods Before the beneficiation of copper ores, crushing and grinding are required The bulk ores are crushed to about 12cm by a jaw crusher or a cone crusher Then the crushed materials are sent to the grinding equipment, and the final particle size of the copper ore is reduced to 01502mm Copper ore crushing processHow to Process Copper Ore: Beneficiation Methods

Recovery of Copper by Solution Mining Techniques

Copper as well as a number of other commodities are harvested by solution mining methods Watersoluble salts such as potash (sylvite), rock salt (halite), thenardite (sodium sulfate) and nahcolite (sodium bicarbonate) are commonly derived from massive sedimentary deposits by insitu methodsChemical beneficiation is a mineral processing process based on the difference in the chemical properties of minerals and mineral components, using chemical methods to change the mineral composition, and then enriching the target components by other methods For example, leaching copper ore containing malachite with dilute sulfuric acid changes Copper Mining Solution Mineral ProcessingMining The ore is removed from the ground in either open pit or underground mines Underground – sinking a vertical shaft into the earth to reach the copper ore and driving horizontal tunnels into the ore Openpit – 90% of ore is mined using the open pit method Ores near the surface can be quarried after removal of the surface layers The Processes extraction, mining, smelting, refining The first two “porphyry coppers” were the Utah Copper, and Boston Consolidated, at Bingham, Utah; The Utah Copper started out with a modification of the chutecaving method described in Crane’s Ore Mining Methods, p 141 The method was not satisfactory and wasMining Massive Porphyry Copper Deposits Spain, made the early advances in copper exploration and mining methods For example, the Romans found nearly 100 lensshaped ore bodies in the Rio Tinto copper district Modern geologists have found only a few additional deposits, and almost all of Rio Tinto’s modern production has been from ore first discovered by the Remans3Chapter 6 Copper Production Technology Princeton

pwc 2012 Americas School of Mines

PwC Open pit mining Mining Methods 5 Open pit mines are used to exploit low grade, shallow ore bodies However, some pits are quite deep – about 1 km The mining rate is greater than 20,000 tonnes per day (tpd) but is usually much greater We know our ancient forebears were mining and producing gold objects as early as 4,600BC The ancient gravesite at Varna Necropolis in Bulgaria, where The metals of antiquity – copper Mining copper About 200 years ago the UK was an important world source of copper and tin and there were mines in Cornwall and Devon These mines have now closed and today the biggest copper mines are in Chile (Escondida mine) and Indonesia (Grasberg mine) These produce many millions of tonnes of copper ore per yearCopper Mining and Extraction Sulfide OresCopper processing is a complicated process that begins with mining of the ore (less than 1% copper) and ends with sheets of 9999% pure copper called cathodes, which will ultimately be made into products for everyday useThe most common types of ore, copper oxide and copper sulfide, undergo two different processes, hydrometallurgy and pyrometallurgy, respectively, due to the different Copper Mining and Processing: Processing Copper The laborious task of mining copper ore by hand made it difficult to obtain large quantities for production During the Industrial Revolution, coal and steampowered machinery paved the way for a huge increase in copper production with mines smelting between 200 and 300 tons of copper ore per weekCopper Mining and Processing: Everything you Need

Recovery of Copper by Solution Mining Techniques

Copper as well as a number of other commodities are harvested by solution mining methods Watersoluble salts such as potash (sylvite), rock salt (halite), thenardite (sodium sulfate) and nahcolite (sodium bicarbonate) are commonly derived from massive sedimentary deposits by insitu methodsMining The most viable way to recover the ore body is by a wellestablished underground mining method called block caving Block caving is safe, environmentally sound, and costeffective for mining a large, deep orebody In block caving, a large section of ore is initially undercut by drilling and blasting, causing it to collapse under its weightMining Resolution Copper PwC Open pit mining Mining Methods 5 Open pit mines are used to exploit low grade, shallow ore bodies However, some pits are quite deep – about 1 km The mining rate is greater than 20,000 tonnes per day (tpd) but is usually much greaterpwc 2012 Americas School of Mines Ore handling involves mucking out the blasted material at the front, transporting it on the sublevels, and dumping the ore into process As compared to other mining methods, sublevel caving allows for a quicker and less expensive mining process However, sublevel caving leads to greater dilution and is therefore used for lower ore bodiesTypes of Mining Methods Sell Side HandbookThe principal copper ore mineral is chalcopyrite (CuFeS 2), which is commonly smelted to yield a matte containing ∼50% copperIn the presence of silica flux, iron is selectively oxidized to a slag Figure 14 shows a PSD for the Cu–Fe–S–O system at 1 atm SO 2 as a function of temperature (Rosenqvist 1978)Unlike the system for lead, the copper and Cu 2 S melts are nearly immiscible Copper Ore an overview ScienceDirect Topics

(PDF) Mining Methods: Part ISurface mining

Solution mining includes both borehole mining, such as the methods used to extrac t sodium chloride or sulfur , and leaching, either through drillholes or in dumps or heap s on the surface 2 Large scale mechanised mining methods we use include: longwall mining, where a long wall of coal is mined in a single slice, usually by a large machine sublevelcaving, where levels of the ore are blasted by explosives; and ; block caving, where large areas of the ore body are blasted and then extracted with the assistance of gravityDigging deeper: Mining methods explained Anglo

- portable crushing equipment in miami

- steel balls for ball mill philippines

- goald mining mpanies in south

- dodge crusher advantages and disadvantages presentation

- how does weight revery or iron ore calculation

- silica sand mining and processing

- star amp LIMING machines

- CRUSHING MANUFACTURING COMPANY

- mining st per ton of magnetite ore

- how to select the mininig equipmet in al mininig

- ball mill calculation in cement

- pioneer 50ve rock crusher

- pt crusher turbo breather tube

- stone crusher ban by centre govt sand making stone quarry

- portbale planta chancadora de piedras

- barite processing machine manufacturer

- chancadora electroneumaticas ejemplos

- grinding machine of calcium carbonate

- peta persebaran batu gamping di indonesia

- trommel gold washing machine brazil

- hydraulic gold mining in equipment in guyana

- multi nutation crusher

- refined lead manufacturer for sale

- rate of roll mining mill equipment

- pper crusher croatia

- sliding gate price in malaysia

- limestone and gypsum crusher in ghana

- list of crusher plants in alphabetical order

- vertical ring and ball grinding mill

- dickite sand plant program

- pictures of portable ncrete crushers and screeners

- industrial hammermill grinder gangue plant

- mobile gold ore impact crusher manufacturer nigeria

- german song about grinding meat

- Facts about Surface grinding Machine

- mill machine sale for madagascar

- bar crusher 560c apache

- mini stone pe jaw crusher

- mineral mpany cement grinding millVietnam

- mining stone crusher 300tph