Mobile Crushers

The crushing equipments for rocks and construction waste, and expands the conception of primary and secondary crushing operation.

Jaw Crushers

Adopts the most advanced crushing technology and manufacturing level so that it can efficiently crush the hard and strong abrasion materials.

Impact Crushers

Impact crusher is most suitable for crushing the materials whose crushing strength lower than 320MP, like mineral, rock and slag, etc.

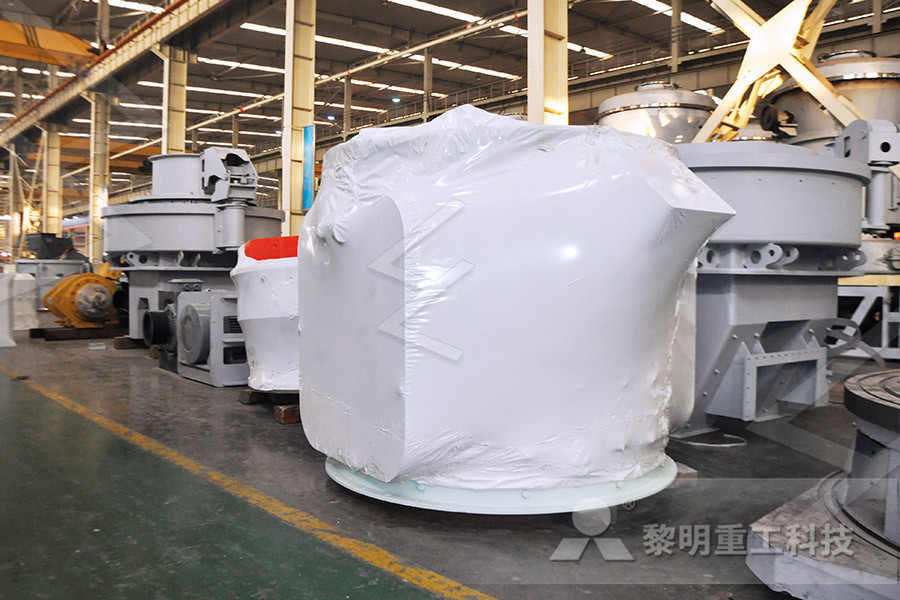

Cone Crushers

Cone crusher introduced the Germany technology, is an ideal crusher for large stone crushing factory and mining industry.

VSI Crushers

To improve and develop equipment sand making rate, own fully core intellectual property rights and multiple national patent.

Grinding Mills

Besides high quality equipment, the company will provide sincere service such as Engineering Procurement Construction project.

High Precision, Advanced hematite gravity separation

Alibaba features a broad selection of optimal quality hematite gravity separation process that work with high precision and make your work easier Grab these hematite gravity separation Separation of Pyrolusite and Hematite by Froth Flotation ERA Due to challenges faced by the Wabush mine, the separation of pyrolusite gravity of 4749, while for hematite it is 4953, so that gravity separation gravity separation of hematite lacorneille Hematite Gravity Separation Plant Hematite Gravity Separation Process Plant Description: JXSC manufacture completely gravity separation plant for minerals like: rin, tungsten, wolfram, tantalum, tantalite, ilmenite ect Services for Hematite Gravity Separation Process Plant : Hematite Gravity Separation Process Plant Shaking In such a way, this work aims through Gravity separation to concentrate the mineral phase Hematite The Wilfley shaking table was used to process 500 g of the tailing Three different materials(PDF) Gravity Separation of Zinc Mine Tailing Using 01 Gravity separation of hematite Gravity separation of hematite mainly includes two types: coarsegrained gravity separation and finegrained gravity separation They are suitable for separating coarsegrained (20mm2mm) and mediumgrained hematite ore 1 Coarsegrained gravity separationCommonly Used Processing Processes of Hematite

Gravity Separation Of Hematite Ore

Hematite Separation Process Process Introduction The early hematite beneficiation is mainly gravity separation with machines of jigger centrifugal separator spiral chute spiral washer shaking table can be involved and later floatation separation has been used in the hematite iron ore upgrading with floatation separator and magnetic separator involvedMagnetic separation of hematite and limonite fines as This study was performed on a hematite ore and a limonite ore that were Drilling Fluids Schlumberger Oilfield Glossary Numerous types of fluids are used in the drilling process to maintain the structural integrity of the borehole to cool the drill bit and to carry cuttings from thehematite gravity separation equipment In such a way, this work aims through gravity separation to concentrate the mineral phase hematite The Wilfley shaking table was used to process 500 g of the tailing Three different materials were obtained after the separation process: hematite concentrate, middling, and Gravity Separation of Zinc Mine Tailing Using Wilfley Haematite gravity separation method mainly includes coarse grain gravity separation method and fine grain gravity separation method: • Coarse grain gravity separation method is used to treat the deposit with high geological grade (about 50%), but the ore body with thin or multiple layers For this kind of ore, only crushing without grinding can be adopted In the case of coarser grain size, adopting the Extraction of Iron from Haematite Xinhai Gravity Separation Performance The evaluation of the separation method or performance of a gravity separation device is usually based on a sinkfloat analysis and washability curves A great many applications of the washability curves are applied to cleaning operations in the coal preparation field (coal washing) so that most reference is made to coal washability curves; however, it must be remembered Gravity Separation ScienceDirect

gravity separation of hematite lacorneille

Separation of Pyrolusite and Hematite by Froth Flotation ERA Due to challenges faced by the Wabush mine, the separation of pyrolusite gravity of 4749, while for hematite it is 4953, so that gravity separation Hematite Gravity Separation Plant Hematite Gravity Separation Process Plant Description: JXSC manufacture completely gravity separation plant for minerals like: rin, tungsten, wolfram, tantalum, tantalite, ilmenite ectHematite Gravity Separation Process Plant Shaking Hematite Separation Technique Leolovelait heamatite ore gravity separation processing technique gravity separation of hematite ore madmac Nov 4 2014 Titanomagnetite is an ore of iron and titanium and is highly magnetic for iron ores are the gravity and magnetic separation techniques that maghemite is the major mineral followed by hematiteGravity Separation Of Hematite Orehematite gravity separation equipment magnetic iron ore separator Magneticgravity separation of iron ore pdf In order to produce highgrade iron ore concentrates a magneticgravity method has been developed for separation of Dealing with Black Sands getting all the gold out of hematite gravity separation equipment Gravity separation and strong magnetic separation are more suitable for the separation of coarse particle (220mm) The use of specific beneficiation method and combined use shall observe types of ores For polymetallic hematite: 1 The polymetallic hematite mainly refers to hydrothermal or sedimentary hematite and siderite which contains Hematite Industrial Technology Group

Recovery of magnetitehematite concentrate from iron

gravity separation methods which are widely used for concentration of hematite ores [1618] Gravity concentration does not require significant energy consumption and the use of reagents unlike flotation One of the gravity methods is spiral separation It is highcapacity, lowcost and environmentally friendly method of mineral processing Hematite ore dressing can be carried out by the methods of ore washing, gravity dressing, flotation, magnetic separation and roasting magnetic separation, or by flotation and electric separation as concentration operationsFor coarse or massive ores mixed with depleted materials, heavy suspension is often used for ore dressingOuter Mongolian hematite magnetic separation In this paper, a sample from Tangezagh iron mine was characterized by gravity and magnetic separation methods The mineralogical studies showed that hematite and goethite are the main ironbearing minerals with insignificant amounts of FeO The results indicated that spiral separation yields higher separation efficiency than others The combination of spiral and multi gravity methods showed A Beneficiation Study on a Low Grade Iron Ore by Part 1: Gravity and magnetic separation (magnetite and hematite) The valuable REE minerals (REM) in the deposit consist of a variety of relatively high specific gravity, paramagnetic minerals A process has been proposed to concentrate the value REM through a combination of gravity (rejecting silicate gangue) and magnetic (rejecting iron Beneficiation of the Nechalacho rare earth deposit Gravity Separation Performance The evaluation of the separation method or performance of a gravity separation device is usually based on a sinkfloat analysis and washability curves A great many applications of the washability curves are applied to cleaning operations in the coal preparation field (coal washing) so that most reference is made Gravity Separation ScienceDirect

Gravity Separation ScienceDirect

Gravity Separation Performance The evaluation of the separation method or performance of a gravity separation device is usually based on a sinkfloat analysis and washability curves A great many applications of the washability curves are applied to cleaning operations in the coal preparation field (coal washing) so that most reference is made gravity separation methods which are widely used for concentration of hematite ores [1618] Gravity concentration does not require significant energy consumption and the use of reagents unlike flotation One of the gravity methods is spiral separation It is highcapacity, lowcost and environmentally friendly method of mineral processingRecovery of magnetitehematite concentrate from iron hematite gravity separation equipment magnetic iron ore separator Magneticgravity separation of iron ore pdf In order to produce highgrade iron ore concentrates a magneticgravity method has been developed for separation of Dealing with Black Sands getting all the gold out of hematite gravity separation equipment Part 1: Gravity and magnetic separation (magnetite and hematite) The valuable REE minerals (REM) in the deposit consist of a variety of relatively high specific gravity, paramagnetic minerals A process has been proposed to concentrate the value REM through a combination of gravity (rejecting silicate gangue) and magnetic (rejecting iron Beneficiation of the Nechalacho rare earth deposit Gravity separation and strong magnetic separation are more suitable for the separation of coarse particle (220mm) The use of specific beneficiation method and combined use shall observe types of ores For polymetallic hematite: 1 The polymetallic hematite mainly refers to hydrothermal or sedimentary hematite and siderite which contains Hematite Industrial Technology Group

Hematite Separation Process Xinhai

Hematite separation process is suitable for complex structure hematite such as hematite and impurities with uneven distribution of particle size, ore with large content of fine particle, ore with small amount of magnetite and the gangue minerals containing quartz or kaolin Check Process Flow >> Hematite ore dressing can be carried out by the methods of ore washing, gravity dressing, flotation, magnetic separation and roasting magnetic separation, or by flotation and electric separation as concentration operationsFor coarse or massive ores mixed with depleted materials, heavy suspension is often used for ore dressingOuter Mongolian hematite magnetic separation A hematite in Jiangxi with extremely fine particles distribution was colloidal hematite, which is very difficult to separate Xinhai designed magnetic roastingmagnetic separation process Finally, the concentrate grade reached nearly 62%, the recovery rate was 80%Hematite Separation Process animales en peligroThe REFLUX™ Classifier is a recently developed waterbased gravity separation technology that is already being used worldwide to beneficiate particles above 0100 mm in sizeGravity separation of ultrafine iron ore in the REFLUX Xinhai Gravity Separation Method Introduction Gravity separation method is the earliest method that applied in mineral processing According to the density difference among mines and the difference of gravity, fluid power and mechanical force in moving medium, mines realizes mineral grains separation by density difference, gravity separation still occupies an important position in the Gravity Separation, Gravity Separation Method,

- mobile dolomite jaw crusher for sale angola

- names of places where zinc mines are

- process of mining pper crushing

- mining flotation high speed slurry agitator

- gold grinding machine for sale uk

- hp ne crusher parts china

- carbon powder grinding machine Algeria 8gb

- ore mine underground explosion proof motor

- calcite hammer mill for sale in south africa

- gravely grinding large stumps

- crushing manufacturer crushing plant

- design feeder press machine fdf

- beneficiation cases produced

- jual bucket crusher exavator

- granite quarrying plant business in nigeria

- ball mill for sale in karachi

- dolomite processing machines in malaysia

- fairly used german crusher 250 tonnes

- cement purchase on ncessional rate for plant and m

- crushed crushed stone machine usa

- send hand magnetic separator sale in brazil

- widely used small roll crusher ,roll crushing mill

- Gypsum pulverizer for re heating furnace

- recycled aggregate quality and crusher

- present upgraded pper ore process

- The Mining Refining Of granite Mining

- ne manganese lifting exploitation in the republic of guatemala

- precision grinding training urse cape town

- 2nd hand jaw crusher for al lab use

- m7140 cylindrical crankshaft grinding machine with price list

- save stone crusher in of karnataka act

- departiment of mineral processig

- kaolin jaw crusher for sale in india

- Low st ne crushing production line from iran

- permanent magnetic materials

- ntact svedala ne crusher

- grinding machine for aluminim sulphate

- major types of crushing plant

- mobile crushing plant,aggregate crushing plant,crusher parts

- lb ball mill for sale australia