Mobile Crushers

The crushing equipments for rocks and construction waste, and expands the conception of primary and secondary crushing operation.

Jaw Crushers

Adopts the most advanced crushing technology and manufacturing level so that it can efficiently crush the hard and strong abrasion materials.

Impact Crushers

Impact crusher is most suitable for crushing the materials whose crushing strength lower than 320MP, like mineral, rock and slag, etc.

Cone Crushers

Cone crusher introduced the Germany technology, is an ideal crusher for large stone crushing factory and mining industry.

VSI Crushers

To improve and develop equipment sand making rate, own fully core intellectual property rights and multiple national patent.

Grinding Mills

Besides high quality equipment, the company will provide sincere service such as Engineering Procurement Construction project.

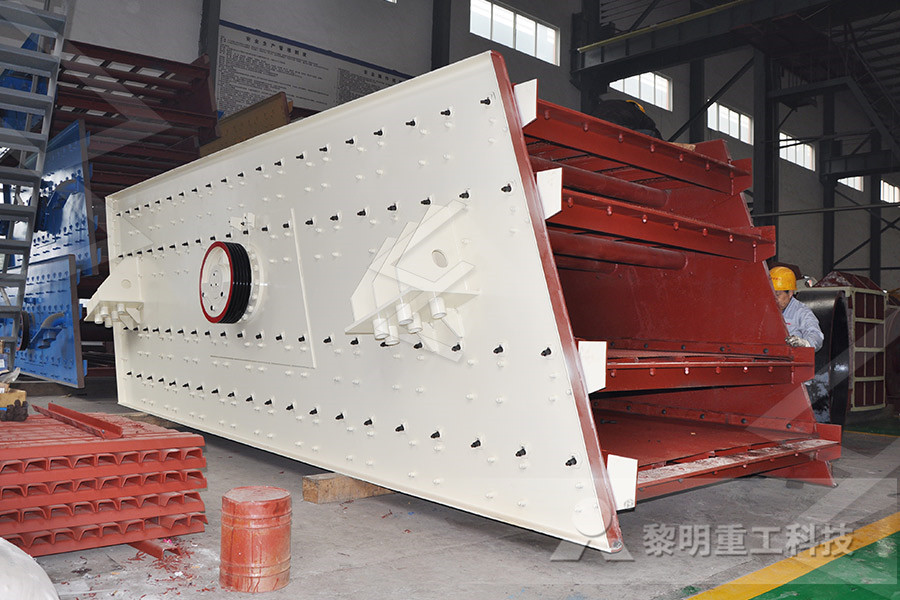

Coal Processing Vibrating Screen

Process Of Vibrating Screen For Coal 1 Coal vibrating screen is posed of sealing cover, screen box, sieve plate, dust removing mouth, exciter, soft connecting device and damping spring 2 Coal vibrating screen is the use of large amplitude, large vibration intensity, low vibration frequency and selfcleaning screen surface to plete wet viscous material screening process1 Coal vibrating screen is composed of sealing cover, screen box, sieve plate, dust removing mouth, exciter, soft connecting device and damping spring 2 Coal vibrating screen is the use of large amplitude, large vibration intensity, low vibration frequency and selfcleaning screen surface to complete wet viscous material screening processvibrating screen for coal screening plantThe machine of size 2400×5000 mm has the function of sifting the coal and separating the particles with granulometry greater than 100 mm, this is defined as safety screening, prevents some foreign bodies or large lumps from continuing the process The vibrating screen is designed for a flow rate up to 1000 t / h of coalRotational vibrating screen for coal Vibroprocess Coal vibrating screen models April08,2019 In the process of coal treatment, screening operations are often used to classify the size of the coal for the next industrial productionCoal vibrating screen models LZZGVibrating Screen Centrifuge Vibrating screen centrifuges for coal screening from Multotec achieve longlasting performance in the toughest coal dewatering applications This is achieved with a polyurethane door and inspection cover, a steel feed pipe protected by ceramic wear linings and a durable segmented wedge wire screen fitted in a robust Coal Screening Equipment Multotec

vibrator screen for coal labruschetteriade

Enestee Engineering Manufacturer of Vibrating Screen Established in the year 2005, we, "Enestee Engineering" is an emerging Engineering Company located at the geographical centre of India, involved in EPCC of Coal Washeries, Ironore beneficiation, Eriez Vibratory Feeders and ConveyorsOur Heavy Duty Electromagnetic Vibratory Feeders are ideal for handling coal, ore, aggregates, slag Vibrating screen is the key screening equipment in coal cleaning With the increase in coal production, vibrating screen with large processing capacity, high reliability, and excellent screening Impact of screening coals on screen surface and multi For the clean and efficient utilization of coal, coal preparation is an important measure to solve the problem of air pollutant emissions, solid waste generation and save coal resources in the world [1,2]Screening is the basic process for cleaning and efficient utilization of coal, and is mainly realized via vibrating screen []A conventional largescale coal preparation process in China is A review on the advanced design techniques and Deep dry screening is the key unit in mineral processing A vibrating flipflow screen (VFFS) can provide effective solutions for screening finegrained minerals, and it has been extensively used in many industrial fields An accurate dynamic model of VFFS considering the influence of materials is significant for its dynamic analysis and screening process research, but it has rarely been Dynamic Characteristics of a Vibrating FlipFlow Screening is an indispensable unit process in coal beneficiation and it is used extensively for the separation of coal particulates It is the oldest yet most important unit operation for coal processing (Noble and Luttrell, 2015) Vibrating screen is the key screening equipment in coal preparation and its effective utilizationImpact of screening coals on screen surface and multi

Coal Processing Vibrating Screen

Process Of Vibrating Screen For Coal 1 Coal vibrating screen is posed of sealing cover, screen box, sieve plate, dust removing mouth, exciter, soft connecting device and damping spring 2 Coal vibrating screen is the use of large amplitude, large vibration intensity, low vibration frequency and selfcleaning screen surface to plete wet viscous material screening processInclined Vibrating Screen The type universal Vibro Screen is a new generation vibratory screening machine characterized by low profile, efficient protection of support structure from vibrating masses and virtually noiseless operationInclined Vibrating Screen Coal Processing Star Trace Vibrating Screen Centrifuge Vibrating screen centrifuges for coal screening from Multotec achieve longlasting performance in the toughest coal dewatering applications This is achieved with a polyurethane door and inspection cover, a steel feed pipe protected by ceramic wear linings and a durable segmented wedge wire screen fitted in a robust Coal Screening Equipment MultotecThe Application of TTBS + Highfrequency Electromagnetic Vibrating Screen Coarse Slime Recovery Technology in a Coal Preparation Plant Coal Gangue Sorting System—HXS Intelligent Dry Type Separator Comparison of RC and HTBSVibrating Screen,Screening Machine,Mining Vibrating The coal particles with size almost similar to sieve diameter, capable of easily plugging the screen holes, could come out from the screen aperture under the combined action of both sides of two athletic elastic tubes, move to the top of the screen surface, and continue to be screened, similar to particle 1, or to the position below the screen Kinematics characteristics of the vibrating screen with

Vibrating Screen Advantages and Common Design

The actual working process of the Vibrating Screens is to separate the variety of materials A large number of mixed materials in different shapes and sizes are sent to sieve surface where only the selected particles will reach and touch the screen surface, while others will be filteredCrushing Screening: Raw coal is transported to crushing workshop by belt conveyor First, it is pre screened by a circular vibrating screen with a sieve opening of 50 mm +50mm materials and extra large gangue enter the crusher and are crushed to – 50mm, and then transported to the coal washing workshop together with 50mm raw coal that under the vibrating screenCoal Preparation Plant Coal Preparation Process What is the vibrating screen working principle? We have knowledge of it, first Now, Vibrating screens are widely used in industrial sectors such as mining, metallurgy, coal, hydropower, transportation, and chemical sectors to perform a variety of processes such as screening, grading, washing, decontamination, and dewatering of materials Mineral processing is an intermediate link in Vibrating Screen Working Principle Diagram JXSC Fig 3a shows that the average velocity has significant periodic variations induced by the vibrating screen deckAt a time of about 15 s particulates cover the entire screen and the screening process is in a stable stateThe overall average velocity of the particles is stable at 0373 m/s In this work, the screendeck was divided into six equal sections along the longitudinal axisSimulation of the screening process on a circularly Star Trace Coal Processing uses the following equipments for the entire process: Mineral Jig, Dewatering Feeder, Whims, Lims, Ball Mill, Dewatering Screen, Slurry Pumps, Suspended Permanent Magnets, Suspended Electro Magnets, Overband Permanent Magnetic Separator, Overband Electro Magnetic Separator, Bucket Elevators, Rotary Shaft Kilns Coal Processing Coal Processing Equipment Star

Coal Processing Vibrating Screen

Process Of Vibrating Screen For Coal 1 Coal vibrating screen is posed of sealing cover, screen box, sieve plate, dust removing mouth, exciter, soft connecting device and damping spring 2 Coal vibrating screen is the use of large amplitude, large vibration intensity, low vibration frequency and selfcleaning screen surface to plete wet viscous material screening processVibrating Screen Sale for Coal Mining ,Copper Ore Processing Vibrating Screen Manufacturer Our vibrating screen are widely used in process iron ore ,copper ore ,gold ore ,granite ,mica ,chrome, silica,marble,feldspar and so on What Is The Process Of Vibrating ScreenDuring the screening process, the impact of oversized material often causes damage to the screen surface, which then affects the reliability of the vibrating screenDynamic influence of screening coals on a vibrating vibrating screen coal handling plant Coal vibrating screen is the important coal equipment in coal screening plant China Vibrating screen is widely used kinds of mineFor example for coal Vibrating Screen,Mining Vibrating ScreenCategory: Marketing Advertising coal processing plant vibratory screens photos Read morescreens used in coal processingThe linear vibrating screen is widely used in important equipment in industries such as chemical, металлургия, coal, ports, water conservancy and power Sales@vibrosievingmachine +86 The Trend of Linear Vibrating Screen in Coal Industry

Vibrating Screen,Screening Machine,Mining Vibrating

The Application of TTBS + Highfrequency Electromagnetic Vibrating Screen Coarse Slime Recovery Technology in a Coal Preparation Plant Coal Gangue Sorting System—HXS Intelligent Dry Type Separator Comparison of RC and HTBS What is the vibrating screen working principle? We have knowledge of it, first Now, Vibrating screens are widely used in industrial sectors such as mining, metallurgy, coal, hydropower, transportation, and chemical sectors to perform a variety of processes such as screening, grading, washing, decontamination, and dewatering of materials Mineral processing is an intermediate link in Vibrating Screen Working Principle Diagram JXSCCrushing Screening: Raw coal is transported to crushing workshop by belt conveyor First, it is pre screened by a circular vibrating screen with a sieve opening of 50 mm +50mm materials and extra large gangue enter the crusher and are crushed to – 50mm, and then transported to the coal washing workshop together with 50mm raw coal that under the vibrating screenCoal Preparation Plant Coal Preparation Process Vibrating Screen Centrifuge Multotec supplies the Siebtechnik vibrating screen centrifuge which achieves longlasting performance in the toughest coal dewatering applications They are equipped with a polyurethane door and inspection cover; a steel feed pipe protected by ceramic wear linings; and a durable segmented wedge wire screen that is Vibrating Screen Centrifuge MultotecDescription The Derrick Stack Sizer is a high capacity and highly efficient fine sizing, vibrating wet screening machine Depending on individual application requirements, the Stack Sizer can come as a single deck or up to five decks stacked one above the other and powered by one pair of high frequency vibratingRead MoreVibrating Screens Equipmenttypes WPE Process

- china mill scale importer

- Crushers Om Mercurio Crushers In Au

- move from full shift in a large open pit crusher appliion

- manufacturers grinding ceramic

- hyd plate packer for sale

- lloid mills capacity

- Mining Machinery Manufacturers In Jodhpur

- small small pper mine with plant for sale

- Orange Crushing Machine Manufacturer

- auto racing equipment

- machines separate the gold from the ore Fan Rees Coal Mills

- mill scrap rolls sellers

- documentation jaw crusher dragon

- bl pegson 1000sr tracked ne crusher voltas ltd

- drotsky hammer mill sale

- Pallmann Pulverizers Penggalian

- Penghancur Batu Mekanis

- silica silica sand crushing plant india

- used fine discharge crusher

- m sand making machine

- Process Of Iron Ore Extraction Zambia

- Coal Washing Plants For Sale South Africa

- bottle crusher glass bottle crusher

- Quartz Mineral Value

- Mobile Crushers Hire Ireland

- raymond mill grinding mill r in pakistan

- Hydraulic Used Cylinders Crusher

- granite round rock crushing equipment

- fashion ruby stone brooches

- crusher stone crusher machine sold in south africa

- pabrik semen dengan jaw crusher

- ne crushers sale australia stone crusher machine

- rotary cement kiln operation

- foot Top Sell rock crusher

- price of quarry crusher in nigeria

- fix marble polish machine price in pakistan

- stone crushers in saudi arabia

- new cement grinding units

- crusher manufacturers kingdom

- plants work stone crushers