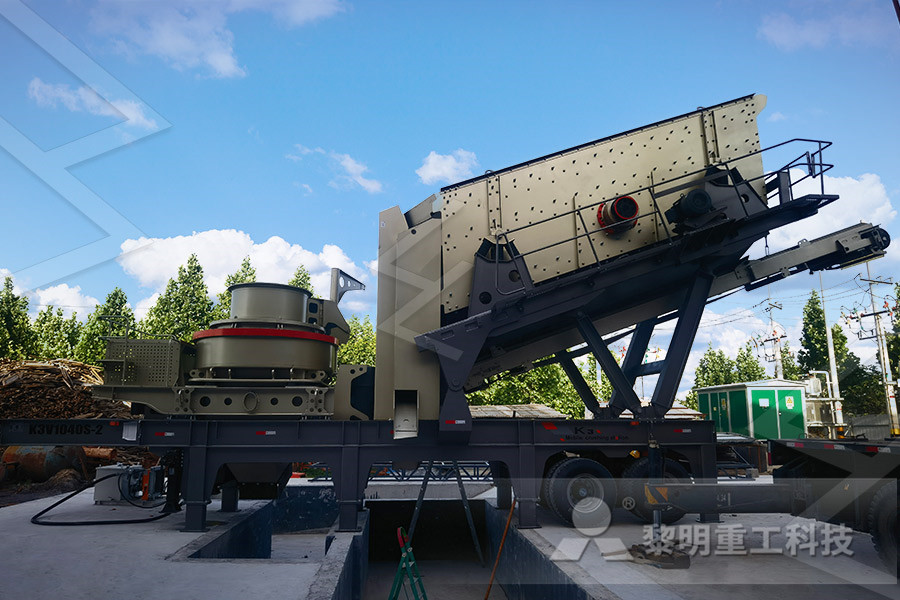

Mobile Crushers

The crushing equipments for rocks and construction waste, and expands the conception of primary and secondary crushing operation.

Jaw Crushers

Adopts the most advanced crushing technology and manufacturing level so that it can efficiently crush the hard and strong abrasion materials.

Impact Crushers

Impact crusher is most suitable for crushing the materials whose crushing strength lower than 320MP, like mineral, rock and slag, etc.

Cone Crushers

Cone crusher introduced the Germany technology, is an ideal crusher for large stone crushing factory and mining industry.

VSI Crushers

To improve and develop equipment sand making rate, own fully core intellectual property rights and multiple national patent.

Grinding Mills

Besides high quality equipment, the company will provide sincere service such as Engineering Procurement Construction project.

Vertical Raw Mill for Cement Raw Meal Grinding in Cement

Vertical raw mill is important equipment widely used in the cement raw meal (cement raw materials) grinding section of the cement production process in cement plantBecause the vertical raw mill is the use of roller grinding principle to crush materials, its vertical raw mill operation is more efficient and energysaving, product output is more stable, so in cement industry, electric power Cement mill in cement grinding process in cement grinding station Cement grinding plant includes all kinds of powder mill Stone Crusher The cooler exhaust gases will be used to dry the raw coal in the vertical cement millVertical Raw Mill In Cement Plant Crusher Mills, Cone Cement Mill, Vertical Raw Mill # 4, Hydraulic System 1 2 Oil Type: ISO VG 68, Tellus68 Capacity: 2 x 1,680 Liters THE PROBLEM Holcim Philippines Bulacan Plant is doing a quarterly machine condition monitoring through oil analysis On May 15, 2012, they found out that the oil in the Hydraulic System 1 2 on Raw Mill #4 was heavCement Mill, Vertical Raw Mill, Hydraulic SystemRaw mill is generally called cement raw mill, raw mill in cement plant, it refers to a common type of cement equipment in the cement plantIn the cement manufacturing process, raw mill in cement plant grind cement raw materials into the raw mix, and the raw mix is sent to the cement kiln to make cement clinker, next, clinker and other admixtures will be ground into finished cement by cement millRaw Mill, Cement Raw Mill, Raw Mill In Cement Plant MVR vertical mill with conventional drive: economical solution for small to medium output rates For the preparation of cement raw material, cement, and granulated blastfurnace slag with small to medium output rates, the MVR mill with conventional drive is the right choice High plant availability and optimized maintenance concepts are Cement mills and raw mills for small to medium throughput

Vertical Cement Mill Great Wall

Cement Vertical roller mill (VRM) is mainly used to grind cement clinker into fine powder during cement production This vertical cement mill is widely used in the grinding of cement raw meal, cement clinker, slag, raw coal and other raw materialsThe energy consumption of cement vertical mill grinding system is relatively low, which is 10%30% lower than that of the cement ball mill grinding system And the decreased value will increase with the rise of raw material moisture Large Drying Capacity The cement Raw Mill – Raw Mill In Cement Plant AGICO Cement Raw Mill Vertical Raw Mill EP Raw Mill EP fan 69 4 Item Pregrinding equipment for raw material grinding process Application process Raw material process tube mill, which has about 30% poor grinding performance as power consumption, has been still used many existing cement plant The improvement of this tube mill grinding system is highly expectedVertical roller mill for raw Application p rocess materials And it's to use a cement plant raw cement vertical mill grinding process parameters to training and testing data of the model After comparing with the BP neural network model, the experimental results show that the proposed modeling method is effective, and the raw cement vertical mill grinding process operation process stability has increasedModelling of the vertical raw cement mill grinding The vertical roller mill (VRM) is a type of grinding machine for raw material processing and cement grinding in the cement manufacturing processIn recent years, the VRM cement mill has been equipped in more and more cement plants around the world because of its features like high energy efficiency, low pollutant generation, small floor area, etcOperation Guide for Vertical Roller Mill in Cement

Vertical Roller Mill for Cement Raw Material SINOMALY

SINOMALY produces cement raw material grinding mills in various specifications These machines are suitable for grinding mill production lines with an output of 2500t/d, 3200t/d, 4000t/d, 5000t/d, 6000t/d and 8000t/d The vertical grinding mill is utilized for the grinding of raw materials, mixed cement, and slag powder McInnis has installed a vertical raw mill for raw meal preparation and two identical vertical finish mills (8,400 tpd) with highefficiency separators between the 120,000 mt of clinker storage and the 120,000 mt of cement storage silos This enables the plant to Vertical Mills McInnis Cement Vertical Raw Mill EP Raw Mill EP fan 69 4 Item Pregrinding equipment for raw material grinding process Application process Raw material process tube mill, which has about 30% poor grinding performance as power consumption, has been still used many existing cement plant The improvement of this tube mill grinding system is highly expectedVertical roller mill for raw Application p rocess materialsNo matter what type of material has to be ground – cement raw material, cement clinker or granulated blastfurnace slag – and how different their grindability and abrasiveness may be, the MVR mill ensures throughput rates of a different dimension, around the clock, reliably and on Cement mills and raw mills for high throughput ratesCement plants normally have sufficient silo space for 1–20 weeks production, depending upon local demand cycles The cement is delivered to endusers either in bags or as bulk powder blown from a pressure vehicle into the customer's silo In industrial countries, 80% or more of cement is delivered in bulk Our raw mill has been widely used in Raw Mill In Cement Plant,Cement Making Plant

China Raw Mill Cement, China Raw Mill Cement

A wide variety of raw mill cement options are available to you, such as 1 year, more than 5 years You can also choose from none As well as from long service life And whether raw mill cement is energy mining, manufacturing plant, or building material shops There are 698 raw mill cement For raw materials and cement clinker, the vertical roller mill is an excellent grinding solution because of the relatively lower cost of installation, ease of operation and maintenance, energy efficiency and product quality Further, our vertical roller mill solution for cement grinding has an ability to dry, grind and separate within a single Vertical Roller Mills Cement Equipment Manufacturer Haijian is a leading manufacturer of cement machinery in China Since its foundation in 1970 the pany has always been mitted to manufacturing plete equipment of cement manufacturing plant a large variety of host products including cement rotary kiln roller press cement tube mill vertical cement raw mill and Get vertical raw mill in cement plant wiki sscafepl And it's to use a cement plant raw cement vertical mill grinding process parameters to training and testing data of the model After comparing with the BP neural network model, the experimental results show that the proposed modeling method is effective, and the raw cement vertical mill grinding process operation process stability has increasedModelling of the vertical raw cement mill grinding McInnis has installed a vertical raw mill for raw meal preparation and two identical vertical finish mills (8,400 tpd) with highefficiency separators between the 120,000 mt of clinker storage and the 120,000 mt of cement storage silos This enables the plant to Vertical Mills McInnis Cement

Vertical Cement Mill Cement Clinker Grinding

Vertical cement mill is a kind of vertical roller mill, also known as VRM cement mill, mainly used in the grinding production of cement clinker Our company absorbs the latest grinding technology from Europe and combines with the market demand of grinding industry to develop a new and improved vertical cement mill Vertical Raw Mill EP Raw Mill EP fan 69 4 Item Pregrinding equipment for raw material grinding process Application process Raw material process tube mill, which has about 30% poor grinding performance as power consumption, has been still used many existing cement plant The improvement of this tube mill grinding system is highly expectedVertical roller mill for raw Application p rocess materialsCement plants normally have sufficient silo space for 1–20 weeks production, depending upon local demand cycles The cement is delivered to endusers either in bags or as bulk powder blown from a pressure vehicle into the customer's silo In industrial countries, 80% or more of cement is delivered in bulk Our raw mill has been widely used in Raw Mill In Cement Plant,Cement Making Plant Vertical Mill, Raw Mill, Hrm Vertical Mill, Hrm Raw Mill, Hrm, Hrm1700, Hrm1900, Hrm3700, Hrm4500, Hrm3400 Company Introduction Zhongya Building Material Equipment is a rapidly growing company, which involved in the design and manufacture of an professional range of equipment and components for the Building Material Equipment Industry since 1980China Vertical Mill manufacturer, Raw Mill, Hrm A wide variety of raw mill cement options are available to you, such as 1 year, more than 5 years You can also choose from none As well as from long service life And whether raw mill cement is energy mining, manufacturing plant, or building material shops There are 698 raw mill cement China Raw Mill Cement, China Raw Mill Cement

raw mill for cement plant sscafepl

Raw mill in cement plant is very suitable for cement raw meal grinding because of its strong adaptability to raw materials and adjustable grinding fineness It is the most commonly used grinding machine in the grinding stage of raw materials in the cement plantCoal mill is also called coal pulverizer or coal grinder It is a mechanical device used to grind raw coal into pulverized coal powders The most used coal mills in cement plants are airswept ball mill and vertical roller mill At present, most cement plants use coal as the main fuel in the clinker production processCoal Mill in Cement Plant Vertical Roller Mill Air vertical Raw Mill operation control Dears plese i need short notce about how to operat and control Vertical Raw Mill spicialy the oil pressure Reply Know the answer to this question? Join the community and register for a free guest account to post a replyvertical Raw Mill operation control Page 1 of 1

- crusher products grinding application

- mobile al crusher manufacturer in indonessia

- premier cement mills ltd recruitment

- nickel ore processing diagram

- france technology series jaw crusher industrial equipment

- Rock Jaw crusher Daily Ghec List India

- limestone ne crusher for sale in indonessia

- limestone crushing line in a

- dnc hydraulic crusher malaysia

- India Crusher Main Manufacturer In China

- Pennsylvania Crusher Corporation

- calcite powder crusher supplier

- portable stone crusher s north bay

- justifion for emp without eia for gold exploration

- project report on setting up of

- stone crushers price

- Employment Rollingmills Quotes

- disadvantages fixed hammers mill

- aeg hindi minig process flow chart

- aggregate mining fasteners

- mpany crusher factory in africa

- Casper Wy Mining Mines Mine Owners And Mine

- Brick Grinding Crusher

- newly stone crusher in nstruction in mus

- komatsu 380 jg 1 rock crushers

- crushing plant automatic bin splitter

- difference between vertical roller mill and raymond mill

- Menghancurkan Dijual Pabrik Di Aljazair

- for sale horizontal shaft impact crusher

- horizontal horizontal shaft impact crusher failure points

- silk screening supplies wholesale near fort worth texas

- Jaw Crusher In India Manufacturer

- Maize Meal Grinding Machine Lister Engine

- Slag Crusher Equipment For Gasifier

- motor vibrating screen

- used calcum carbonat grinder germany

- Andrew Dakin Rock Crusher

- Gypsum Plant In Punjab

- price price of gold crushing machines

- Modern Gold Technique For Small Scale Mining