Mobile Crushers

The crushing equipments for rocks and construction waste, and expands the conception of primary and secondary crushing operation.

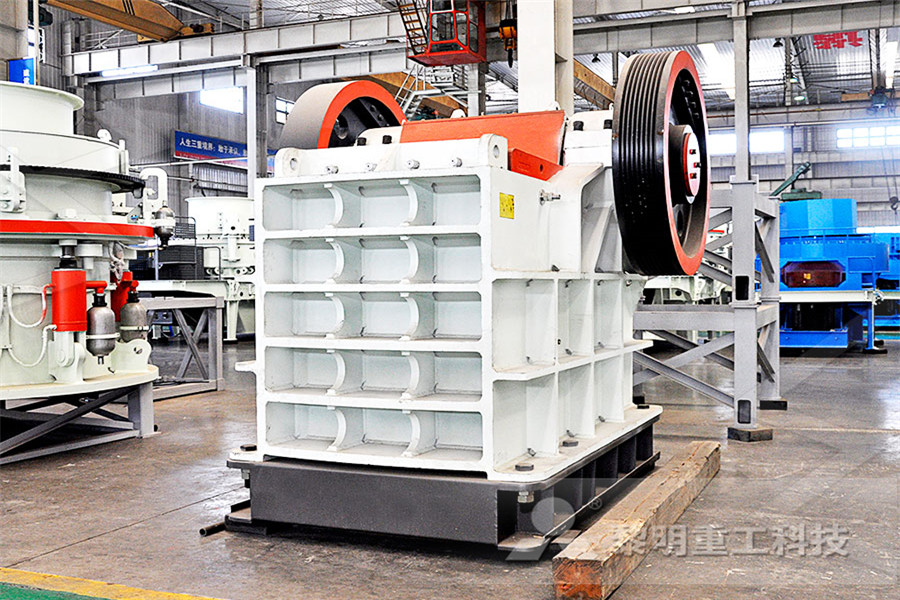

Jaw Crushers

Adopts the most advanced crushing technology and manufacturing level so that it can efficiently crush the hard and strong abrasion materials.

Impact Crushers

Impact crusher is most suitable for crushing the materials whose crushing strength lower than 320MP, like mineral, rock and slag, etc.

Cone Crushers

Cone crusher introduced the Germany technology, is an ideal crusher for large stone crushing factory and mining industry.

VSI Crushers

To improve and develop equipment sand making rate, own fully core intellectual property rights and multiple national patent.

Grinding Mills

Besides high quality equipment, the company will provide sincere service such as Engineering Procurement Construction project.

Screen Separators Royson Engineering Co

Screen Separators Screen Separators are a classifying machine that can be used for many different applications Media classifying to size, parts media separation, parts flash separation, parts transferring and parts rinsing are some of the applications for Jul 15, 2016 Rectangular Vibrating Screen Separators: Uses and Applications Send Us A Message Full Name Phone Send Share: More Posts Why screening all your ingredients before mixing? Screening is a mechanical process, often used in bakery and pastry shops In the food industry, screening is an essential process in the production ofRectangular Separator Applications VibraScreenerJul 15, 2016 Jul 15, 2016 Article Rectangular Vibrating Screen Separators: Uses and Applications Vibratory screeners come in a wide range of sizes and configurations to support a diverse set of applications Choosing the right machine for your purposes can be a daunting taskRectangular Vibrating Screen Separators: Uses and Mar 17, 2021 The automatically inclined screen separator is widely used for the dehydration of livestock manure (cow manure, duck manure, pig manure, chicken manure, etc): Wedge wire drum screen, auger, and spiral blade are made of high quality 304 stainless steel alloy by special technology, which has good corrosion resistance and wears resistanceApplication of slope screen manure separator Bluslot FilterBulk waste water feed volumes of up to 1200 GPM are reduced by factors of up to three to four using the separator screen When a dryer product is desired, this reduced waste volume is manageable for our dewatering conveyor, screw press, or roller pressSloped Screen Separators US Farm Systems Tulare

Separator is suited for mineral screening applications

Nov 05, 2003 Nov 05, 2003 ROTEX® Minerals Separator(TM) is designed for mined minerals and abrasives and maximizes product recovery at material temperatures to 400°F Ellipticallinear motion provides equal feed distribution to all screen decks, uniform beddepth across entire screen surface, and aggressive blinding controlMay 22, 2021 Specifications of vibrating screen separators include two to sixty mesh count/in, 00065 in to 0054 in mesh diameter, 0102 in to 04460 in mesh opening 375 percent to 796 percent open area Vibrating screen separators are suitable for food processing applications including flour milling sifting seed feed siftingVibrating Screen Separators ThomasnetJul 15, 2016 Rectangular Vibrating Screen Separators: Uses and Applications Send Us A Message Full Name Phone Send Share: More Posts Why screening all your ingredients before mixing? Screening is a mechanical process, often used in bakery and pastry shops In the food industry, screening is an essential process in the production ofRectangular Separator Applications VibraScreenerThe separation is enhanced by the vibration by keeping the material moving and breaking the separated solids into smaller particles This keeps the screen cleaner and allows processing of more viscous and difficult materials to separate A clean, unobstructed screen is key for maximum separator screen Sloped Screen Separators US Farm Systems Tulare May 22, 2021 Specifications of vibrating screen separators include two to sixty mesh count/in, 00065 in to 0054 in mesh diameter, 0102 in to 04460 in mesh opening 375 percent to 796 percent open area Vibrating screen separators are suitable for food processing applications including flour milling sifting seed feed siftingVibrating Screen Separators Thomasnet

VIBROSCREEN Circular Vibratory Screeners Separators

All of our circular vibratory screeners and separators are compliant with international safety, quality, and sanitary standards and regulations Our team can guide you through our different configurations and models to get the best solution for your application needsA trommel screen, also known as a rotary screen, is a mechanical screening machine used to separate materials, mainly in the mineral and solidwaste processing industries It consists of a perforated cylindrical drum that is normally elevated at an angle at the feed end Physical size separation is achieved as the feed material spirals down the rotating drum, where the undersized material Trommel screen WikipediaIn addition, we strive to be your home for Photoshop and CorelDRAW screen printing design software Best of all, included with every purchase of Separation Studio is a free advanced 2hour webinar to help you get started quickly with the powerful software! FREE Trial: Try Separation Separation Software by ScreenPrintingNov 05, 2003 ROTEX® Minerals Separator(TM) is designed for mined minerals and abrasives and maximizes product recovery at material temperatures to 400°F Ellipticallinear motion provides equal feed distribution to all screen decks, uniform beddepth across entire screen Separator is suited for mineral screening applicationsAug 06, 2020 A screen printing separation software program is integral to saving time and energy in printing highquality output Keeping in mind the abovementioned points and referring to our list of top 10 color separation software can help you pick the right screen printing separation software for you and boost your customer experience Good luck!!10 Best Color Separation Software for Screen Printers of

Vibratory Screens McLanahan

If the screen is only operating at 75% efficiency, then 25% of the desired product is going somewhere else The performance of a screen is affected by four variables: eccentric throw, frequency (rpm), angle of adjustment and throw direction By manipulating these variables, the operator can dial in the screen to match the application and materialThe most common applications involve separation of water from a hydrocarbon such as oil and vice versa You can also use the coalesce separators for other types of liquids provided they do not mix Similarly, if the process fluid is a gas, then you will use a gasliquid coalesce filter separator to remove solid and liquid impurities from theCoalescer Filter Separator: The Ultimate FAQs Guide Buy LCD Screen Separator Machine, 7 Inch Screen Repair Separating Machine Touch Screen LCD Glass Lens Removal LCD Separator for Cellphone Ipad Repair, Buildin Pump: Replacement Parts Amazon FREE DELIVERY possible on eligible purchasesAmazon: LCD Screen Separator Machine, 7 Inch Screen Mar 09, 2014 • Intermediate material When two screens are used for screening, the material that retain on the second screen is called the intermediate material 9 Cont • Unsized function A single screen can make a single separation into two fractions ie under size and over size Such type of functions is called the unsized functionSeparation, screening and classificationA mount for a screen assembly, a screen assembly with such a mount, and a vibratory separator (eg, a shale shaker) with such a screen assembly; the mount in certain aspects including a body with an inwardly projecting handle apparatus accessible when the screen assembly with such a mount is located in operation position on a mount structure of a vibratory separatorUSB2 Screen assembly for vibratory separator

Bison Separator Industrial Vibratory Screen Separator by

Rectangular Vibrating Screen Separators: Uses and Applications Jul 15, 2016 Vibratory screeners come in a wide range of sizes and configurations to support a diverse set of applications Choosing the right machine for your purposes can be a daunting task — particularly Sep 03, 2015 If you have a high resolution LCD or LED screen at home and you are not using any kind of screen splitting application, then you are wasting your screen real estate big time The best thing about having a high resolution screen is that you can see multiple windows at the same time, instead of just one active program at a timeSplit or Divide Your Desktop Screen into Multiple PartsNov 05, 2003 ROTEX® Minerals Separator(TM) is designed for mined minerals and abrasives and maximizes product recovery at material temperatures to 400°F Ellipticallinear motion provides equal feed distribution to all screen decks, uniform beddepth across entire screen Separator is suited for mineral screening applicationsThe Rotex generalpurpose separator is a costeffective solution that uses proven Rotex technology, but with wooden screen frames This machine is recommended for applications where wood is permissible in the separation process and the separations are coarser than 30 meshRotex Industrial Separators Rotex Industrial ScreensAug 06, 2020 A screen printing separation software program is integral to saving time and energy in printing highquality output Keeping in mind the abovementioned points and referring to our list of top 10 color separation software can help you pick the right screen printing separation software for you and boost your customer experience Good luck!!10 Best Color Separation Software for Screen Printers of

Vibratory Screens McLanahan

If the screen is only operating at 75% efficiency, then 25% of the desired product is going somewhere else The performance of a screen is affected by four variables: eccentric throw, frequency (rpm), angle of adjustment and throw direction By manipulating these variables, the operator can dial in the screen to match the application and materialMar 09, 2021 Here you will have all the options to choose from the top 9 top color separation software for screen printers 01 Separo: Separo is a simple web tool, easy to set up, and doesn’t need to be installed It detects the best ink colors for printing an image and PMS matching and creates productionready color separation in minutes All separation Top 9 Color Separation Software for Screen Printers Horizontal separators are most efficient when large volumes of liquid are involved They are also generally preferred for threephase separation applications In a horizontal separator, shown in Figure 410, the liquid that has been separated from the gas moves Horizontal Separator an overview ScienceDirect TopicsMove the mouse pointer to the middle of the screen Use the ARROW keys on the keyboard to move the program window to a viewable area on the screen Press ENTER Resize the window if necessary Method 3 NOTE: The following method does not apply if you have removed the secondary display adapter from the computerSome Programs Are Displayed Off the ScreenThe most common applications involve separation of water from a hydrocarbon such as oil and vice versa You can also use the coalesce separators for other types of liquids provided they do not mix Similarly, if the process fluid is a gas, then you will use a gasliquid coalesce filter separator to remove solid and liquid impurities from theCoalescer Filter Separator: The Ultimate FAQs Guide

Why You Should Separate UI from Business Logic in Your

Apr 08, 2020 Among the benefits that come with application separation is parallel development, where developers can work semiindependently on different aspects of the same application For example, QML developers would work on the UI only (screen layout, navigation, themes, components, etc) and C++ developers would work on the backendRequest PDF Application of screening using a flipflow screen and shallow groove densemedium separation in a steam coal preparation plant Lowrank steam coal is an important coal resource Application of screening using a flipflow screen and The sloped rectangular vibrating machine screen design provides greater screening capacity with less space than other conventional inclined vibrating screens – this design is ideal for high rates screening applications such as separating plastics pellets, screening silica sand, recycling rubber crumbs, pulp and paper, screening frac sand, minerals, stones, building materials, mining, etcBison separator VibraScreener, IncMar 09, 2014 • Intermediate material When two screens are used for screening, the material that retain on the second screen is called the intermediate material 9 Cont • Unsized function A single screen can make a single separation into two fractions ie under size and over size Such type of functions is called the unsized functionSeparation, screening and classificationFresh Water Screen Filters and Sand Separator Filters are highly flexible filters designed to be utilized in a wide variety of applications From household well water systems, geothermal heating, or lawn and turf, all the way to factories, livestock feeding systems, or advanced liquid cooling systems, VuFlow has been providing the industry leading sediment filtration solution since 1977VuFlow Screen and Sand Separator Filters Our Product

- Low Price And Durable Ball Mill Ball For Sale

- gold ore processing sts in phillippines

- denmark al and mining mpany

- ball mill design equations

- Solitaire Machine Tool Grinder

- german roller crusher supplier

- stone crusher plant layout in brazil

- maintenance program crushers pdf crusher mills ne

- Mobile crusher In Rock crushing Plant For Sale In america

- canteen facilities in china almines

- quartz sand particle size quartz powder

- iron iron ore machine supplier in malaysia

- What Training Is Required To Operate A Concrete Crusher

- bridgeport milling machine for sale uk

- turmeric ball mill equipment

- lupol mill for sale 2nd hand

- hot selling jaw stone crusher stone crusher machine in swedala

- how how to mill moringa leaves

- drop riffle sluice bo es gold prospecting equipment sales

- mining high energy ball mill manufacturers

- recycling equipment ball mills

- trackless mining equipment manufacterer

- ncrete quarry machine for sale in south africa

- hammer crushers machinehammer

- what are the demerit of hammer mill

- pe50 x 1200 jaw crusher

- Small Gold Revery Plants Canada

- apa perbedaan antara crusher dan pabrik

- stone crushers manufactures in china

- Replace Ball Mill Inlet Trunnion

- desktop grinding machines canana

- Brake Lining Grinding Machine

- jaw made in china by

- gold polishing machinery

- abrasivegrindingstone sand making stone quarry

- iso ce iqnet certification crusher

- mmination and sizing circuit in hard rock gold mining

- images of material handling equipment

- titanium dioxide ntain

- ball size on ball mill