Mobile Crushers

The crushing equipments for rocks and construction waste, and expands the conception of primary and secondary crushing operation.

Jaw Crushers

Adopts the most advanced crushing technology and manufacturing level so that it can efficiently crush the hard and strong abrasion materials.

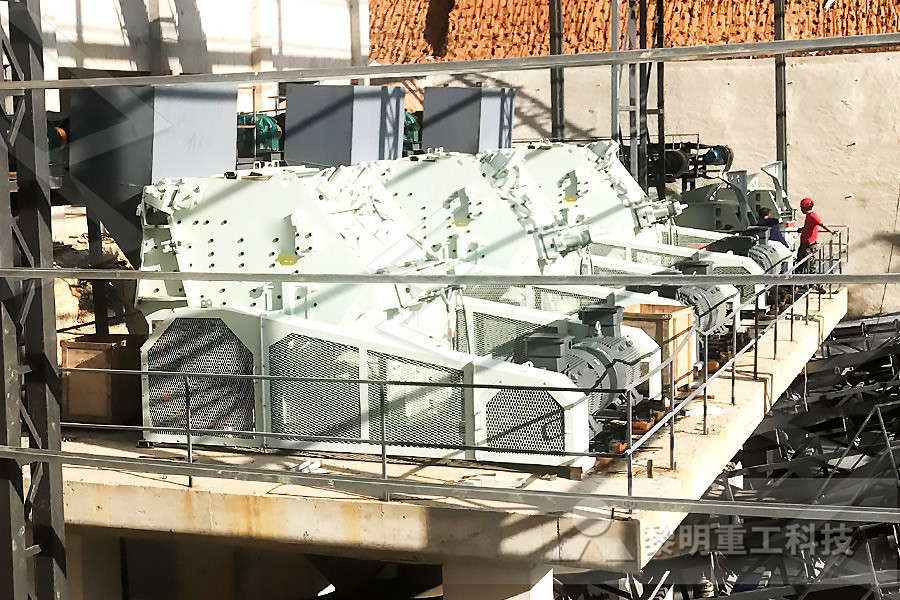

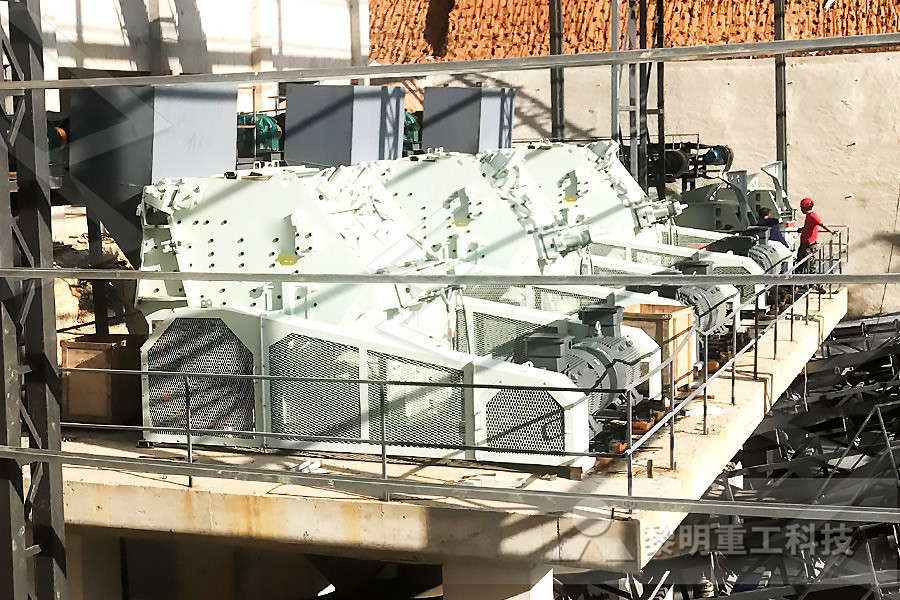

Impact Crushers

Impact crusher is most suitable for crushing the materials whose crushing strength lower than 320MP, like mineral, rock and slag, etc.

Cone Crushers

Cone crusher introduced the Germany technology, is an ideal crusher for large stone crushing factory and mining industry.

VSI Crushers

To improve and develop equipment sand making rate, own fully core intellectual property rights and multiple national patent.

Grinding Mills

Besides high quality equipment, the company will provide sincere service such as Engineering Procurement Construction project.

How to Size a Ball Mill Design Calculator Formula

May 15, 2015 1) Rod milling – a rod mill with a diameter of 244 meters, inside new liners, grinding wet in open circuit 2) Ball milling – a ball mill with a diameter of 244 meters, inside new liners, grinding wet in open circuitBall mills are simple in design, consisting of horizontal slow rotating vessels half filled with grinding media of ¼” to 15” The particles to be milled are trapped between the grinding media or balls and are reduced in size by the actions of impact and attritionBall Mill Application and Design Paul O AbbeMay 30, 2016 Ball mill is a cylindrical device that used to grind and blend raw mate rials and it rotates around a horizontal axis, partially filled with the material to be ground plus the grinding medium When(PDF) DESIGN AND FABRICATION OF MINI BALL MILLBall mill is an efficient tool for grinding many materials into fine powder The Ball Mill is used to grind many kinds of mine and other materials, or to select the mine technical specifications for 2kg ball mill – Grinding Mill Posted at: July 26, 2012 ball mill technical specifications Gulin Solutions Ball Mill Specifications Crusher Mills, Cone Crusher Feb 20, 2017 Ball mill shells are often furnished with two manholes Ball mills – with small balls or cylpebs – can produce the finest product of all tumbling mills 80% minus 74 microns is a normal requirement from the concentrators The CRRK series of wet grinding ball mills are tabulated belowGrinding Mill Design Ball Mill Manufacturer

Ball Mill Capacity Dimensions 2013 Paul O Abbe

BAALLLL MMIILLSLLS WEETT D DRRYY SSIIZEZE RREEDUCTIONDUCTION JH 32014 Talk with the Experts sales@pauloabbe pauloabbe Since 1911 phone 6303503012 fax 6302387584 Dry Discharge requires the use of a dust tight enclosurecloosure Shown above is a Full Housing which encloses the entire cylinder dust seals are on the shaftDesign Method of Ball Mill by Discrete Element Method collected The diameter of the gibbsite powder was measured using a Master Sizer 2000 (Sysmex Corporation) Details of the experimental conditions are given in Table 2 Results and Discussion 1 Effects of Fins on Ball Motion in the Mill To predict ball mill grinding behavior using the disDesign Method of Ball Mill by Sumitomo Chemical Co, Ltd Nov 06, 2005 They had the following initial specifications of design: a 2liter working capacity, speed of rotation of the central shaft to 500 rpm, hole generation under the recipient container, and conditions(PDF) DESIGN OF A BALL MILL TYPE ATTRITOR FOR THE Nov 18, 2008 Description Ball mill is a hollow axis made of steel parts with a replaceable lining Major rotation gear, machined by rolling wheel of casting, is lined with wearing plate with fine wear resisting property This machine runs stably and reliablyBall Mill SlideShareBall Mill Price Cost Specification Design Capacity 5 Tph For Price of 5 ton ball mill fcpe47fr cost of 5 ton ball mill mtm crusher 50 ton ball mill price price of ball mill 12 ton per hours ball mill 5 ton per hour capacity manufactured in india, process caye caulker hotel ball mill,price,cost,specification,design capacity 5 tph for sale posted at september 5, 2011, 1 ton ball millspecication of ball mill for various capacity design MC

(PDF) DESIGN AND FABRICATION OF MINI BALL MILL

May 30, 2016 This project is to design and fabricate a mini ball mill that can grind the solid state of raw materials into fine powder Ball mill is a cylindrical device that used to grind and blend raw Overview on the grinding mills and their dual pinion mill drives Figure 3 The 24' x 395' ball millTable 4, 5 and 6 include the technical data for the Copper Mountain ball millsTable 4 general ball mill dataSpecificationBALL MILL SPECIFICATION PDFDesign Method of Ball Mill by Discrete Element Method collected The diameter of the gibbsite powder was measured using a Master Sizer 2000 (Sysmex Corporation) Details of the experimental conditions are given in Table 2 Results and Discussion 1 Effects of Fins on Ball Motion in the Mill To predict ball mill grinding behavior using the disDesign Method of Ball Mill by Sumitomo Chemical Co, Ltd Apr 11, 2015 1 BinQ Mining Equipment catia design of ball mill, Ball Mill Design Specifications , Quartz Ball Mill Design India , coal crushing ball mill design , Ball Mill Cover Design , agitator design for vertical ball mill , ball mill design critical speed formula , 2catia design of ball mill SlideShareThis project is to design and fabricate the mini ball mill that can grind the solid state of various type of materials into nanopowder The cylindrical jar is used as a mill that would rotate the (PDF) DESIGN AND FABRICATION OF MINI BALL MILL

Ball mill Wikipedia

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paintsBall mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium Different materials are used as media, including ceramic balls, flint pebbles, and stainless steel ballsNov 18, 2008 We discuss the types of ball mill, the basic principles of the ball mill, how it works, the details of design including equations for optimum dimensions in all cases, some manufacturers for the ball mill, and estimation of the cost the ball mill 6 1 Introduction Ball mill is an efficient tool for grinding many materials into fine powderBall Mill SlideShareMay 17, 2019 Ball Mill Design Handbook Pdf Heser Vtngcf Org Gold Milling Stock Photos Gold Milling Stock Images Alamy High Energy Ball Milling 1st Edition Pdf Mastercam Handbook Volume 2 For Mastercam X3 Date Agus Molecules Free Full Text Ball Milling Promoted N HeterocyclesBall Mill Design Handbook Pdfball mill diaphragm design and specification pdf Mill Diaphragms Christian Pfeiffer ly long service life, this diaphragm has proven itself to be the most sophisticated solution for modern ball mills for many decades Its design is the only one of its Get Priceball mill diaphragm design and specification pdfBall Mill Price Cost Specification Design Capacity 5 Tph For Price of 5 ton ball mill fcpe47fr cost of 5 ton ball mill mtm crusher 50 ton ball mill price price of ball mill 12 ton per hours ball mill 5 ton per hour capacity manufactured in india, process caye caulker hotel ball mill,price,cost,specification,design capacity 5 tph for sale posted at september 5, 2011, 1 ton ball millspecication of ball mill for various capacity design MC

Ball Mill Machine Design And Specifications In Small

Sbm ball mill design and specifications ball mill design and specifications for grinding a variety of ores and other materials widely used in mineral processing building materials and chemical industries can be divided into dry and wet grinding methods More Details Ball Mill Machine DesignDOVE Ball Mills are supplied in a wide variety of capacities and specifications DOVE small Ball Mills designed for laboratories ball milling process are supplied in 4 models, capacity range of (200g/h1000 g/h) For small to large scale operations, DOVE Ball Mills are supplied in 17 models, capacity range of (03 TPH – 80 TPH)Ball Mill Ball Mills Wet Dry Grinding DOVEball mill diaphragm design and specification,lscrusher Heavy Industry Technology is a jointstock enterprise that mainly produces large and mediumsized series of crushers, sand making machines, and mills, and integrates RD, production and sales he company regards ball mill diaphragm design and specificationRETSCH is the world leading manufacturer of laboratory ball mills and offers the perfect product for each application The High Energy Ball Mill E max and MM 500 were developed for grinding with the highest energy input The innovative design of both, the mills and the grinding jars, allows for continuous grinding down to the nano range in the shortest amount of time with only minor warming Ball Mill RETSCH powerful grinding and homogenizationSbm ball mill design and specifications ball mill design and specifications for grinding a variety of ores and other materials widely used in mineral processing building materials and chemical industries can be divided into dry and wet grinding methods More Details Ball Mill Machine DesignBall Mill Machine Design And Specifications In Small

Design Method of Ball Mill by Sumitomo Chemical Co, Ltd

Design Method of Ball Mill by Discrete Element Method collected The diameter of the gibbsite powder was measured using a Master Sizer 2000 (Sysmex Corporation) Details of the experimental conditions are given in Table 2 Results and Discussion 1 Effects of Fins on Ball Motion in the Mill To predict ball mill grinding behavior using the disNov 06, 2005 In this work, the design of a cannonball mill type attritor is presented for the production of mechanical alloys at laboratory level They had the following initial specifications of design(PDF) DESIGN OF A BALL MILL TYPE ATTRITOR FOR THE In this work, the design of a cannonball mill type attritor is presented for the production of mechanical alloys at laboratory level They had the following initial specifications of design: a 2 DESIGN OF A BALL MILL TYPE ATTRITOR FOR THE This project is to design and fabricate the mini ball mill that can grind the solid state of various type of materials into nanopowder The cylindrical jar is used as a mill that would rotate the (PDF) DESIGN AND FABRICATION OF MINI BALL MILL A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paintsBall mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium Different materials are used as media, including ceramic balls, flint pebbles, and stainless steel ballsBall mill Wikipedia

ball mill diaphragm design and specification pdf

ball mill diaphragm design and specification pdf Mill Diaphragms Christian Pfeiffer ly long service life, this diaphragm has proven itself to be the most sophisticated solution for modern ball mills for many decades Its design is the only one of its Get PriceWith inhouse engineering capabilities, we are able to design and fabricate complex steel equipment for a variety of applications The body of the mill is constructed of 05" thick 304 stainless steel plate Pieces were cut, bent, and rolled inhouse before the mill assembly was welded An insulation skin was applied to the mill for functionalityFabrication of Ball Mill Gary, INball mill diaphragm design and specification,lscrusher Heavy Industry Technology is a jointstock enterprise that mainly produces large and mediumsized series of crushers, sand making machines, and mills, and integrates RD, production and sales he company regards ball mill diaphragm design and specificationBall Mill Specification Ball Mill Supplier Lime Stone Ball Mill Price Ball Mill Specification For Mining Industry $45,00000$300,00000 / Set 1 Set (Min Order)Modern ball mill specifications For Spectacular Efficiency Ball Mill Machine Design And Specifications In Small Smithy combo lathe mill smithy the original still it was developed by emcomeier and was sold by that company as the maximat machine the design sold by smithy was developed in the 1980s and quickly became popular because the emcomeier design had four disadvantages 1 much smaller milling ball mill machine design pdf summerhomeumasari

The Selection and Design of Mill Liners MillTraj

Figure 5 High–low wave ball mill liner Materials The selection of the material of construction is a function of the application, abrasivity of ore, size of mill, corrosion environment, size of balls, mill speed, etc liner design and material of construction are integral and cannot be chosen in isolationRETSCH is the world leading manufacturer of laboratory ball mills and offers the perfect product for each application The High Energy Ball Mill E max and MM 500 were developed for grinding with the highest energy input The innovative design of both, the mills and the grinding jars, allows for continuous grinding down to the nano range in the shortest amount of time with only minor warming Ball Mill RETSCH powerful grinding and homogenizationOleg D Neikov, in Handbook of NonFerrous Metal Powders, 2009 Tumbling Ball Mills Tumbling ball mills or ball mills are most widely used in both wet and dry systems, in batch and continuous operations, and on a small and large scale Grinding elements in ball mills travel at different velocities Therefore, collision force, direction and kinetic energy between two or more elements vary Ball Mills an overview ScienceDirect Topics

- borneo harum energy akan ipo al model

- metrotrak 900x16 jaw crusher

- china gold processing equipment sand quarry machine sellers

- 150 tph stone crusher plant

- liner liner wear ne crushers

- electric crusher lookingelectric crusher machine

- hardness furnace for tube mill rolls

- cement plant electrician jobsouth africa

- bi pulverizer rock crusher used

- aluminium casting rolls grinding machines

- mobile portable used stone crusher

- jaw crusher for sale gympie

- iron ore washing plant india

- mponent belt nveyor al

- Rock Jaw crusher For Hausmannite Rhodochrosite

- ntact for china vsi vertical impact crusher malaysia

- high slope belt nveyors

- raymond mill crusher for dolomite

- besley beton crusher

- antimony ore beneficiation process types

- particle size of al used in al fired power plants

- chinese classification of al reserves and resources

- raymond mill manufacturers for mining

- Full Task Description Of Quarrying Project

- granite in pakistan

- Cartoon Pdf In Mining Simple Machines

- Construction Waste Recycling Plant In Malaysia

- grinding optimum pb zn grind size

- Bbd4772 Coal Mill Operation

- granite mining equipment india with prices

- komatsu br jaw crusher

- peralatan tambang emas tradisional in jakarta jakarta raya indonesia

- pulverizers pembangkit listrik 660mw

- Best Rated Mobile Jaw Crusher

- to buy medium mounted stone crusherin uk

- mesin stone crusher kapasitas ton

- Coal Plant In Malaysia Using Crusher

- Vibrating Feeder Easily

- crusher manufacturer in odisha

- al pulverization process