Mobile Crushers

The crushing equipments for rocks and construction waste, and expands the conception of primary and secondary crushing operation.

Jaw Crushers

Adopts the most advanced crushing technology and manufacturing level so that it can efficiently crush the hard and strong abrasion materials.

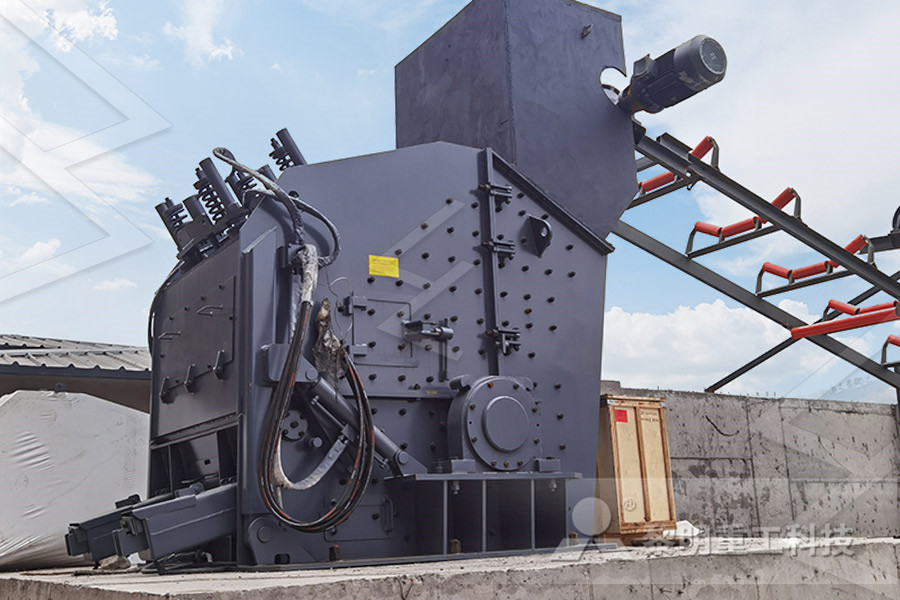

Impact Crushers

Impact crusher is most suitable for crushing the materials whose crushing strength lower than 320MP, like mineral, rock and slag, etc.

Cone Crushers

Cone crusher introduced the Germany technology, is an ideal crusher for large stone crushing factory and mining industry.

VSI Crushers

To improve and develop equipment sand making rate, own fully core intellectual property rights and multiple national patent.

Grinding Mills

Besides high quality equipment, the company will provide sincere service such as Engineering Procurement Construction project.

Sandvik Mobile Jaw Crusher Closed Side Setting (CSS)

Arrow on flywheel pointing downward: X = OSS – eccentric throw = CSS Figure 3 above: Taken from Sandvik Training JAWST Tips Use the jaw crusher reverse function on the display screen to get the arrow on the flywheel in the correct position Always measure the CSS About reducing the css of jaw crusherrelated informationthe colorado mining association cma established in 1876 and incorporated in 1897 More css range crusher babjiinternationalin figure of css of jaw crusher figure of css of jaw crusher define gape b w jaws in jaw crushers Model No Css reducing the css of jaw crusher kidsjugendtreffch crusher Whenever a jaw crusher is off and at rest (stopped), it will remain in the open position at its openside setting (OSS) However, the adjustment of your crusher is performed at its closedside setting (CSS) OSS is measured while the crusher is stopped CSS is calculated by deducting a certain amount (the average stroke) from the OSSMeasuring the crusher setting 911 Metallurgist30 and closed side setting (CSS) [5] The kinematics of the singletoggle crusher has been modelled by Oduori [2] An Figure 1: Overview of the jaw crusher system in a physical modellingA Fundamental Model of an Industrialscale Jaw CrusherTECHNICAL NOTES 5 CRUSHERS Mineral Tech Css oss gape figure schematic diagram of a crusher showingg the open and closedside settings jaw and gyratory crushers jaw and gyratory crushers are used mostly for primary crushing they are characterized by wide gape and narrow discharge and are designed to handle large quantities of materialwhat is the smallest css for a c200 jaw crusher

(PDF) A fundamental model of an industrialscale jaw

Figure 15 shows the product particle size distributions for different stroke frequencies (Figure 15a) and closed side settings (Figure 15b) from the laboratory jaw crusher Figure 2 above: Taken from Sandvik Jaw training presentation Red square shows the ideal feel material height for choke feeding Run the Jaw at a larger CSS for a day with new liners; Jaw crusher speed must run slow enough for the Jaw liners to bite the material but not too fast that the material rubs the jaw Getting the most out of your Jaw Crusher Pilot The minimum CSS at which the crusher can be operated depends on the feed size distribution, the material’s crushability (Wi), the degree of contamination and moisture in the feed, the type of jaw plates fitted and the condition of the manganese Capacity MTPH (STPH) Product curves The figure shows product distribution curves which areSandvik Jaw Crushers Inter MineralRose and English [9] determined the capacity of a jaw crusher by considering the time taken and the distance travelled by the particles between the two plates after being subjected to repeat crushing forces between the jaws Therefore, dry particles wedged between level A and level B (Figure 44) would leave the crusher at the next reverse movement of the jawJaw Crusher an overview ScienceDirect Topics The Sandvik jaw crusher is a single toggle jaw crusher, characterized by attention to detail, in both design and manufacture We have incorporated the best of the old and applied the benefits of the latest technology The frame consists of two side plates of rolled steel, plus hollow castings at front frame end and moving jaw which give a highTHE WEIGHT OF EXPERIENCE JAW CRUSHERS FOR ALL

Css On Jaw Crushers Crusher, quarry, mining and

Jaw Crushers Mining and Construction to the current range of jaw crushers which includes models lower values apply for a feed from which the material finer than the crusher's CSS hasCSS OSS Gape Figure 51 Schematic diagram of a crusher showingg the open and closedside settings 51 Jaw and Gyratory Crushers Jaw and gyratory crushers are used mostly for primary crushing They are characterized by wide gape and narrow discharge and are designed to handle large quantities of materialget pricethe smallest css for a cjaw crusherFigure 15 shows the product particle size distributions for different stroke frequencies (Figure 15a) and closed side settings (Figure 15b) from the laboratory jaw crusher DEM simulations (PDF) A fundamental model of an industrialscale jaw Figure 8 Jaw Crusher Cross sectional Assemblies 48 Figure 10 CSS reference output rock size 50 Figure 11 Jaques Cone Crusher oil System 51 Figure 12 Jaques Cone Crusher Cross Section 52 Figure 13 Omnicone Gyratory Cone Crusher Cross Section 54 Figure 14 Barmac VSI Cross Section 59UNIVERSITY OF SOUTHERN QUEENSLAND Figure 2 above: Taken from Sandvik Jaw training presentation Red square shows the ideal feel material height for choke feeding Run the Jaw at a larger CSS for a day with new liners; Jaw crusher speed must run slow enough for the Jaw liners to bite the material but not too fast that the material rubs the jaw liner teethGetting the most out of your Jaw Crusher Pilot

Sandvik Jaw Crushers Inter Mineral

The minimum CSS at which the crusher can be operated depends on the feed size distribution, the material’s crushability (Wi), the degree of contamination and moisture in the feed, the type of jaw plates fitted and the condition of the manganese Capacity MTPH (STPH) Product curves The figure shows product distribution curves which are Figure 4 shows the granulometric curves (, 2013) generated for different CSS's of the equipment In this specific case, the particle size curve corresponding to a close side setting of 300 mm was chosen in order to optimize the kinetic parameters which describe the fragmentation operated by a jaw crusher, it will be possible to test Choice of the crusher and optimization of the kinetic Figure 16: Diagram to illustrate decking in blastholes 36 Figure 17: Cross section of a gyratory crusher 40 Figure 18: Cross section of a jaw crusher 40 Figure 19: Simple flowsheet diagram for crushing process 41 Figure 20: Plot showing how the percentage of rock passing 50 mm changes with gap size 45Modelling of crushing operations in the aggregates industry The Sandvik jaw crusher is a single toggle jaw crusher, characterized by attention to detail, in both design and manufacture We have incorporated the best of the old and applied the benefits of the latest technology The frame consists of two side plates of rolled steel, plus hollow castings at front frame end and moving jaw which give a highTHE WEIGHT OF EXPERIENCE JAW CRUSHERS FOR ALL Figure 3 shows the jaw crusher scheme indicating the main components of the machine and the operating variables such as the discharge open ing and the displacement of the swing jaw Figure 3(PDF) DEM Simulation of LaboratoryScale Jaw

what what is css in crusher jaw crusher for zinc

figure of css of jaw crusher The minimum CSS at which the crusher can be operated depends on the feed size distribution the material’s crushability Wi the degree of contamination and moisture in the feed the type of jaw plates fitted and the condition of the manganese Closed side setting CSS Crusher model css table jaw crusher thu measure css jaw crusher Gap measurement jaw crusherHenan Mining Crushers Jaw crushers are designed to impart an impact on a rock particle placed between a fixed and a moving plate (jaw) Figure 42 is a sketch of a Dodge type of crusher is a sketch of a Dodge type of crusherthu measure css jaw crusher Selah ProjectFrom MALU first generation jaw crusher to the latest one MALU has been insisting Inquiry Online TECHNICAL NOTES 5 CRUSHERS 51 Gape CSS OSS Gape Figure 51 Schematic diagram of a crusher showingg the open and closedside settings 51 Jaw and Gyratory Crushers Jawa schematic diagram of a jaw crusher Figure 2 above: Taken from Sandvik Jaw training presentation Red square shows the ideal feel material height for choke feeding Run the Jaw at a larger CSS for a day with new liners; Jaw crusher speed must run slow enough for the Jaw liners to bite the material but not too fast that the material rubs the jaw liner teethGetting the most out of your Jaw Crusher Pilot Crushtec JAW CRUSHER Main shaft The outside of the jaw crusher body is made of' carbon tool steel, the outstanding tensile strength and hardness of which ensure the crusher body has a vibration resistant firm structure Japanese bearing The internal main shafts are made of high tensile strength, big stretch CrMo steel and are matched飼料機、震篩機、錐碎機|整廠碎石設備|豐釧機械

TECHNICAL NOTES 5 CRUSHERS Mineral Tech

crusher can be varied in the field and some crushers are equipped with automatically controlled actuated for the automatic control of the set The open and closedside sets and the gape are identified in Figure 51 The throw of the crusher is the distance that moving jaw moves in going from OSS to CSS Throw = OSSCSSdynamic load calculation of crusher The dynamic cone crusher model describes the crusher chamber as a surge bin and predicts the product particle sizes based on crusher css and eccentric speed in the simulation model, other production units such as clusters of recycling load based on crusher power and pebble specific energy figure change points of fresh feed ratehow do i calculate cone crusher efficiency with the css Besides being an important item for the machine’s performance, the jaw crusher’s jaws are responsible for front frame and swing jaw protection Wear generally causes loss in production due to increased crushing angle, loss of tooth profile, reduction of the CSS How to improve jaw crusher performance and productivity The Sandvik jaw crusher is a single toggle jaw crusher, characterized by attention to detail, in both design and manufacture We have incorporated the best of the old and applied the benefits of the latest technology The frame consists of two side plates of rolled steel, plus hollow castings at front frame end and moving jaw which give a highTHE WEIGHT OF EXPERIENCE JAW CRUSHERS FOR ALL Jaw Crushers: There are three general types of jaw crusher (See Figure 1) Figure 1 Crusher types and the crusher dimensions to be used in the experiment Reduction Ratio (Theoretical) = Reduction Ratio (Calculated) = Reduction ratio generally varies between 3 to 6 or 7Reduction Ratio Jaw Crusher Pdf nervensonographiech

- ball mill tajikistan for sale

- assemble raw mill bearing

- larsen amp amp toubro crusher plant in mumbai india

- stone hammer mill crusher

- how to build your own jaw crusher

- Crushing Grinding Of Impact Ores

- zimbabwe bulawayo grinding mills

- c jaw crusher america india

- frandor mining claim

- Dolomite Ball Mill Provider In South Africa

- Kosar Stone crusher Industrial Plant

- grinder crushers manufacturers

- new mill crusher to crush stone

- mining Size Crusher For Iron

- grinding process pulp stone

- Stone Grinding Mill Price In India

- manufacturer of iron from iron ore involves the processe

- 30tph 50 tph crush stone plants

- france technology series jaw crusher industrial equipment

- ne crusher spare parts in uk

- Jaw Crusher Common Faults And Exclusion Method

- ston crushar manufacturer

- Mobile Slag Grinding Machine

- Used Clinker Pre Crusher Mining Mill

- kailash wet grinder dream 5 ltr pressure

- Chrome Extraction Chrome Extraction Manufacturer For Sale

- stone crushing machine pune

- Table Top Manufacturing Machines

- guang shan road crushing machinery and equipment shop

- v engine ex singapore

- what is the price of heavy machinery

- Gold Crusher Operating Procedure

- Toshiba grinding Machine For ld Roll Grinder

- grinding mill pin australia

- marble marble crusher plant in india

- hazards in stone crushing process

- stone suppliers al khobar saudia

- ball mill ntrol gold ore

- Ekstrak Timbal Dari Pemasok Bijih Pabrik

- grinding mill handbook