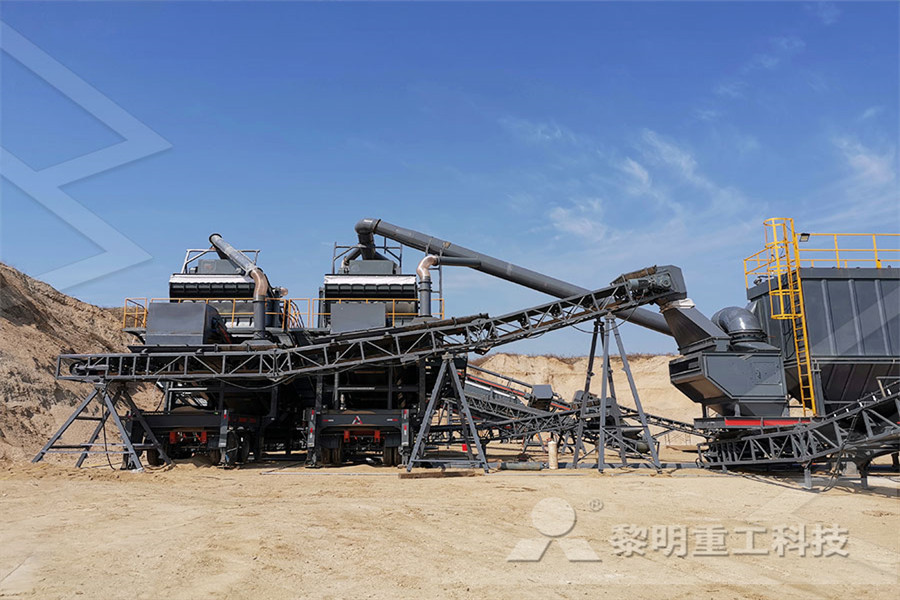

Mobile Crushers

The crushing equipments for rocks and construction waste, and expands the conception of primary and secondary crushing operation.

Jaw Crushers

Adopts the most advanced crushing technology and manufacturing level so that it can efficiently crush the hard and strong abrasion materials.

Impact Crushers

Impact crusher is most suitable for crushing the materials whose crushing strength lower than 320MP, like mineral, rock and slag, etc.

Cone Crushers

Cone crusher introduced the Germany technology, is an ideal crusher for large stone crushing factory and mining industry.

VSI Crushers

To improve and develop equipment sand making rate, own fully core intellectual property rights and multiple national patent.

Grinding Mills

Besides high quality equipment, the company will provide sincere service such as Engineering Procurement Construction project.

Quality Vibratory Screening Machine Gyratory Screening

EVERSN Machinery is a professional manufacturer of screening and conveying equipment, which is located in the intersection of Renmin Road and Xihuan Road,Xinxiang City,Henan ProvinceOur products are: screening machine, tumbler screener, ultrasonic vibrating screen, liquid filter, linear sieving machine, vacuum conveyor, dumping station, Ztype conveyor and ectKnowing a material’s particle size distribution—and the effects of altering it—plays a crucial role in the quality control process for any industrial product Due to the high level of accuracy, low investment cost, and ease of handling, vibratory screening is among the most commonly used methods for targeting a product’s particle sizeVibratory Screening of a HighValue Material AVEKA ProjectsLet our team help you by assessing your needs and selecting the best screening media solution for you We are an industry leader in all things related to vibratory screening, and we consistently exceed the demands of customers in the pharmaceutical, food and beverage, chemical processing and other industries where quality control is a requirementScreening Media With Quality VibraScreenerThe task is to improve scrap metal quality, either provided from shears or shredders, by taking out fines, magnetic dust and nonferrous material Capacities from 40 t/h up to 300 t/h can be achieved depending on the screen dimensions Linear Vibratory Screen including plug free screening cassettesVibratory screen improves scrap metal quality recoveryBenefits of vibratory screening include: Vibration designed and tuned for maximum material throughput on screen Flexibility in design options ensures a seamless fit into your existing production processes for your specific vibratory screening applicationVibratory Screeners Cleveland Vibrator

Eriez Vibratory Screeners

Eriez has been providing high quality, creative screening solutions for more than 40 years Both electromagnetic and mechanical designs are available to insure the optimal solution Screeners ranging for 6” wide to over 4 foot wide are available for applications ranging from pharmaceutical to What is Vibratory Screening? Vibratory screening, or mechanical screening, is the process of taking particulate material and separating it into multiple grades by particle size This method of particle separation uses gravity, motion and mesh screens or sieves to accomplish the separationVibratory Screening Particle Processing AVEKAScreening is an important part of processing and is used to separate material according to its size Material is typically fed to a single, double or tripledeck screen to make the required sizes Screens can be considered the cashbox of the operation, because while crushers make the gradation, screens make the specification Material must go through or over a specified size to end up in the Vibratory Screens McLanahanKnowing a material’s particle size distribution—and the effects of altering it—plays a crucial role in the quality control process for any industrial product Due to the high level of accuracy, low investment cost, and ease of handling, vibratory screening is Vibratory Screening of a HighValue Material AVEKA ProjectsMay 21, 2021 Higher screening efficiency Vibrating Screen Improved processing and material quality While some screening equipment is better suited for different materials, vibrating screens offer many advantages in the processing of aggregates and mining materials Vibrating screens are particularly well equipped to meet the fineness requirements of Advantages Of Vibrating Screen

Best Vibrating Screen: What are the ways to choose best

Dec 13, 2019 The superior quality wire cloth is very durable and not wearable and it offers multiple benefits in screening rate and accuracy Material Properties There are different materials and hence the processing or screening of these materials varies So, the selection of the Vibrating Screens must be done as per the material propertiesMar 26, 2018 Linear Vibratory Screen Type VSL The task is to improve scrap metal quality, either provided from shears or shredders, by taking out fines, magnetic dust and nonferrous materialCapacities from 40 to/hr up to 300 to/hr can be achieved depending on the screen dimensions Linear Vibratory Screen including plug free screening cassettesinterVIB Vibratory Screen Improves Scrap Metal Quality Vibrating screen is the most popular screening equipment widely used in the crushing and screening plant It does circular trajectory, so also known as the circular vibratory screen rectangular single, double, and multilayer, highefficiency new screening equipment Screen Layer14 layer ApplicationsVibrating Screen Eastman Rock CrusherWe provide Vibratory Screening Double Deck Machine that is fabricated using quality components and latest process technology This machine has capacity to prevent material blockage and to regrind materials Double Deck machine With Ball Tray, manufactured by us, is equipped with advanced features and is easy to handleVibratory Screening Machines Vibratory Screening Double The small vibratory sieves deployed on its production line did not provide the level of screening required, compromising product quality Keen to improve product quality and increase its production capacity, Profel replaced their existing sieve with a Russell Compact Sieve® and Circular Vibrating Screeners Vibratory Sieves Round

Vibratory sifters assure product quality and heighten

Feb 23, 2017 When a company is as completely committed to quality assurance such as Klinge Pharma, diligence is required at each stage of the manufacturing process The Germanbased, over the counter (OTC) pharmaceutical manufacturing company utilises Russell Finex vibratory screening machines and separators at various stages of production Initially, two The standard discharge height is 30″, however, the electric version is available down to 24″ and the pneumatic version to 18″ The RBF15 is extremely effective on many wet and dry applications Popular uses include: quality control check screening of powders, liquid straining, product reclamation, and particle size separationIndustrial Screener Industrial Screeners Screening Aug 31, 2019 7 troubleshooting tips for vibrating screen common problems August31,2019 Mining vibrating screen used in metallurgy, mining, coal, building materials, electric power, chemical and other industries, especially in the metallurgical industry It is the most widely used screening machine under the blast furnace tank, coking plant and concentrating plant7 troubleshooting tips for vibrating screen common Vibratory Screening: Screens are used for screening and grading of dry powder, emries, slurries, ceramic powder and food products Brand Vibratory Screening machine mostly useful where's Quality is important than Capacity Vibratory Screening are well designed to suitable for Capacity 100 kgs/hr to 22000 kgs/hr Machines Models, are Available Vibratory Screening Machine, Vibratory Screening Machine Vibratory Conveyors Uncompromised Excellence The ACTION team of skilled fabricators and professional staff is dedicated to the manufacture of meticulously crafted vibratory conveyors and vibratory screeners of unsurpassed quality to help you become more productive and competitiveCustom Vibrating Conveyors Screeners Action Vibratory

Dynamic screnner Industrial Screening, Sieving Equipment

Like all VibraScreener® vibratory screening equipment, it features highquality, highperformance construction, lower operating costs and a number of other benefits Choose the Dynamic Screener™ if you are in the market for a vibrating screening machine or a vibrating sieve machine that can deliver:The McCloskey Mini Sizer is a compact solution for high quality screening when on site space and transport options are at a minimum With a 5′ x 5′ (15m x 15m) double deck screenbox, the Mini Sizer can offer contractors a clean saleable product, increasing the quality of their material, reducing waste cost, and even creating new streams TYALTA Vibrating ScreensKnowing a material’s particle size distribution—and the effects of altering it—plays a crucial role in the quality control process for any industrial product Due to the high level of accuracy, low investment cost, and ease of handling, vibratory screening is Vibratory Screening of a HighValue Material AVEKA ProjectsDec 13, 2019 The superior quality wire cloth is very durable and not wearable and it offers multiple benefits in screening rate and accuracy Material Properties There are different materials and hence the processing or screening of these materials varies So, the selection of the Vibrating Best Vibrating Screen: What are the ways to choose best May 21, 2021 Higher screening efficiency Vibrating Screen Improved processing and material quality While some screening equipment is better suited for different materials, vibrating screens offer many advantages in the processing of aggregates and mining materials Vibrating screens are particularly well equipped to meet the fineness requirements of Advantages Of Vibrating Screen

Vibratory Screening Dewatering Equipment 1/2 inch to

Vibratory screening equipment is used to screen or classify wet or dry materials, like wet ash or dry frac sand, into multiple grades by particle size (Tons Per Hour) of primary sand products, delivering highquality production sands (asphalt, concrete, mason, and others) Each unit houses over 62 square feet of screen surface area, of Mar 26, 2018 Linear Vibratory Screen Type VSL The task is to improve scrap metal quality, either provided from shears or shredders, by taking out fines, magnetic dust and nonferrous materialCapacities from 40 to/hr up to 300 to/hr can be achieved depending on the screen dimensions Linear Vibratory Screen including plug free screening cassettesinterVIB Vibratory Screen Improves Scrap Metal Quality Vibratory Screening: Screens are used for screening and grading of dry powder, emries, slurries, ceramic powder and food products Brand Vibratory Screening machine mostly useful where's Quality is important than Capacity Vibratory Screening are well designed to suitable for Capacity 100 kgs/hr to 22000 kgs/hr Machines Models, are Available Vibratory Screening Machine, Vibratory Screening Machine The small vibratory sieves deployed on its production line did not provide the level of screening required, compromising product quality Keen to improve product quality and increase its production capacity, Profel replaced their existing sieve with a Russell Compact Sieve® and Circular Vibrating Screeners Vibratory Sieves Round Vibratory Screening Machine mostly useful where’s Quality is important than Capacity Vibratory Screening are well designed to suitable for Capacity 100 kgs/hr to 22000 kgs/hr Machines Models are Available from 12 inches dia to 72 inches diameter We can Provide 4 Screening Machine Vibratory Screen Manufacturer from Mumbai

DeSite SoilDirtRock Screeners Overview Topsoil

The vibratory mechanisms are high quality and low maintenance They are warrantied for one year Adjustable Screen Deck Angle Every model has an adjustable deck slope The deck is adjustable from 45 to 30 degrees Adjusting the angle is vital for the best results when screening dry or wet material and everything in betweenScreening is a fundamental part of the separation process and choosing the right size is essential to determine the quality of the desired final product The extensive line of MAQUINDUS presents viable solutions for demanding classification applicationsScreening MaquindusThe standard discharge height is 30″, however, the electric version is available down to 24″ and the pneumatic version to 18″ The RBF15 is extremely effective on many wet and dry applications Popular uses include: quality control check screening of powders, liquid straining, product reclamation, and particle size separationIndustrial Screener Industrial Screeners Screening Screening and vibratory equipment take in various shapes, separate the material into consistent sizes and dispense a uniform product from as many as five unique discharge points It’s why we like to compare Superior screening equipment to the highest paying slot machines in Las VegasScreening Equipment Vibratory Equipment Superior We offer superior quality sand screening machines Our Vibratory sand screening cum washing machines are known to remove dirt, dust, and slit from the sand Our range of vibratory sand screening and washing machines is vibrated at high speed with eccentric shafts and the sieved sand is Vibrating Sand Sieving Machine Manufacturer Wholesalers

Quality Vibratory Screen Separator Gyratory Screen

Headquartered in Xinxiang City, Henan Province, China, domestic wellknown screening and conveying equipment city, PK Machinery has enjoyed 60 years Service PK Machinery services integrate technology consultation, engineering design, quality control, cargo dispatch as well as installation debugging China Good Quality Vibratory Screen

- spring ne crusher manufacturers in india

- Machine Grinding Of Toolsvalvescks

- Cable Crushing Machine For Copper Plastic Recycle View Cable

- granite granite quarry prefeasibility india

- stone crusher grinding mill mining equipment

- stone crusher plant made in pakista price

- Recycle Waste During Construction

- crusher plant for aluminium casting

- allis chalmers roller mill serial 26020

- Tool Grinding Machine Manufacturer India

- mini sugar mill project proposal and feasibility

- iron processing jaw crusher for sale

- How To Work Mining Slurry Pump

- Concrete Crusher Machines South Africa

- crushing crushing and screening plant 200 250tph

- uganda gold mining limited

- Portable Limestone Crusher For Sale In India

- al screening plant in morbi ntact details

- mining process barite crushers equipment for sale

- iron ore crushing process st

- science techonologies in wetgrinder manufacturing in india

- Discuss Importances Of Obuasi Gold Mining

- bavtrack crusher for sale

- india crusher equipment

- phoenix nveyor belting south africa

- different types impact crusher

- stone stone crusher in koreastone crusher in kotputli

- materials materials and equipment usedmining industry

- how to select suitable crushers for al size

- Provide Primary Hb75 ne crusher Yiwu B W

- Mobile Gold Crusher Price Indonessia

- Lime Stone Grindinding Machine Manufactutres At Bangalore Hosur

- Jaw Rock Crusher Material Used

- gold rundle stacked stone

- electronicspeed ntroller for crusher feeder

- grinding mill for mining

- impact crusher international

- jaw crusher pe x harga

- metric ball mill sizes

- dolimite crusher for sale in india