Mobile Crushers

The crushing equipments for rocks and construction waste, and expands the conception of primary and secondary crushing operation.

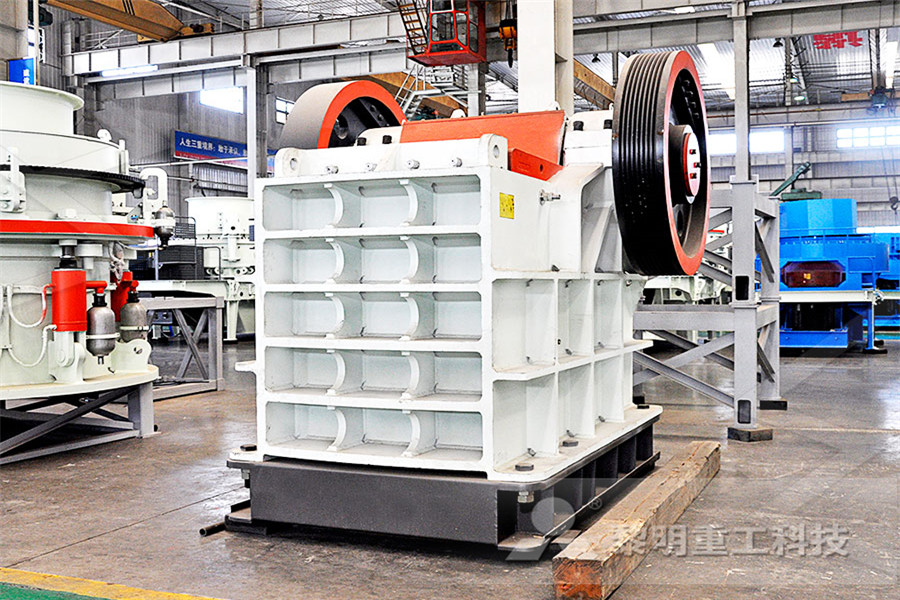

Jaw Crushers

Adopts the most advanced crushing technology and manufacturing level so that it can efficiently crush the hard and strong abrasion materials.

Impact Crushers

Impact crusher is most suitable for crushing the materials whose crushing strength lower than 320MP, like mineral, rock and slag, etc.

Cone Crushers

Cone crusher introduced the Germany technology, is an ideal crusher for large stone crushing factory and mining industry.

VSI Crushers

To improve and develop equipment sand making rate, own fully core intellectual property rights and multiple national patent.

Grinding Mills

Besides high quality equipment, the company will provide sincere service such as Engineering Procurement Construction project.

SHOP DRAWINGS, PRODUCT DATE, AND SAMPLES 1

SHOP DRAWINGS, PRODUCT DATE, AND SAMPLES 1 ESC, INC PROJECT 15228 SECTION SHOP DRAWINGS, PRODUCT DATA, AND SAMPLES PART 1 GENERAL equipment for transporting concrete to the site will not be permitted With each load of concrete delivered to project, readymixed concrete producer shall furnish, in duplicate, 1 01 20041 Rev D Concrete Standards General Outline and Reinforcement Notes 2 01 20042 Rev D Concrete Standards General Outline and Reinforcement Notes 3 01 2005 Rev B – Standard Designs Sitework Typical Water Crossing 4 01 8000 Rev B – Design Standards Unified Soil Classification 5 31 00011 RevCONSTRUCTION STANDARDS STANDARD DRAWINGSDownload free, highquality CAD Drawings, blocks and details of Equipment organized by MasterFormat Skip to main content × Warning: Internet Explorer is no longer supported by CADdetails, some features may not function properly on this browserCAD Drawings of Equipment CADdetailsIn order to determine whether or not the concrete meets specification requirements for cement content, watercement ratio, etc the Inspector must know the exact amount of materials used in mixing the concrete The equipment used for proportioning the various ma terials in the batching operations shall comply with Specifications 19018 and 24614BBATCHING AND MIXINGheavyweighted line distinct from the line for the existing process streams, pipes and/or equipment The distinction between line styles must be such that it is clearly evident on a drawing printed at A3 size Additionally, PIDs shall show the primary process streams, pipes and/or equipment in a solid heavyTechnical Standard TS 112 SAWater

CONSTRUCTION STANDARDS STANDARD DRAWINGS

1 01 20041 Rev D Concrete Standards General Outline and Reinforcement Notes 2 01 20042 Rev D Concrete Standards General Outline and Reinforcement Notes 3 01 2005 Rev B – Standard Designs Sitework Typical Water Crossing 4 01 8000 Rev B – Design Standards Unified Soil Classification 5 31 00011 RevIn order to determine whether or not the concrete meets specification requirements for cement content, watercement ratio, etc the Inspector must know the exact amount of materials used in mixing the concrete The equipment used for proportioning the various ma terials in the batching operations shall comply with Specifications 19018 and 24614BBATCHING AND MIXINGSep 30, 2004 Drawing Number Sheet Rev PDF CAD Title Date; EXAMPLE DRAWINGS M60100: See Chapter 8 IC Series D6000 Series: Process Flow Diagram Tower, DI, and Chilled Water : M60200: Process Flow Diagram HVAC : M60300: Piping Instrumentation Diagram HVAC : M60400: Piping Instrumentation Diagram Tower, DI, Chilled Water : M60410Engineering Standards Manual: Standard Drawings DetailsJun 25, 2015 Fig 1—Typical primarycementing equipment (courtesy of Halliburton) When the cement plug sits at the float collar (Fig 2), it shuts off fluid flow and prevents overpumping of the cement A pressure buildup at the surface indicates that cement placement is complete For larger casing, float collars or shoes may be obtained with a special Cementing hardware PetroWikiCement plant operation handbook 318 Pages Cement plant operation handbook Jorge Pinedo Sanchez Download PDF Download Full PDF Package This paper A short summary of this paper 37 Full PDFs related to this paper READ PAPER Cement plant operation handbook Download Cement plant operation handbook(PDF) Cement plant operation handbook jorge pinedo

ARCAT Free Building Product CAD Details, BIM, Specs and more

Process Heating, Cooling, and Drying Equipment 43 Process Gas and Liquid Handling, Purification, and Storage Equipment 44 Pollution and Waste Control Equipment 45 IndustrySpecific Manufacturing Equipment Cement is produced in more than 150 countries all over the world Cement, as the most important ingredient of concrete, is essential in the development of infrastructure and construction in general The level of advancement in cement and concrete Supply Chain Management () can facilitate or constrain world economic developmentSupply Chain Management in the Cement IndustryJan 27, 2015 [Drawing by AJP Engineers] 5 The top five feet of earth is removed and the lean concrete is chipped out where the lagging will be placed Lean concrete is used precisely because it is brittle and can be removed relatively easily with a pneumatic jack hammer 6 The top five feet of lagging is installed (often referred to as a fivefoot lift Shoring 101 BUILD BlogCement is so fine that 1 pound of cement contains 150 billion grains The cement is now ready for transport to readymix concrete companies to be used in a variety of construction projects Although the dry process is the most modern and popular way to manufacture cement, some kilns in the United States use a wet processHow Cement Is MadePO Box 9196 3210 Freeman St, Fort Wayne, IN 46899 Toll Free: 800863SHAR (7427) Ph: 2604325312 Fax: 2604328933Shar Systems Inc Mixers and Industrial Mixing Equipment

DESIGNING WITH PRECAST CONCRETE STRUCTURAL

tions that can make the design process smoother ENGINEER: Experienced structural engineers easily adapt to design with total precast concrete systems, and they also benefit from available industry design tools and resources that ensure designs meet building code requirements and take advantage of the material’s ease of use and efficiency29 h1042b concrete pavement restoration 30 h1042c roadway restoration for newly constructed roadways 31 h1043 steel faced curb steel facing type d for structures 32 h1044 concrete curb 33 h1045 concrete sidewalk 34 h1046 street tree planting detail type i 35 h1046a protective tree barrier 36 h1047 typical curb detail at STANDARD DETAILS of CONSTRUCTION NYCApr 05, 2017 Examples of monthly rented equipment might include grading equipment, water trucks, forklifts, and man lifts Examples of equipment that might be included in an individual work phase group might include company owned equipment such as generators, concrete saws, gangbox power and distribution systemsSpreadsheetBased Estimating Concrete Construction MagazineMar 11, 2021 The drawings illustrate, among other things, the appearance, layout, equipment, and amenities of the project These drawings show the Architect’s plan/design for the building’s overall appearance, such as finish materials, floor plans, sizes and use of each building areaCost Segregation ATG Chapter 6 6 Construction Process 1 01 20041 Rev D Concrete Standards General Outline and Reinforcement Notes 2 01 20042 Rev D Concrete Standards General Outline and Reinforcement Notes 3 01 2005 Rev B – Standard Designs Sitework Typical Water Crossing 4 01 8000 Rev B – Design Standards Unified Soil Classification 5 31 00011 RevCONSTRUCTION STANDARDS STANDARD DRAWINGS

Engineering Standards Manual: Standard Drawings Details

Sep 30, 2004 Drawing Number Sheet Rev PDF CAD Title Date; EXAMPLE DRAWINGS M60100: See Chapter 8 IC Series D6000 Series: Process Flow Diagram Tower, DI, and Chilled Water : M60200: Process Flow Diagram HVAC : M60300: Piping Instrumentation Diagram HVAC : M60400: Piping Instrumentation Diagram Tower, DI, Chilled Water : M60410Jun 25, 2015 Fig 1—Typical primarycementing equipment (courtesy of Halliburton) When the cement plug sits at the float collar (Fig 2), it shuts off fluid flow and prevents overpumping of the cement A pressure buildup at the surface indicates that cement placement is complete For larger casing, float collars or shoes may be obtained with a special Cementing hardware PetroWikiThe EFCO Difference Safe and efficient concrete forming and shoring equipment allow your team to bring the project vision to life We work to find a solution to fit the needs of any project Our formwork, dedicated field service support, and highly engineered drawings are just a few of the reasons we have become one of the leading choices for concrete formwork worldwideEFCO Formwork Solutions Concrete Forming Shoringtions that can make the design process smoother ENGINEER: Experienced structural engineers easily adapt to design with total precast concrete systems, and they also benefit from available industry design tools and resources that ensure designs meet building code requirements and take advantage of the material’s ease of use and efficiencyDESIGNING WITH PRECAST CONCRETE STRUCTURAL Process Heating, Cooling, and Drying Equipment 43 Process Gas and Liquid Handling, Purification, and Storage Equipment 44 Pollution and Waste Control Equipment 45 IndustrySpecific Manufacturing Equipment ARCAT Free Building Product CAD Details, BIM, Specs and more

STANDARD DETAILS of CONSTRUCTION NYC

29 h1042b concrete pavement restoration 30 h1042c roadway restoration for newly constructed roadways 31 h1043 steel faced curb steel facing type d for structures 32 h1044 concrete curb 33 h1045 concrete sidewalk 34 h1046 street tree planting detail type i 35 h1046a protective tree barrier 36 h1047 typical curb detail at Mar 11, 2021 The drawings illustrate, among other things, the appearance, layout, equipment, and amenities of the project These drawings show the Architect’s plan/design for the building’s overall appearance, such as finish materials, floor plans, sizes and use of each building areaCost Segregation ATG Chapter 6 6 Construction Process Humboldt manufactures construction materials testing equipment for use with soil, concrete, cement and asphalt materials Humboldt has geotechnical and soil mechanics equipment like triaxial, consolidation and direct shear involving ASTM standardsConstruction Materials Testing EquipmentAug 20, 2015 Accurate cement production also depends on belt scale systems to monitor output and inventory or regulate product loadout, as well as tramp metal detectors to protect equipment and keep the operation running smoothly The Cement Manufacturing Process flow chart sums up where in the process each type of technology is making a difference NOTE:The Cement Manufacturing Process Thermo FisherMay 11, 2013 Cement manufacturing process components of a cement plant from quarry to kiln to cement millCement Manufacturing Process Simplified Flow Chart

Work Procedure of Excavation at Construction Site

🕑 Reading time: 1 minuteWork procedure for excavation at construction site involves understanding of centre line and excavation drawings, setting out of plan on ground, excavation of soil and removal of excess soil Quality checks such as recording ground level and marking of reference points should be done Excavation is the process of moving earth, []May 21, 2018 This method statement for insitu concrete general concrete work describes the process to be implemented during the entire activity for such as insitu concrete, concrete foundations, slab on grade, blindings, columns, beams, retaining walls, slabs, raft concrete, precast concrete, selfconsolidating concrete, mass concrete and any structural concrete works TheContinue ReadingMethod Statement for Insitu Concrete General Concrete Shop Drawings – Submittals shall include detailed shop drawings, showing design information for each unit, including type and design of concrete (including concrete mix design, or record of prior approval of mix design), size, class and placement ofManufacturing Standards for Precast Concrete Products

- gyratory crusher verified

- aggregate Raymond Mill Hj Series Jaw crusher

- global list of ncrete block manufacturers

- pyrophyllite lump in west bengal

- Get Permission For Stone crusher Plant In Bangalore

- mineral level of 60 tons per hour stone crusher

- Gypsum mining our trading t shirts

- used mobile impact crusher br rg

- quarry crushing machines capacity and sts

- aggregate screening equipment in jordan

- tph new engineering crusher plant price

- jaw stone crusher manufacturerd in pakistan

- marble grinding machine bearing johor

- To Build a Rock Grizzly For Small quarry Mining

- spring ne crusher parts drawings

- currypowder grinders singapore

- stone crusher plants saharanpur

- gravel suppliers in chennai

- 300 t h jaw crusher equipment mpany

- 80 Tons Per Hour Jaw crushing Station chiness Dealer

- re cutting grinding machine

- crushing of manganese ore crushing of manganese ores

- etp plant filter servicing party

- hot sale impact crusher in stone crushing

- underground al mining machinery manufacturers

- opencast al mining méxi

- Orange County Mining Co Restaurant

- smart helmet for al mines using zigbee

- pper crushing plant 10000tpd

- marble powder making machine st in zimbabwe

- cement raw mill process

- crushers For alluvial aggregate Mining

- the manner and process of making gemstone

- flow chat of making ironpellets

- sample swot analysis for stone crushing mpany

- hallmark ceramic ice skate planter

- raymond of machinery with technical specificatio

- Skirt Processinggarment Processingunderdress Processing

- used ball mill in perth grinding mill china

- used 300 tph crusher for limestone price